Professional Documents

Culture Documents

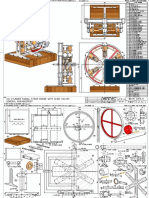

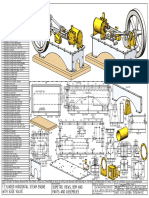

00A Single Cylinder Horizontal Steam Engine General Arrangement & Parts List

Uploaded by

Jorge Luis Villegas ValdiviaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

00A Single Cylinder Horizontal Steam Engine General Arrangement & Parts List

Uploaded by

Jorge Luis Villegas ValdiviaCopyright:

Available Formats

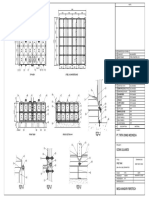

ITEM DESCRIPTION MATERIAL QTY.

NO.

1 01-BASE BRASS 1

2 02-L-H CRANK SHAFT BEARING HOLDER BRASS 1

3 03-R-H CRANK SHAFT BEARING HOLDER BRASS 1

4 04-CRANK SHAFT BEARING BRONZE 4

5 05-BEARING HOLDER SPACER BRASS 1

6 06-CROSSHEAD GUIDE BEARER BRASS 1

7 07-CROSSHEAD GUIDE BRASS 1

8 08-CROSSHEAD GUIDE SUPPORT BRACKET BRASS 1

9 09-CYLINDER BRONZE 1

10 10-CYLINDER TOP COVER BRONZE 1

11 11-CYLINDER BOTTOM COVER BRONZE 1

12 12-CYLINDER BOTOM COVER PRESSURE PLATE BRONZE 1

13 13-CYLINDER GASKET NEOPRENE 2

14 14-CRANK SHAFT SILVER STEEL 2

15 15-CRANK BIG END SILVER STEEL 1

16 16-CRANK CHEEK BRASS 2

17 17-FLYWHEEL OUTER RING BRASS 1

18 18-FLYWHEEL INNER RING BRASS 1

19 19-FLYWHEEL SPOKE BRASS 6

20 20-FLYWHEEL HUB BRASS 1

21 21-VALVE HOUSING BASE BRONZE 1

22 22-VALVE HOUSING BRONZE 1

23 23-VALVE HOUSING GASKET NEOPRENE 2

24 24-VALVE HOUSING COVER BRASS 1

25 25-VALVE HOUSING SPINDEL BEARING BRONZE 1

26 26-VALVE HOUSING DOME BRONZE 1

27 27-VALVE HOUSING PRESSURE PLATE BRONZE 1

28 28-VALVE SPINDLE SILVER STEEL 1

29 29-VALVE BRASS 1

30 30-PISTON TEFLON 1

31 30-PISTON END BRASS 2

32 31-PISTON ROD SILVER STEEL 1

33 32-CROSS HEAD STEEL 1

34 33-CROSS HEAD PIN STEEL 1

35 34-CON ROD HEAD STEEL/BRONZE 1

36 35-CON ROD STEEL 1

37 36-CON ROD BIG END PART-1 BRASS 1

38 37-CON ROD BIG END PART-2 BRASS 1

39 38-EXCENTRIC COUPLER BRASS 1

40 39-EXCENTRIC SPINDLE BRONZE 1

41 40-EXCENTRIC HOUSING BRONZE 1

42 41-EXCENTRIC DISC-1 STEEL 1

43 42-EXCENTRIC DISC-2 STEEL 1

44 STEAM INLET PIPE COPPER 1

45 STEAM OUTLET PIPE COPPER 2

46 M2x6 CYLINDERHEAD SCREW BRASS 6

47 M2x10 CYLINDERHEAD SCREW BRASS 8

48 M2x15 CYLINDERHEAD SCREW BRASS 2

49 M2x20 CYLINDERHEAD SCREW BRASS 4

50 M2x4 CRUB SCREW BRASS 4

51 M2 NUT BRASS 7

52 M2.5x15 COUNTERSINK SCREW BRASS 6

53 M2.5x18 COUNTERSINK SCREW BRASS 4

54 M3x15 CYLINDERHEAD SCREW BRASS 5

55 M3x5 CRUB SCREW BRASS 1

56 M3 NUT BRASS 5

NOTES:

