Professional Documents

Culture Documents

KN Regulator Repair Instructions: Disassembly

Uploaded by

bernardo angeles rojasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KN Regulator Repair Instructions: Disassembly

Uploaded by

bernardo angeles rojasCopyright:

Available Formats

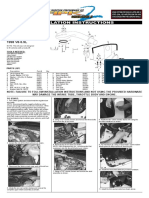

KN Regulator Repair Instructions

Illustrated view of the KN Regulator, including the accessories Automatic Primer (item 15) and Manual

Primer (item 16). Items denoted by asterisks (*) are included in the KN Repair Kit. An adjustment and

lock screw is used on non-tamper resistance models. A steel cap is installed over the adjustment

screw for tamper resistant models. In either case, do not remove the pressure lock screw or steel cap.

The pressure setting is factory pre-set and is not adjustable in the field.

Any maintenance and repair should be performed 1. Dismount the KN regulator and remove from its

by trained and experienced service technicians. installation.

Proper tools and equipment should be used to 2. Begin disassembly by removing the six screws

prevent injury to the servicing technician and (item 10) securing the back cover.

damage to the fuel system or components. Service 3. Break cover loose by tapping around the edge

repairs should always be performed in a safe of the cover using a plastic screwdriver handle.

environment with adequate ventilation. The 4. Remove back cover

technician should always wear protective clothing 5. Move diaphragm back to reveal the two screws

to prevent injury. (item 12) securing the lever pin (item 14) and

remove screws.

DISASSEMBLY 6. Remove pin, gasket, diaphragm and lever

assemblies (items 14, 7, 8, and 6).

To minimize personal injury, shut off the fuel

supply valve and relieve the fuel system

pressure before servicing the fuel system

components.

PPI-107 REV. A IMPCO Technologies Inc. August, 2007

Page 1 of 2 3030 South Susan St.

Santa Ana, Ca. 92704

www.impcotechnologies.com

REASSEMBLY TESTING

1. Inspect and identify the parts of the KN Repair 1. Apply 6 ounces (10.5” in w.c.) of air or gas

Kit (see illustration on the previous page). pressure to inlet side of the regulator.

Components listed below in the Repair Kit are

to be replaced.

2. Wipe both covers clean using safety solvent

and a clean shop towel prior to reassembly.

3. Attach pusher pin on diaphragm (item 8) to Do not exceed the maximum inlet pressure

lever (item 6), ensuring the retaining clip on the of 8 ounces (13.85” in w.c.). Failure to

lever secures the pin. follow this warning may cause the

4. Place top cover face down and place original regulator to leak internally, that may cause

spring in position. serious injury and/or property damage.

5. Slide the pivot pin (item 14) through lever.

6. Mount the lever/diaphragm assembly by 2. Draw a soap bubble across the regulator outlet

placing the pin in slot on back of front cover to verify that no air or gas is flowing through

(along with attached diaphragm) and secure the outlet. If air/gas escapes, the rebuild has

with screws (item 12). Torque to .9 N•m (8 in. failed and the regulator must be replaced.

lbs.). Verify that the spring is properly 3. If no gas/air escapes the outlet, use soap

captured against the lever spring perch. and/or a commercial leak detector to inspect

7. Lay the diaphragm (item 8) flat over back of the seal around the perimeter of the regulator

the front cover, aligning screw holes. for leaks. If leaks are found, the regulator

8. Place gasket (item 7) on top of diaphragm and must be replaced.

align screw holes. 4. If no leaks are found, the regulator can be

9. Place back cover (item 9 or accessory item 15 reinstalled.

or 16) on top of gasket and diaphragm align

“Top” and arrow to outlet on front cover.

10. Align front cover, diaphragm, gasket and back

cover screw holes and secure with six screws

Do not use Teflon tape to seal any LPG

(item 10). Torque to 6.8 N•m (60 in. lbs.).

fittings. Failure to follow this warning may

cause the regulator to leak internally, that

may cause serious injury and/or property

damage.

