Professional Documents

Culture Documents

CQFP Visual Inspection

Uploaded by

Indra NainggolanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CQFP Visual Inspection

Uploaded by

Indra NainggolanCopyright:

Available Formats

Visual Inspection Criteria for Actel CQFP Packages

Thank you for your interest in Actel’s CQFPs.

The following describes the visual inspection and rework process criteria that are

followed at Actel (100% End of Line in-process inspection) and the same applies to

visual rejects reported by end customer.

Lead Defects visual inspection criteria

1. Scrap device if gold covering less than 95% of the total surface area of any lead;

please refer MIL-STD-883E, Method 2009.9, 3.3.5.h.

2. Scrap device if lead bridging and any cracking in at the brazed area; please refer MIL-

STD-883E, Method 2009.9, 3.3.3.d.

3. Scrap device if any indentation or incision on the lead which is deeper than 1/3 the

original lead thickness; please refer MIL-STD-883E, Method 2009.9, 3.3.5.c.

4. If any part of the lead is shifted from its original axis for more than half the distance

between lead space; the device can be reworked; as defined on MIL-STD-1835C,

Requirement 114, detail G and note 11.

5. After the unit has been reworked, visual inspector inspects each reworked lead under

low power scope to insure the following requirements are met.

- The excess metal on a bent lead from rework must be closed to an NCS (non-

conductive trip) tie bar.

- Also, the excess metal from rework must be bent in the direction as shown on

figure of rework device.

- The leads, which have been reworked must, still meet all Lead Defect visual

inspection requirements (as stated above number 1 to 4). Note: Inspection is

done on the whole reworked lead from the brazed area up to the notch, which

is formed by the rework tool.

June 2002 Page 1 of 2

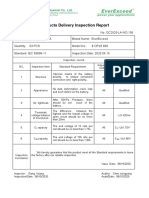

Flow Chart

Inprocess / Visual Rejects from end customer

Lead Defects visual inspection criteria

1) Scrap device if gold covering less than 95% of the total surface area of any lead.

2) Scrap device if lead bridging and any cracking in at the brazed area.

3) Scrap device if any indentation or incision on the lead which is deeper than 1/3 the

FAIL SCRAP

original lead thickness.

PASS

4) If any part of the lead is shifted from its original axis for more than half the

Rework distance between lead space, the device can be reworked as defined on MIL-STD- Gross

1835C, Requirement 114, detail G and note 11.

PASS

After the unit has been reworked, inspect each reworked lead

under low power scope to insure the following requirements Ship

are met.

- The excess metal on a bent lead from rework

must be closed to an NCS (non-conductive trip)

tie bar.

- Also, the excess metal from rework must be bent

in the direction as shown on figure of rework

device in the rework procedure

Note: CQFP package can be reworked as “One time per lead” only

June 2002 Page 2 of 2

You might also like

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Commander Aircraft 112 Service LettersDocument135 pagesCommander Aircraft 112 Service Lettersrop703406No ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- Section 09 Weld QualityDocument32 pagesSection 09 Weld Qualityforlan pinheiro100% (1)

- 323 AgDocument4 pages323 AgAlejandroNo ratings yet

- UntitledDocument11 pagesUntitledRodrigo LeanosNo ratings yet

- @coating Book - Aramco Inspection HandbookDocument126 pages@coating Book - Aramco Inspection HandbookUmair AhmadNo ratings yet

- Spec TransrecDocument9 pagesSpec TransrecSinaNo ratings yet

- Receipt Inspection NS2A4Document11 pagesReceipt Inspection NS2A4islam atifNo ratings yet

- Standard Specification F R ST Aight - Beam Ultrasonic Exa Ination of Steel PlatesDocument3 pagesStandard Specification F R ST Aight - Beam Ultrasonic Exa Ination of Steel Platesanon_935140585No ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Inspection HandbookDocument126 pagesInspection Handbooksteffy18295% (21)

- Aramcoinspectionhandbook 150311084705 Conversion Gate01 PDFDocument126 pagesAramcoinspectionhandbook 150311084705 Conversion Gate01 PDFMuhammed SulfeekNo ratings yet

- Radio Frequency Identification and Sensors: From RFID to Chipless RFIDFrom EverandRadio Frequency Identification and Sensors: From RFID to Chipless RFIDNo ratings yet

- 43765593-Points-to-Recall-API653Document21 pages43765593-Points-to-Recall-API653Akhilesh KeralaNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- API 577 QuestionsDocument14 pagesAPI 577 QuestionsabdoNo ratings yet

- Burnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Document8 pagesBurnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Anonymous i6zgzUvNo ratings yet

- Burnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Document8 pagesBurnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Anonymous i6zgzUvNo ratings yet

- Technical Alert Torque_Rev1xDocument2 pagesTechnical Alert Torque_Rev1xGharib HashemNo ratings yet

