Professional Documents

Culture Documents

BCL119 Portland Drive MEP Particular Specification C1 10042019

Uploaded by

Radu BuzamurgaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BCL119 Portland Drive MEP Particular Specification C1 10042019

Uploaded by

Radu BuzamurgaCopyright:

Available Formats

ME&P Particular Specification

Mechanical, Electrical and Public Health Services

Portland Drive, Mertsham,

Surrey RH1 3JA

ME&P Particular Specification – Portland Drive

This report has been conducted by BOCCA Consulting Ltd and has been checked against our

Quality Operating Procedures.

Issue: C1

Purpose: Tender

Prepared and checked by: Marc Bellamy

Date: 10 APRIL 2019

info@boccaconsulting.com

Tel: 01708 700 103

www.boccaconsulting.com

BCL119 Portland Drive MEP Particular Specification C1 10042019 2

ME&P Particular Specification – Portland Drive

CONTENTS

1. INTRODUCTION

2. SCOPE OF WORKS

3. DEVELOPMENT OF ABRIDGED DESIGN INTENT INFORMATION

4. DESIGN CRITERIA

5. MECHANICAL SERVICES

6. PUBLIC HEALTH SERVICES

7. ELECTRICAL SERVICES

BCL119 Portland Drive MEP Particular Specification C1 10042019 3

ME&P Particular Specification – Portland Drive

1. INTRODUCTION

This particular specification describes the requirements associated with the provision of Mechanical,

Electrical and Public Health services to the new residential development at Portland Drive,

Merstham, Surrey.

The descriptions included in this document describe the extent and nature of the works but do not

attempt to give a full description of the work and moreover do not absolve the contractor from his

responsibility to visit the site and make himself aware of all governing factors which may affect the

content and programme of works and method of construction.

The work undertaken by the Contractor shall comprise the development of the Detailed Design

into a confirmed coordinated and working installation package and the installation of new

Engineering Services systems as described in this document and as detailed in the specifications listed

below.

This document shall be read in conjunction with the following: -

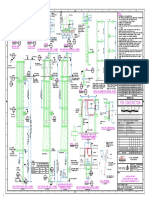

1. ME&P Drawings

2. Stockwool Architectural Drawings

3. David Dexter Structural Engineering Drawings

4. Utility Undertaker Quotes and technical requirements

5. General Specification for Electrical Services

6. General Specification for Mechanical Services

7. General Specification for Public Health Services

The tenderer shall include for developing the clients design intent information and the information

herein into a design development of the remaining items and working installation scheme and to

supply, install, test, commissioning and demonstration of the engineering services works.

BCL119 Portland Drive MEP Particular Specification C1 10042019 4

ME&P Particular Specification – Portland Drive

2. SCOPE OF WORKS

This document provides a detailed design specification for the Mechanical, Electrical and Public

Health services installations forming part of the new redevelopment to Portland Drive, Merstham,

Surrey RH1 3JA.

The project consists of creation of 33 new residential houses, 17 new residential apartments within a

single block, landlords facilities and areas.

The Mechanical, Electrical and Public Health services installation to the development are new

throughout and shall be developed into an installation scheme by the contractor.

The works associated with the Mechanical, Electrical and Public Health services are as follows:

i. Arrangement of new gas meter positions for the new apartments, including new

gas connections to heating and hot water boilers from new meter positions in the

gas meter cupboard to the apartments.

ii. System or Combination Boiler Installations including all interconnecting

pipework, circulating pumps, system water conditioners etc within the houses

and apartments.

iii. Radiator heating installations within the dwellings.

iv. Centralised Mechanical Extract ventilation within the apartments and intermittent

extract fans within the houses, including all plastic flat ducting, proprietary ductwork

connectors, bends and ductwork clips / fixings

v. Insulation of pipe-work systems within the dwellings.

vi. Commissioning of all systems within the dwellings.

vii. Commissioning of all landlords systems.

viii. Arrangement of new Cold-water services for the new apartments and landlords

service including new meters and new boosted main service through the building.

ix. Connection of new bcws into each apartment.

x. Water conditioner installations in each dwelling.

xi. Cold water services in each dwelling.

xii. Hot water services in each dwelling.

xiii. Condensate drainage installation from CME units in each apartment.

xiv. Dry Riser Installations

xv. New foul and waste drainage installations in each dwelling.

BCL119 Portland Drive MEP Particular Specification C1 10042019 5

ME&P Particular Specification – Portland Drive

xvi. Fix only of sanitary fittings in each dwelling.

xvii. Commissioning of all systems including chlorination in each dwelling.

xviii. Cold water services in landlord’s areas.

xix. Water conditioner installations in landlord’s areas.

xx. Commissioning of all landlord’s systems.

xxi. New LV Services distribution panel and connection from UKPN service head

within Block 1.

xxii. New submain distribution services to Landlords and Apartments within Block 1.

xxiii. Connection of DNO supplies into houses.

xxiv. New landlord’s distribution board within Block 1.

xxv. Landlords small power within Block 1.

xxvi. Landlords electric heating within Block 1.

xxvii. Landlords lighting within Block 1.

xxviii. Landlords site wide lighting.

xxix. Landlords Access Control system including entrance panels, apartments handsets

and interconnecting cabling through risers within Block 1.

xxx. Landlords IRS Signal distribution system throughout Block 1.

xxxi. Landlords earthing systems.

xxxii. Consumer units to dwelling.

xxxiii. Small power to each dwelling.

xxxiv. Lighting installations to each dwelling.

xxxv. Power supplies to mechanical equipment to each dwelling.

xxxvi. Fire Detection and alarm systems to each dwelling.

xxxvii. BT and Virgin Media Installations

xxxviii. Earthing Installations

xxxix. Provide commissioning of all systems

i. O&M manuals of completed works

BCL119 Portland Drive MEP Particular Specification C1 10042019 6

ME&P Particular Specification – Portland Drive

ii. Any items not scheduled

BCL119 Portland Drive MEP Particular Specification C1 10042019 7

ME&P Particular Specification – Portland Drive

2.1. Regulations and Standards

The works to which this specification relates shall comply with the following: -

i. CIBSE Design Guides, Technical Memoranda and Commissioning Codes

ii. HVCA DW 144

iii. 17th Edition of the IET Wiring Regulations BS7671

iv. The Electricity at Work Act

v. The Health and Safety at Work Act

vi. The Offices, Shops and Premises Act

vii. The Building Regulation

viii. Local Authorities‟ Byelaws and Regulations

ix. Local Authority Building Control Requirements

x. Water Supply Authorities Byelaws and Safety Regulations

xi. The Water Supply (Water Fittings) Regulations 1999

xii. Control of Substances Hazardous to Health (COSHH) Regulations

xiii. Gas Supply Authority's Requirements and Safety Regulations

xiv. Any other special Licensing Authority's Requirements

xv. All appropriate current British Standards and Codes of Practice

xvi. Construction (Design and Management) Regulations 1994

xvii. All appropriate current British Standards and Codes of Practice

xviii. Construction (Design and Management) Regulations 1994

xix. The Factories Act

BCL119 Portland Drive MEP Particular Specification C1 10042019 8

ME&P Particular Specification – Portland Drive

3. DEVELOPMENT OF DETAILED DESIGN INTENT INFORMATION

The design information provided in the me&p tender documentation defines the Client design intent

requirements.

The information provided contains a Full Specification, which sets the design intent of the M, E and

PH services to be installed. It shall be incumbent upon the Contractor to develop this detailed design

into their own co-ordinated installation drawings, setting out dimensions together with all necessary

technical information necessary to facilitate the M & E and PH installations as described.

The Contractor's coordination duties shall include a review of all design intent drawings, technical

submittals of plant, setting out details, builders work details, fixing and support details, layout of

services routes, co-ordination with the building elements and between services, supply, delivery,

positioning and fixing of all equipment and materials, all labour for installation, supervision and

inspection, specialist labour and all necessary instruments and attendance for testing and

commissioning, provision of operating and maintenance manuals and record drawings and training of

Client staff.

The Contractor will be required to produce fully dimensioned working drawings and to provide

sufficient working details when requested to ensure that the designs are in line with the Specification

and the requirements of the client.

The Contractor shall submit all information for the proposed installation in a timely manner as

agreed at the post tender interviews to ensure that sufficient time is allowed for the Consultants

review and comment and prior to the commencement of the installation work. Any installation

made without prior acceptance shall be made at the Contractor's risk and shall be altered or

amended as necessary to meet (or their appointed representatives) requirements at no additional

cost to the Contract.

