Professional Documents

Culture Documents

P-PRD-04 Initial Flow Control

P-PRD-04 Initial Flow Control

Uploaded by

Pk NimiwalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P-PRD-04 Initial Flow Control

P-PRD-04 Initial Flow Control

Uploaded by

Pk NimiwalCopyright:

Available Formats

Doc No :SEI/IPP/PRO/01

SHRI RAM Rev No :00

ENGG.INDS. Procedure for Initial flow Control

Rev Date:01.04.2018

Page 1 of 4

1. Purpose : To Define a procedure for control the initial flow of the parts during LVPT

2. Scope : All activities performed during LVPT ,Initial Supplies after sample approval (up to some duration

/lots/quantities.

3. Responsibility : Primary : QA-HEAD

Secondary : Production Head ,Stores Head ,Dispatch Head

Definition: First production part (FPP) lot,

A lot of such parts which are manufactured for the very first time after sample approval using actual

mass production process and condition, or which are produced for the first time just after the

implementation of one or more of the following changes :

1) Process Parameter change(e.g feed/angle/press/temp etc.). 2) Tool /Die /Machine/ Equipment

Changes 3) Layout change 4) Relocated plan :5) Supplier Change 6) Operator change 7) Starting

4 manufacturing after long Lay off (i.e 6 months ) 8) ECN Changes

Definition

Initial Product (I/P) : The first piece/part or lot samples from the first lot product during production.

Trial mass production trial SOP of a new part or change point i.e process change supplier change

operator change etc.

5 SYSTEM

INITIAL SUPPLY CONTROL

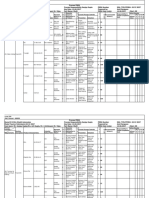

S.NO. INITIAL SUPPLY CONTROL (ISC) PROCESS RESPONSIBILITY REF. DPCUMENT

Information about SOP date : HOD project is responsible

for providing information regarding FPP approval and SOP

5.1 date to HOD QA,PS,WS, Machine Shop and Operation Head Head Projects _____

Through IOM

Head QA is

Deciding Official Person : Designate the person who will responsible for

initial supply

5.2 be over all responsible for the initiating,implementing control unless

_____

communicating with the customer. otherwise specified

by operation Head

Initial supply Control peroid : Fix the initial supply control

peroid with the customer during specification review Head QA / Head

SEI/DEV/F-13

meeting. Note : Default frequency for new parts is three Project

months

5.3

Head QA will inform to all concerned for start of initial

supply control peroid describing start date and end date Head QA SEI/DEV/F-13

based on SOP at customer end.

Identification of process of ISC : Identify the process

5.4 which is producing intial supply control parts with display Prodn/ Quality SEI/QA/F-13A

boards/Sign Boards which warrants the attention of Supervisor

operatrs & management.

Special controls : Decide special controls to be exercised

5.5 during intial supply control period.Limit samples to be Head QA SEI/DEV/F-13

provided on relevant station control item and method of

control is as discusssed in Sr.no. a to g.

PREPARED BY : REVIEWED BY : APPROVED BY : ISSUED BY :

DATE : DATE : DATE : DATE :

Doc No :SEI/IPP/PRO/01

SHRI RAM Rev No :00

ENGG.INDS. Procedure for Initial flow Control Rev Date:01.04.2018

Page 2 of 4

INITIAL SUPPLY CONTROL

S.NO. INITIAL SUPPLY CONTROL (ISC)PROCESS RESPONSIBILITY REF. DOCUMENT

Increased inspection items : Double inspection of All Head QA/ SEI/QA/ F-26

A Quality characteristic specified in Drawing and Control Process/PDI SEI/DEV/F-09

Plan. Engineer

Increased frequency : Half interval of time & double Head QA/ SEI/QA/F-04

B checking in setting approval & also double checking Process/PDI SEI/QA/F-03

frequency in process inspection report & in PDI also. Engineer

Frequent Process Capability (CPK) evaluation : Process

C capability study will be carried out for SC characteristic, Head Machine SEI/QA/F-06

corrective & preventive action for improvement in the shop

Cp/Cpk will be submitted in case of not ok.

