Professional Documents

Culture Documents

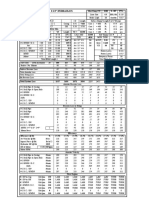

Zaman Textile Processing Unit: Machines Power Consumption

Zaman Textile Processing Unit: Machines Power Consumption

Uploaded by

Abdul Aziz Khan0 ratings0% found this document useful (0 votes)

8 views2 pagesThis document lists the machines in the Zaman Textile Processing Unit along with their operating speeds, running electrical loads in amperes, and power consumption in kilowatts. There are 42 machines listed including singeing machines, bleaching machines, mercerizing machines, printing machines, and others. The running electrical loads range from 4 to 154 amperes. The power consumption ranges from 2 to 88 kilowatts, with the highest consumption for Stenter No. 01. A power factor of 0.83 was used to calculate power consumption in kilowatts.

Original Description:

Original Title

Machines Power Consumption Detail.xlsx

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document lists the machines in the Zaman Textile Processing Unit along with their operating speeds, running electrical loads in amperes, and power consumption in kilowatts. There are 42 machines listed including singeing machines, bleaching machines, mercerizing machines, printing machines, and others. The running electrical loads range from 4 to 154 amperes. The power consumption ranges from 2 to 88 kilowatts, with the highest consumption for Stenter No. 01. A power factor of 0.83 was used to calculate power consumption in kilowatts.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesZaman Textile Processing Unit: Machines Power Consumption

Zaman Textile Processing Unit: Machines Power Consumption

Uploaded by

Abdul Aziz KhanThis document lists the machines in the Zaman Textile Processing Unit along with their operating speeds, running electrical loads in amperes, and power consumption in kilowatts. There are 42 machines listed including singeing machines, bleaching machines, mercerizing machines, printing machines, and others. The running electrical loads range from 4 to 154 amperes. The power consumption ranges from 2 to 88 kilowatts, with the highest consumption for Stenter No. 01. A power factor of 0.83 was used to calculate power consumption in kilowatts.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