The Contractor's coordination shall also include all elements of the design i.e. final connection to

plant, builders work details, design of supports and fixings with due regard to any services outside

the ME and PH services scope of works, which requires support from bracketry provided by the

Contractor.

In addition to the items listed in the scope of works, the Contractor shall be required to fully co-

ordinate all the services on site defined in this and the associated specifications and drawings. In

particular, it shall be the responsibility of the Contractor to fully co-ordinate the Electrical,

Mechanical, Public Health and other services including builder's work. All items of plant shall be

technical reviewed by the design team prior to ordering by the Contractor. To assist this process

the Contractor shall submit full technical details of each plant to confirm that the specification has

been interpreted correctly.

The working drawings shall be completed in a timely fashion to accord with the overall program. A

drawing and technical submittal program shall be prepared and issued to the client team for

approval.

BCL119 Portland Drive MEP Particular Specification C1 10042019 9

ME&P Particular Specification – Portland Drive

4.0 DESIGN CRITERIA

The following shall be used to determine loads and base duties for the purpose of selecting mechanical

services plant and equipment.

4.1. Design Conditions

Internal Conditions (Heating for residential units in existing

building and Heating and Cooling for fifth floor unit)

Houses and Apartments

Hall 21oCdb 19 oCdb

Study 22oCdb 20oCdb

Living Room 22oCdb 20oCdb

Dining Room 22oCdb 20oCdb

Family Room 22oCdb 20oCdb

Kitchen 22oCdb 20oCdb

Bedrooms 21oCdb 20oCdb

Bathrooms / ensuites 24oCdb – 2oCdb

Landings 21oCdb 20oCdb

External Conditions (All Areas)

Comfort Cooling and Heating

Winter -0.4oC / Saturated

Summer 29oCdb / 20oCwb

All in accordance with CIBSE Recommendations.

4.2 Building Fabric "U" Values / Fabric Thermal Performance

The new and existing building fabric values are to be confirmed by the contractor to suit insulation

levels necessary to achieve compliance under AD Part L1A.

4.3 Lighting

The design of the cooling system shall allow for heat gain due to artificial lighting of 15W/m2. (Based

on quantity of wall lights, picture lights, chandeliers, etc.).

4.4 Small Power

The design of the comfort cooling system shall allow for heat gain due to internal equipment (e.g. TV

etc) of 15W/m2.

4.5. Air Changes to Mechanically Ventilated Areas- Kitchen/Wet Areas

BCL119 Portland Drive MEP Particular Specification C1 10042019 10

ME&P Particular Specification – Portland Drive

In accordance with Building Regulation Document F, System 4.

4.6 Ventilation Rates

60 litres/sec via louvre elsewhere within kitchen (extract)

Toilet/Bathrooms/En-suite: 15 litres/sec (extract)

Infiltration Rates:

Bedroom 1 air change per hour

Study 1 air change per hour

Living Room 1 air change per hour

Kitchen 1 air change per hour

Bathroom 2 air changes per hour

En-suite 2 air changes per hour

Toilet 2 air changes per hour

Hallway 1.5 air changes per hour

Please note infiltration rates stated above are as recommended by CIBSE in calculation of heat

losses. The contractor shall make suitable allowance with consideration given to the existing and

final build specifications.

Air Changes

Kitchen: 30 litres/sec via cooker hood (extract)

60 litres/sec via grill elsewhere within kitchen (extract)

Bathrooms/En-suite: 15 litres/sec (extract)

4.7 Noise Criterion

The Building Services Design and selection of equipment shall be in accordance with any Acoustic

Planning Conditions provided by the clients team.

4.8 Internal Heat Gain

Heat output per person shall be assumed as being 80W (sensible) and 60W (latent) @ 22°C.

The following shall be used to determine loads and base duties for the purpose of selecting electrical services

plant and equipment.

4.9 Residential Lighting

GIL155 AD Part L1A

Switching and ceiling / wall points

Architects layouts

SAP Assessors

4.10 Fire Detection and Alarm System

BCL119 Portland Drive MEP Particular Specification C1 10042019 11

ME&P Particular Specification – Portland Drive

BS5839 Part 6: 2004, BS5446 Part 1: 2000

4.11 Installation wiring

BS7671 AD Part P

Code of practice for earthing BS7430

The following shall be used to determine loads and base duties for the purpose of selecting Public Health

services plant and equipment.

4.12 H & CWS

Hot water service flow – 60oC

Hot water service return – 55o

Velocity of hot and cold-water services – 1.0m/s

Minimum pressure of hot and cold-water services – 2.0 bar to draw off points

4.13 Drainage

Above ground soil waste and ventilating system – designed to BSEN 12056:2:200 and BS5572 sized

using the discharge unit method.

BCL119 Portland Drive MEP Particular Specification C1 10042019 12

ME&P Particular Specification – Portland Drive

5. MECHANICAL SERVICES

General

The Contractor shall prepare working drawings and supply and install and set to work the

mechanical engineering services to the development as set out below:

Gas Services

Block 1:

Individual gas supplies shall be taken to each apartment from the SGN installed incoming main within

the ground floor gas meter cupboard.

Connections from the meters for each of the apartments shall be taken to each of the apartments

via an installation of corrugated stainless steel semi-rigid gas piping (CSST) through builders work

risers and ceiling voids as shown on the drawings. Builders work risers and gas meter rooms will be

ventilated to atmosphere - the Contractor shall, through landlords ceiling voids, install the CSST

within a polyethylene flexible sleeve which shall be ventilated at the riser and at the apartment.

The gas services shall terminate in a stop cock at the entry to each apartment, directly below the

heating boiler.

Houses:

Individual gas supplies shall be terminated into a gas meter recessed box external to each house by

SGN.

Connections from the meters into each of the houses shall be taken to each of the apartments via an

installation of yellow MDPE pipework through builders work ducts as shown on the drawings.

The gas services shall terminate in a stop cock at the entry to each apartment, directly below the

heating boiler. Gas services shall be taken to each boiler in every dwelling and to hob positions in

the houses, conducted in screwed steel pipework, terminating in a gas isolator at each position of

use.

Heating Installations to dwellings

Space heating shall be provided to each of the dwellings via an installation of wall mounted high

efficiency gas fired boilers, located, in the main, within a dedicated kitchen cupboard at high level.

As shown on the drawings, the gas-fired boilers will be either combination type units or system

boilers with connections to separate hot water generators.

The boiler shall deliver heat to wall mounted radiators within the dwellings and will produce either

heat for hot water services or hot water services direct, as described later.

A concentric flue shall manage both the combustion air to, and the gases away from each of the boilers,

in the main directly to atmosphere locally, taking the gases away in accordance with British Standards

and local authority requirements.

BCL119 Portland Drive MEP Particular Specification C1 10042019 13

ME&P Particular Specification – Portland Drive

The heating installations shall consist of all interconnecting pipework, circulating pumps, insulation of

pipework, expansion vessels, draw off points, isolating valves etc so as to leave a complete system.

The heating pipework services shall be distributed through the dwellings in ceiling voids and within

partitions and casements to give a fully flush installation; it shall be conducted in copper of the

appropriate sizes, shall be jointed with capillary solder joints, supported at regular intervals and

insulated throughout their installation within the apartments. All pipework to be secured and fixed to

the structure.

Radiator tails shall enter the valves from behind with radiator tail covers covering the tails exits from

the partitions.

All pipework to be laid at a gradient to allow ease of drainage and venting of the system with air vents

at all high points of the system and BS2879 type drain cocks at all low points.

All pipework not within the occupied space or unheated areas shall be insulated so that the overall

efficiency shall not be less than as stated in the Domestic Heating Compliance Guide in accordance

with the Building Regulations section L1A and British Standard 5422.

To protect the system water an inline magnetic filter shall be installed to the return leg of the heating

system pipework. This unit shall be as Worcester Bosch Greenstar System Filter 22Ø; the water

system shall be dosed with a system inhibitor, such as Sentinel, post commissioning.

The main heating controls shall be provided via a hall way located thermostat, with TRVs being fitted

to each radiator (except those in the same space as the thermostat, which shall be fitted with a pair

of lockshields) providing room / zone controls.

Equipment shall be as follows:

Boilers-

Manufacturer: Worcester Bosch Greenstar CDi Classic ErP

Model: 30CDi System boilers & 42CDi Combination boilers

Flue: Concentric 60/100 flue.

