Professional Documents

Culture Documents

HSB 171 ASME SectionVIII Division I F E

Uploaded by

Homar Hernández Junco0 ratings0% found this document useful (0 votes)

32 views2 pagesOriginal Title

HSB-171-ASME-SectionVIII-Division-I-F-E

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views2 pagesHSB 171 ASME SectionVIII Division I F E

Uploaded by

Homar Hernández JuncoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

ASME Section VIII, Division 1

Introduction to Section VIII, Division 1

Course Description: This two-day training course is a basic

introductory overview of the Section VIII, Division 1 Unfired

Pressure Vessels Code. It focuses on the ASME Certificate

Holder engaged in the construction of unfired pressure vessels,

and organizations conducting repairs or alterations of these

vessels under the NBIC.

Topics Covered Material Documentation

−−Test Reports

Organization and Formatting −−Certificates of Compliance

HSB is part of Munich Re of VIII-1

Material Inspection

HSB is a leading specialty Scope of VIII-1 −−Condition

insurer providing equipment −−Pressure and Temperature Scope −−Markings

breakdown, other specialty −−Geometric Scope −−Identification

coverages, inspection services −−Scope Exemptions

and engineering-based risk Subsection C Requirements

management that set the standard Material Requirements −−Accepted Specifications

for excellence worldwide. −−Pressure Retaining −−Fabrication Requirements

We anticipate risks and provide −−Non-pressure Retaining −−NDE Requirements

forward-thinking solutions. −−Acceptability −−Toughness

−−Code Cases

www.munichre.com/HSB −−Product Forms Design Requirements

−−Filler Metals −−Basic Design Philosophy

−−Design Loads

Material Recertification −−Responsibilities for Design

−−Identified −−Parameters

−−Partial Documentation −−Welded Joint Categories

−−Unidentified and Undocumented −−Joint Types and Limitations

−−Differences in product form −−Joint Efficiencies

−−Application of Radiography

Standard Pressure Parts

−−ASME Accepted Product Standard Toughness Requirements

−−Manufacturers’ Standard −−Determining MDMT

−−Pressure and Temperature Rating −−Exempt or Required

−−Notable Exemptions

Material Identification −−Toughness Test Performance

−−Marking Requirements −−Base Metal Tests

−−Coded Markings −−PQR Tests

−−Subdivided Materials −−Production Tests

Hartford Steam Boiler Page 2/2

ASME Section VIII, Division 1

Introduction to Section VIII, Division 1

Fabrication Requirements Postweld Heat Treatment

−− Exemptions

Cutting Plates and Other Stock −− Time at Temperature

−− Cut Edge Examination −− Heating and Cooling Rates

−−Cutting Methods −− Thermocouple Placement

−− Toughness Implications

Forming Shell Sections and Heads

−− Acceptable Forming Methods Pressure Relief

−− Fiber Elongation −− Capacity Certification Selection

−−Shape Conformance and and Installation

Tolerances

Pressure Testing

Welded Attachments −− Test Pressure Determination

−− Welding Requirements −− Test Application

−− Opening in Welds

−− Lugs and Fittings Code Stamping

−− Location

Joint Preparation −− Required Information

−− Edge Alignment

−− Dissimilar Thickness Manufacturers’ Data Reports

−− Tack Welds −− Preparation and Certification

−− Joint Cleaning −− Distribution

−−Record Retention

Welding Requirements

−− Acceptable Welding Processes

−− Procedure and Performance

−− Qualifications

−− Joint Preparation

−− Final Welding Inspection Criteria

For more information contact:

+1-860-722-5767 or

Email: GetInfo@hsb.com

© 2017 The Hartford Steam Boiler Inspection and Insurance Company. All rights reserved.

NOT IF, BUT HOW HSB-171 (New 12/16)

You might also like

- HSB 166 ASME Section I With ASME B31 1 PDFDocument2 pagesHSB 166 ASME Section I With ASME B31 1 PDF278 278No ratings yet

- HSB 169 Asme Sectionv F eDocument2 pagesHSB 169 Asme Sectionv F eSai NaniNo ratings yet

- Laser Welding Audit SummaryDocument3 pagesLaser Welding Audit Summaryalfredo garciaNo ratings yet

- Module Details Gravity and Low Pressure Die Casting Technology C - Casting and Following ProcessesDocument5 pagesModule Details Gravity and Low Pressure Die Casting Technology C - Casting and Following ProcessessalimmalmaliNo ratings yet

- NDT-SA-SATORP-PMI-60 Rev 01-Date-14 Aug-2023Document12 pagesNDT-SA-SATORP-PMI-60 Rev 01-Date-14 Aug-2023Md Abu Hanif RajuNo ratings yet

