Professional Documents

Culture Documents

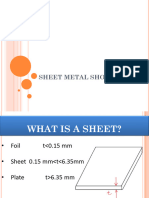

Sheet Metal Working Tools and Techniques

Uploaded by

Karthi KeyanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheet Metal Working Tools and Techniques

Uploaded by

Karthi KeyanCopyright:

Available Formats

1. A tool used for smoothing and forming sheet metal.

i. Planishing hammers

ii. Rivet gun

iii. Dollies

2. A tool is used to remove metal from small areas by cutting out small pieces of metal

i. Torx

ii. Clevis

iii. Hand Nibble

3. Small holes may be punched in sheet metal with a

i. chassis punch

ii. Hand nibble

iii. Band saw

4. The line in which both tension and compression does not take place.

i. Inside edge

ii. Outside edge

iii. Neutral axis

5. Recommended edge distance should be _______diameter of the rivet shank.

i. 2 ½

ii. 1 ½

iii. 3 ½

6. The distance from center of hole to the center of the adjacent hole is called

i. Pitch

ii. Transverse pitch

iii. Edge distance

7. The ratio of the allowable (ultimate) force divided by the applied (design) force minus

1.

i. Fail safe

ii. Margin of safety

iii. Damage tolerance

8. The cross-sectional area of the fastener times the ultimate shear strength of the rivet

material gives

i. Sheet Bearing Load

ii. Fastener Shear Load

iii. Sheet Tensile Load

9. A chemical coating tends to prevent corrosion and helps prevent scratches.

i. Bluing fluid

ii. Zinc chromate

iii. White paint

10. The width of the rivet repair should be ____ times that of the damaged area.

i. Two

ii. Three

iii. Six

11. The number of rivets required for each lap joint in any repair is determined by

a. Shear strength of the sheet metal

b. Tensile strength of the sheet metal

c. Both

You might also like

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- ToolDocument1 pageToolKarthi KeyanNo ratings yet

- Engineering fundamentals guideDocument34 pagesEngineering fundamentals guidesandeepNo ratings yet

- Chapter 2 DrillingDocument18 pagesChapter 2 DrillingNEF RIDERSNo ratings yet

- A 8 SolutionDocument2 pagesA 8 SolutionrobinNo ratings yet

- Module 10 Quarter II Week 4Document18 pagesModule 10 Quarter II Week 4WilmerNo ratings yet

- Me8451 QB2Document32 pagesMe8451 QB2Jayaram R S [MECH]No ratings yet

- Sheet Metal Shop ManualDocument13 pagesSheet Metal Shop ManualSurjit Kumar GandhiNo ratings yet

- Sheet Metal ShopDocument35 pagesSheet Metal ShopAshish SinghNo ratings yet

- Manufacturing Technology - Ii (Me1253 Unit - IDocument26 pagesManufacturing Technology - Ii (Me1253 Unit - IRameez FaroukNo ratings yet

- GNHS Smaw 2ND QuarterDocument8 pagesGNHS Smaw 2ND QuarterJymaer GeromoNo ratings yet

- Maintenance Practices - IIDocument27 pagesMaintenance Practices - IIrashmiameNo ratings yet

- Elements 13Document8 pagesElements 13Jovie Amparo BasasNo ratings yet

- Bahasa Ing MudahDocument3 pagesBahasa Ing MudahRicco Cahya RamadhanNo ratings yet

- MT II - 2 Marks With AnswersDocument40 pagesMT II - 2 Marks With AnswersArulNo ratings yet

- ME6402 MT-II - by Civildatas - Com 12Document14 pagesME6402 MT-II - by Civildatas - Com 12Muhammed SalmanNo ratings yet

- 2 Mark QuDocument5 pages2 Mark QuAshok PradhanNo ratings yet

- How to Drill Holes in Steel SafelyDocument2 pagesHow to Drill Holes in Steel Safelyfebrian alghifariNo ratings yet

- Moulding and Pattern NotesDocument28 pagesMoulding and Pattern Notesprabhu100% (1)

- Imp ExamDocument15 pagesImp ExamMalvin Roix OrenseNo ratings yet

- ME6402 - Manufacturing Technology-Ii: 1. Define Metal CuttingDocument26 pagesME6402 - Manufacturing Technology-Ii: 1. Define Metal CuttingSK NAGOOR VALINo ratings yet

- Rivets and Welded JointDocument37 pagesRivets and Welded JointJohn Kris San LuisNo ratings yet