Heating Controls -

Worcester Bosch EasyControl CT200 (in white)

Radiators -

Manufacturer: Purmo ‘Compact’ or Stelrad ‘Compact’

Dual Fuel Towel Rails -

Manufacturer: Stelrad

Model: Aqua Slimline Towel Rail in Chrome

BCL119 Portland Drive MEP Particular Specification C1 10042019 14

ME&P Particular Specification – Portland Drive

Extract Ventilation

Extract ventilation shall be provided to each of the dwellings via a number of different systems

depending on dwelling type.

Block 1:

Ventilation to the apartments shall be provided by a centralised constantly ventilation mechanical

extract fan with optional integral humidistat sensors for boost extract.

All fans shall be soffit mounted / recessed in the ceiling void and ducted to atmosphere using 204 x

60 or 110 x 54 PVC ductwork. Collapsible fire collars shall be installed as shown on the drawings /

to the BCO's approval / sign off.

Air supply terminals shall be as Waterloo Grilles VA valves.

Specification details for the fans is as shown on the drawings.

Background Ventilators and Recirculation kitchen cooker hoods will be specified by the architect.

Relays shall be installed to allow facilitate boost control by light switches into each served space

(with exception to kitchens). These shall be free-issued by the mechanical contractor to the

electrical contractor for their installation and wiring.

Extract breakout to atmosphere shall be either Titon Hi-speed air bricks or connections to tile

grilles (as specified by the architects).

These systems shall be installed in accordance with AD Part F System 3.

Houses:

Ventilation to the houses shall be provided by local intermittent extract fans with integral humidistat

sensors and light switch control for boost extract.

All fans shall be either wall / soffit mounted / recessed in the ceiling void and ducted to atmosphere

using 204 x 60 or 110 x 54 PVC ductwork. Collapsible fire collars shall be installed as shown on the

drawings / to the BCO's approval / sign off.

Air supply terminals shall be as Waterloo Grilles VA valves.

Extract Fans will be as Greenwood Airvac Samika, type and orientation as shown on the drawings.

Extract to Atmosphere Grilles, Background Ventilators and extract kitchen cooker hoods will be

specified by the architect.

These systems shall be installed in accordance with AD Part F System 1.

Insulation of pipe-work systems

All pipework systems shall be insulated and taped throughout their complete installation.

BCL119 Portland Drive MEP Particular Specification C1 10042019 15

ME&P Particular Specification – Portland Drive

The contractor shall provide Class O Armaflex thermal insulation and identification to all domestic

hot and cold water services in accordance with the following:

Class O Armaflex pipe insulation black in colour, having a class 1 fire rating BS476: Part 7:1987 (surface

spread of flame test) and a Fire Propagation index to BS476 Pa 6 (1989) test with values of 1 less than

12 and less than 6 to comply with the Class O specification as defined in the Building Regulations

Approved Document B Appendix A para A12. Lengths to be close butted. All butt joints longitudinal

seams and joins at fittings shall be sealed with Armaflex 520 or Armaflex NONFLAM adhesive to

provide an unbroken vapour barrier. The adhesive shall be used in accordance with the published

Technical Information sheets. Apply a thin uniform layer to both surfaces to be joined, allow an “open

time” of 2-3 minutes dependent upon ambient conditions – to allow the solvents to evaporate, press

together the surfaces to be joined using firm pressure, allow to cure for 36 hours for the bond to

reach maximum strength and resistance to water vapour.

In addition, all valves and other fittings shall be insulated with purpose made sections fabricated on site

in accordance with the Armaflex Installation Manual from Armacell (latest edition) and other technical

literature. Valve covers shall fully protect flanges and bonnet with only the wheels and stem exposed

and shall be sealed with Armaflex adhesive to prevent ingress of water and water vapour.

The Contractor shall provide Class O Armaflex thermal insulation and identification to all domestic

hot and cold-water services and rainwater pipes in accordance with the following.

For insulation thickness hot water service refer to the following

table: -

15 13

22 19

28 19

Pipe OD in mm Thickness of Insulation in mm

All equipment equal and approved.

Commissioning of all systems in apartments

All systems shall be commissioned in line with the respective standards/ manufacturers

recommendations and offered to the consultant and client team for witnessing / sign off before

handover.

BCL119 Portland Drive MEP Particular Specification C1 10042019 16

ME&P Particular Specification – Portland Drive

6. PUBLIC HEALTH SERVICES

General

The Contractor shall prepare working drawings and supply and install and set to work the public

health engineering services to the development as set out below:

Mains Cold Water Services

Block 1:

Landlords Boosted Cold Water services shall be provided to Block 1via the installation of a new

cold-water storage tank and pump set located within a dedicated plantroom at ground floor level. A

new rising BCWS shall be installed from the plantroom to the central landlords riser where the

BCWS shall rise vertically to high level third floor where it shall terminate in the installation of an

hydraulic arrestor.

The new BCWS will serve the residential section of the building; new connections shall be provided

in the form of a manifold on each level for 3 or 5 no. supplies on each level with connections being

taken into each of the new residential units via Southern Water approved meters.

The new BCWS installation shall be conducted in copper and shall be thermally insulated and be

provided with neoprene inserts to brackets manufactured by Flamco or equal and approved

to achieve continuous vapour seal of the thermal insulation.

The incoming main water services from Southern Water shall be extended to the new tank set. The

BCWS tank and pump set shall have an actual capacity of 2140l; specification details are as shown on

the drawings.

Booster Pumps shall be duty and standby.

The tank and pump set shall be as manufactured by KGN Pillinger, their model EV-1-8/2PH3HME09.

They have prepared a quotation for the project, reference KP41673.

The incoming BCWS to each of the apartments shall be routed and suspended through the

apartment to the heating enclosure, indicated as housing the boiler, where it shall terminate into

mains stop cock at 1500mm AFFL, suitably labelled with an engraved trafflodyte circular tag and

stainless-steel chain, marked to its use.

A mains cold water service shall also be provided to the landlords service within the block 1as

shown on the drawings. This shall consist of 2 external bib taps for irrigation and a bib tap for the

bin store wash down – these connections shall be served via a dedicated Cat 5 Booster Unit as

manufactured by KGN Pillinger, as their unit CAT5/CAB Washdown Booster Set. The Cat 5

booster unit will be located within the ground floor bin store.

Houses:

Individual water supplies shall be taken into each house form a pavement located Southern Water

meter directly outside each house.

BCL119 Portland Drive MEP Particular Specification C1 10042019 17

ME&P Particular Specification – Portland Drive

Connections from the meters into each of the houses shall be taken to each of the apartments via an

installation of blue MDPE pipework through builders work ducts as shown on the drawings.

The water services shall terminate in a stop cock at the entry to each house, directly adjacent the

hot water heater.

Hot and Cold-water services in dwellings

Hot and Cold-water services shall be provided within the dwellings as shown on the drawings; they

shall be installed and tested in accordance with BS 6700:1997, Water Regulations and to the

satisfaction of the Statutory Water Authority.

The cold-water service from the stop cock shall then provide cold water connections to the boiler

and water using appliances and sanitary ware as shown on the drawings.

As described in the mechanical section, hot water is either provided direct, in apartments, using a

combination boiler, and in houses, a system boiler providing heat to a hot water generator.

The hot water generators shall be as Worcester Bosch, as their model Grenstore SC Cylinders.

Capacities shall be as shown on the drawings.

The hot and cold water services shall be distributed through the dwellings in ceiling voids and within

partitions / casements to give a fully flush installation. They shall be conducted in copper of the

appropriate sizes, shall be jointed with capillary solder joints, supported at regular intervals and

insulated throughout their installation within the apartments.

Servicing valves shall be provided on all connections to sanitary ware and fitments.

Stop cocks shall only be installed on the incoming cold-water mains to the dwellings. All other

isolation shall be by means of quarter turn level action ball valves with the exception of the point of

use servicing valves to the draw off points.

Thermostatic mixing valves (point of use) shall be provided to the baths to limit the maximum supply

temperature where not provided as part of the sanitary ware fitments.

The mixing valves shall carry the valve designation to TMV2. The valve shall be provided with unions

at each connector, isolating ball valves, integral strainers, check valve and flushing / test point.

During flushing the valve shall be removed and replaced with a dummy valve. Commissioning of the

valve shall be carried out in accordance with the Manufacturer’s recommendations.