- 6.4 Keynote - HorsleyDocument17 pages6.4 Keynote - HorsleyKrishna KumarNo ratings yet

- Ei-3008 - Sameer Mapari - Sap # 80001413Document14 pagesEi-3008 - Sameer Mapari - Sap # 80001413gayas416No ratings yet

- Abu Dhabi Crude Oil Pipeline Daily Inspection LogDocument1 pageAbu Dhabi Crude Oil Pipeline Daily Inspection LogAhmed AlyNo ratings yet

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 pagesNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNo ratings yet

- TEPL Profile For EngineeringDocument17 pagesTEPL Profile For EngineeringS NileshNo ratings yet

- Drill String DesignDocument3 pagesDrill String Designjefpri simanjuntakNo ratings yet

- EagleBurgmann AX25 ENDocument4 pagesEagleBurgmann AX25 ENswosthi sambitNo ratings yet

- Technical Doc. - Coated Steel Pipe LayingDocument420 pagesTechnical Doc. - Coated Steel Pipe Layingrex0% (1)

- Training Courses For Manufacturing Industry Thors Elearning SolutionsDocument1 pageTraining Courses For Manufacturing Industry Thors Elearning Solutionsgtsi.draftsmanNo ratings yet

- IME - Bolted Flanged Joints Methods & PracticesDocument188 pagesIME - Bolted Flanged Joints Methods & PracticesHeviiNo ratings yet

- 2019 - Saep-1160Document24 pages2019 - Saep-1160smdriyazbashaNo ratings yet

- Saes L 133Document52 pagesSaes L 133AwaisNo ratings yet

- Welding Inspection Handbook PDF 1623987530Document29 pagesWelding Inspection Handbook PDF 1623987530Dross AlssNo ratings yet

- Api 570 PreDocument3 pagesApi 570 PreBhargava NaiduNo ratings yet

- 09 Samss 091Document27 pages09 Samss 091AbhilashNo ratings yet

- Asme Section IX - NewDocument70 pagesAsme Section IX - NewAnaswarps100% (2)

- TutorialDocument64 pagesTutorial2202199122No ratings yet

- Referencias SubseaDocument19 pagesReferencias SubseaEdgar I RamirezNo ratings yet

- High Frequency Welded Pipe SpecificationDocument22 pagesHigh Frequency Welded Pipe SpecificationAwais CheemaNo ratings yet

- Steel Erection Method StatementDocument16 pagesSteel Erection Method StatementPangky AbasoloNo ratings yet

- Materials System SpecificationDocument28 pagesMaterials System SpecificationAli RazaNo ratings yet

- 09-Samss-089 (2018)Document28 pages09-Samss-089 (2018)Ali RazaNo ratings yet

- 09-SAMSS-089 Shop Applied FBE Coating Jan 2018Document28 pages09-SAMSS-089 Shop Applied FBE Coating Jan 2018Ahmed & Rehana MoinuddinNo ratings yet

- Irs T12-2009Document49 pagesIrs T12-2009a K sarkarNo ratings yet

- TSPP8Document76 pagesTSPP8Ian Naylor100% (1)

- SAES-W-014 - Old SpecDocument12 pagesSAES-W-014 - Old SpecMichael TayactacNo ratings yet

- Updated WMS - Welding of Duplex Stainless SteelDocument5 pagesUpdated WMS - Welding of Duplex Stainless Steelcameron toolseeNo ratings yet

- Brochure API 570 (150129) PDFDocument4 pagesBrochure API 570 (150129) PDFMakhfud Edy100% (1)

- Code of Practice For Metal Arc Welding in Structural Steel Bridges Carrying Rail, Rail-Cum-Road or Pedestrian TrafficDocument32 pagesCode of Practice For Metal Arc Welding in Structural Steel Bridges Carrying Rail, Rail-Cum-Road or Pedestrian TrafficMd BIN HASANNo ratings yet

- 02 Samss 012Document10 pages02 Samss 012bmkaleNo ratings yet

- 02 Samss 012 PDFDocument10 pages02 Samss 012 PDFbmkaleNo ratings yet

- Dissimilar Welding JointsDocument12 pagesDissimilar Welding JointsAhmed ELmlahyNo ratings yet

- EDO WMS Fuel Storage Tank R01Document29 pagesEDO WMS Fuel Storage Tank R01ocayli100% (1)