Reaffirmation of operator skills : Provide operator on

the job training for the requirement of initial supply

D control and its significance,Extra care to be taken while Concerned Head SEI/HR/F-06

producing,inspecting the parts. Monitor the skill and

update skill matrix

PREPARED BY : REVIEWED BY : APPROVED BY : ISSUED BY :

DATE : DATE : DATE : DATE :

Doc No :SEI/IPP/PRO/01

SHRI RAM Rev No :00

ENGG.INDS. Procedure for Initial flow Control Rev Date:01.04.2018

Page 3 of 4

INITIAL SUPPLY CONTROL

S.NO. INITIAL SUPPLY CONTROL (ISC)PROCESS RESPONSIBILITY REF. DOCUMENT

Reduced cycles of initial supply control : Observe & record Head

E PS,WS,Machine SEI/QA/ F-29

problems, take countermeasure as per the procedure for CAPA shop

Termination of initial supply control : Consider to

terminate the initial supply control after the completion of

defined period(i.e 3 months) provided; 1. It is confirmed

that the capability of the process can fully satisfy the

specified tolerance/ accuracy requirements (Cpk>1.33 &

5.6 Cp>1.67) 2. It is confirmed that the countermeasure taken CFT & Head QA SEI/DEV/F-13D

for the problems occured during production of FPP lot are

effective. 3. If the countermeasure taken against problems

observed during initial supply control itself are found

effective. If any of the criteria listed above are not met, ISC

period shall be extended till the time all criteria are met.

B. INITIAL PRODUCT CONTROL

S.NO. INITIAL SUPPLY CONTROL (ISC)PROCESS RESPONSIBILITY REF. DPCUMENT

Incharge quality

5.7 Identification of initial product : Identify the initial (PDC/GDC/

SEI/QA/F-13A

product with identification tag. Machine

shop/fetting)

Identification of initial product (Supplier Part) : For

BOP parts, instruct the supplier to submit the parts with

Head purchase/

5,7.1 initial

product identification tag for supplier.Note : Recevie Incharge BOP/RQC SEI/QA/F-13A

the material from supplier with initial product Engineer

identification tag only. If the material is not provided with

the tag, Do not accept such material.

Retention Peroid of inspection Reports : For A parts and

Incharge quality

functional parts, inspection reports must be preserved for (PS/WS/

5.8 Machine ___

min 5 years and incase of general parts min. 3 years or shop)

otherwise as agreed with customer.

Accetance criteria : For the items for which specification

are nor decided or tolerance are not specified in the Head QA/Head

5.9 Project ___

drawing by customer, discuss the acceptance during

engineering standards/ international standards.

PREPARED BY : REVIEWED BY : APPROVED BY : ISSUED BY :

DATE : DATE : DATE : DATE :

Doc No :SEI/IPP/PRO/01

Rev No :00

SHRI RAM

ENGG.INDS. Procedure for Initial flow Control Rev Date:01.04.2018

Page 4 of 4

INITIAL SUPPLY CONTROL

S.NO. INITIAL SUPPLY CONTROL (ISC)PROCESS RESPONSIBILI REF. DPCUMENT

TY

Perormance & durability evalution : Carry out all the

inspection & test as defined in drawing/any maruti

specified test other than drawingwhich has been discussed Incharge

in specification review meeting.if the facility is not Quality

5.10. Inspection Report

available for the inhouse inspection. cosult the external (PS/WS/Mac

lab/company maintain all such records of test Note : hine shop)

Performance shall be given to NABL (ISO 17025) accrediated

Labs/Companies.