The thermostatic mixing valves shall be set to 46oC to provide mixed water temperature to the

baths.

Each WWP overflow from the WC’s shall be provided with integral warning pipe, which forms part

of the siphon to the satisfaction of the Statutory Water Authority.

Drain cocks shall be provided on all low points.

Double check valves shall be provided to the showers and shower bath mixers to comply with the

Water Regulations and Statutory Water Authority requirements.

BCL119 Portland Drive MEP Particular Specification C1 10042019 18

ME&P Particular Specification – Portland Drive

New foul and waste drainage installations throughout

The installation shall be installed and tested in accordance with the Employers Requirements BS EN

12056-2:2000 and Building Regulations.

Primary ventilated soil and waste systems shall be provided to take the foul waste water discharges

from the sanitary ware, fitments, condensate drains pressure / temperature relief lines, and air

conditioning units.

The soil vent pipes and waste vent pipes shall connect to the underground drainage as shown on the

drawings.

Anti siphon pipework shall be provided to prevent trap seal loss and noise production and shall be

routed to the soil and waste vent pipes for termination to atmosphere.

The soil and waste vent pipes within the dwellingss shall be supported by stand alone unistrut system

which shall be mechanically fixed to the floor and soffit. Pipe brackets shall not be fixed to the

partition walls or cavity walls. This support system shall be provided to provide acoustic transmittal.

The stacks shall also be acoustically insulated to comply with Part E of the Building Regulations.

The washing machine shall be provided with trapped standpipes and installed in accordance with the

Manufacturers recommendations.

The dishwasher waste shall be routed to connect directly to the sink traps via a waste hose.

For the full text for Materials and Workmanship reference shall be made to General Specification for

Public Health Services.

Materials for the new internal branch, soil, waste, anti-syphon and condense pipework shall be

unplasticised or modified unplasticised PVC to BS 4514:1983 with solvent weld cement joints

manufactured by Polypipe their 'Terrain Acoustic dB12' Range.

Proprietary intumescent fire stops shall be provided to the unplasticised or modified unplasticised

PVC pipework 50Ømm and above at each and every penetration through floor/roof construction

and compartmentation walls etc.

The unistrut pipe support system shall be manufactured by unistrut metal framing systems.

All waste fittings shall be provided with 75mm UPVC two piece tubular deep seal traps

manufactured by McAlpine Plumbing Products connected directly to the appliance and the discharge

waste pipework.

Waste non-return valves taking the discharge of condensate and pressure / temperature relief lines

from the boilers shall be manufactured by Hepworth Products Ltd – Type Hepvo.

The washing machine waste shall be a trapped stand pipe manufactured by McAlpine plumbing

products.

Automatic air admittance valves shall be manufactured by Marley Plumbing and Drainage Products.

The proprietary WC pan connectors shall be the same manufacturer as the pipework and fittings.

BCL119 Portland Drive MEP Particular Specification C1 10042019 19

ME&P Particular Specification – Portland Drive

The proprietary intumescent fire stops shall be installed strictly in accordance with the

Manufacturer’s recommendations and shall comply with the current Building Regulations and the

Building Control Officer.

Testing & Commissioning

The Contractor shall test and commission the soil, waste and ventilating pipework in accordance

with BS EN 12056-2: 2000 and Section 4.2 of the Standard Specification for Public Health Services.

Water conditioner installations

A magnetic water conditioner shall be provided to each of the dwellings and the landlords supply as

LifeScience WK1 unit.

Lifescience Products Ltd

Ranger's Lodge

Cornbury Park

Oxon

OX7 3HL

Technical Help Line:- +44 (0) 1608 811707

Facsimile:- +44 (0) 1608 819060

info@lifescience.co.uk

Dry Riser Installations

A Dry Permanent rising main is to be installed to enable the Fire and Rescue service to connect to a

water supply at different levels of the building via brigade connections to BS5041.

The dry riser main shall be installed in accordance with the requirements of BS5306 Part 1 1976

(Latest Amendment).

The dry riser system will consist of a 4" galvanised pipe to BS1387 with an enclosed outlet valve

(landing valve) and hydrant tee on each floor of the building. The dry riser will have a two-way inlet

breeching valve with an integral drain valve at ground floor level, built into the front entrance

elevation. An air release valve is situated at the highest point in the riser to allow the automatic

discharge of air as the riser fills and to aid draining down.

The components of the system shall be procured through Delta Fire, equal or approved, consisting

of, but not limited to, the following:

1) Copper alloy 65mm wedge gate vale to BS 5041, Part 2 and BS 5154, with 65mm female

instantaneous hose coupling to BS 336 and loose outlet blank cap and chain.

2) Landing valve boxes, shall be manufacturedn to BS 5041, Part 4, from 2mm thick corrosion

resistant material; finishes to be as Interior designers / Architects Drawings with wired glass lockable

BCL119 Portland Drive MEP Particular Specification C1 10042019 20

ME&P Particular Specification – Portland Drive

door (2 keys) identified on inside of glass in red letters 75mm high "FIREMAIN OUTLET - DRY

RISER". Finished in stainless steel.

3) Two way or four way inlet branching, to suit mains specified to BS 5041, Part 3, with each inlet

having a non-return valve to BS 5154, a 65mm male instantaneous hose coupling to BS 336 and

loose outlet blank cap and chain.

4) Inlet branching boxes, 2mm thick corrosion resistant metal construction to BS 5041, Part 5, with

wired glass lockable doors, (2 keys) identified on inside of glass in red letters 75mm high "FIRE

BRIGADE - DRY RISER INLET", complete with 25mm drain valves (padlocked), drain valve notices

and high point air release valves. Finished in stainless steel.

Fix only of sanitary fittings

The contractor shall provide a price for fixing of the sanitary ware. Refer the architects drawings for

the appropriate schedule.

For all text for materials and workmanship reference shall be made to the General

Specification of Public Health Engineering Services.

Insulation and Identification of Services

The contractor shall provide Class O Armaflex thermal insulation and identification to all domestic

hot and cold water services in accordance with the following:

Class O Armaflex pipe insulation black in colour, having a class 1 fire rating BS476: Part 7:1987 (surface

spread of flame test) and a Fire Propagation index to BS476 Pa 6 (1989) test with values of 1 less than

12 and less than 6 to comply with the Class O specification as defined in the Building Regulations

Approved Document B Appendix A para A12. Lengths to be close butted. All butt joints longitudinal

seams and joins at fittings shall be sealed with Armaflex 520 or Armaflex NONFLAM adhesive to

provide an unbroken vapour barrier. The adhesive shall be used in accordance with the published

Technical Information sheets. Apply a thin uniform layer to both surfaces to be joined, allow an “open

time” of 2-3 minutes dependent upon ambient conditions – to allow the solvents to evaporate, press

together the surfaces to be joined using firm pressure, allow to cure for 36 hours for the bond to

reach maximum strength and resistance to water vapour.

In addition, all valves and other fittings shall be insulated with purpose made sections fabricated on site

in accordance with the Armaflex Installation Manual from Armacell (latest edition) and other technical

literature. Valve covers shall fully protect flanges and bonnet with only the wheels and stem exposed

and shall be sealed with Armaflex adhesive to prevent ingress of water and water vapour.

The Contractor shall provide Class O Armaflex thermal insulation and identification to all domestic

hot and cold water services and rainwater pipes in –accordance with the following.

For insulation thickness hot water service refer to the following

table: -

BCL119 Portland Drive MEP Particular Specification C1 10042019 21

ME&P Particular Specification – Portland Drive

15 13

22 19

28 19

Pipe OD in mm Thickness of Insulation in mm

BCL119 Portland Drive MEP Particular Specification C1 10042019 22

ME&P Particular Specification – Portland Drive

7. ELECTRICAL SERVICES

The Contractor shall complete the abridged design and supply and install and set to work the

mechanical engineering services to the development as set out below:

LV Services

Block 1:

A new 200A TP&N Service shall be bought into Block 1 by UKPN, the local DNO.

From this service head the private works shall be installed such that the building owner / operator

can act as a BNO (Building Network Operator).

Houses:

Individual electrical supplies shall be taken into a recessed meter enclosure outside each house

where the service will terminate into a 100A BS1361 Fused cutout, ready for an energy supplier

installed meter.

Connections from the metered side of the meter into each of the houses shall be taken to each of

the houses via an installation of 25mm² 3C SWA/PVC/PVC cable through builders work ducts as

shown on the drawings.

