Professional Documents

Culture Documents

The CBM Optimizer: Exakt

Uploaded by

David VelandiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The CBM Optimizer: Exakt

Uploaded by

David VelandiaCopyright:

Available Formats

‹EXAKT› ™

The CBM Optimizer

Our Walk-Through Demo................................................ 2

Real Life ................................................................................................ 2

The Demo ............................................................................................. 2

Our Walk-Through Demo Begins .................................... 3

Our PDF Demonstration ....................................................................... 4

The Main Screen................................................................................... 4

Mathematical Models ............................................................................ 6

Inspections Table.................................................................................. 7

Events Table ......................................................................................... 9

Graphical Display................................................................................ 11

Cross Graphs...................................................................................... 12

Modeling.............................................................................................. 13

Preparing the Data ...................................................................... 13

The PHM Parameter Estimation Report ..................................... 20

Amending the Model ................................................................... 22

Groups and Time Intervals.......................................................... 27

Transition Probabilities................................................................ 29

The EXAKT Replacement Decision............................................ 34

Ask Our Experts.................................................................................. 44

Appendix One ..................................................................................... 45

Residual Analysis — Order of Appearance ................................ 45

Residual Analysis — Residuals Against Expectation................. 45

Residual Analysis — Transformed Residuals ............................ 45

Residual Analysis — Variance Stabilized ................................... 45

Residual Analysis — Summary Report....................................... 45

Appendix Two ..................................................................................... 46

Our

Walk-Through Demo

Real Life

It’s really more than a demo… this EXAKT demo reveals the real data from a

client’s replacement analysis. The customer is Cardinal River Coals (CRC),

in Hinton, Alberta, Canada, a major producer of coal… and like all Coal

extractors, CRC uses costly, maintenance-prone heavy equipment.

This analysis was on “wheel-motors”. Wheel motors are Electro-mechanical

motors that drive each wheel of their enormous trucks. Cardinal operates 26

trucks, with 55 wheel-motors and each wheel-motor is valued at around

$85,000.

The assets being analyzed, therefore, are worth $4,675,000. To say that

making the right replacement and repair decisions — deciding when to take a

unit out of service — is an important decision, is definitely an

understatement!

This demo will show you the steps taken to analyze CRC’s wheel-motor data,

and (with lots in between) will conclude with the impressive Pay-Off that

EXAKT delivered.

The Demo

Now… to the Demo. This Demo is designed to “walk” you, step-by-step,

through the sequences of EXAKT — from data input tables, through

modeling, displays, estimation… and finally to decision outputs, in everyday

language. We’ll show you what numbers went in, what happened to them…

and the results CRC obtained.

May we suggest you jot down any questions or comments as you go along.

Near the end of this demo we provide a link for an e-mail message to us for

the purpose of sending along your questions or comments. One of our

experts will promptly reply to you with answers to your questions, or

additional information that you may appear to require.

Now... let’s go to the Walk-Through demo, where, in just a few minutes you

can see how Cardinal River Coals’ data was handled, and the remarkable

results EXAKT produced.

‹ EXAKT› ™ The CBM Optimizer page 2

Our

Walk-Through Demo

Begins

EXAKT has been designed as two distinctive, linked programs. One program

is called “EXAKT For Modeling” and the other is called “EXAKT for

Decisions”. On your computer desktop, they have special icons, that look like

these.

The Modeling program is designed to be used when a particular asset-type is

initially set up for analysis. It’s used at the stage where the data pertaining to

the asset is being examined and diagnosed to make sure it’s “right”, in a

number of respects. For example... is it complete?... does it include any

strange-looking observations?... and are the measures pertaining to the

machine’s condition all statistically valid? EXAKT’S powerful statistical and

graphical analysis tools assist you in getting your data into shape.

Once a model has been developed, it becomes your permanent watchdog

examining each new set of condition as it arrives from whatever source. This

can include your vibration program, your oil analysis program, your

automated distributed control systems or any other performance data.

That watchdog is called “EXAKT for Decisions”. We designed this second

module to be simple and easily configured and integrated with all major

computerized maintenance management systems (CMMSs) and condition

monitoring software. In fact EXAKT becomes the “link” between these two

otherwise isolated programs.

You will see how both programs work, as we walk you through this Demo.

‹ EXAKT› ™ The CBM Optimizer page 3

‹EXAKT› ™

The CBM Optimizer

Our PDF Demonstration

This Demo is designed to lead you, step-by-step, through the sequences of

EXAKT—from data input tables, through modeling, displays, estimation...

and finally to decision outputs.

In everyday language: We’ll show you what numbers have to go in, what

happens to them... and the results you’ll get.

On request, a “Working Demo” is also available. It’s the real program, and

with it you can input a prepared database set, and navigate at will around the

entire software package. The Working Demo requires more time, but

provides hands-on experience with the program, and a live database.

This PDF Demo is the best place to start. If you wish to obtain a copy of the

Working Demo, contact us.

The Main Screen

This is EXAKT’s main screen:

(IMAGE 1)

The pane on the left is a familiar file management and selection tool. Note

that our database has already been selected — CRC_WMOD.mdb. It is from

this panel that one can access EXAKT’s tables queries and programs.

‹ EXAKT› ™ The CBM Optimizer page 4

EXAKT will directly attach to data in your CMMS or from any ODBC

compatible corporate database. An ODBC interface is built into EXAKT to

facilitate the data transfer.

This pane also includes the means to get to a variety of tables, most of which

will be explained later.

The pane on the right contains the Procedures flow-chart. This flow-chart —

and others like it — are “maps” to enable you to keep track of where you are,

and where you’ve been... and where you might be going.

This is the database we’ll be

using — the CRC Cardinal River

Coals data

This is a map of the major

EXAKT Sections.

(IMAGE 2)

Before we get to the important model-building step, we want to illustrate a

procedure where EXAKT will check the database for errors and anomalies.

As part of this data-check we will obtain a report showing the basic statistics

concerning the data.

‹ EXAKT› ™ The CBM Optimizer page 5

Here are what the statistics look like:

This display provides an opportunity to get an overview of the entire sample and

to check for consistency and obvious anomolies. The Number of Histories, for

example, should equal the Number of Beginnings – beginnings are the start-

dates of histories. A history a lifetime record having a beginning, various events,

and an ending. The ending may be an actual failure or a preventive removal.

Mathematical Models

EXAKT uses database tables which it draws upon for its “models”. A model is

a mathematical representation of the relationships between the age-related

failure information, and the key condition indicators. EXAKT uses the term

“covariates” — the readings obtained from condition monitoring such as oil

analysis, vibration readings, thermography, current analysis, pressure

monitoring and so on.

To arrive at the ultimate Decision-Optimization Model we initially build

what is known as a Proportional Hazards Model (PHM). The EXAKT

program does the model building for you, but along the way the user will

contribute added information.

The PHM — or Proportional Hazards Model — provides the risk of failure as

a function of both... (1) time, and (2) the key significant condition indicators.