Handling of Rejected initial : Each & every lot Rejected

during intial supply control shall be critically examinated Incharge

by CFT team (Q.C+Prod.+Dev.Team) for defect and Quality

5.11 SEI/QA/ F-29

necessary CAPA action shall be taken, with exphasis on (PS/WS/Mac

prevention of defect. If necessary FMEA should be hine shop)

modified.

Check of initial product inspection report and tag : Incharge

Before dispatching the product to customer ensure that Quality

5.12 initial product are identified with INITIAL PRODUCT (PDC/GDC/M SEI/QA/F-13A

IDENTIFICATION TAG and / or inspection report as Achine shop/

applicable. Fettling)

PREPARED BY : REVIEWED BY : APPROVED BY : ISSUED BY :

DATE : DATE : DATE : DATE :

You might also like

- JDM A13 - Rev. 05-2015Document35 pagesJDM A13 - Rev. 05-2015Romulo Eduardo100% (1)

- Piling Subcontract: Sinohydro 8th Bureau Hereafter Is Called ADocument11 pagesPiling Subcontract: Sinohydro 8th Bureau Hereafter Is Called ARoger Niu100% (1)

- Site Preparation and Earth WorkDocument31 pagesSite Preparation and Earth WorkGerobak Gaya100% (2)

- Supplier 8D FormDocument3 pagesSupplier 8D FormBen DesireNo ratings yet

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFDocument1 page14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineersNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- PFMEA SampleDocument24 pagesPFMEA SamplePk Nimiwal67% (3)

- Quality Manual: Subject: Procedure For PFMEADocument3 pagesQuality Manual: Subject: Procedure For PFMEAPk Nimiwal100% (3)

- APQP ProcedureDocument9 pagesAPQP ProcedurePk Nimiwal100% (5)

- Oum AimDocument11 pagesOum AimFerasHamdanNo ratings yet

- All Units Ppts Walker Royce PDFDocument110 pagesAll Units Ppts Walker Royce PDFDavid RajuNo ratings yet

- Method Statement For Access Road and Platform Construct Ion in Hilly AreasDocument7 pagesMethod Statement For Access Road and Platform Construct Ion in Hilly AreasRajesh100% (1)

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 pagesPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNo ratings yet

- 15 (QSP-QA - 07) Process & Product AuditDocument3 pages15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- Department: HOT SHOP Auditee: AuditorDocument52 pagesDepartment: HOT SHOP Auditee: AuditorSead ZejnilovicNo ratings yet

- Initial Supply ControlDocument3 pagesInitial Supply ControlKuldeep Chauhan100% (2)

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- Temporary Deviation RequestDocument3 pagesTemporary Deviation RequestSead ZejnilovicNo ratings yet

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDocument9 pagesGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNo ratings yet

- Process Change NoteDocument1 pageProcess Change NoteSUBODHHNo ratings yet

- QMS Formats PDFDocument11 pagesQMS Formats PDFBhavin SukhadiyaNo ratings yet

- Quality System Procedure For Change Point ControlDocument3 pagesQuality System Procedure For Change Point Controlrajesh sharmaNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- System Audit Check SheetDocument8 pagesSystem Audit Check SheetFINAL QUALITYNo ratings yet

- Procedure Name: Amendment RecordDocument6 pagesProcedure Name: Amendment RecordsubbuNo ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- 5 APQP 1 of 3Document3 pages5 APQP 1 of 3P G SumanNo ratings yet

- Supplier Audit Check Sheet For New & NON ISO SupplierDocument7 pagesSupplier Audit Check Sheet For New & NON ISO SupplierManoj Kaushik100% (1)

- PFMEA Review - MOM FormatDocument2 pagesPFMEA Review - MOM FormatMASU BRAKE PADS QANo ratings yet

- Jipl CL Pur 10 Testing Lab AuditDocument8 pagesJipl CL Pur 10 Testing Lab AuditMeghna SharmaNo ratings yet

- Production Validation TemplateDocument1 pageProduction Validation TemplatesathyabalaramanNo ratings yet