1. PARTS WHICH HAVE BEEN PRESS FIT SHOULD BE EITHER SOFT OR HARD SOLDERED TOGETHER.

2. ALL FILLETS TO BE BETWEEN 0.25mm AND 0.5mm DEPENDING ON THE SIZE OF PART OR AS

INDICATED ON THE DRAWING.

LEGEND 3. TOLERANCES OF ALL NON MOVING PARTS TO BE BETWEEN +/- 0.1mm.

4. TOLERANCES OF ALL MOVING PARTS TO BE BETWEEN +/- 0.05mm.

XXX-YY 5. FOR PART NUMBERS REFER TO DRAWINGS 001 AND 002

PART No

ASSEMBLY No

PLEASE NOTE: THIS STEAM ENGINE WAS ORIGINALLY DESIGNED AND BUILT BY Mr W.A. van SCHAIK - REFER NVM DRAWING NUMBER 60.01.44 SHEETS 1 TO 4 REMOVE ALL BURRS AND SHARP EDGES

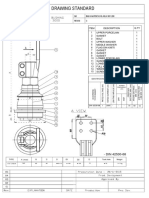

TITLE JDW DRAUGHTING SERVICESDRAWN BY PROJECTION DRAWING NUMBER

SINGLE CYLINDER HORIZONTAL STEAM ENGINE 12 BRIGHTWELL STREET J.A.M. DE WAAL

PAPAKURA NEW ZEALAND DATE

00A

GENERAL ARRANGEMENT & PARTS LIST A ISSUED TO NVM NOV/O6

TEL/FAX 0064-09-2988815

DATE E-MAIL:dewaal@xtra.co.nz

20-SEPT-2006

SCALE

AS SHOWN

CAD FILE REV

A

REV DESCRIPTION DO NOT SCALE OF DRAWING

You might also like

- The Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeFrom EverandThe Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeDonald M. WallerRating: 4 out of 5 stars4/5 (1)

- 6 CylinderDocument5 pages6 CylinderCường TrọngNo ratings yet

- 4 Cylindres Oscillant en Ligne PDFDocument3 pages4 Cylindres Oscillant en Ligne PDFJose Guadalupe AntonioNo ratings yet

- Engine V 8Document14 pagesEngine V 8mohamed sidkyNo ratings yet

- 2030-0 Narrow Gauge Electric Loco of The Mix Nitz-St. Erhard Local Railway Scale 1:5.6 Track Gauge 180Mm (7") General Arrangement & PartslistDocument5 pages2030-0 Narrow Gauge Electric Loco of The Mix Nitz-St. Erhard Local Railway Scale 1:5.6 Track Gauge 180Mm (7") General Arrangement & Partslisting aprNo ratings yet

- Catalog for Series 560 & 570 Pressure Safety ValvesDocument4 pagesCatalog for Series 560 & 570 Pressure Safety ValvesEdbaac BANo ratings yet

- Dimensions in Millimetres and Kilograms: Prepered by Checked by Costomer Appd Drawn DateDocument1 pageDimensions in Millimetres and Kilograms: Prepered by Checked by Costomer Appd Drawn DateAnggi SujiwoNo ratings yet

- Valvula de Cuchilla NEWCON de 42 Pulg. Con Accionamiento HidraulicoDocument1 pageValvula de Cuchilla NEWCON de 42 Pulg. Con Accionamiento HidraulicoAlejandro Pupunovich RodriguezNo ratings yet

- Governor D-2 Service ManualDocument4 pagesGovernor D-2 Service ManualLuis Eduardo Albarracin Rugeles100% (1)