ZAMAN TEXTILE PROCESSING UNIT

MACHINES POWER CONSUMPTION

Sr.no Machine Name Speed Running Load In Ampere Running Load in KW

R S T

1 SINGEING # 01 150 m/min 62 48 48 35

2 SINGEING # 02 100m/min 17 14 15 10

3 GOLLER BLEACHING 42m/min 32 33 47 27

4 BRUGMAN BLEACHING 75m/min 27 33 35 20

5 GOLLER MERCERIZE 40m/min 43 30 33 25

6 BRUGMAN MERCERIZE 75m/min 59 22 24 33

7 THERMOSOL # 01 50m/min 51 58 51 33

8 THERMOSOL # 02

9 GOLLER PADSTEAM 38m/min 35 28 23 20

10 BRUGMAN PADSTEAM

11 BABCOCK WASHING 50m/min 10 10 12 7

12 ROPE WASHING 72m/min 29 30 30 17

13 STENTER NO # 01 47m/min 154 151 145 88

14 STENTER NO # 02 70m/min 95 81 90 54

15 STENTER NO # 03 66m/min 68 71 71 40

16 STENTER NO # 04 80m/min 107 92 98 62

17 STENTER NO # 05 65m/min 81 86 87 50

18 STENTER NO # 06 66m/min 77 60 74 43

19 STENTER NO # 07 55m/min 121 112 107 70

20 ROTARY PRINTING 70m/min 64 63 74 43

21 DIGITAL PRINTING # 01 125m/hr 35 20 23 20

22 DIGITAL PRINTING # 02 228m/hr 23 27 27 16

23 DIGITAL PRINTING (BOLT) 70m/min 73 72 80 46

24 ARIOLI STEAM AGER 33m/min 12 10 12 7

25 SANFORIZE # 01 60m/min 5 5 5 3

26 SNAFORIZE # 02 45m/min 6 6 6 3

27 CALANDER # 01 120m/min 58 51 53 33

28 CALANDER # 02

29 OIL BOILER # 01 N/A 70 70 71 41

30 OIL BOILER # 02 N/A 77 80 83 48

31 C.R.U N/A 41 40 40 24

32 BATCHER ROTATION # 01 N/A 5 5 5 3

33 BATCHER ROTATION # 02 N/A 11 11 11 6

34 JET DYEING # 1

35 JET DYEING # 2

36 JET DYEING # 3

37 JET DYEING # 4

38 JUMBO DYEING #01 5 5.5 5 3

39 JUMBO DYEING #02 15 15 15 9

40 WINCH # 1 4 4 4 2

41 WINCH # 2 4 4 4 2

42 WINCH # 3

Note: Power Factor 0.83 Applied for Kw Calaculation

ZAMAN TEXTILE PROCESSING UNIT

43 WINCH # 4

Note: Power Factor 0.83 Applied for Kw Calaculation

You might also like

- Daily Insp Report For SLV (Tape Coating)Document6 pagesDaily Insp Report For SLV (Tape Coating)Richart SembiringNo ratings yet

- Bobcat 320D Excavator Parts Catalogue Manual SN 223811001 and Above PDFDocument28 pagesBobcat 320D Excavator Parts Catalogue Manual SN 223811001 and Above PDFjnfksmemmsNo ratings yet

- BPM Studio 4.9.1 ManualDocument144 pagesBPM Studio 4.9.1 Manualpirotanis100% (1)

- C & I For Steam TurbineDocument46 pagesC & I For Steam Turbinekumarmm1234100% (4)

- 14c CashManagementDocument76 pages14c CashManagementali iqbalNo ratings yet

- Book 1 Bodymaker CMB - English-7Document23 pagesBook 1 Bodymaker CMB - English-7felipe alfonso guarnizo naranjoNo ratings yet

- Gas / Liquid Separator Sizing K Factor Calculation: DL 28.45 DG 2.843 QG 1.23Document9 pagesGas / Liquid Separator Sizing K Factor Calculation: DL 28.45 DG 2.843 QG 1.23lguardiaNo ratings yet

- Capex, Overhold, CrecimientoDocument40 pagesCapex, Overhold, CrecimientoC CHINCHAYANNo ratings yet

- Upt. Rsud Bali Mandara: Instalasi Bedah Sentral Dan AnestesiDocument3 pagesUpt. Rsud Bali Mandara: Instalasi Bedah Sentral Dan AnestesiariadaketutNo ratings yet

- Elecrical Motors: SR - No. Code Location Sub Section HP KW AMP RPM F.BDocument92 pagesElecrical Motors: SR - No. Code Location Sub Section HP KW AMP RPM F.BKhurrum RajputNo ratings yet

- Main Engine ParametersDocument5 pagesMain Engine ParametersStefas DimitriosNo ratings yet

- Commissionig ListDocument23 pagesCommissionig ListShajar AbbasNo ratings yet

- Company Amoco Field Liuhua 11-1 Well No. Location: SchlumbergerDocument1 pageCompany Amoco Field Liuhua 11-1 Well No. Location: Schlumberger叶芊No ratings yet

- Technical Specification 18Document2 pagesTechnical Specification 18sarvan shivaNo ratings yet

- NewDocument2 pagesNewApril Joy Daniel Bigornia100% (1)

- Sacmi Material PriceDocument1 pageSacmi Material PriceKrishnendu GhoshNo ratings yet

- Ws1081084720 - Emerson Mexico - Cutting Tools Cost BreakdownDocument8 pagesWs1081084720 - Emerson Mexico - Cutting Tools Cost BreakdownalfredNo ratings yet

- 2 PN40 (WCB)Document2 pages2 PN40 (WCB)siddhesh_guessNo ratings yet

- Laboratory Test Report On Plate Load Bearing: (ASTM D 1194)Document3 pagesLaboratory Test Report On Plate Load Bearing: (ASTM D 1194)Joshua John JulioNo ratings yet

