Professional Documents

Culture Documents

Cil - Sop 12

Uploaded by

SergioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cil - Sop 12

Uploaded by

SergioCopyright:

Available Formats

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 1 ( 37)

Valid for:

Blowing Unit SIPA SYSTEMA Type 2914 and 2915

Index:

1. Necessary documents............................................................................................. 3

2. Necessary material.................................................................................................. 3

3. Available spare- and wear-parts.............................................................................. 5

3.1 Spare parts .............................................................................................................. 5

3.2 Wear parts ............................................................................................................... 6

4. Installation of the maintenance-kits “Cylinder” and “Seal-kit” .................................. 7

4.1 Disassembly of the cylinder ..................................................................................... 7

4.2 Disassembly of the seals and guiding...................................................................... 9

4.3 Disassembly, cleaning and mounting of the used cylinder .................................... 10

4.4 Cleaning ................................................................................................................ 11

4.5 Mounting of the new seal kit .................................................................................. 12

4.5.1 Upper shell ..................................................................................................... 12

4.5.2 Housing .......................................................................................................... 13

4.5.3 Seal support ................................................................................................... 13

4.6 Mounting of the dynamic seals .............................................................................. 14

4.7 Mounting of the cylinder......................................................................................... 15

4.7.1 Mounting of the seal support .......................................................................... 15

4.7.2 Preparation of the cylinder.............................................................................. 16

4.7.3 Insert the cylinder in the housing .................................................................... 17

4.7.4 Mounting the piston on the cylinder ................................................................ 18

4.7.5 Mounting the upper shell ................................................................................ 19

5. Installation of the maintenance-kit “Valve bloc” ..................................................... 20

5.1 Disassembling valves P1, P2 and REC (REC-Valve only at Type 2914)............... 20

5.2 Cleaning of the housing and the bloc..................................................................... 22

5.3 Assembling valves P1, P2 and REC...................................................................... 24

5.4 Mounting of the valve bloc ..................................................................................... 25

6. Installation of the maintenance-kit “Exhaust-Valve” .............................................. 26

6.1 Disassembling of the Exhaust Valve...................................................................... 26

6.2 Cleaning of the Exhaust Valve............................................................................... 28

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 2 ( 37)

6.3 Assembling of the EXH-valve ................................................................................ 30

6.4 Mounting of the EXH-valve .................................................................................... 31

7. Installation of the maintenance-kit “Compensation-Valve” .................................... 32

7.1 Disassembling of the “Compensation Valve” ......................................................... 32

7.2 Cleaning of the Compensation Valve..................................................................... 34

7.3 Assembling of the “Compensation Valve”.............................................................. 35

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 3 ( 37)

1. Necessary documents

TVV-N-2914 + 2915 Art. no.: 185.952.01

2. Necessary material

- Maintenance-kit SIPA SYSTEMA Type 2914 with recuperation art.-no.: 179.505.01

Composed of: - Maintenance-kit cylinder art.-no.: 179.328.01 *

- Maintenance-kit valve bloc art.-no.: 179.366.01

- Maintenance-kit exhaust valve art.-no.: 179.449.01

- Maintenance-kit compensation valve art.-no.: 187.211.01

- Seal-kit SYSTEMA art.-no.: 185.657.00

- one M6 Stud screw 184.292.06

- four M8 hexagonal bolts

- four washer (M8)

- one little jar (12ml) of grease (OPTIMOL OBEEN UF1)

*) In the maintenance-kit “cylinder” there are comprised also the cylinder. It is possi-

ble to get the maintenance-kit SIPA SYSTEMA Type 2914 without the cylinder. In

this case you have to order the maintenance-kit art.-no.: 179.505.02 (than you get

the maintenance-kit “cylinder” without the cylinder. Consult 4.3

The Eugen Seitz AG recommend to order the hole maintenance-kit 179.505.01

(incl. the cylinder), because the cylinder get also battered.

- Maintenance-kit SIPA SYSTEMA Type 2915 (without recuperation) article number:

179.635.01

Composed of: - Maintenance-kit cylinder art.-no.: 179.328.01 *

- Maintenance-kit valve bloc art.-no.: 179.631.01

- Maintenance-kit exhaust valve art.-no.: 179.449.01

- Maintenance-kit compensation valve art.-no.: 187.211.01

- Seal-kit SYSTEMA art.-no.: 185.657.00

- one M6 Stud screw 184.292.06

- four M8 hexagonal bolts

- four washer (M8)

- one little jar (12ml) of grease (OPTIMOL OBEEN UF1)

*) In the maintenance-kit “cylinder” there are comprised also the cylinder. It is possi-

ble to get the maintenance-kit SIPA SYSTEMA Type 2915 without the cylinder. In

this case you have to order the maintenance-kit art.-no.: 179.635.02 (than you get

the maintenance-kit “cylinder” without the cylinder. Consult 4.3

The Eugen Seitz AG recommend to order the hole maintenance-kit 179.635.01

(incl. the cylinder), because the cylinder get also battered.

