Professional Documents

Culture Documents

Method Statement - Cable Tray Erection

Uploaded by

soubhagyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement - Cable Tray Erection

Uploaded by

soubhagyaCopyright:

Available Formats

METHOD STATEMENT FOR CABLE TRAY INSTALLATION

1.0 OBJECTIVE

To provide guide lines for erection of all types of cable trays or cable trays with all

accessories viz. Bends, Tees, Cross. The types of cable trays /cable trays are as

follows:

1. Ladder Type Cable Trays of all sizes as per BOQ.

2. Perforated /Solid Type Cable Trays of all sizes.

2.0 REFERENCE :

1. Approved Drawings

2. Manufacturers Specifications

3.0 INSTRUMENTS/TOOLS & PLANTS :

PP ropes, scaffolding, drilling machine & spanner sets, Loading/Unloading tools and

tackles.

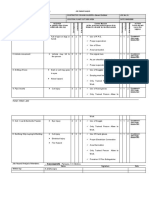

Sl.No. Procedure Responsibility Check By

1. Prior to cable tray installation works, complete all the Site Engineer Site-in-charge

erection of cable tray supports.

2. Clean the cable tray supports through the entire route of the Site Engineer Site-in-charge

cable trays.

3. Examine the drawing of cable tray layout Site Engineer Site-in-charge

drawing, with respect to the general layout

4 Survey the entire route of cable trays for Site Engineer Site-in-charge

existing hindrance at site due to other system

works viz. piping, air ventilation etc.

5 Report any Interference to the erection agency Site Engineer Site-in-charge

of the client.

6 Check that support installation for straight runs Site Engineer Site-in-charge

(i.e. other than accessories) is over and Support

Erection Report is completed and signed.

7. Shift the Cable trays required as per approved Site Engineer Site-in-charge

drawings from stores to the locations either

manually or by a truck .Not more than three

days inventory shall be stored at site.

8 Carry out Physical verification for any damage. Site Engineer Site-in-charge

9 Cut the Cable trays with hack saw to proper Site Engineer Site-in-charge

length required at site and avoid sharp edges

and make necessary holes for couplers, earthing

flats with drilling machines.

10 No where gas cutting should be done. Site Engineer Site-in-charge

11 Place the Cable trays & accessories on the Site Engineer Site-in-charge

supports, join them by coupler plates/ fishplates

and nut, bolts & washers as per approved

drawing.

12 Align the Trays properly and fix on the supports Site Engineer Site-in-charge

with clamps as per approved drawings.

13 Erect the Support for accessories as per support Site Engineer Site-in-charge

erection procedure

14 Complete the Cable Tray earthing as per the Site Engineer Site-in-charge

approved procedure.

15 Number the cable trays as per approved layout Site Engineer Site-in-charge

drawing of latest revision and cable installation

note.

METHOD STATEMENT FOR CABLE TRAY INSTALLATION

Sl.No. Procedure Responsibility Check By

16 Provide with GI wire mesh enclosure to all floor Site Engineer Site-in-charge

openings of cable trays up to a height of 2 m for

physical protection of personnel

17. If covering of the cable trays are Site Engineer Site-in-charge

mentioned in the approved GA

drawing, execute the same after

completion of cable laying and

final dressing

18 PRECAUTION: Site Engineer Site-in-charge

1. Bolts nuts etc. to be provided immediately after

erection of cable trays, and duly tightened.

2.Cable trays to be properly stored in erection location.

3. Loose materials inside the cable tray to be removed.

4.While working at height safety belt to be used

5. Proper scaffolding to be made while working.

19 Safety Measures:

1. Work permit to be taken before start of the work. Tool box meeting to be

ensured everyday for the said work.

2. Adequate area lighting to be ensured in all the work places including sub

station before start of the works. For Shifting of Cable trays from storage yard

to work place, proper lifting tools & tackles, hydra & truck / trailor with good

condition to be ensured and the same to be certified by competent person.

3. Proper stacking of the cable trays to be ensured near the work place.

4. Transportation supervisor should be made responsible to guide the trailor &

alert the people during transportation.

5. Cable tray loading and unloading to be done manually only.

6. All the cut outs should be closed and edge protection to be ensured in the

working area.

7. Proper scaffold to be installed for the areas of work at height & proper ladder

to be used for access.

8. Proper manual handling procedure to be followed during the lifting of cable tray

support from ground to elevated platform with the help of pp rope.

9. Life line to be tied while work at height. Workers to ensure proper PPEs before

start of work. Fall arrester system has to be ensured while doing the vertical

cable tray erection.