- Ford ABS Plating Spec.Document7 pagesFord ABS Plating Spec.Pieter100% (2)

- Inspection Handbook PDFDocument20 pagesInspection Handbook PDFSamuel JohnNo ratings yet

- Radiographic Shell InspectionDocument6 pagesRadiographic Shell InspectionHassan Ali HassanNo ratings yet

- E435 Steel PlatesDocument4 pagesE435 Steel PlatesLeina Rosa Wilches AtencioNo ratings yet

- Asme RT Wps SECTION 8Document6 pagesAsme RT Wps SECTION 8Hassan Ali HassanNo ratings yet

- Houston Impact of J-STD-001F and IPC-A-610F ChangesDocument36 pagesHouston Impact of J-STD-001F and IPC-A-610F Changeswayneseal1No ratings yet

- Engineering Specifications - Inspection: Rev. FDocument17 pagesEngineering Specifications - Inspection: Rev. Fstephen lewellen100% (1)

- Ebs1 Aaaa00 Saqa Prqa 0016Document7 pagesEbs1 Aaaa00 Saqa Prqa 0016SERT-QA/QC- BUZNo ratings yet

- Hardness Test Procedure Whith EquotipDocument4 pagesHardness Test Procedure Whith EquotipSoiar IuNo ratings yet

- ACFMDocument10 pagesACFMAnson MartinNo ratings yet

- GF-4172-QC-EI-FM-0005, Rev. 4 CHECKLIST FOR UNDERGROUND CABLE LAYING WORKS-ReplacedDocument3 pagesGF-4172-QC-EI-FM-0005, Rev. 4 CHECKLIST FOR UNDERGROUND CABLE LAYING WORKS-ReplacedsureshNo ratings yet

- Fibre Distribution and Management SystemDocument28 pagesFibre Distribution and Management SystemRakesh Ranjan0% (2)

- Mps & Itt - Spiral SteelDocument23 pagesMps & Itt - Spiral SteelSiswo YuwonoNo ratings yet

- Icea Nema S-61-402 Parte 4Document23 pagesIcea Nema S-61-402 Parte 4DamiánNo ratings yet

- Sa 435Document3 pagesSa 435KHALED OSMANNo ratings yet

- SAUDI ARAMCO MPT INSPECTIONDocument6 pagesSAUDI ARAMCO MPT INSPECTIONphilipyapNo ratings yet

- Inspection HandbookDocument127 pagesInspection HandbookWalter Rueda100% (2)

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- API 650 Tank Fabrication and Inspection RequirementsDocument14 pagesAPI 650 Tank Fabrication and Inspection RequirementsFucKerWengieNo ratings yet

- Failure Analysis With RDSODocument2 pagesFailure Analysis With RDSOP.S.RoyNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19Document3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19harisNo ratings yet

- Manual Ultrasonic Testing Procedure for 26Document12 pagesManual Ultrasonic Testing Procedure for 26Rohit Kumar Mishra100% (1)

- PCB Acceptability StandardsDocument5 pagesPCB Acceptability StandardsAnn Marian CadaoNo ratings yet

- Astm A435 A435m-90 (1996)Document2 pagesAstm A435 A435m-90 (1996)FeteneNo ratings yet

- Technical Specification for LT AC Distribution BoardDocument41 pagesTechnical Specification for LT AC Distribution BoardPrashant TrivediNo ratings yet

- Overhead Crane Inspection ProceduresDocument5 pagesOverhead Crane Inspection ProceduresRonniNo ratings yet

- API-653 Tank Inspection RequirementsDocument12 pagesAPI-653 Tank Inspection RequirementsEngr Shahid AliNo ratings yet

- It0404 20 PDFDocument5 pagesIt0404 20 PDFIvan MauricioNo ratings yet

- Ultrasonic Testing of Steel PlatesDocument2 pagesUltrasonic Testing of Steel PlatesHarshkulNo ratings yet

- Saudi Aramco Test Report: Cable Tray, NEMA VE 1 Static Load Testing SATR-P-3301 3-Jul-18 ElectDocument4 pagesSaudi Aramco Test Report: Cable Tray, NEMA VE 1 Static Load Testing SATR-P-3301 3-Jul-18 Electkarthi51289No ratings yet

- CDL - 33 - TECH - SPECIFICAITON Tower Erection PDFDocument22 pagesCDL - 33 - TECH - SPECIFICAITON Tower Erection PDFDony RamdhaniNo ratings yet

- A 435 - A 435M - 90 (2012) PDFDocument2 pagesA 435 - A 435M - 90 (2012) PDFأسامة وحيد الدين رمضانNo ratings yet

- Corrosion and Cracking of Bottom Scrapers in Continuous DigestersDocument27 pagesCorrosion and Cracking of Bottom Scrapers in Continuous DigestersIndra NainggolanNo ratings yet

