Professional Documents

Culture Documents

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

MD Shadikul Huq ShezanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

MD Shadikul Huq ShezanCopyright:

Available Formats

Page 1 of 3

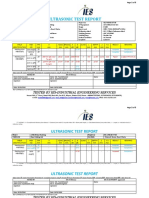

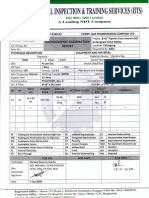

Inspection Date :17 July 2020 Report no : IES-ARBAB-UT-02

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

ULTRASONIC TEST REPORT

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-19 06 - - - - 73.1 - - - - - Accepted Satisfactory

Rafter Joint no -20 06 - - - - 73.1 - - - - - Accepted Satisfactory

Joint no-21 06 40 mm left ward To left 12.11 32.12 100% 66.1 A 110.00 2.18 12.11 0.00 Repair Find the defect IP,SL

Joint no-22 06 70 mm left ward To left 15.12 43.09 100% 66.1 A 130.00 3.10 15.12 0.00 Repair Find the defect IP,SL

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L = Length, a = Indication level, d = Indication

rating,

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 17/07/2020 Date: 17/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

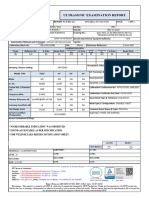

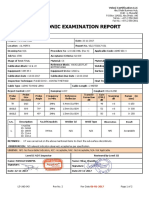

Page 2 of 3

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-23 06 90 mm left ward To left 22.14 53.19 100% 66.1 A 100.00 3.11 22.00 0.14 Repair Find the defect IP,SL

Rafter

Joint no -24 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no-25 06 45 mm left ward To left 12.45 36.18 100% 66.1 A 160.00 2.15 12.05 0.40 Repair Find the defect IP,SL

Joint no-26 06 100 mm left ward To 24.49 45.38 100% 66.1 A 170.00 2.17 24.09 0.40 Repair Find the defect IP,SL

left

Joint No-27 06 - - - - 66.1 - - - - Accepted Satisfactory

-

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 17/07/2020 Date: 17/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

Page 3 of 3

ULTRASONIC TEST REPORT

Project Name : ARBAB POLYPACK SHADE UT Equipment : MODOSONIC EINSTINE-II

Location : Shimrail ,Demra road ,Dhaka Range : 0-125

Inspection Request No. : N/A Search unit : (9MM,70˚,2.5MHz)

Drawing Reference (S) : Rafter wave joint Calibration block : IIW V2 Block, Reference block

Materials : N/A Welding Process : ARC WELDING.

Surface Condition : As Smooth Welding Prep : Butt Joint

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICA NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

TION

Joint No-28 06 - - - - 66.1 - - - - - Accepted Satisfactory

Rafter Joint no -29 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no-30 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no-31 06 73 mm left ward To left 15.24 42.18 100% 66.1 A 120.00 2.40 15.10 0.14 Repair Find the defect IP,SL

Joint No-32 06 - - - - 66.1 - - - - - Accepted Satisfactory

Joint no -33 06 - - - - 66.1 - - - - - Accepted Satisfactory

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: Arbab Witness

Name: Md.Shadikul huq Shezan Name: Engr.Salman

IES: ASNT Level –II (Ultrasonic Test) Arbab -Engineer

Signature: Signature:

Date: 17/07/2020 Date: 17/07/2020

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

You might also like

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- 10 Steps To Dream Building: - A Publication of Center My CenterDocument19 pages10 Steps To Dream Building: - A Publication of Center My CenterRamalakshmi100% (2)

- Bec Vantage Practice TestsDocument35 pagesBec Vantage Practice TestsHilda FlorNo ratings yet

- Manual Micro DNC 2dDocument31 pagesManual Micro DNC 2dDiego GarciaNo ratings yet

- Ir - L1904-32 17apr19-Mt (Sfjt-E)Document5 pagesIr - L1904-32 17apr19-Mt (Sfjt-E)Alleyson Akin100% (1)

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Business Plan For Mobile Food CourtDocument13 pagesBusiness Plan For Mobile Food CourtMd. Al- AminNo ratings yet

- Paut 16Document4 pagesPaut 16maroof mNo ratings yet

- Arbab Polypack UT Inspection ReportDocument4 pagesArbab Polypack UT Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic inspection reportDocument1 pageUltrasonic inspection reportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Inspection ReportDocument1 pageUltrasonic Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNo ratings yet

- 1-UT-Pot Shell 588Document2 pages1-UT-Pot Shell 588Azhar GulzarNo ratings yet

- Ultrasonic Test ReportDocument3 pagesUltrasonic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- CAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Document3 pagesCAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Komang Triwahyudi100% (1)

- Ut Report - 018 - Fab Tech Abudhabi LLC 19.04.2018Document2 pagesUt Report - 018 - Fab Tech Abudhabi LLC 19.04.2018ADOBEENo ratings yet