The electrical service shall terminate in an isolator integral to the consumer unit of the house

served.

LV Services distribution to Landlords and Apartments within Block 1

As shown on the drawings the existing UKPN Service head arrangement is to be located within a

riser cupboard at ground floor within Block 1.

The Contractor shall provide a new 200A TP&N Isolator and Ryefield type LV Services Distribution

Panel to provide a supply to the landlord and to each of the apartments. The Contractor shall

include liaison to ensure the works herein comply with the requirements of UKPN who own the

supply to the development, along with working with the respective energy suppliers and the tenants

to facilitate the meter installations.

The Landlords service shall supply a MCB Distribution Board.

The LV Services Distribution panels shall be to UKPN Ltd's requirements and facilitate

lockable/sealable front cover, BS88 withdrawable fuse links, and common earth bar, commonly

referred to as a Ryefield Panel.

The contractor shall install plywood meter boards and a network of 150mm square galvanised steel

trunking with all necessary slots and grommets cut ready for the positioning of meters and

termination of the un-switched fused ways and the outgoing submain service cables to each of the

apartments and the landlords.

The outgoing submain cables shall be run on tray work at high level through the common areas and

risers of the building to the apartments in the building. LV Distribution cabling shall be conducted in

BCL119 Portland Drive MEP Particular Specification C1 10042019 23

ME&P Particular Specification – Portland Drive

XLPE/SWA/LSF cable as shown on the drawings. The supplies shall terminate within double pole

switch disconnectors integral to the Apartment Consumer Units.

The Consumer Units to dwellings shall be as MK Sentry and shall be surface mounted, insulated and

shall be replete with all necessary earth / neutral busbars, shields, and MK protection devices as

scheduled on the typical apartment drawing and developed to suit each apartment.

The landlords consumer unit shall be a Schneider Electric / Merin Gerin, metal and surface mounted

Landlords internal lighting within Block 1

The contractor shall supply and install the complete internal lighting installation throughout the

landlords section of the building as shown on the drawings.

Emergency lighting shall be provided within the main lighting system to a NM/3 system and to meet the

requirements of BS7671 parts 1 & 7.

The complete lighting installation shall be wired from the landlords distribution board and shall be

controlled locally; there shall be key switches adjacent the distribution board for isolation purposes for

maintenance etc.

All internal lighting cabling shall be carried out in either single cored 6491X lsf cabling in trunking /

conduit or multi-core 6242Y flat insulated and LSF sheathed cables with integral core CPC (twin and

earth), run on tray work for multiple runs and the structure for single runs; in all cases, disconnection of

luminaires from the lighting circuit shall be conducted using PCR2000 roses or choc-boxes either fixed

to besa boxes on the side of the cable basket or recessed in building fabrics. All cables in / out of the roses

/ besa boxes will be grometted.

Cables shall be hidden within the building structure and fabric and run clipped to the walls and

mechanically protected by suitable sized metal capping before final finishes are applied. The complete

installation shall be flush.

Galvanised steel back boxes shall be employed throughout, fixed behind the partition face on

pattresses (no drywall self fixing/supporting boxes shall be accepted) with acoustic baffles between

rooms.

Landlords external lighting

The contractor shall supply and install the complete external lighting installation throughout the

development to suit the layouts as shown on the drawings.

The complete lighting installation shall be wired from the Landlords Distribution Boards and shall be

controlled automatically via a time clock, located in a din rail enclosure below the landlords db, with a

remote photocell.

All external lighting cabling shall be carried out in XLPE/SWA/LSF cabling, buried direct with

identification tape thereover.

Photocells and PIR's shall be as MG / Schiender.

BCL119 Portland Drive MEP Particular Specification C1 10042019 24

ME&P Particular Specification – Portland Drive

Landlords Electric Heating to Block 1

The contractor shall supply and install electric heating to the common areas of Block 1 which shall

consist of electric panel radiators.

The electric radiator shall be wall mounted and horizontal in its orientation, as Creda Heating - Nobo

Heating NFC4N with integral thermostat control.

The electric radiators shall be wired as single phase and neutral, radial circuit and shall be fed from the

landlords distribution board DB/LL2. Controls shall be via a time clock and contactor controlling the

operation times of the circuit.

Landlords Access Control System to Block 1

The contractor shall supply and install an access control system to the block 1 to provide automation of

access into the building.

The system shall consist of a Apex Video Door entry System as supplied and manufactured by

ENTROTECH LTD. Contact John Cossey of ENTROTECH LTD on 01506 886230 or

johncossey@entrotec.co.uk.

The contractor shall avail themselves of ENTROTEC LTD drawing WIR/SCH 07 18/010V which details

the wiring arrangements for this system to compliment the position shown on the drawings.

Landlords IRS System to Block 1

The contractor shall supply and install a TV distribution system as set out on the drawings and as

specified in Sky Homes Specification 'Sky Homes Specification for a coaxial Integrated Reception System

New Build MDU' version 3.02 (or the latest edition available before setting to work) dated January

2016.

The system shall consist of all signal collectors, distribution cabling, amplifiers splitters to the main

system and all amplifier / splitters within the apartments.

The system shall allow for interactive systems therefore uplinks will be provided from the future

satellite main position within the apartment.

The signal collectors shall be roof mounted facing BSkyB satellite (SE23). The installing contractor shall

be CAI accredited and shall provided a signal test information as necessary to confirm the systems

operation.

All outlets shall be to match the outlets specified under general small power.

Picture modulators will be provided to allow CCTV signals from the access control system to be

transmitted onto the system to allow the occupiers to monitor the entrances upon receipt of a request

to enter.

Sky Wiring for Houses

The contractor shall supply and install a TV distribution system as set out on the drawings and as

specified in Sky Homes Specification 'Sky Homes Specification for a coaxial Integrated Reception System

BCL119 Portland Drive MEP Particular Specification C1 10042019 25

ME&P Particular Specification – Portland Drive

New Build Individual Homes' version 2.01 (or the latest edition available before setting to work) dated

January 2003.

The system shall consist of all distribution cabling, amplifiers splitters within the houses.

The system shall allow for interactive systems therefore uplinks will be provided from the future

satellite main position within the house.

The future signal collector position shall be roof mounted facing BSkyB satellite (SE23). The installing

contractor shall be CAI accredited and shall provide a signal test information as necessary to confirm

the systems operation.

All outlets shall be to match the outlets specified under general small power.

Small power to dwellings

Small power shall be provided throughout the dwellings to supply power to general purpose small

power outlets, mechanical services installations, and kitchen appliances, which shall be controlled in a

grid switch manner.

Small power within the dwellings shall consist of recessed wall 13A rated, three pin DP switched and

shuttered with dual earth terminals, 1 or 2 gang socket outlets and switched or non switched fused

connection units with or without neon indicators complying with BS1363.

Accessories shall be sourced from ranges as follows:

Accessory type Location

DETA Slimline White Plastic All accommodation rooms

DETA Vimark All back of house areas

DETA Metalclad Plant rooms and risers and service cupboards

All internal small power cabling shall be carried out in multi-core 6242Y flat insulated and sheathed

cables with integral core CPC (twin and earth). Cables shall be hidden within the building structure

and fabric; the complete installation shall be flush.

Galvanised steel back boxes shall be employed throughout, fixed behind the partition face on

pattresses (no drywall self fixing/supporting boxes shall be accepted) with acoustic baffles between

rooms.

Lighting installations to dwellings

The contractor shall supply and install the complete internal lighting installation throughout the

apartments to suit the layouts as shown on the drawings.

Pattresses shall be provided behind all switch ways and recessed lights. Galvanised steel back boxes shall

be employed throughout, fixed behind the partition face on pattresses (no drywall self fixing/supporting

boxes shall be accepted) with acoustic baffles between rooms.

BCL119 Portland Drive MEP Particular Specification C1 10042019 26

ME&P Particular Specification – Portland Drive

Click in connectors shall be provided for every lighting connection as 'Click Flow' 16A Push in

Connectors to allow ease of disconnection for servicing and for isolation of control gear/lamps etc

during insulation resistance testing.

All internal lighting cabling shall be carried out in multi-core 6242Y flat insulated and sheathed cables

with integral core CPC (twin and earth).

Cables shall be hidden within the building structure and fabric. The complete installation shall be flush.