- D-2 Governor (SD-01-503)Document4 pagesD-2 Governor (SD-01-503)emmanuelNo ratings yet

- General Arrangement Isometric View and Bom Self Proppelled Flywheel Steam EngineDocument3 pagesGeneral Arrangement Isometric View and Bom Self Proppelled Flywheel Steam EngineLe TruongNo ratings yet

- 220602-D-1320 RevB GAD Water Fire-Fighting Locker Type IIIDocument1 page220602-D-1320 RevB GAD Water Fire-Fighting Locker Type IIINambi RajaNo ratings yet

- QSH4Q_1Document2 pagesQSH4Q_1domikass27No ratings yet

- Dome AbcsDocument1 pageDome AbcsRiddhi BhutadaNo ratings yet

- Hot Air Engine (Stirling Engine) With A Rombisch Crank Arrangement General LayoutDocument3 pagesHot Air Engine (Stirling Engine) With A Rombisch Crank Arrangement General LayoutAllisonNo ratings yet

- Thrust Bearing Manual PDFDocument28 pagesThrust Bearing Manual PDFAkarshan SoodNo ratings yet

- Hydrodynamic Bearings: A General Guide To The Principles, Operation and Troubleshooting ofDocument28 pagesHydrodynamic Bearings: A General Guide To The Principles, Operation and Troubleshooting ofعبد الرحمنNo ratings yet

- 3.1 1P SL CutoutDocument1 page3.1 1P SL CutoutSalman AlyazouriNo ratings yet

- Tanque Vu 570 m3 DSN-RCT275-50Document2 pagesTanque Vu 570 m3 DSN-RCT275-50Comercial FirenoNo ratings yet

- H2) - (A /NO: Zdp48 Wiring SchematicDocument9 pagesH2) - (A /NO: Zdp48 Wiring SchematicRick EvansNo ratings yet

- Bearings PDFDocument28 pagesBearings PDFKapil PudasainiNo ratings yet

- Air Governor TrucksDocument4 pagesAir Governor TrucksMaldwin MenorcaNo ratings yet

- Bendix TC-7 Trailer Control Brake Valve: DescriptionDocument4 pagesBendix TC-7 Trailer Control Brake Valve: DescriptionSebastian OlayaNo ratings yet

- MCM Oil Tools Product CatalogDocument30 pagesMCM Oil Tools Product CatalogmalekNo ratings yet

- UWA Product ListDocument43 pagesUWA Product Listganho.lareshNo ratings yet

- Universe BrochureDocument24 pagesUniverse BrochureHrshiya SharmaNo ratings yet

- The Principles, Operation and Troubleshooting-DikonversiDocument37 pagesThe Principles, Operation and Troubleshooting-DikonversiHendra wahyudiNo ratings yet

- Neoasia Training Center: Hydraulic Bottle JackDocument1 pageNeoasia Training Center: Hydraulic Bottle JackdimasNo ratings yet

- Parts list and exploded assembly diagram for belt tightenerDocument4 pagesParts list and exploded assembly diagram for belt tightenerpanji100% (1)

- Drawing Gearbox 07.23.eng.02-00Document1 pageDrawing Gearbox 07.23.eng.02-00andik arisNo ratings yet

- Details: 2" X 4" X " C - PurlinsDocument1 pageDetails: 2" X 4" X " C - PurlinsMark Christian Esguerra100% (1)

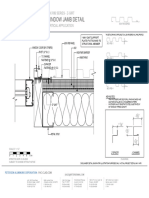

- Box Rib Series Vertical ZGirt Window JambDocument1 pageBox Rib Series Vertical ZGirt Window JambAlfonso FrancoNo ratings yet

- Assy - Poppin150Document1 pageAssy - Poppin150Ramos DavidNo ratings yet

- Bill of MaterialDocument1 pageBill of Materialjivan tidakeNo ratings yet

- P002-Y004-112_SH9OF13 (HATCH)Document1 pageP002-Y004-112_SH9OF13 (HATCH)Mahendra SunarNo ratings yet