- Daily Insp Report For SLV (Polymeric Sheet Coating)Document2 pagesDaily Insp Report For SLV (Polymeric Sheet Coating)Richart SembiringNo ratings yet

- Curvas de HumedadDocument42 pagesCurvas de HumedadJesus PeredaNo ratings yet

- Water ConsumptionDocument11 pagesWater Consumptionmayis40No ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- Update 1500 DDR Well 1612B-BK16 - 24-05-2017Document1 pageUpdate 1500 DDR Well 1612B-BK16 - 24-05-2017Them Bui XuanNo ratings yet

- Hatchery BLDG Scope of Work For Minor Civil Works - S-CURVE 123010Document19 pagesHatchery BLDG Scope of Work For Minor Civil Works - S-CURVE 123010hampshireiiiNo ratings yet

- Aquacraft RateDocument2 pagesAquacraft RateT JNo ratings yet

- Check ListDocument19 pagesCheck ListrobertoNo ratings yet

- Packing ListDocument2 pagesPacking ListAneesh ConstantineNo ratings yet

- I N V O I C E Packing ListDocument10 pagesI N V O I C E Packing ListToty GusmaoNo ratings yet

- 8.5mva FINIAL Test ReportDocument5 pages8.5mva FINIAL Test ReportRyan JohnNo ratings yet

- Hyundai Himate 231228Document5 pagesHyundai Himate 231228safihelcokNo ratings yet

- Tube Products of India Avadi, Chennai-54 Connected Load SummaryDocument12 pagesTube Products of India Avadi, Chennai-54 Connected Load SummaryanandpurushothamanNo ratings yet

- ITP Pre Hydrotest GIGLDocument1 pageITP Pre Hydrotest GIGLSarthak EnterprisesNo ratings yet

- Lewis Marine Supply 2021.12.08 CompareDocument11 pagesLewis Marine Supply 2021.12.08 Compare381tutNo ratings yet

- Concrete Pour Record - 030: Al Shahad Tower February 17, 2016 C40/20 Retaining Wall at Basement 5Document3 pagesConcrete Pour Record - 030: Al Shahad Tower February 17, 2016 C40/20 Retaining Wall at Basement 5klynchelleNo ratings yet

- Petrol BillDocument1 pagePetrol Billkisholay.debNo ratings yet

- 077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuDocument1 page077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuChakravarthy BharathNo ratings yet

- Lot Preparation Table - 050336Document14 pagesLot Preparation Table - 050336Kaye GuceNo ratings yet

- Tube Products of India Avadi, Chennai-54 Connected Load SummaryDocument5 pagesTube Products of India Avadi, Chennai-54 Connected Load SummaryanandpurushothamanNo ratings yet

- 9 Radiator Installation PDFDocument3 pages9 Radiator Installation PDFAnonymous aufoLkcwhZNo ratings yet

- APICOM Parts Comparison With 2002 QuotationDocument5 pagesAPICOM Parts Comparison With 2002 QuotationiocsachinNo ratings yet

- S.No. Machine Brand Model / TypeDocument2 pagesS.No. Machine Brand Model / TypeAbdul Aziz KhanNo ratings yet

- Screenshot 2023-07-11 at 12.36.33 PMDocument3 pagesScreenshot 2023-07-11 at 12.36.33 PMNGRD MotorsNo ratings yet

- Required Laboratory Appratus For 01 PKG: JAGDAMBA Construction SURAJPURDocument2 pagesRequired Laboratory Appratus For 01 PKG: JAGDAMBA Construction SURAJPURchitranjan4kumar-8No ratings yet

- Plumbing ItemsDocument4 pagesPlumbing ItemsGurumoorthi PNo ratings yet

- Pubg Mobile Bushkas SpreadsheetDocument6 pagesPubg Mobile Bushkas SpreadsheetimranNo ratings yet

- Nizwa Project Electrical & Lighting Work - Telephone Conduit WiringDocument14 pagesNizwa Project Electrical & Lighting Work - Telephone Conduit Wiringqazalbash1109588No ratings yet