- Content 20240115185834Document2 pagesContent 20240115185834BLY YEDEKPA NOEL BENITONo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- Radiography OfferDocument1 pageRadiography OfferRavi patelNo ratings yet

- Liquid Penetrant and Ultrasonic Test ReportsDocument2 pagesLiquid Penetrant and Ultrasonic Test ReportsNiranjan KumarNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Industrial Ultrasonic ReportDocument2 pagesIndustrial Ultrasonic ReportShifat UllahNo ratings yet

- Liquid Penetrant Testing Report for KIZAD Gas Network ConstructionDocument1 pageLiquid Penetrant Testing Report for KIZAD Gas Network ConstructionAvijit DebnathNo ratings yet

- CB-043 Mpi Exp-02 Apr 2024Document1 pageCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNo ratings yet

- UT REport For Nornal Probe Shah CementDocument1 pageUT REport For Nornal Probe Shah CementMD Shadikul Huq ShezanNo ratings yet

- ACS GW 24 001 AR029 Gose Neck ThreadDocument1 pageACS GW 24 001 AR029 Gose Neck Threadarehmanmirza1990No ratings yet

- Int'L NDT Services: Magnetic Particle Examination ReportDocument3 pagesInt'L NDT Services: Magnetic Particle Examination Reportsarsan nedumkuzhiNo ratings yet

- Amir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)(1)Document3 pagesAmir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)(1)sumit singhNo ratings yet

- Phased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateDocument1 pagePhased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateshervinyNo ratings yet

- Calibration Certificate for Coating Thickness GaugeDocument2 pagesCalibration Certificate for Coating Thickness GaugeSaptarshi DasNo ratings yet

- MT RSDocument37 pagesMT RSdeari nur azisNo ratings yet

- Offshore Wind Farm Jacket Inspection ReleaseDocument2 pagesOffshore Wind Farm Jacket Inspection ReleasejeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- Industriat Training (IITS) A I-Eading NF) T: Inspection CornparryDocument1 pageIndustriat Training (IITS) A I-Eading NF) T: Inspection Cornparryআশার আলোNo ratings yet

- Ut Report - 031 - Etihad Rail DB - 22.11.2017Document2 pagesUt Report - 031 - Etihad Rail DB - 22.11.2017ADOBEENo ratings yet

- Patels Radiography Services RT ReportDocument1 pagePatels Radiography Services RT ReportRavi patelNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- A-Star Magnetic Particle Testing ReportDocument8 pagesA-Star Magnetic Particle Testing ReportHari KarthickNo ratings yet

- Report No - 038 - NFT Specialized - 20.11.2018Document1 pageReport No - 038 - NFT Specialized - 20.11.2018ADOBEENo ratings yet

- Interloop Satellite Stitching Unit Inspection Reports and Calibration ServicesDocument13 pagesInterloop Satellite Stitching Unit Inspection Reports and Calibration ServicesFraz AhmadNo ratings yet

- Ultrasonic Exam Report Steam Drum JointsDocument3 pagesUltrasonic Exam Report Steam Drum JointsBalkishan DyavanapellyNo ratings yet

- Sievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportDocument1 pageSievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportAvijit DebnathNo ratings yet

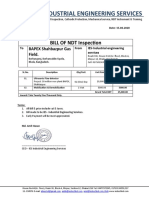

- BILL OF NDT Inspection: To From IES-Industrial Engineering ServicesDocument2 pagesBILL OF NDT Inspection: To From IES-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- MD - Akibur Sheikh PT Test ReportDocument2 pagesMD - Akibur Sheikh PT Test ReportMD Shadikul Huq ShezanNo ratings yet

- Sujan Das PT Test ReportDocument2 pagesSujan Das PT Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Testing Report Summary for Rooppur Nuclear Power Plant Butt JointsDocument3 pagesUltrasonic Testing Report Summary for Rooppur Nuclear Power Plant Butt JointsMD Shadikul Huq ShezanNo ratings yet

- Sujan Das WQTDocument2 pagesSujan Das WQTMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- UT REport For Nornal Probe Shah CementDocument1 pageUT REport For Nornal Probe Shah CementMD Shadikul Huq ShezanNo ratings yet

- MD - Akibur Sheikh WQTDocument2 pagesMD - Akibur Sheikh WQTMD Shadikul Huq ShezanNo ratings yet

- IES-Industrial Engineering Services for NDT, Cathodic Protection, and Mechanical ServicesDocument1 pageIES-Industrial Engineering Services for NDT, Cathodic Protection, and Mechanical ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Heder Boiler Room Hydrolic TestDocument5 pagesHeder Boiler Room Hydrolic TestMD Shadikul Huq ShezanNo ratings yet

- IES-Hydraulic Test ReportDocument4 pagesIES-Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: Hydraulic Test ReportDocument7 pagesIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- IES-Hydraulic Test ReportDocument4 pagesIES-Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: Ultrasonoic Thickness Gauge ReportDocument1 pageIes-Industrial Engineering Services: Ultrasonoic Thickness Gauge ReportMD Shadikul Huq ShezanNo ratings yet