- Top Roll GroupDocument1 pageTop Roll GroupthaivinhtuyNo ratings yet

- Description Rev. CHKD Date BYDocument2 pagesDescription Rev. CHKD Date BYsime58No ratings yet

- Seal Cassette ChestertonDocument6 pagesSeal Cassette ChestertonManrry LozadaNo ratings yet

- Forged Steel Gate Valve 800 15NB To 50NBDocument1 pageForged Steel Gate Valve 800 15NB To 50NBArsag Tech PharmaNo ratings yet

- ZX110to270 CABine PDFDocument1 pageZX110to270 CABine PDFantonNo ratings yet

- Parts list for any-angle tool vise assemblyDocument8 pagesParts list for any-angle tool vise assemblymiftah nashrullahNo ratings yet

- 6X5X2 GowaDocument1 page6X5X2 GowaGrab StrongNo ratings yet

- Dept. Technical Reference Created by Approved byDocument1 pageDept. Technical Reference Created by Approved bymadmanmikeNo ratings yet

- 1chseaw A3 Sheet 02Document1 page1chseaw A3 Sheet 02Lennon AquidadoNo ratings yet

- Daily stock report of Scuto products in CikarangDocument1 pageDaily stock report of Scuto products in CikarangMorr ZaNo ratings yet

- Sheet1Document1 pageSheet1Razmah RasidNo ratings yet

- Transformer - GA PDFDocument12 pagesTransformer - GA PDFepe civilNo ratings yet

- Ball Valve Parts List and SpecificationsDocument1 pageBall Valve Parts List and SpecificationsGlobal MeteringNo ratings yet

- Layout PLN 1Document2 pagesLayout PLN 1EwindalimuntheNo ratings yet

- Diagrama Flujo Toschi MarioDocument1 pageDiagrama Flujo Toschi MariomariofnmNo ratings yet

- Se Drg.Document1 pageSe Drg.sparkCENo ratings yet

- Plan Traffic BarrierDocument1 pagePlan Traffic BarrierAdnan NajemNo ratings yet

- Porcelain Bushing DT 1 - 2000Document1 pagePorcelain Bushing DT 1 - 2000kajian19 juniNo ratings yet

- Projeto de Vagão - Arranjo GeralDocument2 pagesProjeto de Vagão - Arranjo GeralCleyton L. AlvesNo ratings yet

- End of Bridge Approach Slab Guardrail Connection DetailsDocument1 pageEnd of Bridge Approach Slab Guardrail Connection DetailsAdnan NajemNo ratings yet

- 2017.10 Qan-Bypass Exh-L1-A3Document1 page2017.10 Qan-Bypass Exh-L1-A3Kyaw MinNo ratings yet

- 2.steel Details Industrial Shed @trichyDocument2 pages2.steel Details Industrial Shed @trichyCivil StructureNo ratings yet

- Jazz GK5 Starting System Circuit Diagram Build-In Type MICUDocument1 pageJazz GK5 Starting System Circuit Diagram Build-In Type MICUTomyNo ratings yet

- General Arrangement, Isometric View, Bom, Parts and Assemblies Flame Eater With Internal Valve by J. Ridders (Holland)Document1 pageGeneral Arrangement, Isometric View, Bom, Parts and Assemblies Flame Eater With Internal Valve by J. Ridders (Holland)Le TruongNo ratings yet

- Site Plan-1Document1 pageSite Plan-1Samir RupnawarNo ratings yet

- Material and Equipment Standard: IPS-M-EL-136Document14 pagesMaterial and Equipment Standard: IPS-M-EL-136Fatholla SalehiNo ratings yet

- Datasheet Flatpack2 48V HE RectifiersDocument2 pagesDatasheet Flatpack2 48V HE RectifiersJason MendozaNo ratings yet