The Decision Model blends the risk of failure with the relative costs of a

failure. That blend produces a model that will generate the optimum decision

‹ EXAKT› ™ The CBM Optimizer page 6

for any given future set of condition measurements taken on that machine,

component or assembly. The model constitutes a “maintenance policy” that,

if consistently applied, guarantees the lowest long run costs of maintenance.

Building the PHM and the Decision Models is a straightforward process. The

user can easily follow each step of the procedure using the appropriate

EXAKT functions.

The procedure, in fact, is so simple that the user may be tempted to

invoke it prematurely before having adequately verified the data for

obvious errors. But It is critical that you first employ EXAKT's powerful

and friendly data evaluation tools to weed out and correct obvious errors

in the data.

Here’s why.

EXAKT will provide you with many clues and in some cases informative

statements about the data requiring your attention. An example of a

data record in error is one whose working age for a given inspection is

lower than that of an inspection on a previous date. This is a common

error due to mis-transcribing the equipment's hour-meter. Other

common errors are missing "B" (beginning) events. EXAKT will point out

all such errors for you to correct. You will spend most of your modeling

effort in rooting out these errors, and in the process, becoming very

familiar, indeed intimate, with the data. Experienced maintenance

people should perform this task or be consulted often in this data

"cleaning" phase.

As we said above...EXAKT uses a number of tables from which it draws

data for its “models”. Let’s look at some of these tables in order to see

the data EXAKT requires. We’ll start with the Inspections Table.

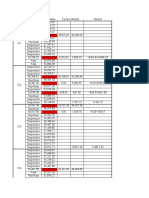

Inspections Table

The Inspections Table contains observed values taken from Condition-Based

Monitoring inspections. The Inspections Table (Image 4) includes a number

of headings for its columns.

‹ EXAKT› ™ The CBM Optimizer page 7

WORKING AGE

Expressed in

cumulative hours

of the machine

part, assembly or

component that is

being inspected

DATE

Date of

observation

IDENT is the

identification number

of the item being

analyzed

(IMAGE 4)

You may then want to return to the Main Screen, and, to obtain a description

of your covariates you would click on VARDESCRIPTION.

(IMAGE 4)

‹ EXAKT› ™ The CBM Optimizer page 8

When you get there, you will see that it is a table that provides you with a

place to record the names of the covariates, units of measurement, and

optional comments.

(IMAGE 6)

Events Table

Let’s look at the Events table. To get to it, you would click on EVENTS in the

left pane.

(IMAGE 8)

‹ EXAKT› ™ The CBM Optimizer page 9

These event codes

represent significant events

- the beginning (B) of a

history, oil changes (OC),

and an “Ending with

Failure”(EF). The user may

include additional events

that will influence the model

(for example alignments,

mechanical adjustments,

and so on).

(IMAGE 9)

You’ll note it has columns similar to the Inspections Table... but the focus

here is on the data in the Working Age and Event columns. This data is the

real data from Cardinal River Coals’ CMMS records.

The Events Table provides lifetime data which allows you to see how long

the item ran (the Working Age) before it failed or until it was “suspended”

(explained below). Other rows record other events such as an oil change

(OC) or minor repair.

An ending-by-suspension event (ES) indicates equipment removal for

reasons other than failure. That could be for a preventive action or

simply due to expedience because the equipment was available (also

called opportunistic maintenance)

A TS event (temporary suspension) indicates that the unit is still

operating at the time of this analysis.

An EF event indicates ending by failure. EXAKT uses all of these events

together with the condition data to build a proportional hazards model

(PHM).

Here is the EventsDescription Table. There is no limit to the number of types

of events that can be defined in this table. The reason that one would include

a particular event is that the event is known to affect the covariates and

influence the risk of failure. For example an OC (oil change) event would

reduce all the wear metal readings to zero and reset the additive readings to

those of new oil. A shaft-coupling alignment event would reduce radial and

axial vibration readings to some lower value. These “covariates on event”

data are set up in the COVARIATESONEVENT table.

‹ EXAKT› ™ The CBM Optimizer page 10

(IMAGE 10)

Graphical Display

With the working version of EXAKT, to see a graphical display of the

inspections information you would go to VIEW on the Menu Bar and select

Inspections.

The Graphical Display is a most useful feature of EXAKT, and offers many

attractive options. It is a display that fully-synchronizes inspections data with

a graphical picture. For example, you can click on any inspection record in

the right-panel inspections table, and when you do, the graphical point

corresponding the record will be identified on the graph by a vertical line.

Or vice versa — you can click on any point on a graph and the information

corresponding to it will be highlighted in the inspection table to the right.

Various sizes, colors and other display options are at your fingertips as well.

There is a graph for

every covariate —

Al, Cu, Cr, Fe, etc

By clicking on

any point on a

graph you may

highlight the

same value on

the table Clicking on any

point in the table

will highlight the

corresponding point

in the graph

(IMAGE 11)

‹ EXAKT› ™ The CBM Optimizer page 11

Similar graphs are available for data from other tables. By using these tools

you can easily locate and correct anomaliesin this data cleaning phase of

your modeling exercise

Cross Graphs

Another of EXAKT’s powerful tools, the “cross-graph”, will reveal the data in

ways that will point out further possible problems or inconsistencies.

Furthermore the cross graph illustrates correlation between pairs of

numerical variables.

This Cross-Graph shows

the relationship between

Fe (Iron) and Working

Age

(IMAGE 12)

You can choose to examine the relationship between a particular covariate

— say, iron — and Working Age. Or you can choose to look at the

relationship between pairs of covariates — say, between iron and chromium.

‹ EXAKT› ™ The CBM Optimizer page 12

This one illustrates the

relationship between Fe (Iron)

and Chromium (Cr)

(IMAGE 13)

This information can helpful in building the “model” — the important

mathematical expression that describes the relationships between the age-

related failure information, and the covariates.

Modeling

Preparing the Data

We’re now at the “Modeling” phase, where the user or analyst must work with

the information to construct models. These models are constructed for a

single machine or component, or for a fleet of similar equipment.

To do this you would return to the Procedures Window, and click DATA

PREPARATION.

‹ EXAKT› ™ The CBM Optimizer page 13

Click here to

begin creating

a model

(IMAGE 14)

Your selection brings you to:

Your next selection

(IMAGE 15)

‹ EXAKT› ™ The CBM Optimizer page 14

Click the ENTER GENERAL DATA button and this will bring up the following

dialog box where you enter the specified information:

Enter PROJECT TITLE –

A general description

Enter the general name of

the machine part,

assembly or component

(IMAGE 16) The Time Unit you’re

Enter a specific description

of the part or assembly–

working in.

Once the General Project Data has been entered, a click on the OK button

will bring you back to the Procedures window, where you will click on the

INPUT DATA WITH COVARIATES button.

Click here

(IMAGE 17)

Once you do this the data from the Inspections Table and the Events Table

will be merged to create two new tables to be used in model calculations. In a

‹ EXAKT› ™ The CBM Optimizer page 15

“live” session, you culd look at the activity-bar in the lower-left corner of your

screen and see this activity in progress.

A brief explanation — what is the difference between Data With

Covariates and Data Without Covariates?

Data With Covariates is the sequence we are using for this demo. It

means that condition readings have been obtained and are available for

analysis.