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 4 ( 37)

Tools (for both Types (2914 and 2915):

- Special tool kit for SIPA SYSTEMA art.-no.: 185.805.00 (please order the tool kit

separately) Composed of: - One special tool for the slotted round nut

- One special tool for the seal support

- One assembly spike

- One assembly ring

- Allen keys, wrench size: 4, 5 and 6

- Two screwdrivers size 4mm;

- flat wrenches size 13mm and 55mm

- A rag or a brush and spirit

- Loctite 243 or equivalent

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 5 ( 37)

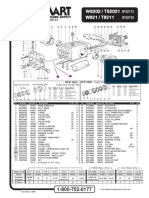

3. Available spare- and wear-parts

3.1 Spare parts

Fixed restrictor for EXH-valve (option): EXH-valve: 179.449.00

179.420.01

5/2-way valve: Pilot valve for EXH-

TBD Valve: 161.709.00

Solenoid valve for pilot

valve: 160.882.01

Exhaust restrictor (2x):

171.547.04

Pilot valve for Blowing-

Valves: 187.259.00

Support sheet for

Actorbox: 183.962.01 Solenoid valve for pilot

valves: 160.976.01

Damper (3x):

183.947.01 Pilot valve for Blowing-

Valve: 187.253.00

Solenoid valve for pilot

Cylinder kpl.:

valve: 160.976.01

179.328.00

Compensation Valve: 187.211.00 P1 Restrictor,

Pilot valve for Comp.-Valves: 187.249.00 composed of: - 177.894.0001 (1x)

Solenoid valve for pilot valves: 160.882.01 - 165.406.05 (1x)

- 183.909.01 (1x)

Bypass plate (alternative for compensation valve)

- 109.152.13 (3x)

Composed of: - 186.557.01 (1x)

- 109.153.22 (2x)

Comp. Restrictor, composed of: - 179.189.01 (1x)

- 179.178.01 (1x)

Remark: - 113.244.04 (1x)

„Composed of“ means that you have to order al article numbers to get - 109.126.23 (1x)

the hole spar assembly. - 109.152.10 (2x)

For example to get the Bypass plate you have to order:

1 pc. 186.557.01 (plate)

2 pcs 109.153.22 (screw)

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 6 ( 37)

3.2 Wear parts

Maintenance-kit exhaust valve: 179.449.01

Maintenance-kit

cylinder:

185.657.00

Maintance-kit REC:

189.579.0001

Maintance-kit P1:

189.579.0001

Maintance-kit P2:

189.579.0001

Cushioning ring:

179.328.00

Maintenance-kit compensation valve 187.211.01

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 7 ( 37)

4. Installation of the maintenance-kits “Cylinder” and “Seal-kit”

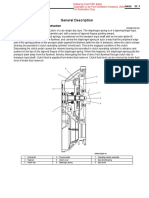

4.1 Disassembly of the cylinder

Relief the pressure in the machine

Remove the cover from the blowing

unit by unscrew the four M5 screws

cover

M5 screws

M8 hexagonal bolts

Remove the blowing unit SYPA SYSTEMA

from the machine by unscrew the four M8

screws

M6 threads

M8 screws

M8 bolts

Remove the upper shell by unscrew the

four M8 hexagonal bolts (secured with Loc-

tite 243).

There are two M6 threads where you can

screw in two bolts for pull out the upper

shell

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 8 ( 37)

Remove the o-ring, the dynamic seal including o-ring (cut it carefully with a scalpel or equiva-

lent) and dispose of. Remove the guiding and the scrapper and dispose of.

scrapper

guiding

dynamic seal incl. o-ring

o-ring

Remove the self locking slotted round nut by using the special tool (Special tool kit for SIPA

SYSTEMA art.-no.: 185.805.00 ) and a flat wrench, size 55mm.