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramDocument2 pagesShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalNo ratings yet

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- Needs and Expectations, Turtle ChartDocument1 pageNeeds and Expectations, Turtle ChartChiheb GNo ratings yet

- QMP-05 - Corrective ActionDocument5 pagesQMP-05 - Corrective Actionom cnc100% (1)

- Siegel Robert Automotive Layered Process Audit ChecklistDocument12 pagesSiegel Robert Automotive Layered Process Audit Checklistmahesh KhatalNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

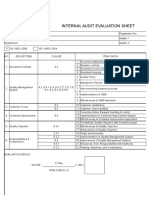

- Internal Audit Evaluation SheetDocument16 pagesInternal Audit Evaluation SheetHarnani Nanik100% (1)

- Kunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsDocument2 pagesKunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsSandeep VermaNo ratings yet

- Suppliers Quality Assurance Manual (PDFDrive)Document135 pagesSuppliers Quality Assurance Manual (PDFDrive)umtNo ratings yet

- TMT Procedure - Management Review P2Document1 pageTMT Procedure - Management Review P2sumanNo ratings yet

- Apqp Time Plan: Risk AnalysisDocument4 pagesApqp Time Plan: Risk AnalysisRakesh PandeyNo ratings yet

- Delphi Technologies Customer Specific Requirements: For Use With ISO 9001:2015 and IATF16949:2016Document15 pagesDelphi Technologies Customer Specific Requirements: For Use With ISO 9001:2015 and IATF16949:2016Ram100% (1)

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Supplier Deviation Request FormDocument2 pagesSupplier Deviation Request Formjainik shahNo ratings yet

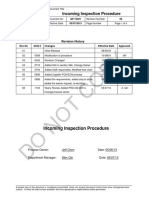

- QP 74301 Rev 08 Incoming Inspection ProcedureDocument9 pagesQP 74301 Rev 08 Incoming Inspection ProcedureAngeline D'AlmaidaNo ratings yet

- Procedure For ApqpDocument19 pagesProcedure For ApqpRaja RehaNo ratings yet

- COMP-OPP-01 Procedure For Control and Validation of ProductionDocument4 pagesCOMP-OPP-01 Procedure For Control and Validation of ProductionISODCC DSPINo ratings yet

- APQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareDocument2 pagesAPQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareselvamNo ratings yet

- Internal Audit Check Sheet MaintDocument3 pagesInternal Audit Check Sheet MaintRamdas Paithankar100% (1)

- Quality Control: and Inspection SystemDocument32 pagesQuality Control: and Inspection SystemAshley Kane P. DumayNo ratings yet

- Part Submission Warrant: Yes NoDocument1 pagePart Submission Warrant: Yes NoRaja DuraiNo ratings yet

- QSP Qad 08Document2 pagesQSP Qad 08prabha_1No ratings yet

- PPAP Check ListDocument4 pagesPPAP Check ListSameer SaxenaNo ratings yet

- APQP Responsibility MatrixDocument3 pagesAPQP Responsibility MatrixSuraj RawatNo ratings yet

- 53 MSA PlanDocument2 pages53 MSA PlanPk NimiwalNo ratings yet

- Process Capability Plan FormDocument4 pagesProcess Capability Plan FormMani Rathinam RajamaniNo ratings yet

- DWM FormatDocument4 pagesDWM Formatdharmendra ChaurasiaNo ratings yet

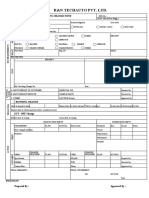

- R&N Techauto Pvt. LTD.: Engineering Change NoteDocument3 pagesR&N Techauto Pvt. LTD.: Engineering Change NoteUttrakhand Vibes- OriginalNo ratings yet

- PPAP ChecklistDocument2 pagesPPAP ChecklistSudhagarNo ratings yet

- Responsibility and Authority - QMSDocument47 pagesResponsibility and Authority - QMSDisha Shah50% (2)