Power supplies to mechanical equipment to dwellings

The contractor shall supply and install in the scheduled locations a "dual fuel" towel rail, consisting of

the towel rail, electric heating element and all associated plumbing, work, etc.

The contractor shall carry out the complete electrical works associated with these items, consisting

of fused connection unit, flex outlet, together with protective devices, cables and cable containment

etc as deemed necessary so as to tender the installation a whole operative.

Each towel rail shall be wired a single phase and neutral radial circuit.

The supply shall consist of a flush, wall-mounted, switched fused connection unit, (fused at 13A) with

neon located outside the bathroom/WC in a subtle hidden location. The fused connection unit shall

be engraved with the words "TOWEL RAIL".

Final connection to each towel rail shall be made using a flush wall mounted, flex outlet located directly

below the bottom to the towel rail leg.

Final connection wiring between flex outlet and the tower rail shall be carried out using three core

(CU), UK (CMA) reference: 318TQ, heat resistant flexible cable with integral CPC.

3 pole fan isolators shall be installed for al intermittent extract fans in houses, and 13A SFCU’s for all

CMVEs in apartments.

Relays shall be installed to allow facilitate boost control by light switches into each served space

(with exception to kitchens). These shall be free-issued by the mechanical contractor to the

electrical contractor for their installation and wiring.

Fire Detection and alarm systems to dwellings

The contractor shall supply and installed mains powered fire detection and alarm system as shown on

the drawings. Equipment shall be as manufactured by messr's Aico.

Aico Ltd

Mile End Business Park

Maesbury Road

Oswestry

Shropshire

SY10 8NN

Tel: 01691 664100

Fax: 01691 664111

BCL119 Portland Drive MEP Particular Specification C1 10042019 27

ME&P Particular Specification – Portland Drive

e-mail: enquiries@aico.co.uk

System Type: Smoke Alarm System

A smoke alarm system is designed to protect occupants from fire. The

British Standard BS 5839 Pt.6:2013 gives detailed recommendations for alarm

systems in dwellings and the information in this document is based on these.

Other relevant standards and guidance exists, for example the Local

Authority

Property Type: Single Storey

Level of Protection: Medium Protection (Category LD2)

The escape routes (Hallways, Landings etc.) are covered along with the high

fire risk areas (Kitchen & Living Room). Gives good protection to the

occupants

Alarm Power

/Back-up: Mains Powered with Lithium Back-up (Grade D)

Alarms are powered from the mains power supply but will automatically

switch to Lithium cell back-up if the mains power fails. The Lithium cells will

last the life of the alarm (10yrs) and are completely tamperproof.

Alarm Types: Multi-Sensor Alarms

Multi-Sensor alarms have two sensor elements – optical and heat – and give

the best response to all fire types, from fast flaming to slow smouldering, so

will be used in the majority of areas. The Kitchen would require a Heat

alarm due to the nature of the environment.

Hallway: Multi-Sensor Fire Alarm Product

Number: Ei2110

Living Room/Kitchen: Multi-Sensor Fire Alarm Product

Number: Ei2110

Alarm

Interconnection: Hard-wired Interconnection

Cabling is installed between every alarm to provide the link between them. If

an alarm is triggered, it will send a signal down this cabling and all other

alarms will sound. Consideration should be taken on the disruption

generated when installing the cabling.

Additional Features: Alarm Controller

To give occupants extra control over their alarm system, a wall mounted

Alarm Control Switch will be fitted to give three extra functions:

Test – Test alarms

Locate – Find the source of the alarm when all are sounding

BCL119 Portland Drive MEP Particular Specification C1 10042019 28

ME&P Particular Specification – Portland Drive

Silence – Silence alarms

Alarm Controller

Product Number: Ei1529RC

BT and Virgin media cabling

The contractor shall supply, install and liaise with BT and Virgin Media to provide a complete Comm

/ Telephony system within the building.

The groundworks contractor, through the CMs management, will install all of the sitewide duct etc,

and the electrical contractor the private side of the wiring installation, along with coordinating their

works with the BT representative. The same applies for Virgin Media.

BT:

BT will be delivering ‘Fibre to Premises (FTTP) product’ to the development. This will include all site

wide services, duct infrastructure and installations to Houses and Apartments. The electrical

contractor will be responsible for the following works:

Block 1:

From the BT installed Incoming Fibre Joint box within the ground floor riser cupboard, run BT free

issued ‘EZ bend Cable’ to each apartment, terminating into a ONT position within the apartment.

From the Optical termination Position (ONT) position within the main space (shown as BT ONT on

the drawings) the electrical contractor install the ONT and associated Battery back-up unit (BBU)

and provide all associated cable containers, back boxes and outlet plates as required. The electrical

contractor will also run all necessary data cables etc to slave positions as shown on the drawings.

Cableways for the main routes through the landlords risers are shown on the drawings.

Houses:

From the External BT CSP position, run a connectorised fibre cable (free issued by BT to suit the

lengths advised by the electrical contractor) to the Optical termination Position (ONT) position

within the main space (shown as BT ONT on the drawings) and install the ONT and associated

Battery back up unit (BBU) and provide all associated cable containers, back boxes and outlet plates

as required. The electrical contractor will also run all necessary data cables etc to slave positions as

shown on the drawings.

The complete specification is outlined in ‘How to build a fibre Network developer Guide Version 4

– March 2017’ and can be found here:

http://www.ournetwork.openreach.co.uk/resources/site1/General/Downloads/fibre_developer_hand

book.pdf

BCL119 Portland Drive MEP Particular Specification C1 10042019 29

ME&P Particular Specification – Portland Drive

LAN wiring within the houses will not be installed.

Block 1 Landlords areas:

The electrical contractor shall coordinate the installation of copper PSTN line from the BT installed

master to the lift communication equipment.

Virgin Media:

Virgin Media will be delivering services to the development. This will include all site wide services,

duct infrastructure and installations to Houses and Apartments. The electrical contractor will be

responsible for the following works:

Block 1:

From the Virgin Media installed Incoming Distribution Box located within the ground floor riser

cupboard, run Virgin Media free issued ‘Siamese RG6’ cabling to each apartment, terminating into an

Internal Termination Box (ITB) position within the apartment, along with all Virgin Master Outlets in

the hallway cupboard and slave positions adjacent BT positions, conducted in 2c telephone cables

(procured by Electrical Contractor), and Virgin TV outlets adjacent BT positions, conducted in RG6

coax cable (supplied free by VM).

Cableways for the main routes through the landlords risers are shown on the drawings.

Houses:

From the External Virgin Media External Termination Box (ETB) located on the front of the houses,

run Virgin Media free issued RG6 coax cabling to a Virgin Master Outlets in the main master and

slave positions adjacent BT positions, conducted in 2c telephone cables (procured by Electrical

Contractor), and blank plate covered single gang boxes, ready for Virgin TV outlets, adjacent TV

positions, conducted in RG6 coax cable (supplied free by VM).

The complete specification is outlined in ‘Virgin Media Residential New Build Technical Information

to support your on-site deployment’ and can be found here:

https://keepup.virginmedia.com/content/networkExpansion/doc/virgin_media_new_build_developers

_guide_v1.4.pdf

Landlords MOV System (excluding opening vent - by Principle Contractor)

The contractor shall supply and install a single zone AOV Control Unit and all associated devices as

shown on the drawings. The system shall be wired in FP200 fire resistant cabling.

The system shall be designed in compliance with the European standard EN:12101 and as

manufactured by:

AOV Controls

Custom Electronics Ltd

Unit 4,

Willows Business Centre,

BCL119 Portland Drive MEP Particular Specification C1 10042019 30

ME&P Particular Specification – Portland Drive

Newburn Bridge Road,

Blaydon,

Tyne and Wear, NE21 4SQ

Tel: 0191 414 3160.

Earthing Installations

The contractor will provide an earthing system comprising of main earthing terminal or bar, circuit

protective conductors, main equipotential bonding conductors and supplementary bonding for

earthing the electrical installation, the general mass of the building and incoming services to the

general mass of the earth.

The installation shall be in accordance with BS 7671, BS 7430 and the Regional Electricity Company's

(REC) requirement for protected multiple earth (PME).

The Electrical Services Contractor shall make all necessary tests both as the installation proceeds

and on completion, to ensure the effectiveness of the earthing installation and its compliance with BS

7671.

In no circumstances are fixings, which are being used for other purposes, to be utilised for an

earthing termination. If an earthing terminal is not provided on the apparatus, the Electrical Services

Contractor shall form an effective earthing terminal by drilling, tapping and installing the necessary

nuts, bolts and washers. All protective conductors shall be connected to earthing terminals by means

of crimped lugs.