Remove the cylinder out of the bloc (push the cylinder down)

Remove the piston and the cushioning rings out of the bloc and dispose of

special tool for the slotted round nut

self locking slotted round nut

cushioning rings

piston

cushioning ring

push the cylinder down

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 9 ( 37)

4.2 Disassembly of the seals and guiding

Remove the stud screw (caution, it’s secured with Loctite 243) and dispose of.

Unscrew the seal support by using the special tool (incl. in the special tool kit for SIPA

SYSTEMA art.-no.: 185.805.00). Don’t injure the cylinder bore.

Remove the dynamic seal including o-ring (cut it carefully with a scalpel or equivalent)

from the seal support and dispose of.

Remove carefully the o-ring, the dynamic seal including o-ring (cut it carefully with a

scalpel), guiding and the scrapper from the housing and dispose of.

special tool for the seal

support

seal support

dynamic seal incl. o-ring

(cut it carefully with a

scalpel) dispose of

stud screw dispose of

o-ring dispose of

dynamic seal incl. o-ring

(cut it carefully with a

scalpel) dispose of

guiding dispose of

scrapper dispose of

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 10 ( 37)

4.3 Disassembly, cleaning and mounting of the used cylinder

If you ordered the whole Maintenance-kit SIPA SYSTEMA Type 2914 (with recupera-

tion) art.-no.: 179.505.01 respective Maintenance-kit SIPA SYSTEMA Type 2915

(without recuperation) art.-no.: 179.635.01 (as Eugen Seitz AG recommend it) you can

dispose of the used cylinder.

If you wish to use the used cylinder (consult chapter 2 “Necessary material”) please

follow the following instructions:

Remove the o-ring and the cushioning ring

cushioning ring

o-ring

Clean the used cylinder with spirit and a rag and/or a brush

Mount from the maintenance-kit “piston” (art.-no 185.655.00) the outer cushioning ring

and the static o-ring

o-ring

outer cushioning ring

For mounting the cylinder consult chapter 4.7

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 11 ( 37)

4.4 Cleaning

Clean the cylinder bore, the M6 thread and the seal

support with spirit and a rag and/or a brush. Dry it

with compressed air

Seal support

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 12 ( 37)

Clean the upper shell with spirit and a rag and/or a brush.

Dry it with compressed air

4.5 Mounting of the new seal kit

4.5.1 Upper shell

Mount from the seal kit (art.-no.: 185.657.00) the scrapper, the guiding, the dynamic

seal with the o-ring and the static o-ring. For a better mounting you can grease the o-

rings and the scrapper slightly with OPTIMOL OBEEN UF1 food fat grease (incl. in the

maintenance-kit SIPA SYSTEMA). For the mounting of the dynamic seal please con-

sult chapter 3.6

scrapper

guiding

dynamic seal incl.

o-ring

o-ring

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 13 ( 37)

4.5.2 Housing

Mount from the seal kit (art.-no.: 185.657.00) the scrapper, the guiding, the dynamic

seal with the o-ring and the static o-ring. For a better mounting you can grease the o-

rings and the scrapper slightly with OPTIMOL OBEEN UF1 food fat grease (incl. in the

maintenance-kit SIPA SYSTEMA). For the mounting of the dynamic seal please con-

sult chapter 4.6

o-ring

dynamic seal incl. o-ring

guiding

scrapper

4.5.3 Seal support

Mount from the seal kit (art.-no.: 185.657.00) the dynamic seal with the o-ring and the

static o-ring. For a better mounting you can grease the o-ring slightly with OPTIMOL

OBEEN food fat grease (incl. in the maintenance-kit SIPA SYSTEMA). For the mount-

ing of the dynamic seal please consult chapter 4.6

dynamic seal incl. o-ring

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 14 ( 37)

4.6 Mounting of the dynamic seals

1. Place the o-ring into the groove

2. Compress the rod seal into a

kidney shape. The seal must

have no sharp bends (Figure 1)

Figure 1

3. Place the seal ring in com-

pressed form into the groove und

push against the o-ring in the di-

rection of the arrow (Figure 2)

4. After placing into the grove, form

the seal into a ring again in the

groove by hand

5. Finally calibration the seal ring

using the piston rod

Figure 2

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 15 ( 37)

4.7 Mounting of the cylinder

4.7.1 Mounting of the seal support

Grease the thread of the seal support slightly with OPTIMOL OBEEN UF1 grease (incl. in

the maintenance-kit SIPA SYSTEMA)

Screw in the seal support with the special tool. Don’t injure the cylinder bore.