- Module 7 - Summary: 7A - ASME Section IX Weld Procedure Qualification 7B - ASME Section IX Welder QualificationDocument42 pagesModule 7 - Summary: 7A - ASME Section IX Weld Procedure Qualification 7B - ASME Section IX Welder Qualificationkapster KannourNo ratings yet

- 01 Samss 012 2014Document10 pages01 Samss 012 2014lhanx2No ratings yet

- Materials System SpecificationDocument22 pagesMaterials System SpecificationbalajiNo ratings yet

- ECVN Company ProfileDocument22 pagesECVN Company ProfilethanhluanvtNo ratings yet

- Poisson and Youngs ONG Design and AnalysisDocument1 pagePoisson and Youngs ONG Design and Analysisjesu daniel vNo ratings yet

- 09 Samss 091Document27 pages09 Samss 091Abdelrahman AwadallahNo ratings yet

- Distribución Preguntas API 1104 PDFDocument2 pagesDistribución Preguntas API 1104 PDFLora BoydNo ratings yet

- Saes-H-002 - ArmacoDocument29 pagesSaes-H-002 - ArmacoVenkat Gokila DT100% (1)

- 09 Samss 089-2016Document26 pages09 Samss 089-2016lhanx2No ratings yet

- Asme Boiler and Pressure Vessel Codes: SectionsDocument68 pagesAsme Boiler and Pressure Vessel Codes: Sectionsajay thomasNo ratings yet

- Method Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Document19 pagesMethod Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Habib ur rahmanNo ratings yet

- 01-SAMSS-012Document11 pages01-SAMSS-012Abrar HussainNo ratings yet

- LR Weld Certification Guide v1.3 SubscribeDocument24 pagesLR Weld Certification Guide v1.3 SubscribeSergio Jesus SanjurjoNo ratings yet

- Reconciliation of Welding ConsumablesDocument24 pagesReconciliation of Welding ConsumablesHema Nandh100% (1)

- Top CO - Catalog February 2015 - R6 PDFDocument36 pagesTop CO - Catalog February 2015 - R6 PDFzapspazNo ratings yet

- 01 Samss 044 PDFDocument11 pages01 Samss 044 PDFAbdul Rahim ShaikhNo ratings yet

- Weld Acceptance Criteria and Repair Procedures Arc Welds and Arc Brazes - SteelDocument32 pagesWeld Acceptance Criteria and Repair Procedures Arc Welds and Arc Brazes - SteelLuis zamora100% (2)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- DPI620 Genii IS Manual PDFDocument98 pagesDPI620 Genii IS Manual PDFHomar Hernández JuncoNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument7 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingHomar Hernández JuncoNo ratings yet

- Im2755 97eDocument18 pagesIm2755 97eRubiccello TscaNo ratings yet

- Model-20-40-41-60-61S-Solidfront Heavy Duty All Ss Gauges PDFDocument2 pagesModel-20-40-41-60-61S-Solidfront Heavy Duty All Ss Gauges PDFHomar Hernández JuncoNo ratings yet

- Wellmark Series 2600 PDFDocument6 pagesWellmark Series 2600 PDFHomar Hernández JuncoNo ratings yet

- Wellmark Series 2600 PDFDocument6 pagesWellmark Series 2600 PDFHomar Hernández JuncoNo ratings yet

- Model-20-40-41-60-61S-Solidfront Heavy Duty All Ss Gauges PDFDocument2 pagesModel-20-40-41-60-61S-Solidfront Heavy Duty All Ss Gauges PDFHomar Hernández JuncoNo ratings yet

- 2600 Series Catalog R3Document96 pages2600 Series Catalog R3Mrr Afrasiabi100% (1)

- Model-20-40-41-60-61S-Solidfront Heavy Duty All Ss Gauges PDFDocument2 pagesModel-20-40-41-60-61S-Solidfront Heavy Duty All Ss Gauges PDFHomar Hernández JuncoNo ratings yet

- SS CTCDocument8 pagesSS CTCbladimir1971No ratings yet

- CASH ACME FVX - SpecDocument2 pagesCASH ACME FVX - SpecHomar Hernández JuncoNo ratings yet

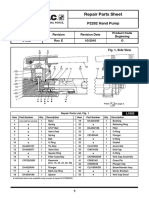

- Repair Parts Sheet for Hand Pump Product Code P2282Document4 pagesRepair Parts Sheet for Hand Pump Product Code P2282Yeison Prasca MartinezNo ratings yet

- Architecture in The AnthropoceneDocument265 pagesArchitecture in The Anthropoceneziyad fauziNo ratings yet