Data Without Covariates means that condition readings are not

available — you have “events” information, and the table to go with it,

but you do not have “Inspections” information — but you may wish to

proceed, nevertheless, to analyze the need for replacement by using

only time-based failure (and suspension) data.

After the data have been loaded, click on the MODELING button in the Data

Preparation for Modeling View.

Next…click on

this button

(IMAGE 18)

Your Data Preparation View will change to the Modeling View, and you would

click on the Weibull PHM button —

‹ EXAKT› ™ The CBM Optimizer page 16

This one

(IMAGE 19)

— to get to the Weibull PHM View. Here you would click on Select

Covariates

‹ EXAKT› ™ The CBM Optimizer page 17

Click on

Select

Covariates

(IMAGE 20)

‹ EXAKT› ™ The CBM Optimizer page 18

The Model Variables dialog box will appear:

(IMAGE 21)

This part of the model-building process requires a little explanation.

First, note that EXAKT requires a sub-model name. Why? It’s because the

user would likely look at several variations of a Proportional Hazards Model

(PHM) before finally settling on a particular one. Thus the models are

assigned different names to identify them throughout the modeling session.

In the dialogue box shown above, all the covariates are shown as “available”,

but unselected. In other words, no selection of any particular covariates has

been made yet. But to begin with actual modeling, it is recommended that all

the covariates be “selected” (i.e., moved into the selected box to the right).

‹ EXAKT› ™ The CBM Optimizer page 19

The covariates are

selected by clicking this

arrow

Click OK to tell EXAKT

to create the first of our

two models — the

Weibull Proportional

Hazards Model (PHM)

(IMAGE 22)

With all the covariates now selected and in the right-hand box, you would

click the OK button. This initiates the model-building process.

The PHM Parameter Estimation Report

What’s happening now is that the Weibull PHM (Proportional Hazards Model)

is being created through an intensive multiple regression procedure with the

purpose of finding significant correlations between condition data and event

data, particularly failure event data. Once the model has been created, a

report will appear — PHM Parameter Estimation.

This report shows the parameter estimates for the “All-Covariates” model for

that particular machine part, assembly or component. Two tables will be

shown on the screen.

‹ EXAKT› ™ The CBM Optimizer page 20

In the next step the non-

significant covariates (N),

will be de-deselected

(IMAGE 23)

One table is — Summary of Events and Censored Values

A sample of 50 wheel motors was available for analysis. There were 176

“histories” related to these, since a given wheel motor might have more than

one history, due to its being repaired or renewed, and brought back into

service as “new”.

This table shows us that on 88 occasions the use of a wheel motor was

terminated by failure, and on 41 occasions the wheel motor’s life was

suspended. (See previous explanation of failures versus suspensions). This

information comes from the Events Table, described earlier.

The other table is Summary of Estimated Parameters (Based on ML

Method). (ML means “Maximum Likelihood”.)

This table includes a number of columns pertaining to the statistical

estimation procedure. Only the first three columns need be considered by the

maintenance professional building the optimal decision model. (The other

columns are fully described in the appendix).

Please focus on the “Sign. (Significance) column, where you will note “N” and

“Y” codes. “N” indicates that a given covariate is non-significant. The

recommended procedure is to de-select these covariates one-at-a-time in

‹ EXAKT› ™ The CBM Optimizer page 21

order of decreasing “p-values” until we arrive at a workable model – one that

contains only significant covariates.

Amending the Model

Many of the covariates (TO BE SELECTED LATER) are shown as not

significant so we will amend the model by de-selecting one covariate — the

one that has the highest p-value

This is done by closing the current Models Variables window, which will

display the Weibull PHM flow-chart, where, once again, the SELECT

COVARIATES button will be clicked.

This will bring you, again, to the Model Variables box where you will de-select

the covariate described above.

This is an iterative process which will be repeated until we arrive at a model

that contains only significant covariates. Image 24, below, represents the

model arrived at by the end of the elimination process. It contains only two

significant covariates, Iron (Fe) and Corrected Sediment (CorrSed).

Only two covariates —

iron and corrected

sediment — remain now

(IMAGE 24)

Once a model has been developed it is important to evaluate how “good” it is.

How closely does it “fit” the actual data from which it was generated in the

previous steps? If it does not fit well enough, the model should be rejected

since it will probably not provide maintenance decisions with an gadequate

level of confidence. The Goodness-of-Fit test provides an objective tool with

which to accept or reject the model at this point. To obtain this you would

click on Summary Report in the Weibull PHM flow-chart. The report looks

like this:

‹ EXAKT› ™ The CBM Optimizer page 22

(IMAGE 25)

Note that the model, according to this (Kolmogorov-Smirnov) statistical test

method is “not rejected”.

Before we leave this stage of the demo, let us refer to the right-hand

panel of buttons called “Residual Analysis”. Under Residual Analysis

you will see options that provide you with various graphical measures of

goodness-of-fit of the PHM we have decided to use. These options are

explained in the appendix to this Walkthrough Demo.

After closing the Proportional Hazards Model, you will come again to the

Modeling Weibull PHM View of the Procedures window.

‹ EXAKT› ™ The CBM Optimizer page 23

These options

are explained in

our appendix.

(IMAGE 26)

Clicking the TRANSITION PROBABILITY MODEL button displays Image 27 — the

Transition Probability Model view of the Modeling process.

‹ EXAKT› ™ The CBM Optimizer page 24

Click here

(IMAGE 27)

‹ EXAKT› ™ The CBM Optimizer page 25

Click on the COVARIATE BANDS button.

(IMAGE 28)

Covariate bands refer to the ranges of an inspection measurement which the

analyst feels are roughly related to the state of health of the equipment.

EXAKT will later calculate the probability of moving from any state to any

other state (the transition probability) in the next inspection period. EXAKT

proposes a set of default bands for each covariate. It Is recommended,

however that the analyst display each significant covariate in a cross graph

with time to visually determine the number of states and a reasonable range

for each state. Clustering of dense and less dense areas of points on the

cross graph help to determine the covariate bands. EXAKT will not allow the

analyst to select bands which do not have a significant number of points with

which to calculate the transition probabilities to that state.

What do the bands mean? These bands, or ranges, define the condition

measurement readings that can be interpreted as, for example, low,

medium, high and very high. That is, high contamination, low pressure,

medium voltage, low vibration — whatever the indicator is for the

condition that is being monitored.

In our demo, therefore, we have five bands for iron, and five bands for

Sediment. These are the only two covariates used in the final PHM.

We see the iron readings fall in the range between 0-to-2693 (see the

text at the bottom of the box) having intervals 0-50, 50-150, 0-400,

400-900, and 900 and greater. These are not default bands but were

selected on the basis of current practices at Cardinal River Coals and

reflect the severity of iron particles with respect to the condition of this

equipment.

‹ EXAKT› ™ The CBM Optimizer page 26

Groups and Time Intervals

It is possible that two or more significant covariates are related to one

another. In that case the transition model will be more accurate if they were

“grouped” together. A trial and error process is provided at this point for the

analyst to test certain grouping hypothesis. EXAKT will calculate the

transition probabilities of the group and determine whether indeed those

covariates are related. If EXAKT rejects the hypothesis then the grouping

should be removed.