Secured the seal support with the stud screw from the maintenance kit. Bond the stud screw

with Loctite 243 or equivalent

special tool for the seal

support

seal support

stud screw

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 16 ( 37)

4.7.2 Preparation of the cylinder

Take the cylinder from the maintenance-kit cylinder art.-no.: 179.328.01 and remove

the self locking slotted round nut and the piston with the inner cushioning rings

Piston with the inner

cushioning rings

Self locking slotted

round nut

Mount the assembly ring into the groove of the cylinder

Attach the assembly spike on the cylinder

assembly ring

assembly spike

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 17 ( 37)

4.7.3 Insert the cylinder in the housing

assembly Insert the cylinder carefully in the housing.

spike

NOTICE:

Don’t grease the cylinder. The dynamic seals and guiding

are designed for dry running conditioning

assembly

ring

clamp area (diameter 99)

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 18 ( 37)

4.7.4 Mounting the piston on the cylinder

Insert the lower “inner cushioning ring”

Insert carefully the piston (don’t injure the cylinder bore)

Screw in the self locking slotted round nut with the special tool. To secure the cylinder

against twisting clamp the cylinder at the clamp area shown on picture at chapter

3.7.3

special tool for the slotted round nut

self locking slotted round nut

piston

lower “inner cushioning ring”

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 19 ( 37)

4.7.5 Mounting the upper shell

Insert the upper shell (for better inserting, grease the marked area slightly with OP-

TIMOL OBEEN UF1 grease (incl. in the maintenance-kit SIPA SYSTEMA)

Screw in the four M8 hexagonal bolts with the washer (incl. in the maintenance-kit

SIPA SYSTEMA ) torque = 20Nm and secure it with Loctite 243 or equivalent

Remove the assembly spike and the assembly ring

CAUTION:

Assembly It is absolutely necessary to mount the as-

spike sembly ring into the groove of the cylinder

and attach the assembly spike on the cylin-

der as described on chapter 3.7.2 before

you insert the upper shell. Otherwise the

dynamic seals, the guiding and the scraper

get hurt.

Assembly

ring NOTICE:

Don’t grease the cylinder. The dynamic

seals and guiding are designed for dry run-

ning conditioning

M8 hexagonal bolts

Washer

Grease the upper shell in this area

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 20 ( 37)

5. Installation of the maintenance-kit “Valve bloc”

5.1 Disassembling valves P1, P2 and REC (REC-Valve only at Type 2914)

Unscrew the seven M8 bolts

Pull the housing from the bloc. Use two screwdrivers as shown on the picture below

Dispose of the used parts

Remove the control spools, the flanges, the pistons and the o-ring from the bloc and dispose

them off. At type 2915 there are only the P1- and the P2- valve.

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 21 ( 37)

Parts for REC-valve

only at Type 2914

Control spools O-ring

Flanges

Pistons

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 22 ( 37)

5.2 Cleaning of the housing and the bloc

Clean the bores with spirit and a rag and/or a brush. After cleaning dry the housing.

You can use compressed air.

Grease slightly the bearing surface with optimol OBEEN UF1 food fat grease (included

in the maintenance kit).

Optimol OBEEN UF1 food fat grease (included in the maintenance kit)

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 23 ( 37)

Clean also the valve nests of the bloc

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 24 ( 37)

5.3 Assembling valves P1, P2 and REC

Take the control spools transportation protections

and flanges out of the

transportation protec-

tions

And mount them within 5

minutes in the housing.

Also mount the pistons

and the o-ring into the

housing

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 25 ( 37)

5.4 Mounting of the valve bloc

Push the valve bloc on the bloc

Screw down the seven M8 bolts torque: 20 Nm

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 26 ( 37)

6. Installation of the maintenance-kit “Exhaust-Valve”

6.1 Disassembling of the Exhaust Valve

Remove the Silencer from the exhaust valve

Unscrew the four M6 bolts and remove the exhaust valve from the centering support

M6 bolts

centering support

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 27 ( 37)

Pull the cover from the housing, remove the

o-ring from the cover and dispose it of

Pull the piston out from the housing and dis-

pose it of

Take both of the o-rings from the housing

and dispose them of

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 28 ( 37)

6.2 Cleaning of the Exhaust Valve

Clean the bore with spirit and a rag and/or a brush. After cleaning dry the housing. You

can use compressed air.

Grease slightly the bearing surface with optimol OBEEN UF1 food fat grease (included

in the maintenance kit).

Optimol OBEEN UF1 food fat

grease (included in the mainte-

nance kit)

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 29 ( 37)

Clean also the valve seat at the centering support

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 30 ( 37)

6.3 Assembling of the EXH-valve

Take the piston out transportation protections

of the transporta-

tion protections

And mount it within

5 minutes in the

housing.

