Professional Documents

Culture Documents

Introduction: Need For: MCMT Mapping Course Outcomes Woth Program Outcomes

Introduction: Need For: MCMT Mapping Course Outcomes Woth Program Outcomes

Uploaded by

Kalai Arasan0 ratings0% found this document useful (0 votes)

6 views3 pagesOriginal Title

UCMP MAPPING.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesIntroduction: Need For: MCMT Mapping Course Outcomes Woth Program Outcomes

Introduction: Need For: MCMT Mapping Course Outcomes Woth Program Outcomes

Uploaded by

Kalai ArasanCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

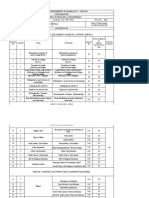

MCMT MAPPING COURSE OUTCOMES WOTH PROGRAM OUTCOMES.

COURSE COURSE TOPICS COURSE OUTCOMES PROGRAM OUTCOMES BLOOMS

CODE CORRELATION LEVEL (1- TAXONOMY

LOW, 2-MEDIUM, 3-HIGH) PARAMETER

UCMP INTRODUCTION: Need for The student is able to

PO1-Engineering

non-traditional machining know the need for non-

Knowledge.(3) Remembering,

methods- classification of traditional machining

modern machining processes – methods and the PO5-Modern tool usage.(3)

considerations in process

student is able to know

selection, applications.

about ultrasonic PO7-Environment and

Ultrasonic machining –

machining method & sustainability.(3)

Elements of the process,

mechanics of material its various parameters. PO10-Lifelong learning.(3) Understanding

removal, MRR process

parameters, economic

considerations, applications

and limitations.

UCMP ELECTRO – CHEMICAL

MACHINING: Fundamentals The student shall PO1-Engineering Remembering

Knowledge.(3)

of electro chemical machining, understand the Understanding

electrochemical grinding, principle of working of

electro chemical honing and electrochemical Applying

deburring process, metal PO7-Environment and

machining method and sustainability.(2)

removal rate in ECM, Tool

design, Surface finish and the student is able to

identify the process PSO2-Automation, Operation

accuracy, economic aspects of and Maintenance.(2)

parameters of ECM.

MCMT MAPPING COURSE OUTCOMES WOTH PROGRAM OUTCOMES.

ECM – Simple problems for

estimation of metal removal

rate, fundamentals of

chemical, machining,

advantages and applications.

UCMP THERMAL METAL

REMOVAL PROCESSES: The student is able to PO1-Engineering

Knowledge.(3) Remembering

General principle and know the general

applications of Electric principle and PO5-Modern tool usage.(3) Understanding

Discharge Machining, Electric applications of EDM,

Discharge Grinding and wire PO7-Environment and Applying

EDG and Wire EDM sustainability.(2)

EDM – Power circuits for

EDM, Mechanics of metal process.

PSO2-Automation, Operation

removal in EDM, Process and Maintenance.(2)

parameters, selection of tool

electrode and dielectric fluids,

surface finish and machining

accuracy, characteristics of

spark eroded surface.

UCMP Electron Beam Machining,

Laser Beam Machining - Basic The student is able to PO1-Engineering Remembering

Knowledge.(3)

principle and theory, know the general Understanding

mechanics of material principle of EBM, PO5-Modern tool usage.(3)

removal, process parameters, Applying

LBM & the mechanics

efficiency & accuracy, PO7-Environment and

applications of material removal sustainability.(2)

MCMT MAPPING COURSE OUTCOMES WOTH PROGRAM OUTCOMES.

involved in various

PSO2-Automation, Operation

processes.

and Maintenance.(2)

UCMP Plasma Machining:

The student is able to PO1-Engineering Remembering

Application of plasma for

Knowledge.(3)

machining, metal removal know the application Understanding

mechanism, process of ARC machining, PO5-Modern tool usage.(3)

parameters, accuracy and metal removal Applying

surface finish and other PO7-Environment and

mechanisms & various sustainability.(2)

applications of plasma in

manufacturing industries. process parameters

involved in it. PSO2-Automation, Operation

and Maintenance.(2)

UCMP Abrasive jet machining, Water

The student is able to PO1-Engineering Remembering

jet machining and abrasive

Knowledge.(3)

water jet machining: Basic know about abrasive Understanding

principles, equipments, jet machining, water PO5-Modern tool usage.(3)

process variables, mechanics jet machining, abrasive Applying

of material removal, MRR, PO7-Environment and

water jet machining sustainability.(2)

application and limitations.

and the process

Magnetic abrasive finishing, PSO2-Automation, Operation

abrasive flow finishing, variables involved in

and Maintenance.(2)

Electro stream drilling, shaped it.

tube electrolytic machining.