5. Leak check all serviced fuel system fittings.

KN Repair Kit (IMPCO P/N 039-99) Components

Item Part Number Description Qty UM

6 039-00-20 Lever & Seat Assembly 1 EA

7 G1-26263 Gasket, Secondary Diaphragm 1 EA

8 039-00-30 Diaphragm, Assy Reg Vmq Mod Kn 1 EA

10 076-00-15 Screw 10-32X5/8 Torx Pan Stlzn 3 EA

12 076-00-08 Screw 4-40X1/4 Torxph Tt Stlzn 2 EA

14 076-00-35 Pivot Pin 1 EA

PPI-107 REV. A IMPCO Technologies Inc. August, 2007

Page 2 of 2 3030 South Susan St.

Santa Ana, Ca. 92704

www.impcotechnologies.com

You might also like

- ANSON Inline Check ValveDocument4 pagesANSON Inline Check ValveNamikaze Minato0% (1)

- H25CT Manual+LindeDocument513 pagesH25CT Manual+LindeJorge Moreno100% (11)

- H25CT Manual+LindeDocument513 pagesH25CT Manual+LindeJorge Moreno100% (11)

- A230 B60Z - B80ZDocument104 pagesA230 B60Z - B80ZMONTECARLO8850% (2)

- 95ZV Cargador Frontal KawazakiDocument194 pages95ZV Cargador Frontal Kawazakibernardo angeles rojas100% (3)

- ISO 3952-1 Kinematic Diagrams - Graphical Symbols, Part 1Document13 pagesISO 3952-1 Kinematic Diagrams - Graphical Symbols, Part 1Phạm Hữu PhướcNo ratings yet

- Threads and Thread CuttingDocument56 pagesThreads and Thread Cuttingcpojha100% (1)

- Model 11A17-001 Regulator: Rebuild InstructionsDocument12 pagesModel 11A17-001 Regulator: Rebuild Instructionsluis tocoraNo ratings yet

- A 1020Document16 pagesA 1020Pong KrubNo ratings yet

- Prestige - Medical - 2100 - Service - Manual Steam SterilizerDocument13 pagesPrestige - Medical - 2100 - Service - Manual Steam SterilizerGigi CostelusNo ratings yet

- Sci Mop Bombas Espuma Cgp80 - ChemguardDocument13 pagesSci Mop Bombas Espuma Cgp80 - Chemguarddiuska13No ratings yet

- KNN 57 1506 2 - InstDocument2 pagesKNN 57 1506 2 - InsthavvkxjNo ratings yet

- 303-08 P1396 RepairDocument6 pages303-08 P1396 Repairmarcelo ustarezNo ratings yet

- 1967-68 Mustang Without Factory AirDocument23 pages1967-68 Mustang Without Factory AirnilusomegaNo ratings yet

- SB3 1 102Document6 pagesSB3 1 102jussmeeeNo ratings yet

- Red JacketDocument8 pagesRed JacketTok NazriNo ratings yet

- Kc11 Series Sealless Non-Metallic Centrifugal Pumps Installation & Maintenance InstructionsDocument5 pagesKc11 Series Sealless Non-Metallic Centrifugal Pumps Installation & Maintenance InstructionsEdwin Collado FigueroaNo ratings yet

- Datex Ohmeda Excel 210 Modulus Maintenance ProceduresDocument31 pagesDatex Ohmeda Excel 210 Modulus Maintenance ProceduresBiomédica Hospital San JoséNo ratings yet

- SCA Series Inverted Bucket Steam TrapsDocument8 pagesSCA Series Inverted Bucket Steam TrapsJuan ZamoraNo ratings yet

- Ca55 MixerDocument7 pagesCa55 MixerramoNo ratings yet

- ATS73 Maint ManDocument12 pagesATS73 Maint Manpr_oilNo ratings yet

- TW580Document2 pagesTW580Ghassan ALkikiNo ratings yet

- Instalación de Piston y BielaDocument3 pagesInstalación de Piston y BielaBrayan Sánchez ParedesNo ratings yet