Also mount the o-

rings into the hous-

ing

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 31 ( 37)

6.4 Mounting of the EXH-valve

Position the EXH-valve on the centering support and screw down the four M6 bolts torque

7Nm.

Screw in the silencer

M6 bolts

centering support

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 32 ( 37)

7. Installation of the maintenance-kit “Compensation-Valve”

7.1 Disassembling of the “Compensation Valve”

Unscrew the two M6 bolts and remove the compensation valve from the bloc

Compensation valve

M6 bolts

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 33 ( 37)

Pull the cover from the housing and dispose both of the o-rings of

Pull the control spool with the spring out of the housing and dispose them of

Take the piston out of the housing and dispose it of

Pull the valve seat out of the housing. Take the two o-ring from the valve seat and dispose

them off

Dispose of the three o-ring from the housing

control spool

valve seat piston o-rings cover

with springs

o-rings

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 34 ( 37)

7.2 Cleaning of the Compensation Valve

Clean the bore with spirit and a rag and/or a brush. After cleaning dry the housing. You

can use compressed air.

Grease slightly the bearing surface with optimol OBEEN UF1 food fat grease (included

in the maintenance kit).

Optimol OBEEN UF1 food

fat grease (included in the

maintenance kit)

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 35 ( 37)

7.3 Assembling of the “Compensation Valve”

Take the control transportation protection springs control spool piston

spool with the

spring out of the

transportation pro-

tection

And mount it within

5 minutes into the

housing.

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 36 ( 37)

Mount the o-ring at the valve seat

o-ring from the maintenance kit

Insert the valve

seat in the hous-

ing.

Mount the o-rings

from the mainte-

nance kit at the

housing

Mount the o-ring

at the cover

Mount the o-ring

at the housing.

Insert the cover

in the housing

Insert the M6

bolts

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

Assembly instruction of TVV-N-2914 + 2815

Maintenance kit

Seite 37 ( 37)

Position the compensation valve and screw down the two M6 bolts, torque 7Nm

Compensation valve

M6 bolts

Edition: November, R. Schnetzer Revision 00

Department: PET Datum / Visum: O. Rymann

dd.mm.yyyy 185.952.01

Departmen: PV Datum / Visum: K. Odermatt

dd.mm.yyyy Original mit Visum im "TD-Original-Ordner" abgelegt!

You might also like

- CDM835E - Manual de Partes PDFDocument155 pagesCDM835E - Manual de Partes PDFhumberto67% (6)

- QSB7 G5 Engine With PowerCommand 1 2 C220D5E PartsManual PDFDocument56 pagesQSB7 G5 Engine With PowerCommand 1 2 C220D5E PartsManual PDFtyler100% (2)

- LPE 240 Service ManualDocument164 pagesLPE 240 Service ManualNgo Ngoc Tu100% (5)

- Series 90 Pumps: Repair InstructionsDocument80 pagesSeries 90 Pumps: Repair InstructionsEdgarRetuerto50% (2)

- Auxitrol Mannual 759197-FDocument255 pagesAuxitrol Mannual 759197-FGumaMohamed25% (4)

- STT 330 ManuelDocument183 pagesSTT 330 ManuelOzzyNo ratings yet

- WP320L WP460LDocument59 pagesWP320L WP460Ljohn smithNo ratings yet

- 09 - Yzf - R1 - en YecDocument81 pages09 - Yzf - R1 - en YecOscar Melgar80% (5)

- S01 Hydraulic Cylinders - TMKDocument8 pagesS01 Hydraulic Cylinders - TMKAnonymous iu95trpxNNo ratings yet

- 307-01bZF 6HP26Document91 pages307-01bZF 6HP26luke89% (9)

- 06 Kit Manual Yzf r6 Eng - 334741 PDFDocument43 pages06 Kit Manual Yzf r6 Eng - 334741 PDFCarlosManuelSilvaCorreiaNo ratings yet

- Catálogo de Peças Do Motor SCANIA DC9Document275 pagesCatálogo de Peças Do Motor SCANIA DC9giovani martinsNo ratings yet

- Data & Specifications: 3299N030 4-Stroke EnginesDocument9 pagesData & Specifications: 3299N030 4-Stroke EnginesShadi MuhammedNo ratings yet

- Briggs&Stratton Bunton 28N707 18hnxKXAnfBhU7yDocument18 pagesBriggs&Stratton Bunton 28N707 18hnxKXAnfBhU7ysilbersixNo ratings yet