You might also like

- Pharm Phlash Pharmacology Flash Cards 3rd Edition Ebook PDFDocument61 pagesPharm Phlash Pharmacology Flash Cards 3rd Edition Ebook PDFkeith.cruz838100% (41)

- Motion Basketball Offense SampleDocument11 pagesMotion Basketball Offense SampleJeff Haefner88% (17)

- Catalogo de Partes C80Document142 pagesCatalogo de Partes C80RafaelNo ratings yet

- 01 AAU Level 1 Test Standard Unit 1Document3 pages01 AAU Level 1 Test Standard Unit 1AMELIA AVILES CARRION100% (1)

- Ec6013 Ampmc MSMDocument94 pagesEc6013 Ampmc MSMsakthi mareeswari100% (1)

- Building With Earth A Guide To Flexible-Form Earthbag ConstructionDocument91 pagesBuilding With Earth A Guide To Flexible-Form Earthbag Constructionjhnmayor83% (6)

- ME306 Advanced Manufacturing TechnologyDocument4 pagesME306 Advanced Manufacturing Technologynandan144No ratings yet

- Un Conventional Machining Process NotesDocument174 pagesUn Conventional Machining Process Notesban murthy0% (1)

- Me 8073 UcmpDocument21 pagesMe 8073 UcmpAjay SriramNo ratings yet

- Evaluaton of 3D Printing of Admixture Concrete Geopolymer Material For Concrete StructureDocument42 pagesEvaluaton of 3D Printing of Admixture Concrete Geopolymer Material For Concrete StructureIzwan SaifudinNo ratings yet

- UCM Course InformationDocument14 pagesUCM Course InformationThiyagu SundaramNo ratings yet

- Maulana Abul Kalam Azad University of Technology, West BengalDocument45 pagesMaulana Abul Kalam Azad University of Technology, West BengalDebarshi GhoshNo ratings yet

- Unconventional Machining Processes: Subject Code: A70359 Regulations: R15-JNTUH Class: IV Year B. Tech MECH I SemDocument16 pagesUnconventional Machining Processes: Subject Code: A70359 Regulations: R15-JNTUH Class: IV Year B. Tech MECH I Sem312817116012 Ganesh RamNo ratings yet

- 17ME82Document213 pages17ME82Srinivas V BhatNo ratings yet

- Lee 2016Document12 pagesLee 2016Tushar SarkarNo ratings yet

- Cad Cam Course ContentDocument6 pagesCad Cam Course ContentVivek CNo ratings yet

- Ucmp R13 SyllDocument2 pagesUcmp R13 SyllN Dhanunjaya Rao BorraNo ratings yet

- NTMT & PPC - Course HandoutDocument6 pagesNTMT & PPC - Course HandoutmanispnNo ratings yet

- Major Project (Zeroth Review)Document10 pagesMajor Project (Zeroth Review)RUSHENDAR REDDYNo ratings yet

- MMP NotesDocument81 pagesMMP NotestatiNo ratings yet

- Micro and Nano ManufacturingDocument3 pagesMicro and Nano ManufacturingMohammed Asif NNo ratings yet

- NTM Module 1Document19 pagesNTM Module 1RishiJpNo ratings yet

- Mechanical Systems and Signal Processing: Lingmi Zhang, Tong Wang, Yukio TamuraDocument13 pagesMechanical Systems and Signal Processing: Lingmi Zhang, Tong Wang, Yukio TamuraGiacomo EspositoNo ratings yet

- Ptam CP 25.7.22Document8 pagesPtam CP 25.7.22SAMUEL SANJAY RAJA R MECHNo ratings yet

- Machining Science: Jigs & FixturesDocument77 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- Ucmp First Mid Course FileDocument160 pagesUcmp First Mid Course FileAraveetiCSReddyNo ratings yet

- Gujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807Document2 pagesGujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807ganeshNo ratings yet