- Fluid Catalytic Cracking Process and Apparatus For Maximizing Light Olefins or Middle Distillates and Light OlefinsDocument25 pagesFluid Catalytic Cracking Process and Apparatus For Maximizing Light Olefins or Middle Distillates and Light OlefinsIndra NainggolanNo ratings yet

- Graphitization of Steels in Elevated Temperature ServiceDocument1 pageGraphitization of Steels in Elevated Temperature ServiceIndra NainggolanNo ratings yet

- API Recommended Practice 584: Integrity Operating WindowsDocument2 pagesAPI Recommended Practice 584: Integrity Operating WindowsusamafalakNo ratings yet

- Naphthenic Acid Analysis Tan - Nan - Nat-Ms: COQG Meeting September 29, 2005Document14 pagesNaphthenic Acid Analysis Tan - Nan - Nat-Ms: COQG Meeting September 29, 2005Indra NainggolanNo ratings yet

- Task 14 - Ejectors in VDUDocument1 pageTask 14 - Ejectors in VDUIndra NainggolanNo ratings yet

- Exceeding Expectations: Please Visit Us at Our Website or Contact Us at 800 286-2208Document3 pagesExceeding Expectations: Please Visit Us at Our Website or Contact Us at 800 286-2208Indra NainggolanNo ratings yet

- Appendix A TMSF For CUIDocument7 pagesAppendix A TMSF For CUIIndra NainggolanNo ratings yet

- Task 15 - LPG Plant ConstructionDocument1 pageTask 15 - LPG Plant ConstructionIndra NainggolanNo ratings yet

- Design Phase DeliverablesDocument21 pagesDesign Phase DeliverablesIndra NainggolanNo ratings yet

- Verify DeButanizer Conditions Task GuideDocument1 pageVerify DeButanizer Conditions Task GuideIndra NainggolanNo ratings yet

- Affected Material: - Carbon Steel - Low Alloy Steel - 300 Series SSDocument2 pagesAffected Material: - Carbon Steel - Low Alloy Steel - 300 Series SSIndra NainggolanNo ratings yet

- Task 17 - LPG Tank PlantDocument1 pageTask 17 - LPG Tank PlantIndra NainggolanNo ratings yet

- Indonesian Trainer Vacancy Information 070219Document2 pagesIndonesian Trainer Vacancy Information 070219Indra NainggolanNo ratings yet

- Task 3 - Verify Process UnitsDocument1 pageTask 3 - Verify Process UnitsIndra NainggolanNo ratings yet

- Task 22 - FCC DocumentDocument1 pageTask 22 - FCC DocumentIndra NainggolanNo ratings yet

- Check Out This Video:: Refining-Royalty-Free-Stock-Video-Footage/001-D378-24-372Document1 pageCheck Out This Video:: Refining-Royalty-Free-Stock-Video-Footage/001-D378-24-372Indra NainggolanNo ratings yet

- Caustic-Corrosion 3Document2 pagesCaustic-Corrosion 3Indra NainggolanNo ratings yet

- Caustic-Corrosion - 5Document2 pagesCaustic-Corrosion - 5Indra NainggolanNo ratings yet

- Task 24 - FCC VideosDocument1 pageTask 24 - FCC VideosIndra NainggolanNo ratings yet

- CREEP, CRACKS AND FITNESS FOR SERVICE - MegChem (Pty) LTDDocument8 pagesCREEP, CRACKS AND FITNESS FOR SERVICE - MegChem (Pty) LTDIndra NainggolanNo ratings yet

- Caustic-Corrosion 1Document2 pagesCaustic-Corrosion 1Indra NainggolanNo ratings yet

- Caustic-Corrosion - 4Document2 pagesCaustic-Corrosion - 4Indra NainggolanNo ratings yet

- Task 23 - FCC Video Graphic AnimationDocument1 pageTask 23 - FCC Video Graphic AnimationIndra NainggolanNo ratings yet

- Bacteria - Types, Characteristics, Where They Live, Hazards, and MoreDocument21 pagesBacteria - Types, Characteristics, Where They Live, Hazards, and MoreIndra NainggolanNo ratings yet

- PHD Thesis B CacciapuotiDocument209 pagesPHD Thesis B CacciapuotiIndra NainggolanNo ratings yet

- Hussain and Robinson Erosion in Seawater and SandDocument18 pagesHussain and Robinson Erosion in Seawater and SandIndra NainggolanNo ratings yet

- Stainless Steels: and Specialty Alloys For Pulp, Paper and Biomass ConversionDocument144 pagesStainless Steels: and Specialty Alloys For Pulp, Paper and Biomass ConversionIndra NainggolanNo ratings yet