The earthing system for the building shall be TN-C-S.

Earthing conductors shall have a Green/Yellow sheath. Circuit Protective Conductors (CPC's) -

Shall have LSF insulation with a minimum cross-sectional area detailed in table 54G of BS 7671.

Cable Armouring - May be used as a CPC. Where the armouring has an insufficient CSA, provide an

additional single-core (Cu), CPC cable strapped to the outside of the appropriate armoured cable

using proprietary cable ties.

Conduit and/or trunking - Shall not be used as a protective conductor or earth path. However,

conduit/ trunking shall be fully bonded.

Circuit protective conductor installation shall form a continuous earth fault return path.

A protective conductor within a non-metallic cable containment system shall terminate on each

outlet box. For a final ring circuit, the circuit protective conductor shall be run in the form of a ring

having both ends connected to the associated earth bar or terminal.

All outlet boxes shall incorporate an earthing terminal and a green/yellow LSF conductor, equal in

size to the circuit conductor and shall connect this terminal to its associated accessory.

For all text for materials and workmanship reference shall be made to the General

Specification of Electrical Engineering Services.

BCL119 Portland Drive MEP Particular Specification C1 10042019 31

You might also like

- A-STR-STD-000-30053-0 - STD Details of Ladders SHT 1 PDFDocument1 pageA-STR-STD-000-30053-0 - STD Details of Ladders SHT 1 PDFHUSSEIN FNEISHNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Optcl System in Orissa 400kv Bid DocumentDocument223 pagesOptcl System in Orissa 400kv Bid Documentranjish_007100% (1)

- Hydraulic Services DesignDocument10 pagesHydraulic Services DesignSeenivasan GovindarajNo ratings yet

- Mep ELECTRICAL SpecificationsDocument274 pagesMep ELECTRICAL SpecificationsAnonymous sSFrqPbfL9No ratings yet

- BOOK - 3 Plumbing Services Tender Specifications & BOQDocument102 pagesBOOK - 3 Plumbing Services Tender Specifications & BOQPrakash Arthur100% (1)

- Zone One by Colson Whitehead Full Novel (TOTALLY LEGIT 100% NOT SCAM) (Dont Sue PLSSS)Document10 pagesZone One by Colson Whitehead Full Novel (TOTALLY LEGIT 100% NOT SCAM) (Dont Sue PLSSS)Maloloy Alfonso Remedios DeGuzmanNo ratings yet

- Technical Specification For Highmast & Street LightingDocument40 pagesTechnical Specification For Highmast & Street LightingAnupamMishraNo ratings yet

- 2014 Underground Electric Construction StandardsDocument53 pages2014 Underground Electric Construction StandardsJosé Martín Peña TorresNo ratings yet

- Hading Over&Taking Over PossessionDocument17 pagesHading Over&Taking Over Possessionswaroopa N100% (1)

- Specification For Electrical, and Allied Works I. General Condition of Contract: 1 GeneralDocument15 pagesSpecification For Electrical, and Allied Works I. General Condition of Contract: 1 GeneralRyan MecinaNo ratings yet

- 1.2) MSO Fitting-Out Guide - v2017 June (Non A&A)Document50 pages1.2) MSO Fitting-Out Guide - v2017 June (Non A&A)KUNG HIM CHANNo ratings yet

- Sprinkler System and Wet RiserDocument94 pagesSprinkler System and Wet Riseryrmukund100% (1)

- Mkushi Civil BOQDocument216 pagesMkushi Civil BOQmatshona0% (1)

- 10 Vol Ii Sec 4 Fire Protection Alarm and Gas Suppression Works Technical Specifications PDFDocument116 pages10 Vol Ii Sec 4 Fire Protection Alarm and Gas Suppression Works Technical Specifications PDFrajaNo ratings yet

- Commissioning Process For Buildings and Systems: ANSI/ASHRAE/IES Addendum A To ANSI/ASHRAE/IES Standard 202-2013Document6 pagesCommissioning Process For Buildings and Systems: ANSI/ASHRAE/IES Addendum A To ANSI/ASHRAE/IES Standard 202-2013anmellaNo ratings yet

- General Technical Specification - Turnkey WorkDocument8 pagesGeneral Technical Specification - Turnkey WorkpvenkyNo ratings yet

- MOS For Road ConstructionDocument7 pagesMOS For Road ConstructionHussam WaleedNo ratings yet

- 1 Technical ProposalDocument64 pages1 Technical ProposalNana BarimaNo ratings yet

- Annex I - 20160721 BoQ Car Park Refurbishment and Security Upgrade UN SiteDocument49 pagesAnnex I - 20160721 BoQ Car Park Refurbishment and Security Upgrade UN SiteSolomon AhimbisibweNo ratings yet

- Electrical General NotesDocument5 pagesElectrical General NotesjustineNo ratings yet

- Sg. Lebam - BQ (Bridge Only)Document7 pagesSg. Lebam - BQ (Bridge Only)Wan75% (4)

- Proposal - Prof Servcs Agmt For Mechanical Electrical Plumbing Engineering Services For Fire Station No 9Document5 pagesProposal - Prof Servcs Agmt For Mechanical Electrical Plumbing Engineering Services For Fire Station No 9bhavin24uNo ratings yet

- B ME Utilities and Existing Services V10Document10 pagesB ME Utilities and Existing Services V10Zaimi ZamaludinNo ratings yet

- 16453-Grounding & Bonding Telecommunication SystemDocument6 pages16453-Grounding & Bonding Telecommunication SystemuddinnadeemNo ratings yet

- WBSETCL Technical SpecificationDocument8 pagesWBSETCL Technical SpecificationAyaz Ahmad KhanNo ratings yet

- ConduitDocument77 pagesConduitkamlNo ratings yet

- Technical Specification 1Document73 pagesTechnical Specification 1mudassir mNo ratings yet

- Automative Department Tender PDFDocument252 pagesAutomative Department Tender PDFbhanu singhNo ratings yet

- Electrical SpecificationsDocument19 pagesElectrical SpecificationsMarilou BasalloNo ratings yet

- Oaks MallDocument86 pagesOaks MallWei Yang LimNo ratings yet

- Rongo university-Volume-II PDFDocument401 pagesRongo university-Volume-II PDFShreekant KeraiNo ratings yet

- 6.explanatory Notes (GES) Dec'2018Document47 pages6.explanatory Notes (GES) Dec'2018santhosh kumar t mNo ratings yet

- Electrical Systems OverviewDocument5 pagesElectrical Systems OverviewrandieNo ratings yet

- General ProvisionsDocument6 pagesGeneral Provisionstristan guarinoNo ratings yet

- Specifications and Installation Guide For Underground Service To Residential DevelopmentsDocument79 pagesSpecifications and Installation Guide For Underground Service To Residential DevelopmentsAhmad JrDtNo ratings yet

- Commercial Building Requirements: Building Department - 2 Complete Plan SetsDocument4 pagesCommercial Building Requirements: Building Department - 2 Complete Plan SetsRubina Shaukat KhanNo ratings yet

- Cop201201e Code of Practice 2012Document27 pagesCop201201e Code of Practice 2012blackdogpkNo ratings yet

- Nu Division 22 Combined 20170330Document235 pagesNu Division 22 Combined 20170330Jothimanikkam SomasundaramNo ratings yet

- Specification For Park City-clubhouse-Rev 0Document332 pagesSpecification For Park City-clubhouse-Rev 0ThatnguyentonNo ratings yet

- BLDG. SPECS-BAGONG SILANG ELEM SCHOOL-Const of 2 Storey 8 Classroom School Bldg-Aug 2018Document6 pagesBLDG. SPECS-BAGONG SILANG ELEM SCHOOL-Const of 2 Storey 8 Classroom School Bldg-Aug 2018Julius Robertson FraneNo ratings yet

- Sample SowDocument41 pagesSample Sowamir11601No ratings yet

- Division 23 SpecificationsDocument119 pagesDivision 23 SpecificationsLoraine AnnNo ratings yet

- Mech SpecDocument49 pagesMech Spechusseint66No ratings yet

- 13amp Ring Main Isolation Switch How It Effects Power UkDocument30 pages13amp Ring Main Isolation Switch How It Effects Power Ukapi-6701026No ratings yet