A pointer locates the Groups option on the image, above.

If different wear-metals were known to originate in entirely different parts of

the engine under analysis there would be of no physical reason to group

these different covariates together.

EXAKT can help you decide whether or not the groups you set up are

statistically significant. This can be determined by clicking on the Test

Grouping button on the Analysis menu of the Transition Probability Model

Procedures Window.

For the purposes of this demo, we will not create and test covariate groups.

Click OK. Go to TIME INTERVALS on the Transition Probability Model

Procedures Window. Our pointer locates it on the image, below.

‹ EXAKT› ™ The CBM Optimizer page 27

The Time Intervals

button

(IMAGE 29)

Similarly to “groups”, EXAKT can test certain assumptions regarding the

covariate behavior in different time intervals in an equipment’s life. For

example during the first 1500 hours the probability of transition from low to

high may be different from that at another period, say beyond 1500 hours.

Once again the analyst can test various hypothesis in this regard.

Click on Time Intervals. This option allows you to set a time-period for the

values you wish to analyze. One way this can be useful is in taking into

account that the behavior of the condition-measurements might vary during

different stages of the unit’s life. The early part of its life (the run-in period),

the normal working duration (the major part of the unit’s life), and the final

stage of its life (the wear-out period) may need to be analyzed separately.

This option gives you the opportunity of doing so.

‹ EXAKT› ™ The CBM Optimizer page 28

EXAKT can help you decide whether or not the time intervals you set up are

statistically significant. This can be determined by clicking on the TEST

HOMOGENEITY button on the Analysis menu of the Transition Probability

Model Procedures Window.

Transition Probabilities

EXAKT uses transition probabilities to build upon the PHM previously

created. They provide a further level of refinement to the ultimate decision

model. The transition probabilities are available to be viewed by the analyst if

necessary to more deeply understand the model or to test various grouping

and time interval hypotheses. Otherwise, it is not necessary to examine the

transition probability tables in order to build the eventual decision model.

Click on Transition Rates in the Rates Transition Probability Model

Procedures Window

to prepare the background information for the calculation of the transition

matrix — its long name is The Markov Chain Model Transition Probability

Matrix.

Clicking on Transition Rates causes EXAKT to calculate every single

probability of every significant condition indicator (covariate) going from any

given state to any other state before the next inspection. Not only that, it

calculates every probability of a covariate moving to another state conditional

on the states of the other significant covariates.

It is not necessary that the analyst use this information — it is available for

study, if necessary. Whether studied or not however, these “transition

probabilities” form a powerful part — together with the PHM — of the final

decision model.

‹ EXAKT› ™ The CBM Optimizer page 29

Click on

Transition Rates

(IMAGE 30)

‹ EXAKT› ™ The CBM Optimizer page 30

This brings up this screen... the Transition Probability Model Procedures

Window with the active DISPLAY MATRIX button.

The Display Matrix

button

(IMAGE 31)

Clicking on the DISPLAY MATRIX button brings up the Display Transition

Probabilities window.

From this window one may study the transition probabilities by using the

settings to display them in different ways. For example, we can ask EXAKT

to show us the probability of iron moving from any state to any others state.

Then we can set conditions to display iron’s transition probabilities, given

states of the other covariates. Once again, it is not necessary for the analyst

to study these transition matrices – but they are there for deeper probing, if

necessary.

‹ EXAKT› ™ The CBM Optimizer page 31

Choose the variable you want to

see transition probabilities for

This button, if activated, will

command that only one

variable be calculated.

(IMAGE 32)

Click on the variable IRON in this example. Provide the approximate

inspection interval in the appropriate box, say 300.

You have the option of examining the transition probability matrix more

closely by considering also the influence of transitions of one covariate on

those of another. This is done by deactivating the radio button “ignore”. At

that moment you need specify a transition of the other variable.

If you deactivate the Ignore radio button, it means you want to see how the

transitions of one variable (covariate) affects another. For the demo, we will

provide no further detail here, but it is important to know that this option is

available.

Click OK. This will bring to the screen a report on the Markov Chain Model

Transition Probability Matrix.

‹ EXAKT› ™ The CBM Optimizer page 32

White on-blue

numbers

reflect the

severity of the

condition. (The

high numbers

are “worse”).

64%

(IMAGE 33)

This is an example of a transition matrix for iron, where the other significant

covariate has been ignored.

Referring to the table above, we can see that the covariate under analysis is

iron, and that five levels of readings have been established. (That

establishment would have been done in the model-building phase we

covered earlier).

The five levels indicate the severity of the condition such as light

contamination to very heavy contamination. If the second level of severity,

where the readings are 50 to 150 indicate. say, “medium” contamination, the

table would tell you that there is a 64% (0.638362) probability of the

measurement being in the same range at the next inspection, a 19.3%

probability of it having worsened to the next higher level of severity (150-to-

400), a 3.3% chance of it having reached the next state (400 to 900) and a

0.6% of chance of it having reached the worst state (above 900) before the

next inspection.

‹ EXAKT› ™ The CBM Optimizer page 33

The EXAKT Replacement Decision

Now click on DECISION MODEL in the Flow-Chart.

Click on

Decision

Model button

(IMAGE 34)

Clicking Decision Model causes EXAKT to build its most important output —

the Optimal Decision Replacement Model. The process incorporates all of

the work that went on earlier. — the data-preparation effort, the PHM, and

the TPM…together with the cost information. The Replacement Decision

Model emerges. The maintenance decision-makers may now confidently

apply this model as a “watchdog” to monitor future condition data, and to

deliver the optimal decision each time.

‹ EXAKT› ™ The CBM Optimizer page 34

But before it can do that it needs additional information from you.

Primarily it needs the costs of a planned repair as well as those of a repair

that has been provoked by an unexpected failure. The costs of downtime,

overtime, and all other expenses connected to an unexpected failure should

be included in the latter.

Next, click on DECISION MODEL PARAMETERS.

Click here

(IMAGE 35)

‹ EXAKT› ™ The CBM Optimizer page 35

You will display the Decision Model Parameters window.

Replacement and Failure Cost

Information is introduced here.

(IMAGE 36)

It is already partly filled in from prior information when we were in the Data

Preparation and General Data phase, much earlier.

You have an option to choose a replacement strategy:

Variant 1 assumes that it is feasible make a replacement between

inspections.

Variant 2 assumes that replacement can be made only at the time of a

scheduled inspection.

We have chosen VARIANT ONE, because the working reality of the equipment

studied at Cardinal River Coal was such that it was not possible to carry out a

repair or replacement except at regular inspection times. EXAKT will assume

that reality when it renders future replacement decisions.

In the “Cost” panel, 20 was entered as the replacement cost (parts and

labor). The value 60 for was entered for failure costs (parts, labor and

downtime). For the Cost Unit, $1000 was entered. This means that a

Planned replacement cost is $20000 and a Failure Cost is $60000. Note that

250 was entered for the duration of the inspection interval, and 500 for

regular maintenance event such as an Oil Change, corresponding to the

interval recorded in the Events Table.