- Installation and Commissioning Kits For Industrial Ni-Cd Pocket Plate BatteriesDocument4 pagesInstallation and Commissioning Kits For Industrial Ni-Cd Pocket Plate BatteriesSunshine LoveNo ratings yet

- Rollgliss 1Document425 pagesRollgliss 1Fabio Andrés CancinoNo ratings yet

- 7970 1 en 0509 PDFDocument94 pages7970 1 en 0509 PDFOlusegun OlugbadeNo ratings yet

- Illustrated Parts List 28T700: Model SeriesDocument13 pagesIllustrated Parts List 28T700: Model SeriesteddiprintNo ratings yet

- R1 2015 KMDocument66 pagesR1 2015 KMefrainNo ratings yet

- Parts Manual: Serial Number TML01-01 To TML01-225Document78 pagesParts Manual: Serial Number TML01-01 To TML01-225walmadasanNo ratings yet

- Adixen 2021 SDDocument45 pagesAdixen 2021 SDRuben PiepersNo ratings yet

- Quincy QT Series Model QT-5Document18 pagesQuincy QT Series Model QT-5mkaukolaNo ratings yet

- TMTW Orbital Motor Repair InstructionDocument24 pagesTMTW Orbital Motor Repair InstructionServicio TLMNo ratings yet

- H1 115-130-147-165 Pumps Repair Instructions - 520L0874 - Rev AC - April 2008Document48 pagesH1 115-130-147-165 Pumps Repair Instructions - 520L0874 - Rev AC - April 2008Jose Manuel Barroso Pantoja100% (1)

- Maintenance: Ca PKX 27 / Ca SLDDocument16 pagesMaintenance: Ca PKX 27 / Ca SLDCoil98No ratings yet

- Alcatel SD C1 C2 UsersManual 1Document45 pagesAlcatel SD C1 C2 UsersManual 1Gt-Dios David100% (1)

- OUTER MAST (Figure 11-1) : Two Stage Full Free-LiftDocument16 pagesOUTER MAST (Figure 11-1) : Two Stage Full Free-LiftMelwyn FernandesNo ratings yet

- 9845000020-01 - Installation of ER Kit On GA 90-180 (&VSD)Document10 pages9845000020-01 - Installation of ER Kit On GA 90-180 (&VSD)BRUNO MARDEGANNo ratings yet

- Webasto Retrofit Dogrzewacz Telestart Timer ENBDocument25 pagesWebasto Retrofit Dogrzewacz Telestart Timer ENBiwo3211231No ratings yet

- Alle K-Infos EnglischDocument134 pagesAlle K-Infos EnglischasalinaspadillaNo ratings yet

- UC22/UC27: Aftermarket Parts ListDocument14 pagesUC22/UC27: Aftermarket Parts ListAmmar BaigNo ratings yet

- Curapuls/670Document60 pagesCurapuls/670klauditza_med0% (2)

- Series 90 42cc Pump - PM - 520L0838 - Rev BB - April 2008Document68 pagesSeries 90 42cc Pump - PM - 520L0838 - Rev BB - April 2008Jose Manuel Barroso PantojaNo ratings yet

- HP By-Pass Valve ManualDocument70 pagesHP By-Pass Valve ManualVamsikrishna LakamsaniNo ratings yet

- Crack Detection KitDocument47 pagesCrack Detection KitTrolldaddyNo ratings yet

- VBU Part List&Maintenance Schedule 2020-9101-000Document42 pagesVBU Part List&Maintenance Schedule 2020-9101-000Jano GoñiNo ratings yet

- RSE 220-01-777 - Parts ListDocument106 pagesRSE 220-01-777 - Parts ListCentrifugal Separator100% (1)

- Marzo - Manual de Bpl-2023Document306 pagesMarzo - Manual de Bpl-2023Javier De Luna CanoNo ratings yet

- Richter™ Operating Instructions For Ball Valves: Series KNA/KNAPDocument14 pagesRichter™ Operating Instructions For Ball Valves: Series KNA/KNAPAli ToamaNo ratings yet

- Operating Manual For Disc Brake Type SF 10-40Document42 pagesOperating Manual For Disc Brake Type SF 10-40Quốc Viêtj HuỳnhNo ratings yet

- Design 1018SDocument25 pagesDesign 1018SJesus BolivarNo ratings yet

- PAS WP121L-WP151L Marine WAs - en - GB - 1804Document39 pagesPAS WP121L-WP151L Marine WAs - en - GB - 1804jarekNo ratings yet