- S/No C/No PT No Nomenclature A/U QTY Wheel Loader 2021Document5 pagesS/No C/No PT No Nomenclature A/U QTY Wheel Loader 2021Pannalal RajwarNo ratings yet

- EOS01204Document1 pageEOS01204Lesley-Anne RowandNo ratings yet

- CT Tower EffectivenessDocument17 pagesCT Tower Effectiveness0817me111051No ratings yet

- Book EngineDocument15 pagesBook EngineTulus PrasetyoNo ratings yet

- SalermDocument2 pagesSalermCarol GamarraNo ratings yet

- RFQ End El 24 9509 E1Document2 pagesRFQ End El 24 9509 E1mlcfceloobooNo ratings yet

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-114 - Injection PumpDocument14 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-114 - Injection PumpMANUALESNo ratings yet

- Saisw-2 TP221 DDR N°45 22-03-2024Document3 pagesSaisw-2 TP221 DDR N°45 22-03-2024Abdellah AbdellahNo ratings yet

- Filter Press Mass Balance TemplateDocument11 pagesFilter Press Mass Balance TemplatesalesNo ratings yet

- Power Unit AssemblyDocument6 pagesPower Unit AssemblyJJ Philippa ChnlNo ratings yet

- Asta Shinnagata SanbankaDocument19 pagesAsta Shinnagata Sanbankaaditya agasiNo ratings yet

- Order DetDocument2 pagesOrder DetAalam PanahNo ratings yet

- Mass Spectrometry: Instrumentation, Interpretation, and ApplicationsFrom EverandMass Spectrometry: Instrumentation, Interpretation, and ApplicationsRolf EkmanNo ratings yet

- S.No. Machine Brand Model / TypeDocument2 pagesS.No. Machine Brand Model / TypeAbdul Aziz KhanNo ratings yet

- XGB e 130207 PDFDocument60 pagesXGB e 130207 PDFAbdul Aziz KhanNo ratings yet

- Abdul Aziz Khan: ObjectiveDocument6 pagesAbdul Aziz Khan: ObjectiveAbdul Aziz KhanNo ratings yet

- Motor Controllers AC Semiconductor Motor Controller Types RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - BDocument4 pagesMotor Controllers AC Semiconductor Motor Controller Types RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - BAbdul Aziz KhanNo ratings yet

- Electrical Shedule AugustDocument1 pageElectrical Shedule AugustAbdul Aziz KhanNo ratings yet

- Electrical Panel Room Repairing JobDocument1 pageElectrical Panel Room Repairing JobAbdul Aziz KhanNo ratings yet

- Electrical Department Increment List: S.NO. Emp. No - Emp Name Designation Salary Increment Amnt Proposed SalaryDocument1 pageElectrical Department Increment List: S.NO. Emp. No - Emp Name Designation Salary Increment Amnt Proposed SalaryAbdul Aziz KhanNo ratings yet

- Abdul Rauf KhanDocument2 pagesAbdul Rauf KhanAbdul Aziz KhanNo ratings yet

- Life Saving Kits For M.V. SubstationsDocument2 pagesLife Saving Kits For M.V. SubstationsAbdul Aziz KhanNo ratings yet

- Abstract Report PDFDocument7 pagesAbstract Report PDFShridhar SrinivasanNo ratings yet

- DRV8243-Q1 Automotive H-Bridge Driver With Integrated Current Sense and DiagnosticsDocument78 pagesDRV8243-Q1 Automotive H-Bridge Driver With Integrated Current Sense and DiagnosticsRakesh SutharNo ratings yet

- Control (If, For, While)Document6 pagesControl (If, For, While)TigereNo ratings yet

- 7420 Datasheet PDFDocument4 pages7420 Datasheet PDFOMAR ALEJANDRO LONGORIA VAZQUEZNo ratings yet

- Objective of Orientation ProgramDocument4 pagesObjective of Orientation ProgramSoso SoosNo ratings yet

- SITRAIN Catalog Rev072516Document98 pagesSITRAIN Catalog Rev072516Franklin EgejuruNo ratings yet