‹ EXAKT› ™ The CBM Optimizer page 36

Click OK. You will see the Cost Function graph.

(IMAGE 37)

This is a kind of “sensitivity” graph. In our demo, the flat shape of the line

shows that the replacement policy does not have to be strictly followed.

Costs are not greatly affected if the replacement time varies. The Cost

Function graph shows the minimum costs per hour we can achieve and the

cost per hour if we follow a failure-replacement policy.

Note the dip in the Cost curve. The deeper the dip, the more savings you

derive from using the Optimal decision model. The difference between the

low point on the curve and the dashed line equals the savings relative to a

run-to-failure policy.

You can also get at this graph by clicking Cost Function in the Analysis

window. For even more information, after opening the Cost Function Graph

you can click VIEW on the Menu Bar to choose VIEW FULL REPORT and get a

full report (including summary of cost analysis) along with the graph. You will

see this when you get to Image 40. Close the window.

‹ EXAKT› ™ The CBM Optimizer page 37

Click on OPT REPLACEMENT POLICY to get the chart “Optimal Replacement

Age”.

(IMAGE 38)

The optimal replacement graph is the two dimensional embodiment of the

entire model which in fact can contain multiple dimensions. This "magic" has

been made possible by the clever use of a "composite" covariate which is a

weighted sum of influences of each significant covariate on the risk of failure.

The shape of the red, yellow, and green regions embody the cost, PHM, and

transition probability models. The result is a revolutionary way to judge a

given set of condition data to render the best (optimal) decision. (More on

this, below…see Image 42).

Close, and click on SENSITIVITY OF OPTIMAL POLICY. This displays the

Sensitivity of Optimal Policy graph.

‹ EXAKT› ™ The CBM Optimizer page 38

Represents the

sensitivity of

the Optimal

Policy to

changes in the

cost estimate

for planned

repairs

(IMAGE 39)

Our publication, “The CBM Optimizer News”, explains the graph, this way:

This graph, Sensitivity of Optimal Policy — reveals, for your particular

operation, just how important accurate cost data is to the ultimate

replace-or-don’t-replace decisions. It allows you to get comfortable

with two things...one is how the cost-data precision affects the hazard

level (the level at which a replacement is recommended), and the

other is whether you should plan less, or more, preventive

replacements.

The curve shows whether or nor accurate cost data is required to

identify the optimal policy. For example if the cost ratio is between

about 8 and 12 — in the “flat” region — it indicates it is not crucial that

a precise estimate of the ratio of the cost consequences of failure

versus preventive replacement is required. On the other hand, due to

the steep slope of the curve between a cost ratio of 2 and 4, this

indicates that the optimal replacement decision is highly dependent

upon the ratio — and therefore efforts should be made to obtain an

accurate figure.

Here’s an even more detailed explanation —

In real situations, the actual ratio of failure and planned repair costs, may

not be well known. Furthermore the dynamics of industry are such that costs

can change with changing technology, production, and market conditions.

Therefore one would like to know, to what degree one's true costs and one's

optimal policy would change with changes in costs. Sensitivity analysis is

the method to determine this. The software generates a graph and

corresponding tabular data

‹ EXAKT› ™ The CBM Optimizer page 39

Red Solid Line — If the actual cost ratio (CR) differs today from that

specified when the model was built, that means that the current policy (as

dictated by the Optimal Replacement Graph of Image 38) may no longer be

optimal. The red line tells how much, in percentage, more will be expended

above the calculated optimal cost/unit time for actual cost ratio by adhering

to the policy.

For example, if the actual cost ratio is 5 and we are using a model which

was based on CR=3, then the increase in optimal cost incurred by following

that (wrong) policy is around 6%. In other words the red graph represents

the sensitivity of costs to changes in CR.

Blue Dashed Line — Again, assume the actual cost ratio has strayed from

what was assumed when the model was built. Assume we were to rebuild

the model using the new ratio. The blue line tells how much the new optimal

cost would differ from that of the original model. In other words the blue line

represents the sensitivity of the optimal policy to changes in CR. (Note that

the sensitivity graphs assume that only Cf (failure repair cost) changes and

Cr (planned repair cost) remains unchanged.)

You can also call up a full report for this, as with the Optimal Replacement

Decision Graph, by clicking on VIEW on the Menu Bar, and choosing VIEW

FULL REPORT.

(IMAGE 40) These are the actual

savings obtained in this

The bottom portion of the Full real-life

Report, onanalysis

Cardinalfor River

Coal, shows the

Cardinal River Coal

potential savings obtained compared to a policy of replacing-only-on-failure

— an impressive 25.6%. In practice CRC replaced some wheel motors prior

to failure, but generally they replaced most motors only after failure. Thus the

savings shown would be in reality slightly less than they would have been,

had a consistent “roof” policy had been followed.

Incidentally, these savings were calculated using a cost ratio — (the ratio of

the cost of a operating replacement versus a preventive replacement) — of

“3”. If the ratio had been “5” the savings would have been nearly 44%, and if

the ratio had been “6” the savings would have been 50%!

We have now built our statistical decision model, and we are confident we

can use it for decisions. This will eventually be “saved”. Close your window.

‹ EXAKT› ™ The CBM Optimizer page 40

(IMAGE 41)

Click on Decisions

Click on the DECISIONS button on the flow-chart.

In the case of the Cardinal River Coals data, this will display a list of wheel

motor idents from which you can choose an item on which you would like to

make a decision. By clicking on Decisions you will actually run the model for

any of the equipment in the database. Later, by using only the EXAKT for

Decisions Program you will be able to apply the model to any unit for

"automated" monitoring. This will display the Replacement Decision graph.

Again, you have the opportunity of getting a full report if you wish.

‹ EXAKT› ™ The CBM Optimizer page 41

This analysis was

done retroactively.

The wheel-motor

actually DID FAIL

subsequent to the

last inspection

shown here. Had

EXAKT been

applied, the failure

would have been

avoided.

(IMAGE 42)

For the everyday maintenance practitioner who just wants to get an answer

to a simple question, i.e., should we keep on running, or should we replace

right now?”, he or she will turn to the EXAKT Replacement Decisions chart and

immediately find the answer on a clear unambiguous graph.

EXAKT assumes that regular inspections are being carried out, so the

position of the right-most dot on the chart will provide one of three

possible actions related to the inspection interval policy.

If your dot is in the green region, then the decision is to continue operating

until the next scheduled inspection.

If your dot is in the yellow region — Replace Before Next Inspection — it’s a

warning signal which says although you’re getting “close” to a possible failure

event, the risk of failure combined with the benefits of running a while longer

means that you may be able to delay replacement. It’s an invaluable help in

planning because it allows you to forecast the maintenance work-load and

down-time eventualities in the near-term.

If your dot is in the red area, EXAKT is telling you to Replace Immediately

because the risk of imminent failure is very high.

The Optimal Decisions graph. A disarmingly simple diagram that, in fact,

delivers the most profound and extraordinarily useful output of the entire

EXAKT software package!