- 1) PPAP YHA VIBRACOUSTIC Production)Document31 pages1) PPAP YHA VIBRACOUSTIC Production)Pk NimiwalNo ratings yet

- Process Wise Level Wise Skill Req. For Opr.Document1 pageProcess Wise Level Wise Skill Req. For Opr.Prakash kumarTripathiNo ratings yet

- Required Doc For IATFDocument3 pagesRequired Doc For IATFAbhayNo ratings yet

- PSI First Article Inspection ReportDocument3 pagesPSI First Article Inspection ReportwentropremNo ratings yet

- What Are APQP and PPAPDocument3 pagesWhat Are APQP and PPAPignaunaqNo ratings yet

- CAPA Burr (TSSR)Document3 pagesCAPA Burr (TSSR)Mohit Singh100% (1)

- Gauge Repeatablity & Reproduciblity With Part Variation (10 Parts, 3 Appraisers & 3 Trials)Document1 pageGauge Repeatablity & Reproduciblity With Part Variation (10 Parts, 3 Appraisers & 3 Trials)Pk NimiwalNo ratings yet

- Packaging Details: Vendor Name & AddressDocument4 pagesPackaging Details: Vendor Name & AddressPk NimiwalNo ratings yet

- ? What Are The Existing Controls, Ns What Are The Actions ForDocument10 pages? What Are The Existing Controls, Ns What Are The Actions ForPk NimiwalNo ratings yet

- Quality Evaluation, Problem and Follow Up Results Pdca FormatDocument1 pageQuality Evaluation, Problem and Follow Up Results Pdca FormatPk Nimiwal100% (1)

- Test Request Form 2021Document2 pagesTest Request Form 2021Pk NimiwalNo ratings yet

- Process Flow Diagram: M/S: Shree Ram Engineering Industry, RohtakDocument2 pagesProcess Flow Diagram: M/S: Shree Ram Engineering Industry, RohtakPk NimiwalNo ratings yet

- 1) PPAP YHA VIBRACOUSTIC Production)Document31 pages1) PPAP YHA VIBRACOUSTIC Production)Pk NimiwalNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- Target For ProductivityDocument1 pageTarget For ProductivityPk NimiwalNo ratings yet

- Project Handling ProcedureDocument8 pagesProject Handling ProcedurePk NimiwalNo ratings yet

- MSA PlanDocument1 pageMSA PlanPk NimiwalNo ratings yet

- Master TimingDocument4 pagesMaster TimingPk NimiwalNo ratings yet

- MRM FormatDocument3 pagesMRM FormatPk NimiwalNo ratings yet

- ABS Completed Recipt of Enquiry / Drawing Along With Spec DRG./ Ref. Sample No Action Required, Activity Finished As Per PlanDocument3 pagesABS Completed Recipt of Enquiry / Drawing Along With Spec DRG./ Ref. Sample No Action Required, Activity Finished As Per PlanPk NimiwalNo ratings yet

- Apqp Activities MatrixDocument7 pagesApqp Activities MatrixPk Nimiwal100% (1)

- 5M Change SheetDocument7 pages5M Change SheetPk NimiwalNo ratings yet

- APQP Final ProcedureDocument9 pagesAPQP Final ProcedurePk NimiwalNo ratings yet

- Rev - No. Date: S.no. Process Stage Potential Failure Potential Cause of Failure PreventionDocument3 pagesRev - No. Date: S.no. Process Stage Potential Failure Potential Cause of Failure PreventionPk NimiwalNo ratings yet

- History Sheet: History of Production SpecificationsDocument4 pagesHistory Sheet: History of Production SpecificationsPk NimiwalNo ratings yet

- 53 MSA PlanDocument2 pages53 MSA PlanPk NimiwalNo ratings yet

- 5M TagDocument1 page5M TagPk NimiwalNo ratings yet

- 5M CHANGE ProcedureDocument8 pages5M CHANGE ProcedurePk Nimiwal100% (1)