- CEO MappingDocument3 pagesCEO MappingJavedNo ratings yet

- # 1 - IntroductionDocument42 pages# 1 - IntroductionRohan RautNo ratings yet

- Assignment 5Document1 pageAssignment 5utkarshtyagi2307No ratings yet

- Question Paper Code:: (10×2 20 Marks)Document2 pagesQuestion Paper Code:: (10×2 20 Marks)jastraNo ratings yet

- Unit 8: Non-Traditional Machining ProcessesDocument40 pagesUnit 8: Non-Traditional Machining ProcessesManish Kumar ChaudharyNo ratings yet

- Asg1 Amp Jan2010Document3 pagesAsg1 Amp Jan2010muhamadsaidiNo ratings yet

- 02 Ucm SyllabusDocument1 page02 Ucm SyllabusSamuelHericNo ratings yet

- AIMTDR2016 - Full - Length PaperDocument6 pagesAIMTDR2016 - Full - Length PaperMM GoudNo ratings yet

- Assignment Question Set On Modern Manufacturing ProcessDocument1 pageAssignment Question Set On Modern Manufacturing ProcessSagar KhanNo ratings yet

- Mech Vi Non Traditional Machining (10me665) NotesDocument45 pagesMech Vi Non Traditional Machining (10me665) Notesnikhil0% (1)

- 16mec324 Cad Cam Cim Question BankDocument8 pages16mec324 Cad Cam Cim Question BankAbdalmalek ShamsanNo ratings yet

- What Is ESE/ IES ?: General Studies & Engineering AptitudeDocument4 pagesWhat Is ESE/ IES ?: General Studies & Engineering AptitudeSuresh BabuNo ratings yet

- Handouts: Kongunadu College of Engineering and Technology (Autonomous)Document59 pagesHandouts: Kongunadu College of Engineering and Technology (Autonomous)Akilesh SNo ratings yet

- EWS Me 1,2,3 CO PO MappingDocument4 pagesEWS Me 1,2,3 CO PO MappingYogesh ChaudhariNo ratings yet

- FormatDocument10 pagesFormatProf. Jitendra SatputeNo ratings yet

- R18 4-2 B.Tech - OpenElectivesDocument4 pagesR18 4-2 B.Tech - OpenElectives20WH1A0557 KASHETTY DEEKSHITHANo ratings yet

- Ee601 Emd CCP Jan 2024Document9 pagesEe601 Emd CCP Jan 2024sagar manjrekarNo ratings yet

- 1.1 AM OverviewDocument28 pages1.1 AM OverviewSoundararajanNo ratings yet

- Un Conventional Machining Processes SyllabusDocument2 pagesUn Conventional Machining Processes SyllabusKalai ArasanNo ratings yet

- ME8073 - UNCONVENTIONAL MACHINING PROCESSES SyllabusDocument2 pagesME8073 - UNCONVENTIONAL MACHINING PROCESSES SyllabusP.N. MohankumarNo ratings yet

- 20EC6601CDocument2 pages20EC6601Cdivyaj3107No ratings yet

- Advanced Manufacturing Process: Course Code:13ME1149 L TPC 4 0 0 3Document3 pagesAdvanced Manufacturing Process: Course Code:13ME1149 L TPC 4 0 0 3anuragNo ratings yet

- Old Question Paper and SolutionncmDocument26 pagesOld Question Paper and SolutionncmHARSH MALVIYANo ratings yet

- MMP SyllabusDocument1 pageMMP SyllabusShiba Narayan SahuNo ratings yet

- Modern Optimization Techniques For Advanced MachiningDocument9 pagesModern Optimization Techniques For Advanced MachiningPrapto PraptNo ratings yet

- Ucm SyllabusDocument2 pagesUcm Syllabusarun2386No ratings yet

- 6th Sem SyllabusDocument16 pages6th Sem SyllabusSOUMIK DASNo ratings yet

- ME (Updated)Document2 pagesME (Updated)AanjanayshatmaNo ratings yet

- MPD ASSIGNMENT-2Document1 pageMPD ASSIGNMENT-2Prinkesh MauryaNo ratings yet

- EDM Process Optimisation Via Predicting A Controller Model: Computational Materials Science and Surface EngineeringDocument7 pagesEDM Process Optimisation Via Predicting A Controller Model: Computational Materials Science and Surface EngineeringNalla MohamedNo ratings yet