‹ EXAKT› ™ The CBM Optimizer page 42

Essentially, we have walked you through all of EXAKT. That is, you have

seen how a model is created, and you have seen several outputs pertaining

to decision-making. So why do we offer, in addition, a program called

“EXAKT for Decisions”?

The answer is that users have suggested they wanted a portion of EXAKT —

the modeling portion — to be un-available to persons other than the

modelers in the organization. This way, decision-makers — mangers,

planners, schedulers, maintenance supervisor, and so on — can freely use

EXAKT with no danger of altering or destroying the model. EXAKT for

Decisions, uses the established models for future decision making, but

leaves their originals intact.

Users of the “EXAKT for Decisions” program can generate all the output that

really matters. For example they can generate the Replacement Decisions

Graphs as already illustrated. They can also generate a useful Report that

displays all the assets, individually or grouped by, say, location, or type.

Here’s an example of such a report as it pertains to Cardinal River Coal.

(IMAGE 43)

The EXAKT decision module can be set up to automatically generate the

most current optimal decisions. The data is stored in an MS Access database

and can be accessed directly by your organization's own CMMS

(computerized maintenance management system).

‹ EXAKT› ™ The CBM Optimizer page 43

Ask Our Experts

Earlier we suggested you note any questions that arose as you walked

through the demo. Here, now, is your opportunity to send them along to us.

Please include, at the beginning of your message – Your Name, Job-Title,

Organization, Telephone-Number, and Geographical Location (address not

necessary). We look forward to hearing from you. To e-mail us, click here.

Please note our e-mail address is expertquestion@oliver-group.com.

‹ EXAKT› ™ The CBM Optimizer page 44

Appendix One

Residual Analysis — Order of Appearance

This chart demonstrates the difference between the PHM forecast and actual

observed histories. If the fit is “statistically good” it would be expected that

these differences — (i.e., residuals) — would lie within the 90% confidence

interval. In this example we notice that one censored observation and one

failure observation lie outside the 95% limit.

Residual Analysis — Residuals Against Expectation

This chart has taken the residuals on the previous graph and ordered them

by magnitude with the theoretical expected values being on the x-axis. A

perfect fit would have all observations lie on the 45° straight line. This is an

additional check on the goodness of fit of the PHM.

Residual Analysis — Transformed Residuals

The scaling has been transformed so that all residuals must lie in the range

0-to-1. The reason, essentially, is to facilitate interpretation of the residuals.

Residual Analysis — Variance Stabilized

This is another transformation and is virtually identical to the previous graph

but this transformation takes into account variations in data to compensate

for the increasing variance associated with larger residual values.

Residual Analysis — Summary Report

The report “PHM Goodness-of-Fit Test” gives a summary of carrying out the

Kolomorgov-Smirnov (K-S) goodness-of-fit test on the PHM.

‹ EXAKT› ™ The CBM Optimizer page 45

Appendix Two

The Estimates are used in the Proportional Hazards Model. The PHM is

as follows:

β −1

βt γ 1Z1 ( t ) + ... +γ p Z p ( t )

h( t ) = e

η η

where t denotes time, Z1 (t ) ,..., Z p (t ) are p condition variables and

β , η and γ 1 ,..., γ p are parameters to be estimated from the data.

To show how the values in the estimates column are used in the PHM

model, we will now substitute these values in the model, above.

3.693−1

3.693 t

h( t ) = e 1.337 nerf ( t ) +1.701 pitation( t ) +.0107 gobbing ( t )

18230 18230

Sign — Indicates whether, from a statistical viewpoint, one or more (or

perhaps, none) of the parameters — (one in this case — gobbing) — is

not statistically significant in the context of estimating risk based upon a

PHM..

Standard Error — The values here are used to establish whether or not

the estimates in the second column are statistically significant.

Wald — The values here are obtained from the values in the Estimates

and Standard Errors columns through a transformation process.

DF — Degrees of Freedom. Tells us the Wald statistic is distributed

through a chi-square distribution with one degree of freedom.

p-value — This column is obtained from tables of the Chi-square

distribution and indicates whether the Wald statistic is significantly large.

If it is, the p-value will be small, demonstrating that the previously-

calculated estimate is significant, and a Y (for “yes”) would be produced

in the 3rd (Sign) column.

exp of est — Exponent of the Estimate... Along with the associated 95%

confidence interval on that exponent, provides the statistician with

additional insights into the significance of the estimates.

‹ EXAKT› ™ The CBM Optimizer page 46

You might also like

- Simulink ®Document92 pagesSimulink ®RumeshNo ratings yet

- Overall Equipment EffectivenessDocument27 pagesOverall Equipment EffectivenessMarciano ZanottoNo ratings yet

- CamWorks TutorialDocument36 pagesCamWorks TutorialPako Nuñez67% (3)

- SimMechanics 2nd Generation Introduction ExampleDocument40 pagesSimMechanics 2nd Generation Introduction ExampleStefan Spasic100% (2)

- Life Cycle Costing Decisions For Asset Managers (Compatibility Mode)Document165 pagesLife Cycle Costing Decisions For Asset Managers (Compatibility Mode)David VelandiaNo ratings yet

- BW Query GuidelinesDocument10 pagesBW Query GuidelinesyshriniNo ratings yet

- Power Platform Admin and Governance WhitepaperDocument120 pagesPower Platform Admin and Governance WhitepaperGiancarlo Herrera100% (1)

- Get Start CSDocument278 pagesGet Start CSAnjireddy ThatiparthyNo ratings yet

- Hspice Simulation ManualDocument694 pagesHspice Simulation Manualapi-26731722100% (1)

- 4-7 The Law of Sines and The Law of Cosines PDFDocument40 pages4-7 The Law of Sines and The Law of Cosines PDFApple Vidal100% (1)

- Maximo 7.1 Integration Framework Configuration BasicsDocument36 pagesMaximo 7.1 Integration Framework Configuration Basicsnitinkr80No ratings yet

- Tips & TricksDocument24 pagesTips & TricksVishwanath Todurkar100% (4)

- Qy130v633 Operation ManualDocument414 pagesQy130v633 Operation ManualumamNo ratings yet

- User'S Guide: Simelectronics 1Document83 pagesUser'S Guide: Simelectronics 1Gabriel Aparecido FonsecaNo ratings yet

- Black Veil BridesDocument2 pagesBlack Veil BridesElyza MiradonaNo ratings yet

- Femap Getting StartedDocument148 pagesFemap Getting StartedMSC Nastran BeginnerNo ratings yet

- Curvefit MATLAB ToolboxDocument288 pagesCurvefit MATLAB Toolboxkulov1592No ratings yet

- Software and System Development using Virtual Platforms: Full-System Simulation with Wind River SimicsFrom EverandSoftware and System Development using Virtual Platforms: Full-System Simulation with Wind River SimicsNo ratings yet

- MatlabDocument131 pagesMatlabMahesh Makwana100% (3)

- Operational Readiness Guide - 2017Document36 pagesOperational Readiness Guide - 2017albertocm18100% (2)

- System Performance Modeling Software - Copy YbDocument18 pagesSystem Performance Modeling Software - Copy Ybapi-249066222No ratings yet