- Coleman Generator L0807053Document12 pagesColeman Generator L0807053Jody WoodenNo ratings yet

- SB 10091506 2280Document28 pagesSB 10091506 2280sesentorodriguezNo ratings yet

- 09-2916 Regulador Series Four WaukeshaDocument14 pages09-2916 Regulador Series Four WaukeshaMaria Fernanda Bonilla SalasNo ratings yet

- Clutch ManualDocument16 pagesClutch ManualCO BDNo ratings yet

- Datex Ohmeda Modulus II W 7810 Ventilator Maintenance ProceduresDocument38 pagesDatex Ohmeda Modulus II W 7810 Ventilator Maintenance ProceduresgimenNo ratings yet

- Atlas Copco Service & Maintenance InstructionsDocument20 pagesAtlas Copco Service & Maintenance Instructionsaaron alicanoNo ratings yet

- AFC Sensor de Presion PDFDocument10 pagesAFC Sensor de Presion PDFCharlie BrownNo ratings yet

- Chute Assist Installation Instructions Rev1016 FinalDocument13 pagesChute Assist Installation Instructions Rev1016 FinalGabriel Castillo MuñozNo ratings yet

- Cambio de HortonDocument8 pagesCambio de HortonGabriel Castillo MuñozNo ratings yet

- p077 02 PDFDocument8 pagesp077 02 PDFJuan ZamoraNo ratings yet

- Manual GA 160Document8 pagesManual GA 160Aldo Marcelo Soliz AngolaNo ratings yet

- Interbrake AEBDocument6 pagesInterbrake AEBKarim BaddagNo ratings yet

- Camshaft Timing: Testing and AdjustingDocument8 pagesCamshaft Timing: Testing and AdjustingsxturboNo ratings yet

- John Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)Document17 pagesJohn Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)laopaodunNo ratings yet

- Master Solenoid Kit: MS KM-175 93Document1 pageMaster Solenoid Kit: MS KM-175 93Guilherme ZoboliNo ratings yet

- KTA 50 CoolPac 0908-0156Document7 pagesKTA 50 CoolPac 0908-0156Ahmed AbdullahNo ratings yet

- Cooling Fan Belt TensionerDocument13 pagesCooling Fan Belt Tensionerakuncbm.hillconNo ratings yet

- Agitators: Instructions - Parts ListDocument10 pagesAgitators: Instructions - Parts ListAlejo CGNo ratings yet

- Camshaft Gear - Remove and Install: SMCS - 1210-010Document4 pagesCamshaft Gear - Remove and Install: SMCS - 1210-010ToispuoliNo ratings yet

- Series 1204: Orange Research IncDocument3 pagesSeries 1204: Orange Research IncWilson VelásquezNo ratings yet

- Esquema Hidraulico ManitouDocument26 pagesEsquema Hidraulico Manitouctorres_505746No ratings yet

- Kysor Service GuideDocument24 pagesKysor Service GuideAlex Renne ChambiNo ratings yet

- Camshaft Gear - Remove and InstallDocument4 pagesCamshaft Gear - Remove and InstallbejoythomasNo ratings yet

- Technical Handbook: Four Nozzles Vacuum Filling MachineDocument12 pagesTechnical Handbook: Four Nozzles Vacuum Filling MachineAshish MishraNo ratings yet

- Manual Arranque NeumaticoDocument52 pagesManual Arranque NeumaticoSabry Socarrás AarónNo ratings yet

- Front Suspension Cylinder Cap Capscrew ImprovementDocument4 pagesFront Suspension Cylinder Cap Capscrew ImprovementSandro GastanagaNo ratings yet

- Iom TorqmaxDocument10 pagesIom TorqmaxReddy SadhanaNo ratings yet

- Installation Procedure: NoticeDocument5 pagesInstallation Procedure: Noticerakhikishore143No ratings yet

- Model 21150 Differential Sticking TesterDocument31 pagesModel 21150 Differential Sticking Testerwaleed El-azabNo ratings yet

- Toyota Yaris: Instruction ManualDocument21 pagesToyota Yaris: Instruction ManualruswidNo ratings yet