10. No lose materials like nut bolts, coupler plates, spanners washers etc should

be left on the trays or working platform. Separate bags should be used to keep

this materials while at work. If required any material should be brought to the

top with the help of only PP rope.

11. Welding machine to be connected to proper power distribution board with

ELECB, metal clad plug and socket, doubly earthed. Earthing cable to be

provided with crimping lug.

12. Proper house keeping to be maintained and fire extinguishers to be provided in

sub station area.

13. Hose of the gas cutting set to be checked by soup solution and hose clamp to

be used. Flash back arrester to be ensured at both torch and cylinder end.

Correct size nozzles to be ensured and proper clearance to be maintained

between job and nozzle. Condition of the regulator, hose and torch to be

checked. Stone lighter to be used.

14. Grinding Wheel rpm to be checked and to be ensured for correctness. Grinding

m/c wheel guard is to be ensured.

15. Proper PPEs are to be ensured for all the activities.

You might also like

- Method Statement - Cable LayingDocument5 pagesMethod Statement - Cable LayingsoubhagyaNo ratings yet

- Method Statement - Bus BarDocument2 pagesMethod Statement - Bus Barsoubhagya100% (1)

- Method Statement For Electrical Surface Conduit InstallationDocument14 pagesMethod Statement For Electrical Surface Conduit Installationshareyhou100% (1)

- Cable Installation MethodDocument7 pagesCable Installation MethodAhmad Dagamseh100% (1)

- Method Statement For Cable Containment For CablesDocument15 pagesMethod Statement For Cable Containment For CablesshareyhouNo ratings yet

- Method Statement - Panel ErectionDocument2 pagesMethod Statement - Panel ErectionsoubhagyaNo ratings yet

- Installation of UPS Method StatementDocument8 pagesInstallation of UPS Method Statementanon_534254691No ratings yet

- Ms-Cable Tray InstallationDocument7 pagesMs-Cable Tray InstallationVane DG100% (1)

- FO Cable Pulling MethodDocument3 pagesFO Cable Pulling Methodnice hossainNo ratings yet

- Method Statement For Cable & TerminationDocument6 pagesMethod Statement For Cable & TerminationRajuNo ratings yet

- Method Statement For Cable Tray Manual Lifting and InstallationDocument5 pagesMethod Statement For Cable Tray Manual Lifting and InstallationVeronica De Jesus100% (1)

- Method Statement For The Installation of TransformerDocument11 pagesMethod Statement For The Installation of TransformerShaikh Ahamed100% (1)

- Godrej SOP for Erecting Poles with HardwareDocument7 pagesGodrej SOP for Erecting Poles with HardwareVIKAS SINGH BAGHELNo ratings yet

- Earthing Method StatementDocument5 pagesEarthing Method StatementMuhammad Saqib AsifNo ratings yet

- Method Statement For MV Switchgear (Inspire)Document5 pagesMethod Statement For MV Switchgear (Inspire)Gajendran Sriram50% (2)

- M. Statment Lines - OHL Instal & TestingDocument27 pagesM. Statment Lines - OHL Instal & Testingahmedshah512100% (1)

- Shut Down Procedure (Tata Steel)Document19 pagesShut Down Procedure (Tata Steel)Prakash Kumar100% (1)

- Electrical Panel - Equipment Installation Method StatementDocument8 pagesElectrical Panel - Equipment Installation Method Statementadnanakhtarhrp60% (5)

- Risk Assessment Form: 1 Biophysical HazardsDocument5 pagesRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- Rev02-Work Method Statement For LV and MV Motor InstallationDocument14 pagesRev02-Work Method Statement For LV and MV Motor InstallationMahaboob PashaNo ratings yet

- Work Method Statement For X-A T#31 To 34Document8 pagesWork Method Statement For X-A T#31 To 34Twin Bulls100% (1)

- Electrical Method StatementDocument7 pagesElectrical Method StatementDylanNo ratings yet

- Method Statement Transformer InstallationDocument2 pagesMethod Statement Transformer Installationphilipyong92% (13)

- Installation of MV LV Switchgear & Panels - Method StatementDocument3 pagesInstallation of MV LV Switchgear & Panels - Method Statementfathonix100% (2)

- Method Statement For Busduct System RevisedDocument16 pagesMethod Statement For Busduct System Revisedhadi50% (2)

- Method Statement For Installation of Cables, Wires & Termination - Rev02.Document27 pagesMethod Statement For Installation of Cables, Wires & Termination - Rev02.RaulSaavedra88% (8)

- Cable Tray InstallationDocument7 pagesCable Tray Installationareef007No ratings yet