- 1 MergedDocument93 pages1 MergedAditiNo ratings yet

- VMAX3 Design Demo GuideDocument64 pagesVMAX3 Design Demo Guidehemanth-07No ratings yet

- 41-How To Calculate Air Temp in Unconditioned SpacesDocument3 pages41-How To Calculate Air Temp in Unconditioned Spacesalmig200No ratings yet

- Designing SOCs with Configured Cores: Unleashing the Tensilica Xtensa and Diamond CoresFrom EverandDesigning SOCs with Configured Cores: Unleashing the Tensilica Xtensa and Diamond CoresRating: 5 out of 5 stars5/5 (2)

- Top 20 MS Excel VBA Simulations, VBA to Model Risk, Investments, Growth, Gambling, and Monte Carlo AnalysisFrom EverandTop 20 MS Excel VBA Simulations, VBA to Model Risk, Investments, Growth, Gambling, and Monte Carlo AnalysisRating: 2.5 out of 5 stars2.5/5 (2)

- Tutorial CYMDIST PDFDocument209 pagesTutorial CYMDIST PDFAlan100% (3)

- SAT APIIT APU ASSIGNMENT A+ Grade Yong Hong ManDocument52 pagesSAT APIIT APU ASSIGNMENT A+ Grade Yong Hong ManMan Zai100% (2)

- MSF ExcelProgrammingPrimerDocument38 pagesMSF ExcelProgrammingPrimerandre_tfjrNo ratings yet

- Getting StartedDocument164 pagesGetting StartedManikanda SubramanianNo ratings yet

- Match ManualDocument76 pagesMatch ManualThala VeriyanNo ratings yet

- Table C: Download Tablecurve 2D® Trial VersionDocument5 pagesTable C: Download Tablecurve 2D® Trial VersionhesticaestebanNo ratings yet

- Aerospace Toolbox 2Document410 pagesAerospace Toolbox 2Anonymous TVDaNPeNo ratings yet

- Performance Tuning Waits QueuesDocument98 pagesPerformance Tuning Waits QueuesalexcadimaNo ratings yet

- Optimum EMS Handbook Final RevDocument25 pagesOptimum EMS Handbook Final RevfullkuleNo ratings yet

- How to Improve COPA Report Performance Using Summarization LevelsDocument32 pagesHow to Improve COPA Report Performance Using Summarization LevelsTarun AggarwalNo ratings yet

- KEMP Exchange 2010 Deployment Guide 5 1Document38 pagesKEMP Exchange 2010 Deployment Guide 5 1Layan ThadaniNo ratings yet

- 2015 eCATT TUTORIALDocument51 pages2015 eCATT TUTORIALVarun BishtNo ratings yet

- How To Use Awr SoftwareDocument182 pagesHow To Use Awr Softwarenagesh100% (1)

- CAE and CAM Research Report SummaryDocument12 pagesCAE and CAM Research Report Summaryshaharyar ahmedNo ratings yet

- Data Acquisition With CP-2002/2003 Micro-GC Control: Operation ManualDocument72 pagesData Acquisition With CP-2002/2003 Micro-GC Control: Operation ManualSusana MujicaNo ratings yet

- 1762 pm001d en PDocument271 pages1762 pm001d en PneoflashNo ratings yet

- Why You Should Use EyecatchersDocument5 pagesWhy You Should Use EyecatchersAtthulaiNo ratings yet

- Advances in On Board Diagnostics - 2010 - HD - Diesel EnginesDocument29 pagesAdvances in On Board Diagnostics - 2010 - HD - Diesel EnginesBargav SrinivasanNo ratings yet

- SL GsDocument80 pagesSL GsRizky DsNo ratings yet

- Choosing the Right Power Electronics Simulation ToolDocument10 pagesChoosing the Right Power Electronics Simulation ToolAli H. NumanNo ratings yet

- Micro ComputingDocument228 pagesMicro Computingwww.otomasyonegitimi.comNo ratings yet

- BPC 75 NW Operation GuideDocument68 pagesBPC 75 NW Operation GuidekprjgdNo ratings yet

- Iea5b701 - OLTEPDocument90 pagesIea5b701 - OLTEPhnyNo ratings yet

- Oracle® Internet Expenses: Implementation and Administration Guide Release 11iDocument294 pagesOracle® Internet Expenses: Implementation and Administration Guide Release 11iSyam Sundar SureNo ratings yet

- Emlab: Release NotesDocument79 pagesEmlab: Release NoteskgskgmNo ratings yet

- Matlab System Id ToolboxDocument274 pagesMatlab System Id ToolboxhernandopradaNo ratings yet

- EQExpress V4-NPSDocument55 pagesEQExpress V4-NPSKhan FaisalNo ratings yet

- Hypermesh BasicsDocument230 pagesHypermesh Basicsanup_22988No ratings yet

- Project TemplateDocument37 pagesProject Templateanon_825088514No ratings yet

- BMC Atrium Orchestrator Workflow Development Best PracticeWorkflow Development Best PracticeDocument17 pagesBMC Atrium Orchestrator Workflow Development Best PracticeWorkflow Development Best PracticegunalprasadgNo ratings yet

- CIM-4 11 0-UserDocument194 pagesCIM-4 11 0-UserfrhdsabahiNo ratings yet

- Siemens Siprotec 6md63Document54 pagesSiemens Siprotec 6md63Maulana Aji WicaksonoNo ratings yet

- Volume11 Issue2 Verification Horizons Publication HRDocument60 pagesVolume11 Issue2 Verification Horizons Publication HRDeniz KurtNo ratings yet

- 6 - Comp SciDocument22 pages6 - Comp SciZo775 YoutubeNo ratings yet

- Data Transformation COM API Reference: Informatica B2B Data Exchange™Document24 pagesData Transformation COM API Reference: Informatica B2B Data Exchange™mailramkNo ratings yet

- OATC StreetSmarts What Scripts Book 07-10-13Document40 pagesOATC StreetSmarts What Scripts Book 07-10-13doodie_mcdoodooNo ratings yet

- Securing Windows Server 2008: Prevent Attacks from Outside and Inside Your OrganizationFrom EverandSecuring Windows Server 2008: Prevent Attacks from Outside and Inside Your OrganizationNo ratings yet

- Database Benchmarking and Stress Testing: An Evidence-Based Approach to Decisions on Architecture and TechnologyFrom EverandDatabase Benchmarking and Stress Testing: An Evidence-Based Approach to Decisions on Architecture and TechnologyNo ratings yet

- Base de Datos A-Frame TMEFDocument41 pagesBase de Datos A-Frame TMEFDavid VelandiaNo ratings yet

- AMM09 Cerrejon 1b. Beverage StrategyDocument2 pagesAMM09 Cerrejon 1b. Beverage StrategyDavid VelandiaNo ratings yet

- EXAKT-Reliability Centered Knowledge BookDocument349 pagesEXAKT-Reliability Centered Knowledge BookDavid VelandiaNo ratings yet

- Gas Meter ProblemDocument1 pageGas Meter ProblemDavid VelandiaNo ratings yet

- AMM09 Cerrejon 1a. Maintenance StrategyDocument6 pagesAMM09 Cerrejon 1a. Maintenance StrategyDavid VelandiaNo ratings yet