- PistonDocument5 pagesPistonAna Paula Maia LimaNo ratings yet

- Masoneilan+ +87+and+88+Series+Spring+and+Diaphragm+Actuator+IOMDocument24 pagesMasoneilan+ +87+and+88+Series+Spring+and+Diaphragm+Actuator+IOMAsterixNo ratings yet

- 1977 Jeep-1977 TSBDocument126 pages1977 Jeep-1977 TSBperzaklieNo ratings yet

- Final Laboratory Activity 2Document8 pagesFinal Laboratory Activity 2Angel CareNo ratings yet

- Megastream Control Valves: General InstructionsDocument4 pagesMegastream Control Valves: General InstructionsCarlos Alberto Dum GomezNo ratings yet

- Reparación Inyectores DensoDocument22 pagesReparación Inyectores DensoMarcoNo ratings yet

- Ajuste de VentiladorDocument9 pagesAjuste de VentiladorRobert Canchanya ProcilNo ratings yet

- 79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)Document12 pages79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)COILED TUBINGNo ratings yet

- Maintenance and Testing ManualDocument13 pagesMaintenance and Testing ManualCarlos AcNo ratings yet

- Manual pl0495503 PDFDocument12 pagesManual pl0495503 PDFfelipesaraabrilcarolNo ratings yet

- 2005 Radium Shock Service ManualDocument16 pages2005 Radium Shock Service ManualvoxborNo ratings yet

- Kysor On/Off Rear Air Fan Drive: Installation - ServiceDocument12 pagesKysor On/Off Rear Air Fan Drive: Installation - ServiceeloyabnerNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- RC CobraDocument12 pagesRC CobraNikolai GeorgievNo ratings yet

- Model Ev & Pev Series: Two-Stage Regulator Repair Kit InstructionsDocument15 pagesModel Ev & Pev Series: Two-Stage Regulator Repair Kit Instructionsluis tocoraNo ratings yet

- Model E & Pe Series: Two-Stage Regulator Repair Kit InstructionsDocument16 pagesModel E & Pe Series: Two-Stage Regulator Repair Kit Instructionsbernardo angeles rojasNo ratings yet

- Model L: Two-Stage Regulator Repair Kit InstructionsDocument14 pagesModel L: Two-Stage Regulator Repair Kit Instructionsbernardo angeles rojasNo ratings yet

- SL4640 SL4840 SL5640 SL6640 Skid Loader Deutz Engine Parts Manual 917108C PDFDocument88 pagesSL4640 SL4840 SL5640 SL6640 Skid Loader Deutz Engine Parts Manual 917108C PDFJuan Esteban Ordoñez Bonilla100% (1)

- Motor BlazerDocument196 pagesMotor BlazerFrancisco Abreu100% (1)

- DONALDSON APLICACION FILTROS F116014-Forklifts PDFDocument197 pagesDONALDSON APLICACION FILTROS F116014-Forklifts PDFrolandoNo ratings yet

- GS 2046 PDFDocument168 pagesGS 2046 PDFRomusNo ratings yet

- Forks: Quick Reference GuideDocument48 pagesForks: Quick Reference GuideMONTECARLO88No ratings yet

- ManlifDocument224 pagesManlifJorge ContrerasNo ratings yet

- Models: LG1 & LG3: Legacy Gold Series Battery Charger Owner's ManualDocument26 pagesModels: LG1 & LG3: Legacy Gold Series Battery Charger Owner's Manualbernardo angeles rojasNo ratings yet

- IMPCO RegulatorsDocument61 pagesIMPCO RegulatorsNikolai GeorgievNo ratings yet

- GPS - Crown PE3000Document33 pagesGPS - Crown PE3000Carlos RamirezNo ratings yet

- Haulotte HA16 18PXDocument74 pagesHaulotte HA16 18PXtiagomacviva100% (1)

- Genie Z-30 20NDocument138 pagesGenie Z-30 20Nbernardo angeles rojasNo ratings yet