- Syllabus 2.0Document10 pagesSyllabus 2.0awesomesiddharth2001No ratings yet

- Open Electrive I - VI Semester - AICTE Model Curriculum 2020-21Document11 pagesOpen Electrive I - VI Semester - AICTE Model Curriculum 2020-21seenubarman12No ratings yet

- 2ET1000103T Applied-PhysicsDocument3 pages2ET1000103T Applied-PhysicsvjbhavsarhmspceNo ratings yet

- 3 1 PDFDocument15 pages3 1 PDFGjk ChaitanyaNo ratings yet

- Electrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyFrom EverandElectrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyRating: 4 out of 5 stars4/5 (1)

- Advanced Test Methods for SRAMs: Effective Solutions for Dynamic Fault Detection in Nanoscaled TechnologiesFrom EverandAdvanced Test Methods for SRAMs: Effective Solutions for Dynamic Fault Detection in Nanoscaled TechnologiesNo ratings yet

- Topology Optimization and AI-based Design of Power Electronic and Electrical Devices: Principles and MethodsFrom EverandTopology Optimization and AI-based Design of Power Electronic and Electrical Devices: Principles and MethodsNo ratings yet

- Model Set 2 FeaDocument2 pagesModel Set 2 FeaKalai ArasanNo ratings yet

- Dhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Document7 pagesDhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Kalai ArasanNo ratings yet

- IE8693-Production Planning and ControlDocument20 pagesIE8693-Production Planning and ControlKalai ArasanNo ratings yet

- Government of Tamil Nadu Directorate of Technical Education Tamil Nadu Engineering Admission - 2020Document3 pagesGovernment of Tamil Nadu Directorate of Technical Education Tamil Nadu Engineering Admission - 2020Kalai ArasanNo ratings yet

- Group Number Group Category Group Coordinator Module Code Name/Duration Module Coordinator/department Credit Details L T P CDocument2 pagesGroup Number Group Category Group Coordinator Module Code Name/Duration Module Coordinator/department Credit Details L T P CKalai ArasanNo ratings yet

- Assignment Questions: Unit I Subjective QuestionsDocument2 pagesAssignment Questions: Unit I Subjective QuestionsKalai ArasanNo ratings yet

- CAD Coaching Class 2017-18Document4 pagesCAD Coaching Class 2017-18Kalai ArasanNo ratings yet

- Ucmp QuestionsDocument6 pagesUcmp QuestionsKalai ArasanNo ratings yet

- TC MergedDocument2 pagesTC MergedKalai ArasanNo ratings yet

- Non-Traditional Machining Processes: ME 355, Introduction To Manufacturing ProcessesDocument22 pagesNon-Traditional Machining Processes: ME 355, Introduction To Manufacturing ProcessesKalai ArasanNo ratings yet

- IV B.Tech II Sem. (ME) Academic PlansDocument16 pagesIV B.Tech II Sem. (ME) Academic PlansKalai ArasanNo ratings yet

- Ucmp Course File: Qis College of Engineering TechnologyDocument1 pageUcmp Course File: Qis College of Engineering TechnologyKalai ArasanNo ratings yet

- Unit - 1Document1 pageUnit - 1Kalai ArasanNo ratings yet

- Ucmp Case StudyDocument1 pageUcmp Case StudyKalai ArasanNo ratings yet

- Ucmp Detailed PlanDocument13 pagesUcmp Detailed PlanKalai ArasanNo ratings yet

- Evaluation of Mechanical Properties of Al-Tic Composites Reinforced With Carbon Nano TubesDocument4 pagesEvaluation of Mechanical Properties of Al-Tic Composites Reinforced With Carbon Nano TubesKalai ArasanNo ratings yet

- Design and Optimization of Rotary Jet Spinning Process For Production of MicrofibersDocument7 pagesDesign and Optimization of Rotary Jet Spinning Process For Production of MicrofibersKalai ArasanNo ratings yet

- Edited Copy in Ieee .MetDocument4 pagesEdited Copy in Ieee .MetKalai ArasanNo ratings yet

- Kalaiyarasan Eg CPDocument15 pagesKalaiyarasan Eg CPKalai ArasanNo ratings yet

- Un Conventional Machining Processes SyllabusDocument2 pagesUn Conventional Machining Processes SyllabusKalai ArasanNo ratings yet

- Dhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Document8 pagesDhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Kalai ArasanNo ratings yet

- R08791 Modelingandsimulat Objec VE:: L TP C 3 3 ToDocument1 pageR08791 Modelingandsimulat Objec VE:: L TP C 3 3 ToKalai ArasanNo ratings yet

- UCMP Content Beyond SyllabusDocument1 pageUCMP Content Beyond SyllabusKalai ArasanNo ratings yet

- Testing Solid Insulation of Electrical Equipment: Facilities Instructions, Standards, and Techniques Volume 3-1Document69 pagesTesting Solid Insulation of Electrical Equipment: Facilities Instructions, Standards, and Techniques Volume 3-1denzil_1000100% (12)

- KKT List 12101Document15 pagesKKT List 12101K2O2No ratings yet

- Last Rank p8nDocument3 pagesLast Rank p8n019AJAY KRISHNA PNo ratings yet

- Do You Need An Ashtray For CigarsDocument23 pagesDo You Need An Ashtray For Cigarsdanishfiverr182No ratings yet

- CV Template SolvoDocument1 pageCV Template SolvoJhayandChris Los Mas Finos100% (1)

- S&SCycle Air Filter Inst 51-1045Document1 pageS&SCycle Air Filter Inst 51-1045Jonathan BanksNo ratings yet

- USAID Graphics Standards Manual and Partner Co Branding Guide February 2016 PDFDocument66 pagesUSAID Graphics Standards Manual and Partner Co Branding Guide February 2016 PDFSyafira Ayudarechta Tara WenditaNo ratings yet

- Paramount Digital BookletDocument16 pagesParamount Digital BookletHASSAAN UMMENo ratings yet

- DxDiag - GrifoDocument16 pagesDxDiag - GrifoCaetano OlchanheskiNo ratings yet

- The Cognitive FunctionsDocument5 pagesThe Cognitive FunctionsMoon5627No ratings yet

- Print Outs and Stamp Papers - Tara Chand Inder Sain and Passco Impex PVT LTDDocument2 pagesPrint Outs and Stamp Papers - Tara Chand Inder Sain and Passco Impex PVT LTDSubhash JainNo ratings yet

- ECA 2 LAb REPORT 6Document13 pagesECA 2 LAb REPORT 6Atyia JavedNo ratings yet

- The Crusades - Final Assignment (Answer Key)Document3 pagesThe Crusades - Final Assignment (Answer Key)api-284208938No ratings yet

- The Fourth Seal Rev 6: 7-8: EagleDocument1 pageThe Fourth Seal Rev 6: 7-8: Eaglel mapepetaNo ratings yet

- 25 Bar TricksDocument2 pages25 Bar TricksRahul Ramesh100% (1)

- Chapter 14Document9 pagesChapter 14kayrul70No ratings yet

- QUIZ ASSIGNMENT NO. 2 Dynamic of Rigid BodiesDocument2 pagesQUIZ ASSIGNMENT NO. 2 Dynamic of Rigid BodiesAicelleNo ratings yet

- Managing Brands Over Time - CHPTR - 7Document18 pagesManaging Brands Over Time - CHPTR - 7Vineet AbrahamNo ratings yet

- EE 1403 DESIGN OF ELECTRICAL APPARATUS Question BankDocument4 pagesEE 1403 DESIGN OF ELECTRICAL APPARATUS Question BankBavi ThraaNo ratings yet

- Dontike Srikanth: Career Profile & Career ObjectiveDocument4 pagesDontike Srikanth: Career Profile & Career ObjectivesupriyaNo ratings yet

- ACOMAF Part 23 The HouseDocument83 pagesACOMAF Part 23 The HouseYasmin MilcentNo ratings yet

- Ray Optics Worksheet 1Document2 pagesRay Optics Worksheet 1Karthika UmashankarNo ratings yet

- Harrison Bergeron QuestionsDocument1 pageHarrison Bergeron QuestionsRod FobertNo ratings yet

- Ong Kim SengDocument2 pagesOng Kim SengDrSunanda MitraNo ratings yet

- Toothbrush SurveyDocument24 pagesToothbrush SurveyCharuta Jagtap TekawadeNo ratings yet