- Bacteria - What Is Microbiology - Microbiology SocietyDocument6 pagesBacteria - What Is Microbiology - Microbiology SocietyIndra NainggolanNo ratings yet

- USP FriabilityDocument2 pagesUSP Friabilityshdph100% (1)

- Finding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Document39 pagesFinding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Jernel Raymundo80% (5)

- VDR G4 Manual Steinsohn PDFDocument185 pagesVDR G4 Manual Steinsohn PDFVariya Dharmesh100% (1)

- Dream Life - Allan HobsonDocument307 pagesDream Life - Allan HobsonJose MuñozNo ratings yet

- 2020.07.31 Marchese Declaration With ExhibitsDocument103 pages2020.07.31 Marchese Declaration With Exhibitsheather valenzuelaNo ratings yet

- DOJ OIG Issues 'Fast and Furious' ReportDocument512 pagesDOJ OIG Issues 'Fast and Furious' ReportFoxNewsInsiderNo ratings yet

- CellphoneBill PDFDocument6 pagesCellphoneBill PDFRaza KhanNo ratings yet

- Quantification Skills in The Construction IndustryDocument34 pagesQuantification Skills in The Construction IndustryBRGRNo ratings yet

- Malabsorption and Elimination DisordersDocument120 pagesMalabsorption and Elimination DisordersBeBs jai SelasorNo ratings yet

- Nettoplcsim S7online Documentation en v0.9.1Document5 pagesNettoplcsim S7online Documentation en v0.9.1SyariefNo ratings yet

- Lecture Euler EquationDocument33 pagesLecture Euler EquationYash RajNo ratings yet

- DSC analysis of hair denaturationDocument2 pagesDSC analysis of hair denaturationDiosel Rezia PrazaNo ratings yet

- Sato Printer Api Reference DocumentDocument34 pagesSato Printer Api Reference Documentsupersteel.krwNo ratings yet

- Hotel Engineering Facilities: A Case Study of Maintenance PerformanceDocument7 pagesHotel Engineering Facilities: A Case Study of Maintenance PerformanceHoh Pui KeiNo ratings yet

- Why it's important to guard your free timeDocument2 pagesWhy it's important to guard your free timeLaura Camila Garzón Cantor100% (1)

- Intermediate Accounting 2 - CL NCL Lecture NotesDocument2 pagesIntermediate Accounting 2 - CL NCL Lecture NotesRacheel SollezaNo ratings yet

- GMS175CSDocument4 pagesGMS175CScorsini999No ratings yet

- Major Project Report - Template 2021Document18 pagesMajor Project Report - Template 2021vamkrishnaNo ratings yet

- 02 1 Cohen Sutherland PDFDocument3 pages02 1 Cohen Sutherland PDFSarra AnitaNo ratings yet

- Tugas Bahasa Inggris Analytical Exposition Text: Disusun Oleh: Nama:Hansel Hendrawan Effendy Kelas:XI IPA 1Document4 pagesTugas Bahasa Inggris Analytical Exposition Text: Disusun Oleh: Nama:Hansel Hendrawan Effendy Kelas:XI IPA 1Hansel HendrawanNo ratings yet

- Unit 7 Noun ClauseDocument101 pagesUnit 7 Noun ClauseMs. Yvonne Campbell0% (1)

- Tle 10 4quarterDocument2 pagesTle 10 4quarterCaryll BaylonNo ratings yet

- TLM4ALL@1 Number System (EM)Document32 pagesTLM4ALL@1 Number System (EM)jkc collegeNo ratings yet

- DataSheet IMA18-10BE1ZC0K 6041793 enDocument8 pagesDataSheet IMA18-10BE1ZC0K 6041793 enRuben Hernandez TrejoNo ratings yet

- Unit 2 Water Treatment Ce3303Document18 pagesUnit 2 Water Treatment Ce3303shivaNo ratings yet

- INA128 INA129: Features DescriptionDocument20 pagesINA128 INA129: Features DescriptionCDDSANo ratings yet

- Syllabus PTSV3Document21 pagesSyllabus PTSV3Pablito Quispe RuizNo ratings yet

- IT-02 Residential StatusDocument26 pagesIT-02 Residential StatusAkshat GoyalNo ratings yet

- HNM Announcement Flyer enDocument2 pagesHNM Announcement Flyer enJali SahiminNo ratings yet

- Factory Test Report For OPzS 800 EED-20041724 2VDocument3 pagesFactory Test Report For OPzS 800 EED-20041724 2VmaherNo ratings yet

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Estimator's General Construction Manhour ManualFrom EverandEstimator's General Construction Manhour ManualRating: 4.5 out of 5 stars4.5/5 (20)

- How to Build a Tiny Portable House: With Plans and InstructionsFrom EverandHow to Build a Tiny Portable House: With Plans and InstructionsRating: 4 out of 5 stars4/5 (1)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)