- 01 - Scope of Work - SPECDocument4 pages01 - Scope of Work - SPECjigarNo ratings yet

- BMMR Educational Session March 26 2018 618425 7Document141 pagesBMMR Educational Session March 26 2018 618425 7hazel gabaynoNo ratings yet

- Civil Module for Thermal Power ProjectsDocument202 pagesCivil Module for Thermal Power ProjectsksshashidharNo ratings yet

- Engineering Consultancy Services: Tender Document FORDocument69 pagesEngineering Consultancy Services: Tender Document FORKalai SelvanNo ratings yet

- Assignment 1: CON105 Services For Construction ProjectsDocument16 pagesAssignment 1: CON105 Services For Construction ProjectsPJ LeotaNo ratings yet

- Specification PipaDocument103 pagesSpecification Pipamechanical 1No ratings yet

- ELECTRICAL PROJECT SPECIFICATION FOR HOUSING DEVELOPMENTDocument9 pagesELECTRICAL PROJECT SPECIFICATION FOR HOUSING DEVELOPMENTmasoodaeNo ratings yet

- RUS publishes final rule on electric engineering, architectural services and design policiesDocument40 pagesRUS publishes final rule on electric engineering, architectural services and design policiesEIGENVAL249100% (1)

- FR2 SoS For BIM Modelling (GBC Engineering) P01Document10 pagesFR2 SoS For BIM Modelling (GBC Engineering) P01ramatchatNo ratings yet

- Bath SpecsDocument2,337 pagesBath Specs404 System ErrorNo ratings yet

- Scottish Technical Handbook 2010Document618 pagesScottish Technical Handbook 2010wdfearonNo ratings yet

- Extension Plans and SpecsDocument24 pagesExtension Plans and SpecsAsunaNo ratings yet

- Scope of Work To Supply and Install Warehouse, Trailers, Latrine Trailers, and Utilities at Tent City Air Base, KuwaitDocument41 pagesScope of Work To Supply and Install Warehouse, Trailers, Latrine Trailers, and Utilities at Tent City Air Base, KuwaitAzharudin ZoechnyNo ratings yet

- IFB EPRU 001 2015 Technical Specification Part1Document71 pagesIFB EPRU 001 2015 Technical Specification Part1Cristopher JavidoNo ratings yet

- MEPTechDocument593 pagesMEPTechHumaid Shaikh100% (1)

- Distribution TransformersDocument17 pagesDistribution Transformersvenkateswaran.M venkateswaran.MNo ratings yet

- tn183 Specs Scheules Drgs Vol1 p2Document155 pagestn183 Specs Scheules Drgs Vol1 p2tejzabNo ratings yet

- Manual of STD ProceduresDocument354 pagesManual of STD ProceduresMuhammad Jawad AnsariNo ratings yet

- NHBC 2019 PDFDocument398 pagesNHBC 2019 PDFRadu Buzamurga100% (1)

- 1690-SPEC-002-CONCRETE SPECIFICATION - P1 - Concrete Specification - Preliminary - P1Document23 pages1690-SPEC-002-CONCRETE SPECIFICATION - P1 - Concrete Specification - Preliminary - P1Radu BuzamurgaNo ratings yet

- Conservation Saxon Our Kerbs at A Glance: GuideDocument2 pagesConservation Saxon Our Kerbs at A Glance: GuideRadu BuzamurgaNo ratings yet

- Europa Block Spec SheetDocument2 pagesEuropa Block Spec SheetRadu BuzamurgaNo ratings yet

- Buiding Regulation Doc HDocument64 pagesBuiding Regulation Doc HShailendra RamchurnNo ratings yet

- Installation Details For Cropped Granite SettsDocument3 pagesInstallation Details For Cropped Granite SettsRadu BuzamurgaNo ratings yet

- Common Transitional Words and PhrasesDocument2 pagesCommon Transitional Words and PhrasesRadu BuzamurgaNo ratings yet

- Specification Construction OperativeDocument2 pagesSpecification Construction OperativeRadu BuzamurgaNo ratings yet

- Builder and 2 Vol 1 NAVEDTRA 14043 1993 NavyDocument332 pagesBuilder and 2 Vol 1 NAVEDTRA 14043 1993 NavyRosemary SimaoNo ratings yet

- Health Safety and EnvironmentDocument35 pagesHealth Safety and EnvironmentRadu BuzamurgaNo ratings yet

- AJ Handbook of Building StructureDocument389 pagesAJ Handbook of Building StructureRadu Buzamurga100% (1)

- Health Safety and EnvironmentDocument35 pagesHealth Safety and EnvironmentRadu BuzamurgaNo ratings yet

- PromatUK DURASTEEL® Guide Commercial 0820015 PDFDocument4 pagesPromatUK DURASTEEL® Guide Commercial 0820015 PDFHeba S. Al-saudiNo ratings yet

- Cold-Formed Steel and Mid-Rise ConstructionDocument46 pagesCold-Formed Steel and Mid-Rise ConstructionJose Leonardo Quintero GüellNo ratings yet

- Experimental and Theoretical Studies On GFRG Panels Have Been Carried Out at IIT MadrasDocument21 pagesExperimental and Theoretical Studies On GFRG Panels Have Been Carried Out at IIT MadrasTeZa GoudNo ratings yet

- Your Imagination, Our Composites.: Pergolas & Finsproduct CatalogueDocument5 pagesYour Imagination, Our Composites.: Pergolas & Finsproduct CatalogueRohan KulkarniNo ratings yet

- JD - Internship at CyondDocument2 pagesJD - Internship at CyondStupidity TalksNo ratings yet

- Firestopping Standard Details Guide 14mbDocument76 pagesFirestopping Standard Details Guide 14mbJohn TrimmNo ratings yet

- View 2Document132 pagesView 2MimoNo ratings yet

- Analysis Tower BTS Related ItemsDocument35 pagesAnalysis Tower BTS Related Itemsvivekananda sharmaNo ratings yet

- National Highways of Infrastructure Development Corporation LTDDocument30 pagesNational Highways of Infrastructure Development Corporation LTDMudit MehraNo ratings yet

- Repuestos Horno Teka ht490Document10 pagesRepuestos Horno Teka ht490IcursoCLNo ratings yet

- Design Guide 07 Plywood Box BeamsDocument36 pagesDesign Guide 07 Plywood Box BeamsTaimoo NaseemNo ratings yet

- Master Schedule for Electric Facility - Meghna 2nd BridgeDocument3 pagesMaster Schedule for Electric Facility - Meghna 2nd Bridgegau shresNo ratings yet

- Tabla de Tipos de ConcretosDocument1 pageTabla de Tipos de ConcretosHumberto MorenoNo ratings yet

- 4.check list-SKYDocument2 pages4.check list-SKYsudhakarthekingNo ratings yet

- Basement 3Document1 pageBasement 3Nur MasturinaNo ratings yet

- Bulacan Loft: Product SpecificationsDocument22 pagesBulacan Loft: Product SpecificationsLang AwNo ratings yet

- Flat Belt Drive: Smaller Pulley Bigger Pulley Flat Belt Smaller Pulley Bigger Pulley Flat BeltDocument1 pageFlat Belt Drive: Smaller Pulley Bigger Pulley Flat Belt Smaller Pulley Bigger Pulley Flat BeltSagan PreetNo ratings yet

- 712 1984Document14 pages712 1984thehellboyhorns2352No ratings yet

- H364822-PM028-240-242-0001 - SOW ReviewDocument23 pagesH364822-PM028-240-242-0001 - SOW ReviewVictor WatambgwaNo ratings yet

- ARUP Embodied Carbon Concrete 1Document17 pagesARUP Embodied Carbon Concrete 1Gabriel MacaulayNo ratings yet

- Strength of Pin Material on Komatsu PC-200 Excavator Tooth BucketDocument2 pagesStrength of Pin Material on Komatsu PC-200 Excavator Tooth Bucketarisha rinaldiNo ratings yet

- Jotun Loading TableDocument26 pagesJotun Loading TableOsama KheadryNo ratings yet

- Upang Cea 2bsme Mae109 P1Document32 pagesUpang Cea 2bsme Mae109 P1Althea ManlaNo ratings yet

- Atk - 001844-Mos-Acm-0002 - 00 - Method Statement For Formworks Cooling Tower FoundationDocument15 pagesAtk - 001844-Mos-Acm-0002 - 00 - Method Statement For Formworks Cooling Tower Foundationtiote moussaNo ratings yet