- Machining 1 Miguel TamayoDocument2 pagesMachining 1 Miguel TamayoMIGUEL ANDRES TAMAYO LOPEZNo ratings yet

- Unit-I: 1. What Is Draft Allowance? How Is It Provided For Patterns?Document19 pagesUnit-I: 1. What Is Draft Allowance? How Is It Provided For Patterns?Jegan ParamasivamNo ratings yet

- MT Ii 2 MarksDocument19 pagesMT Ii 2 MarksNIVAS S. SNo ratings yet

- Worksheet No11ThreadingDocument4 pagesWorksheet No11ThreadingKher Bee A. PingolNo ratings yet

- Key 2Document22 pagesKey 2Jury.rahulNo ratings yet

- Different Types of Sheet Metal Operations Are:: 1. Shearing OperationDocument10 pagesDifferent Types of Sheet Metal Operations Are:: 1. Shearing OperationSai Asrith KonagallaNo ratings yet

- Machine Design-I and II Lecture NotesDocument37 pagesMachine Design-I and II Lecture NotesAzeem MohammadNo ratings yet

- Practical 1 SheetmetalDocument7 pagesPractical 1 SheetmetalSyamira ZakariaNo ratings yet

- 1 PDFDocument93 pages1 PDFRomart BarosaNo ratings yet

- DiplomaManufacturingProcessImportant2 3MarksQuestions AnswersEnglish PDFDocument36 pagesDiplomaManufacturingProcessImportant2 3MarksQuestions AnswersEnglish PDFSathya NarayananNo ratings yet

- Lec3 - Metal CuttingDocument49 pagesLec3 - Metal CuttingFELIX KEUYANo ratings yet

- TR4 SP4 Metal PaintingDocument5 pagesTR4 SP4 Metal PaintingEriane GarciaNo ratings yet

- Advantages of Metal CastingDocument6 pagesAdvantages of Metal CastingHarshGuptaNo ratings yet

- Multiple Choice Question Set 1Document12 pagesMultiple Choice Question Set 1Muskan AgarwalNo ratings yet

- Assignment 1 SolutionDocument7 pagesAssignment 1 Solutiontoursena44No ratings yet

- 7TEC Revision QuestionsDocument7 pages7TEC Revision QuestionsricgotrunoverNo ratings yet

- Sheet Metal Shop GuideDocument37 pagesSheet Metal Shop Guideeafz111No ratings yet

- Repot FoundryDocument14 pagesRepot FoundryMuhd HazwanNo ratings yet

- Sand Casting Answer The Following QuestionsDocument7 pagesSand Casting Answer The Following QuestionsprabhuNo ratings yet

- Metal Casting 3Document23 pagesMetal Casting 3bhushan wandreNo ratings yet

- Metal Casting Methods & PropertiesDocument189 pagesMetal Casting Methods & Propertieskiran kittuNo ratings yet

- PERIODICAL EXAMINATION IN SMAWDocument3 pagesPERIODICAL EXAMINATION IN SMAWalvin madahan100% (1)

- Metal Tray (Sheet Metal) : Aim: To Make A Metal Tray Out of A Given Sheet Metal of DimensionsDocument4 pagesMetal Tray (Sheet Metal) : Aim: To Make A Metal Tray Out of A Given Sheet Metal of DimensionsVivek AnbuNo ratings yet

- ABE054 Long AssignmentDocument4 pagesABE054 Long AssignmentJie ChanNo ratings yet

- Iii. 90 DegreeDocument1 pageIii. 90 DegreeKarthi KeyanNo ratings yet

- Last Name, First Name: - UMD Directory IDDocument8 pagesLast Name, First Name: - UMD Directory IDYealshaday BirhanuNo ratings yet

- Manufacturing Technology - I Unit - I: 2 Marks Question & AnswersDocument15 pagesManufacturing Technology - I Unit - I: 2 Marks Question & AnswersSK NAGOOR VALI100% (1)

- Sheet Metal ShopDocument43 pagesSheet Metal ShopBhaskar KandpalNo ratings yet

- Mandaue City College Final Exam Review for CarpentryDocument7 pagesMandaue City College Final Exam Review for CarpentryAB12A3 - Lauron Nicole NiñaNo ratings yet

- Manufacturing Processes: KKKM2833Document4 pagesManufacturing Processes: KKKM2833SajjadNo ratings yet

- Metal Cutting TechnologyDocument22 pagesMetal Cutting Technologydema_diasNo ratings yet