- Change Details Planed/Un Planned/Ab Normality Corrective Action (As Per 5M Rules) Machine No. & Name Part No. & Part NameDocument2 pagesChange Details Planed/Un Planned/Ab Normality Corrective Action (As Per 5M Rules) Machine No. & Name Part No. & Part NamePk NimiwalNo ratings yet

- Materials System SpecificationDocument8 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- Activity and Artifact Views of A Secure Software Development ProcessDocument6 pagesActivity and Artifact Views of A Secure Software Development ProcessRenataEMJNo ratings yet

- A 266 - A 266M - 03 Qti2ni0wmw - PDFDocument4 pagesA 266 - A 266M - 03 Qti2ni0wmw - PDFCristian CanavidesNo ratings yet

- Ladotd - 2018-07-19 Rev 8Document780 pagesLadotd - 2018-07-19 Rev 8Mike2322No ratings yet

- Project TemplateDocument37 pagesProject Templateanon_825088514No ratings yet

- Po # 5998-Subcontract - Firefighting Work-Reda Trading & Development Co. For Machinery &equipment Ltd.Document9 pagesPo # 5998-Subcontract - Firefighting Work-Reda Trading & Development Co. For Machinery &equipment Ltd.Saleh El-hawaryNo ratings yet

- Specification Sheets in Garment IndustryDocument3 pagesSpecification Sheets in Garment Industryakshu_4rfriends56% (9)

- Mil STD 883 5Document157 pagesMil STD 883 5Eduardo José TagleNo ratings yet

- Vendor - Directory 01.07.19-31.12.19 PDFDocument216 pagesVendor - Directory 01.07.19-31.12.19 PDFsumitshyamal0% (1)

- Filler Metals Selector GuideDocument32 pagesFiller Metals Selector GuideAleiser Quevedo AcuñaNo ratings yet

- PPAP 4th Edition ManualDocument75 pagesPPAP 4th Edition Manualjsr_shi100% (5)

- SPEC. FOR ELECTRIC HEATER SYSTEM rg6s911388003 - 001Document11 pagesSPEC. FOR ELECTRIC HEATER SYSTEM rg6s911388003 - 001Muthiah MuruganNo ratings yet

- Incident Management ITIL®4 Practice Guide: View Only - Not For Redistribution © 2019Document33 pagesIncident Management ITIL®4 Practice Guide: View Only - Not For Redistribution © 2019sharon magaya100% (1)

- Method Statement For Installation of DI Pipes at HETDocument9 pagesMethod Statement For Installation of DI Pipes at HETJahangir AlamNo ratings yet

- SMRP CMRPDocument5 pagesSMRP CMRPpooria abediny100% (2)

- Azspu Major ProjectsDocument24 pagesAzspu Major ProjectsMirzaNo ratings yet

- Sx-Ca5xx Om 1999 PDFDocument327 pagesSx-Ca5xx Om 1999 PDFTNo ratings yet

- 6 Konsep Project Charter SingkatDocument28 pages6 Konsep Project Charter SingkatNanda AzharyNo ratings yet

- SECTION 07531 Elastomeric Sheet RoofingDocument8 pagesSECTION 07531 Elastomeric Sheet RoofingIm ChinithNo ratings yet

- Standar Soportes Sierra GordaDocument117 pagesStandar Soportes Sierra GordaClaudio PuentesNo ratings yet

- Project Report Auto Saved)Document186 pagesProject Report Auto Saved)Dheeraj Kumar GoharNo ratings yet

- CNG LNG Notes: To Be DefinedDocument9 pagesCNG LNG Notes: To Be DefinedCubzlookNo ratings yet

- 2011 03 15 Comm Plan Rev 01Document138 pages2011 03 15 Comm Plan Rev 01Jawad Kamal100% (1)

- 077100fl RennerDocument18 pages077100fl RennerabobeedoNo ratings yet