- Zaldivar Et Al. 2017 (Dopamine Is Signaled by Mid-Frequency Oscillations and Boosts Output Layers Visual Information in Visual Cortex)Document30 pagesZaldivar Et Al. 2017 (Dopamine Is Signaled by Mid-Frequency Oscillations and Boosts Output Layers Visual Information in Visual Cortex)FRANCISCO ELI LEZAMA GUTIERREZNo ratings yet

- Model146C DynamicGasCal 156file - 18125Document150 pagesModel146C DynamicGasCal 156file - 18125api-26966403100% (1)

- Audi SSP 822703 4 2 L v8 Fsi Engine VolkswagenDocument4 pagesAudi SSP 822703 4 2 L v8 Fsi Engine Volkswagenmiriam100% (34)

- A Perspective in Accelerated Orthodontics With Aligner Treatment 2017 Seminars in OrthodonticsDocument7 pagesA Perspective in Accelerated Orthodontics With Aligner Treatment 2017 Seminars in Orthodonticsdruzair007No ratings yet

- Open Fracture Classification and TreatmentDocument70 pagesOpen Fracture Classification and TreatmentKelly Khesya100% (1)

- Power Grid Corporation of India Limited Construction ManagementDocument8 pagesPower Grid Corporation of India Limited Construction ManagementRahul RanjanNo ratings yet

- Bitumen Water ProofingDocument23 pagesBitumen Water ProofingAkshthagowda848_1952No ratings yet

- 3 Uscg BWM VRPDocument30 pages3 Uscg BWM VRPdivinusdivinusNo ratings yet

- CCTmanual 56Document226 pagesCCTmanual 56Jim Barrón GarcíaNo ratings yet

- CIB 357th MeetingDocument49 pagesCIB 357th MeetingbarkhaNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19Premal PatelNo ratings yet

- Wiring Diagrams Model Yk (Style G) Liquid Chillers Optiview Control Center With SSS, LV VSD W/ Modbus, & MV VSDDocument30 pagesWiring Diagrams Model Yk (Style G) Liquid Chillers Optiview Control Center With SSS, LV VSD W/ Modbus, & MV VSDAbdulSattarNo ratings yet

- Wall Mountable Switches - Wall Mounting GuideDocument3 pagesWall Mountable Switches - Wall Mounting GuideMarcos FilipeNo ratings yet

- Forward Blocking ModeDocument10 pagesForward Blocking ModeSmithi SureshanNo ratings yet

- Mathematics 2nd Quarter Test With TOSDocument8 pagesMathematics 2nd Quarter Test With TOSRona Mae Aira AvilesNo ratings yet

- 02-A Guide To Chinese Classical MythologyDocument22 pages02-A Guide To Chinese Classical MythologyNguyen Pham Thien ThanhNo ratings yet

- TR019999012181 enDocument37 pagesTR019999012181 enAliTronic1972No ratings yet

- II PUC PHYSICS - Previously Appeared Questions and Answers For 2021 Exam by MANJUNATH BDocument52 pagesII PUC PHYSICS - Previously Appeared Questions and Answers For 2021 Exam by MANJUNATH BVishal Ramesh100% (1)

- Syngo - Via: HW Data SheetDocument4 pagesSyngo - Via: HW Data SheetCeoĐứcTrườngNo ratings yet

- YZF-R15: Parts & AccessoriesDocument55 pagesYZF-R15: Parts & AccessoriesSiam HussainNo ratings yet

- BA Anchor Data SheetDocument17 pagesBA Anchor Data SheetbrodieNo ratings yet

- Man and Mystery Vol 13 - Monsters and Cryptids (Rev06)Document139 pagesMan and Mystery Vol 13 - Monsters and Cryptids (Rev06)Pablo Jr AgsaludNo ratings yet

- Carte Blanche: The New James Bond Novel by Jeffery DeaverDocument12 pagesCarte Blanche: The New James Bond Novel by Jeffery DeaverSimon and Schuster0% (1)

- Physical Education Week 1 ActivitiesDocument4 pagesPhysical Education Week 1 ActivitiesTummys TummieNo ratings yet

- Panasonic DMP BDT230PDocument87 pagesPanasonic DMP BDT230PaldoNo ratings yet

- JAOP Progress ReportDocument36 pagesJAOP Progress ReportnidhisasidharanNo ratings yet

- 2015 - 3 Lennar Concord Proposal PDFDocument148 pages2015 - 3 Lennar Concord Proposal PDFEric LiptonNo ratings yet

- Viscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Document40 pagesViscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Majid KhanNo ratings yet

- Advances in The Study of The Genetic Disorders PDFDocument484 pagesAdvances in The Study of The Genetic Disorders PDFhayamasNo ratings yet