- Catalog Piese - Turbo Chiesel-Great PlainsDocument104 pagesCatalog Piese - Turbo Chiesel-Great PlainsGabriel TrifanNo ratings yet

- Instructions For Installation and Maintenance: Equipment: TypeDocument47 pagesInstructions For Installation and Maintenance: Equipment: TypeRODRIGONo ratings yet

- HPBFP Arv ManualDocument16 pagesHPBFP Arv ManualjprakashbandaruNo ratings yet

- Murelle HE 25-30 - 55 GB - InstDocument44 pagesMurelle HE 25-30 - 55 GB - InstPodaruNo ratings yet

- TW514Document32 pagesTW514Rafael Charry AndradeNo ratings yet

- Spare Parts Catalog: Bühler AG CH-9240 Uzwil, Switzerland Phone +41 71 955 11 11 Fax +41 71 955 33 79Document304 pagesSpare Parts Catalog: Bühler AG CH-9240 Uzwil, Switzerland Phone +41 71 955 11 11 Fax +41 71 955 33 79Angel Luis AmadorNo ratings yet

- 62-02460 - Rev - C - Manual de Peças, Compressor 05KDocument19 pages62-02460 - Rev - C - Manual de Peças, Compressor 05KBianca PinudoNo ratings yet

- Technical Data Sheet: Rothe Erde Large Diameter Slewing BearingDocument19 pagesTechnical Data Sheet: Rothe Erde Large Diameter Slewing BearingAkash RockNo ratings yet

- Instruction Manual: Flow Pad Size12 Without GrateDocument20 pagesInstruction Manual: Flow Pad Size12 Without GrateBata ZivanovicNo ratings yet

- Service Manual: Date: 11.01.2005Document449 pagesService Manual: Date: 11.01.2005michael pachecoNo ratings yet

- 06.08.02.S4 A320DL SLIDE RAFT-SpecificationDocument10 pages06.08.02.S4 A320DL SLIDE RAFT-SpecificationFly WingsNo ratings yet

- Service NewsDocument19 pagesService NewsMuhammad HardiusNo ratings yet

- Manual de Partes Genie Tml4000nDocument82 pagesManual de Partes Genie Tml4000nRicardo UrielNo ratings yet

- Caterpillar 416E Maintenance ManualDocument58 pagesCaterpillar 416E Maintenance ManualJose Alejandro100% (2)

- Zb35 EngineDocument26 pagesZb35 Enginetotcsab100% (1)

- Installation, Operation and Maintenance of Airflex@ CM Marine ClutchDocument12 pagesInstallation, Operation and Maintenance of Airflex@ CM Marine Clutchaiyubi2No ratings yet

- Manual User E5CN OmronDocument236 pagesManual User E5CN OmronSergioNo ratings yet

- Indag Ostmodul en 2011-02 02 PDFDocument2 pagesIndag Ostmodul en 2011-02 02 PDFSergioNo ratings yet

- Delta InverterDocument173 pagesDelta InverteroarionIIINo ratings yet

- INDAG Rotary Piston Pump: Gentle Conveyance and DosingDocument4 pagesINDAG Rotary Piston Pump: Gentle Conveyance and DosingSergioNo ratings yet

- GS-Valve: DN 15 Up To DN 250Document3 pagesGS-Valve: DN 15 Up To DN 250SergioNo ratings yet

- Operating Instructions: Multiturn Actuator Pneumatic - MechanicalDocument9 pagesOperating Instructions: Multiturn Actuator Pneumatic - MechanicalSergioNo ratings yet

- Operating Instructions: Overflow Valves Typ 5076Document9 pagesOperating Instructions: Overflow Valves Typ 5076SergioNo ratings yet

- 8044 eDocument6 pages8044 ePreet ShahNo ratings yet

- Operating Instructions: 3-Way Ball Cock Type 403x, 413x, 423xDocument15 pagesOperating Instructions: 3-Way Ball Cock Type 403x, 413x, 423xSergioNo ratings yet

- Operating Instructions: 3-Way Ball Cock Type 403x, 413x, 423xDocument15 pagesOperating Instructions: 3-Way Ball Cock Type 403x, 413x, 423xSergioNo ratings yet

- Operating Instructions: Overflow Valves Typ 5076Document9 pagesOperating Instructions: Overflow Valves Typ 5076SergioNo ratings yet