- Procedure Based MaintDocument27 pagesProcedure Based Maintnish1802No ratings yet

- EXAKT-Reliability Centered Knowledge-SlideLinesDocument40 pagesEXAKT-Reliability Centered Knowledge-SlideLinesDavid VelandiaNo ratings yet

- SETUPDocument1 pageSETUPDavid VelandiaNo ratings yet

- Equipment component event history recordsDocument26 pagesEquipment component event history recordsDavid VelandiaNo ratings yet

- Eventos Adicionales Sep28 Oct12Document2 pagesEventos Adicionales Sep28 Oct12David VelandiaNo ratings yet

- Project InstructionDocument2 pagesProject InstructionDavid VelandiaNo ratings yet

- CAT240 Motor - EXAKT Analysis and Model Building Example at CerrejoncoalDocument22 pagesCAT240 Motor - EXAKT Analysis and Model Building Example at CerrejoncoalDavid VelandiaNo ratings yet

- Set Monitoreo Signos Vitales Componentes SC - Motor BasicoDocument4 pagesSet Monitoreo Signos Vitales Componentes SC - Motor BasicoDavid VelandiaNo ratings yet

- Function Analysis ExerciseDocument21 pagesFunction Analysis ExerciseDavid VelandiaNo ratings yet

- 8 - Appendix Three Time Value of Money 2010 (Compatibility Mode)Document13 pages8 - Appendix Three Time Value of Money 2010 (Compatibility Mode)David VelandiaNo ratings yet

- DatosDocument40 pagesDatosDavid VelandiaNo ratings yet

- 5 - Chapter Five Mtce Resource Requirements 2010 (Compatibility Mode)Document27 pages5 - Chapter Five Mtce Resource Requirements 2010 (Compatibility Mode)David VelandiaNo ratings yet

- 3-Chapter Three Inspection Decisions 2010 (Compatibility Mode)Document92 pages3-Chapter Three Inspection Decisions 2010 (Compatibility Mode)David VelandiaNo ratings yet

- Solution of Gas MeterDocument2 pagesSolution of Gas MeterDavid VelandiaNo ratings yet

- 4 - Chapter Four Cap Equipment Repl Decisions 2010 (Compatibility Mode)Document49 pages4 - Chapter Four Cap Equipment Repl Decisions 2010 (Compatibility Mode)David VelandiaNo ratings yet

- 1-Intro Session Aug 2010 (Compatibility Mode)Document33 pages1-Intro Session Aug 2010 (Compatibility Mode)David VelandiaNo ratings yet

- Nowlan HeapDocument170 pagesNowlan HeapDavid VelandiaNo ratings yet

- AMM09 Cerrejon 1a. Maintenance StrategyDocument6 pagesAMM09 Cerrejon 1a. Maintenance StrategyDavid VelandiaNo ratings yet

- AMM09 3 Assessments and BenchmarkingDocument60 pagesAMM09 3 Assessments and BenchmarkingDavid VelandiaNo ratings yet

- AMM00 - Cash FlowDocument2 pagesAMM00 - Cash FlowDavid VelandiaNo ratings yet

- 2-Chapter Two Comp Repl Decisions 2010 (Compatibility Mode)Document94 pages2-Chapter Two Comp Repl Decisions 2010 (Compatibility Mode)David VelandiaNo ratings yet

- 3-Chapter Three Inspection Decisions 2010 (Compatibility Mode)Document92 pages3-Chapter Three Inspection Decisions 2010 (Compatibility Mode)David VelandiaNo ratings yet

- 7 Ways of Looking at Grammar China EditDocument20 pages7 Ways of Looking at Grammar China EditAshraf MousaNo ratings yet

- FLG 212 Study GuideDocument19 pagesFLG 212 Study GuidecynthiaNo ratings yet

- Chapter Three 3.0 Research MethodologyDocument5 pagesChapter Three 3.0 Research MethodologyBoyi EnebinelsonNo ratings yet

- Ndeb Bned Reference Texts 2019 PDFDocument11 pagesNdeb Bned Reference Texts 2019 PDFnavroop bajwaNo ratings yet

- 2.e-Learning Chapter 910Document23 pages2.e-Learning Chapter 910ethandanfordNo ratings yet

- Bajaj Internship ReportDocument69 pagesBajaj Internship ReportCoordinator ABS100% (2)

- Super BufferDocument41 pagesSuper Bufferurallalone100% (1)

- Main Application of Fans and BlowerDocument5 pagesMain Application of Fans and Blowermissy forlajeNo ratings yet

- SOYER Bend Testing Device BP-1Document2 pagesSOYER Bend Testing Device BP-1abdulla_alazzawiNo ratings yet

- A Grammar of Awa Pit (Cuaiquer) : An Indigenous Language of South-Western ColombiaDocument422 pagesA Grammar of Awa Pit (Cuaiquer) : An Indigenous Language of South-Western ColombiaJuan Felipe Hoyos García100% (1)

- FINANCIAL REPORTSDocument34 pagesFINANCIAL REPORTSToni111123No ratings yet

- India: Soil Types, Problems & Conservation: Dr. SupriyaDocument25 pagesIndia: Soil Types, Problems & Conservation: Dr. SupriyaManas KaiNo ratings yet

- Biokimia - DR - Maehan Hardjo M.biomed PHDDocument159 pagesBiokimia - DR - Maehan Hardjo M.biomed PHDHerryNo ratings yet

- A. Lesson Preview / Review: This Document Is The Property of PHINMA EDUCATIONDocument11 pagesA. Lesson Preview / Review: This Document Is The Property of PHINMA EDUCATIONTherese Anne ArmamentoNo ratings yet

- Appendix A - Status Messages: Armed. Bad Snubber FuseDocument9 pagesAppendix A - Status Messages: Armed. Bad Snubber Fuse이민재No ratings yet

- Steady State Modeling and Simulation of The Oleflex Process For Isobutane Dehydrogenation Considering Reaction NetworkDocument9 pagesSteady State Modeling and Simulation of The Oleflex Process For Isobutane Dehydrogenation Considering Reaction NetworkZangNo ratings yet

- Enzyme KineticsDocument13 pagesEnzyme KineticsMohib100% (1)

- Teaching Methods in The PhilippinesDocument2 pagesTeaching Methods in The PhilippinesTonee Marie Gabriel60% (5)

- Quick Reference To Psychotropic Medications: AntidepressantsDocument2 pagesQuick Reference To Psychotropic Medications: AntidepressantsNaiana PaulaNo ratings yet

- Luxand FaceSDK DocumentationDocument117 pagesLuxand FaceSDK DocumentationrdhartzNo ratings yet

- TN Govt RecruitmentDocument12 pagesTN Govt RecruitmentPriyanka ShankarNo ratings yet

- GFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportDocument21 pagesGFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportRayane LimaNo ratings yet

- Viennot - 1979 - Spontaneous Reasoning in Elementary DynamicsDocument18 pagesViennot - 1979 - Spontaneous Reasoning in Elementary Dynamicsjumonteiro2000No ratings yet