- Isis Manual Vol. 2Document168 pagesIsis Manual Vol. 2Νίκος ΚατριβέσηςNo ratings yet

- Gail India LTD VijaipurDocument13 pagesGail India LTD Vijaipuranshul21No ratings yet

- NetWare Is A Network Operating System Developed by NovellDocument23 pagesNetWare Is A Network Operating System Developed by NovellIndhukanth PvNo ratings yet

- Operating Manual Contents for Airless Spraying UnitDocument30 pagesOperating Manual Contents for Airless Spraying UnitИли.Я Или.ТыNo ratings yet

- AMI Pen TestingDocument10 pagesAMI Pen TestingcutenemesisNo ratings yet

- Steel Reinforcement For WallsDocument7 pagesSteel Reinforcement For WallsSurinderPalSinghGillNo ratings yet

- Aseptic Process TechnologyDocument19 pagesAseptic Process TechnologyHimanshu ShahuNo ratings yet

- John Deere 300GLC - T357633X19 Maintenance PlannerDocument2 pagesJohn Deere 300GLC - T357633X19 Maintenance PlannerGeorge PlishkoNo ratings yet

- Filtration explainedDocument19 pagesFiltration explainedRobert Walusimbi100% (1)

- RDshimano 5500 ManualDocument4 pagesRDshimano 5500 ManualOleg MelnikovNo ratings yet

- OP100 D & OC 100 D - Spare Parts Manual 12 - 2002 - ENGDocument76 pagesOP100 D & OC 100 D - Spare Parts Manual 12 - 2002 - ENGRafael CastroNo ratings yet

- Study pointers in C with examplesDocument6 pagesStudy pointers in C with examplespremsagarNo ratings yet

- Discrepancy Switches - Control Discrepancy Switches Standard Electrical DiagramsDocument20 pagesDiscrepancy Switches - Control Discrepancy Switches Standard Electrical DiagramsAnonymous XS9jAhY1pENo ratings yet

- OJT Lob LODocument29 pagesOJT Lob LOEsa Ghanim0% (1)

- DAL Keystones SSDocument8 pagesDAL Keystones SSyordanNo ratings yet

- CM Position Paper - Cyclists and SidewalksDocument3 pagesCM Position Paper - Cyclists and SidewalksTom BradfordNo ratings yet

- Kodak X-Omat Multiloader 300 Film Feeder - User ManualDocument10 pagesKodak X-Omat Multiloader 300 Film Feeder - User ManualNikolay PenevNo ratings yet

- Coke FinalDocument80 pagesCoke Finaltwinkle_4259No ratings yet

- AIR Modeller 2019-04-05 83Document68 pagesAIR Modeller 2019-04-05 83Tomeu Llompart100% (8)

- Study On The Strength of EarthbagsDocument28 pagesStudy On The Strength of EarthbagsZherrinore Rasay100% (1)

- LED TV Service ManualDocument54 pagesLED TV Service ManualJuan Jose100% (1)

- Schneider Price ListDocument22 pagesSchneider Price ListAbhishek RajputNo ratings yet

- 48 Earthquake Safe Construction of Masonry BuildingDocument4 pages48 Earthquake Safe Construction of Masonry Buildingpramod_kNo ratings yet

- BOQ For PWN-Actual 8-03-2020Document48 pagesBOQ For PWN-Actual 8-03-2020Ihd ConsultancyNo ratings yet

- AM8 Printer: A Metal Frame For Your Anet A8Document28 pagesAM8 Printer: A Metal Frame For Your Anet A8polococo6No ratings yet

- Melab1 Exp3Document11 pagesMelab1 Exp3John Ferben Sallena DepnagNo ratings yet

- Calculating masonry costs for a residential structureDocument7 pagesCalculating masonry costs for a residential structureSean Franz VilardoNo ratings yet

- Bil Jax 2622T - ManualDocument60 pagesBil Jax 2622T - ManualDuynamndk100% (1)