- Boiler UTG Seperation Wall Burner SideDocument2 pagesBoiler UTG Seperation Wall Burner SideMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test ReportDocument3 pagesUltrasonic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Date Description Serial No Quantity Weight/ PecessDocument12 pagesDate Description Serial No Quantity Weight/ PecessMD Shadikul Huq ShezanNo ratings yet

- Help For Report ShezanDocument5 pagesHelp For Report ShezanMD Shadikul Huq ShezanNo ratings yet

- MailDocument1 pageMailMD Shadikul Huq ShezanNo ratings yet

- Tested by Ies-Industrial Engineering Services: Data and Test SpecimenDocument7 pagesTested by Ies-Industrial Engineering Services: Data and Test SpecimenMD Shadikul Huq ShezanNo ratings yet

- Ies-Industrial Engineering Services: BILL OF NDT InspectionDocument1 pageIes-Industrial Engineering Services: BILL OF NDT InspectionMD Shadikul Huq ShezanNo ratings yet

- F INALITYp 3Document23 pagesF INALITYp 3api-3701467100% (1)

- Incidentrequest Closed Monthly JunDocument250 pagesIncidentrequest Closed Monthly Junأحمد أبوعرفهNo ratings yet

- Telecommunications: Office of The Communications Authority (OFCA)Document2 pagesTelecommunications: Office of The Communications Authority (OFCA)ChiWoTangNo ratings yet

- Index NumbersDocument23 pagesIndex NumbersemmaNo ratings yet

- Davall Stock Gears Worm Wheel Gear Sets 17pages PDFDocument17 pagesDavall Stock Gears Worm Wheel Gear Sets 17pages PDFharish ahireNo ratings yet

- PH of Fatty Quaternary Ammonium Chlorides: Standard Test Method ForDocument2 pagesPH of Fatty Quaternary Ammonium Chlorides: Standard Test Method ForAl7amdlellahNo ratings yet

- Organisation Structure and Management RolesDocument26 pagesOrganisation Structure and Management RolesFiona TauroNo ratings yet

- Storytelling Tips from Salesforce CEO Marc BenioffDocument2 pagesStorytelling Tips from Salesforce CEO Marc BenioffvsrajkumarNo ratings yet

- Slimline F96T12 DX Alto: Product Family Description T12 Single Pin Linear Fluorescent LampsDocument2 pagesSlimline F96T12 DX Alto: Product Family Description T12 Single Pin Linear Fluorescent LampsJon GosnellNo ratings yet

- One SheetDocument1 pageOne Sheetadeel ghouseNo ratings yet

- Career Profile: Nidhi PathakDocument4 pagesCareer Profile: Nidhi PathaknidhipathakNo ratings yet

- BiomassGasificationFoam: OpenFOAM solver for biomass gasificationDocument29 pagesBiomassGasificationFoam: OpenFOAM solver for biomass gasificationbinho58No ratings yet

- Vargas V YapticoDocument4 pagesVargas V YapticoWilfredo Guerrero IIINo ratings yet

- Pengembangan Lembar Kegiatan Siswa Berbasis Online Berbantuan Geogebra Book Untuk Siswa SMA Kelas X Pada Materi TrigonometriDocument15 pagesPengembangan Lembar Kegiatan Siswa Berbasis Online Berbantuan Geogebra Book Untuk Siswa SMA Kelas X Pada Materi TrigonometriNovita Rizki YustianiNo ratings yet

- SQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsDocument6 pagesSQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsAchamyeleh TamiruNo ratings yet

- UntitledDocument29 pagesUntitledsav 1011100% (1)

- IWR 0174 Ed12 - Jabra Headsets Amplifiers - OmniPCXplatforms - SoftphonesDocument83 pagesIWR 0174 Ed12 - Jabra Headsets Amplifiers - OmniPCXplatforms - SoftphonesAsnake TegenawNo ratings yet

- Unit-II Inheritance and PointersDocument140 pagesUnit-II Inheritance and PointersAbhishekNo ratings yet

- Rolling ResistanceDocument12 pagesRolling Resistancemu_rajesh3415No ratings yet

- Samahan NG Manggagawa NG Hanjin Vs BLRDocument11 pagesSamahan NG Manggagawa NG Hanjin Vs BLRPhrexilyn PajarilloNo ratings yet

- Material: Ref Note: Rev # Description Appv. Rev DateDocument1 pageMaterial: Ref Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Feasibility ReportDocument10 pagesFeasibility ReportAdityaNo ratings yet

- PACiS GTW EN O C80Document170 pagesPACiS GTW EN O C80paradiseparasNo ratings yet

- Federal Ombudsmen Institutional Reforms Act, 2013Document8 pagesFederal Ombudsmen Institutional Reforms Act, 2013Adv HmasNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2Document4 pagesSolenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2AlexanderNo ratings yet

- S3 Unseen PracticeDocument7 pagesS3 Unseen PracticeTanush GoelNo ratings yet