- Objective: Perform Lap Joint On The Given Aluminium Structure Using Blind RivetsDocument2 pagesObjective: Perform Lap Joint On The Given Aluminium Structure Using Blind Rivetsanon_549151529No ratings yet

- Summative Assessment Test - IDocument1 pageSummative Assessment Test - Ijuza mia ministerio100% (3)

- Post Test in Smaw TechnolympicsDocument6 pagesPost Test in Smaw TechnolympicsYza VelleNo ratings yet

- Sheet MetalDocument29 pagesSheet Metalbtbte23080architaNo ratings yet

- WorkshopDocument10 pagesWorkshopAhmed KucherNo ratings yet

- Sheet Metal OperationsDocument7 pagesSheet Metal OperationsThabiso MmesoNo ratings yet

- Indust QpaperDocument1 pageIndust QpaperKarthi KeyanNo ratings yet

- Out QP For FdeeDocument1 pageOut QP For FdeeKarthi KeyanNo ratings yet

- Course OutcommeeDocument1 pageCourse OutcommeeKarthi KeyanNo ratings yet

- Outcome For FDDocument1 pageOutcome For FDKarthi KeyanNo ratings yet

- Course Outcome For FDDocument1 pageCourse Outcome For FDKarthi KeyanNo ratings yet

- Pad Aer QpaperDocument1 pagePad Aer QpaperKarthi KeyanNo ratings yet

- Hig QualifDocument1 pageHig QualifKarthi KeyanNo ratings yet

- Iad QpaperDocument1 pageIad QpaperKarthi KeyanNo ratings yet

- U 1 1Document1 pageU 1 1Karthi KeyanNo ratings yet

- FromforDocument2 pagesFromforKarthi KeyanNo ratings yet

- U 1 1Document1 pageU 1 1Karthi KeyanNo ratings yet

- Harmony Towards Cultural, Regional, Linguistic, Communal Socioeconomic and Other Diversities (Within 500 Words)Document1 pageHarmony Towards Cultural, Regional, Linguistic, Communal Socioeconomic and Other Diversities (Within 500 Words)Karthi KeyanNo ratings yet

- ExplainDocument1 pageExplainKarthi KeyanNo ratings yet

- Computer Science Engineering Brain Teasers & Android AppsDocument1 pageComputer Science Engineering Brain Teasers & Android AppsKarthi KeyanNo ratings yet

- Write Description in Maximum of 500 WordsDocument2 pagesWrite Description in Maximum of 500 WordsKarthi KeyanNo ratings yet

- Harmony Towards Cultural, Regional, Linguistic, Communal Socioeconomic and Other Diversities (Within 500 Words)Document1 pageHarmony Towards Cultural, Regional, Linguistic, Communal Socioeconomic and Other Diversities (Within 500 Words)Karthi KeyanNo ratings yet

- File No Metric No. and Title: Documents NeededDocument1 pageFile No Metric No. and Title: Documents NeededKarthi KeyanNo ratings yet

- 18 5.3.2 Institution Facilitates Students'Document1 page18 5.3.2 Institution Facilitates Students'Karthi KeyanNo ratings yet

- Iii. ConstantDocument1 pageIii. ConstantKarthi KeyanNo ratings yet

- Harmony Towards Cultural, Regional, Linguistic, Communal Socioeconomic and Other Diversities (Within 500 Words)Document1 pageHarmony Towards Cultural, Regional, Linguistic, Communal Socioeconomic and Other Diversities (Within 500 Words)Karthi KeyanNo ratings yet

- Harmony Towards Cultural, Regional, Linguistic, Communal Socioeconomic and Other Diversities (Within 500 Words)Document1 pageHarmony Towards Cultural, Regional, Linguistic, Communal Socioeconomic and Other Diversities (Within 500 Words)Karthi KeyanNo ratings yet

- File No Metric No. and Title: Documents NeededDocument1 pageFile No Metric No. and Title: Documents NeededKarthi KeyanNo ratings yet

- 28 6.5.1 Internal Quality Assurance Cell (IQAC) Has ContributedDocument1 page28 6.5.1 Internal Quality Assurance Cell (IQAC) Has ContributedKarthi KeyanNo ratings yet

- Iii. 90 DegreeDocument1 pageIii. 90 DegreeKarthi KeyanNo ratings yet

- I. SixDocument1 pageI. SixKarthi KeyanNo ratings yet

- ToDocument2 pagesToKarthi KeyanNo ratings yet

- Upload 1Document1 pageUpload 1Karthi KeyanNo ratings yet

- NaDocument1 pageNaKarthi KeyanNo ratings yet