- Simplifying Algebraic Expressions From HOLTDocument18 pagesSimplifying Algebraic Expressions From HOLTDaniela Huertas Carrasco [STUDENT]No ratings yet

- System Life Cycle For IGCSE 2020Document8 pagesSystem Life Cycle For IGCSE 2020HikmaNo ratings yet

- Customer Demand Planning at Lucent Technologies: Mark A. Moon John T. Mentzer Dwight E. Thomas, JRDocument8 pagesCustomer Demand Planning at Lucent Technologies: Mark A. Moon John T. Mentzer Dwight E. Thomas, JRspk_indusNo ratings yet

- Loss Functions For Image Restoration With Neural Networks: Hang Zhao, Orazio Gallo, Iuri Frosio, and Jan KautzDocument11 pagesLoss Functions For Image Restoration With Neural Networks: Hang Zhao, Orazio Gallo, Iuri Frosio, and Jan KautzStephen LauNo ratings yet

- Feasibility Study Definition - How Does It WorkDocument10 pagesFeasibility Study Definition - How Does It WorkaliranagNo ratings yet

- Sprinkler Cabinets 3, 6, & 12 Sprinklers, 1/2 or 3/4 Inch NPT 6 ESFR Sprinklers, 3/4 or 1 Inch NPT General Description Technical DataDocument4 pagesSprinkler Cabinets 3, 6, & 12 Sprinklers, 1/2 or 3/4 Inch NPT 6 ESFR Sprinklers, 3/4 or 1 Inch NPT General Description Technical Datacarlos vegaNo ratings yet

- DP-A120 USB Interface Kit I-F-42 InstallationDocument10 pagesDP-A120 USB Interface Kit I-F-42 InstallationLuis GomezNo ratings yet

- JPL Tower John Jacob JPL CorporationDocument4 pagesJPL Tower John Jacob JPL CorporationAlvin AbilleNo ratings yet

- Tah9505bk 00 Dfu EngDocument14 pagesTah9505bk 00 Dfu EngYoshiyyáhu HoffmanNo ratings yet

- RTN 905 2F BrochureDocument2 pagesRTN 905 2F BrochureDiHLoSNo ratings yet

- NPSH and CavitationDocument1 pageNPSH and CavitationSofiane HalimiNo ratings yet

- A View of Cloud ComputingDocument6 pagesA View of Cloud ComputingmasharabNo ratings yet

- "Creating and Formatting Chart": It Skill Lab - 2Document41 pages"Creating and Formatting Chart": It Skill Lab - 2Chetan SinghNo ratings yet

- Itc101 AsmDocument5 pagesItc101 AsmNhat Mai Hoang AnhNo ratings yet

- Arba Minch University Institute of Technology: Information Security AssignmentDocument2 pagesArba Minch University Institute of Technology: Information Security Assignmentfiker123No ratings yet

- Time-Efficient and Cost-Effective Network Hardening Using Attack GraphsDocument13 pagesTime-Efficient and Cost-Effective Network Hardening Using Attack GraphsLatwPIATNo ratings yet

- Fintech and The Nigerian Fintech SpaceDocument10 pagesFintech and The Nigerian Fintech SpaceOvoke OhwoganohwoNo ratings yet

- Simulation of PMSM Speed Control System-53291344Document6 pagesSimulation of PMSM Speed Control System-53291344Mmahm 1238No ratings yet

- Basic Working Drawing: Why Are Working Drawings Used?Document21 pagesBasic Working Drawing: Why Are Working Drawings Used?Brett AmbilNo ratings yet

- PCO100CLK0: - Scheda Orologio Per pCO1/ Clock Card For pCO1Document1 pagePCO100CLK0: - Scheda Orologio Per pCO1/ Clock Card For pCO1Mohamed AliNo ratings yet

- CS3401-ALGORITHMS QB OriginalDocument51 pagesCS3401-ALGORITHMS QB OriginalramaniraniNo ratings yet