- Operating Instructions: Multiturn Actuator Pneumatic - MechanicalDocument9 pagesOperating Instructions: Multiturn Actuator Pneumatic - MechanicalSergioNo ratings yet

- GS-Valve: DN 15 Up To DN 250Document3 pagesGS-Valve: DN 15 Up To DN 250SergioNo ratings yet

- 8044 eDocument6 pages8044 ePreet ShahNo ratings yet

- Operating Instructions: 3-Way Ball Cock Type 403x, 413x, 423xDocument15 pagesOperating Instructions: 3-Way Ball Cock Type 403x, 413x, 423xSergioNo ratings yet

- Punch Unit Type 3260 B702 Parts Location and ListDocument14 pagesPunch Unit Type 3260 B702 Parts Location and ListargonNo ratings yet

- Lifan Dieselmotor C186FD enDocument29 pagesLifan Dieselmotor C186FD enWilmer Lance EstupiñanNo ratings yet

- Ashok LeylanadDocument11 pagesAshok LeylanadJay SuryaNo ratings yet

- Still Steds Diesel Fork Truck Rx70 60 Rx70 70 Rx70 80 Rx70!80!900 Parts ManualDocument20 pagesStill Steds Diesel Fork Truck Rx70 60 Rx70 70 Rx70 80 Rx70!80!900 Parts ManualAlbert100% (46)

- P5k PMS PartlistDocument30 pagesP5k PMS PartlistuserfileNo ratings yet

- Saildrive 130 150 Workshop Manual 7742984Document100 pagesSaildrive 130 150 Workshop Manual 7742984Simon100% (2)

- K3 V280 SpecsDocument1 pageK3 V280 SpecsJuan AcostaNo ratings yet

- Machine Design-I: Design of Screw & NutDocument10 pagesMachine Design-I: Design of Screw & Nutprajwal kandalkarNo ratings yet

- Hatlapa Compressor L Series L20 L35Document2 pagesHatlapa Compressor L Series L20 L35Jan100% (2)

- Boom-Bucket Hydraulic lh410Document24 pagesBoom-Bucket Hydraulic lh410Miguel RomoNo ratings yet

- SM AppaDocument14 pagesSM Appajose luis peña zetaNo ratings yet

- Digital 125452 S 5756 Tinjauan Persepsi LiteraturDocument12 pagesDigital 125452 S 5756 Tinjauan Persepsi Literaturneon erzNo ratings yet

- Cop 1638Document4 pagesCop 1638Mohan Charanchath100% (1)

- Common Rail C4 4 C6 6 Cat PDFDocument110 pagesCommon Rail C4 4 C6 6 Cat PDFDanNo ratings yet

- Manual-Tren de Engranajes PlanetariosDocument9 pagesManual-Tren de Engranajes PlanetariosPaul CarcasiNo ratings yet

- N55 EngineDocument100 pagesN55 EngineSean SchultzNo ratings yet

- TGB Slewing BearingDocument36 pagesTGB Slewing BearingRafael FurquimNo ratings yet

- TB BW 4406Document2 pagesTB BW 4406xiaochi1989No ratings yet

- GAZELLE Brochure UK OptDocument97 pagesGAZELLE Brochure UK Optboblenaze0% (1)

- Manual SprinterDocument1,458 pagesManual SprinterRafa Diaz95% (21)

- API 650 Manhole Torque ValuesDocument2 pagesAPI 650 Manhole Torque Valuesivan rocoNo ratings yet

- Subject: Pump and Driver AlignmentDocument5 pagesSubject: Pump and Driver Alignmentmohamed elejmiNo ratings yet

- 2009-2011 Toyota Venza Electrical Wiring DiagramsDocument479 pages2009-2011 Toyota Venza Electrical Wiring DiagramsAlfie EpsteinNo ratings yet

- Eaton Illustrated Parts ListDocument24 pagesEaton Illustrated Parts ListDarknezzNo ratings yet

- EGB-2P Kit-54006Document10 pagesEGB-2P Kit-54006Maaz BilgramiNo ratings yet

- A Guide To Marine Air Compressor PDFDocument78 pagesA Guide To Marine Air Compressor PDFResfiyan Tri Sukma AnggaraNo ratings yet

- Installation & Intial Line UpDocument154 pagesInstallation & Intial Line UpWerberth MoreiraNo ratings yet

- Training Manual D350-Slide DEALER1Document270 pagesTraining Manual D350-Slide DEALER1ahmed100% (1)

- WS202 W921 PDFDocument1 pageWS202 W921 PDFCristian D. Rodríguez VillamizarNo ratings yet