- Ppi-4-116 RC VFF30Document15 pagesPpi-4-116 RC VFF30Kaynã MelloNo ratings yet

- WeaponDocument29 pagesWeaponangelic hans100% (1)

- KSFO Jeppesen 2018Document6 pagesKSFO Jeppesen 2018corina vargas cocaNo ratings yet

- LaporanThermograf Blowdown Valve #1Document13 pagesLaporanThermograf Blowdown Valve #1Engineering PLTU BanjarsariNo ratings yet

- Pressure Drop Calculation - Primary Pump & Secondary PumpDocument6 pagesPressure Drop Calculation - Primary Pump & Secondary PumpAzher ANo ratings yet

- DN5 SCH: LG THK NBDocument56 pagesDN5 SCH: LG THK NBGauravNo ratings yet

- Vertical Milling Machine Catalog PDFDocument2 pagesVertical Milling Machine Catalog PDFDharmik SoniNo ratings yet

- ASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-25-27Document3 pagesASME B18.2.6 2010 (1) - Fasteners For Use in Structural Applications-25-27Andres SilveyraNo ratings yet

- Manual For Pneumatic Automatic Feeder SpecificationDocument18 pagesManual For Pneumatic Automatic Feeder SpecificationhaisamnagyNo ratings yet

- Technical Data: Model GPY Electric Fire Pump ControllerDocument1 pageTechnical Data: Model GPY Electric Fire Pump Controllerneng hengNo ratings yet

- Ir Pc-Sharp-3way-Minipilot Product-Page English v4Document1 pageIr Pc-Sharp-3way-Minipilot Product-Page English v4Adriano Moyses OutlookNo ratings yet

- Catalog No. 64: Drilling MachinesDocument41 pagesCatalog No. 64: Drilling MachinesTuyenNo ratings yet

- Sheet Refurbishment Command Shaft UPM UDocument5 pagesSheet Refurbishment Command Shaft UPM UЛюбить ЕннеттNo ratings yet

- Valves: Rice List ofDocument16 pagesValves: Rice List ofakshatjain3001No ratings yet

- Basic Components of Ahu and Fcu, Fan and Duct SystemsDocument113 pagesBasic Components of Ahu and Fcu, Fan and Duct SystemsSka dooshNo ratings yet

- Day 9 Time: 3 Hours Level of Understanding Participant MaterialsDocument51 pagesDay 9 Time: 3 Hours Level of Understanding Participant MaterialsAmit Singh UppNo ratings yet

- BRNO CZ 452 ManualDocument15 pagesBRNO CZ 452 ManualTim JNo ratings yet

- Tohnichi - Katalog 2012 ENDocument72 pagesTohnichi - Katalog 2012 END.T.No ratings yet

- G0758Document68 pagesG0758Roger_74100% (2)

- Proc Deer 2021Document21 pagesProc Deer 2021inforumdocsNo ratings yet

- Woodworking - Basics-Shopjigs PDFDocument4 pagesWoodworking - Basics-Shopjigs PDFv00d00blues100% (1)

- RSDocument52 pagesRSgargi yesareNo ratings yet

- Survey Lab Report 1Document9 pagesSurvey Lab Report 1ZAINAL NAEM0% (2)

- Sears Scroll SawDocument6 pagesSears Scroll Sawamauri bittencourtNo ratings yet

- M&M Lab Viva QuestionsDocument4 pagesM&M Lab Viva QuestionsHarish MurthyNo ratings yet

- Grinding Lab ManualDocument4 pagesGrinding Lab ManualArun kumar rouniyar100% (1)

- Manufacturer Name Item ID Manufacturers Part Number Part Description QuantityDocument1 pageManufacturer Name Item ID Manufacturers Part Number Part Description QuantityIndustrial Garage SalesNo ratings yet

- NAFA Guide To Air Filtration 8Document17 pagesNAFA Guide To Air Filtration 8Mohammad IsmailNo ratings yet

- Cartilla Cabezal Nqu y NQ Ok.Document1 pageCartilla Cabezal Nqu y NQ Ok.ElderNo ratings yet