- Method Statement For Protection TestingDocument4 pagesMethod Statement For Protection TestingAfanda Rodgers100% (3)

- Method of Statement and JSA For Live Line Crosssing in PXIDocument8 pagesMethod of Statement and JSA For Live Line Crosssing in PXITwin BullsNo ratings yet

- Method Statement For The Installation of TransformerDocument2 pagesMethod Statement For The Installation of Transformeramg007100% (3)

- Method Statement - 115kV 100 MVA Transformer InstallationDocument75 pagesMethod Statement - 115kV 100 MVA Transformer Installationessam khalilNo ratings yet

- Method Statement For Installation of LV Power, Control and Low Current System Cables, Glands and AccessoriesDocument5 pagesMethod Statement For Installation of LV Power, Control and Low Current System Cables, Glands and Accessoriesmidhun muraliNo ratings yet

- Tower ErectionDocument4 pagesTower Erectionparry_handa220100% (1)

- METHOD STATEMENT - Transformer InstallationDocument2 pagesMETHOD STATEMENT - Transformer Installationanuraj arackal100% (2)

- Method Statement - Cable Joint LVDocument4 pagesMethod Statement - Cable Joint LVanuraj arackal60% (5)

- Dismantling Method StatementDocument53 pagesDismantling Method Statementmilosevicsasa11100% (1)

- Method Statement For Battery ChargerDocument6 pagesMethod Statement For Battery ChargerUtku Can Kılıç100% (1)

- Dry Type Transformer Installation MSDocument2 pagesDry Type Transformer Installation MSHansika Rajapaksha100% (1)

- Installation Ms Gi ConduitDocument9 pagesInstallation Ms Gi ConduitrkssNo ratings yet

- 12-SOP For Cable TerminationsDocument2 pages12-SOP For Cable TerminationsAbhay Godbole80% (5)

- Specification 33 KV LineDocument18 pagesSpecification 33 KV LineSatyaprasad NimmakayalaNo ratings yet

- Method Statement HT Switch GearDocument2 pagesMethod Statement HT Switch GearNasrul Syahmi100% (2)

- TRANSFORMER INSTALLATIONDocument20 pagesTRANSFORMER INSTALLATIONGodwin Arigbonu83% (6)

- 11kV ChecklistDocument2 pages11kV Checklistsofyan_shah25% (4)

- Method Statement For Installation of SwitchboardsDocument5 pagesMethod Statement For Installation of SwitchboardsDimitris NikouNo ratings yet

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDocument15 pages000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- Method Statement For Transmission Line Lanco PDFDocument37 pagesMethod Statement For Transmission Line Lanco PDFAmar WadoodNo ratings yet

- MOS For Electrical Conduit InstallationDocument8 pagesMOS For Electrical Conduit Installationanas BieNo ratings yet

- Jsa For Cable Tray ErectionDocument2 pagesJsa For Cable Tray Erectionanko heroNo ratings yet

- BEW - Method Statement For DB Dressing and Cable GlandingDocument8 pagesBEW - Method Statement For DB Dressing and Cable GlandingArun UdayabhanuNo ratings yet

- MV Cable Pulling and Installation Method StatementDocument9 pagesMV Cable Pulling and Installation Method StatementMark Tristan Vallesteros100% (6)

- Install 33KV Power Transformer MethodDocument7 pagesInstall 33KV Power Transformer MethodBabu50% (2)

- Method Statement For Conduits WiringDocument8 pagesMethod Statement For Conduits WiringÖmeralp SakNo ratings yet

- Work Method Statement For Lightning Protection SystemDocument8 pagesWork Method Statement For Lightning Protection SystemWCLNo ratings yet

- Checklist For Cable Try Fabrication and EractionDocument2 pagesChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- Method Statement For Installation of Low Voltage CablesDocument7 pagesMethod Statement For Installation of Low Voltage Cablestsraj1071% (7)

- Cable Ladder Method of Statement.Document4 pagesCable Ladder Method of Statement.Ahmad DagamsehNo ratings yet

- 01 Method Statment G I Conduit Access Rev 02Document5 pages01 Method Statment G I Conduit Access Rev 02mahroof mkuttyNo ratings yet

- 00 - MS - MV Cable Pulling and InstallationDocument9 pages00 - MS - MV Cable Pulling and Installationanon_534254691100% (1)

- Cable Tray Method StatementDocument8 pagesCable Tray Method StatementNidhin Mohan0% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument5 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- JSA Material UnlodingDocument3 pagesJSA Material UnlodingsoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Bore well drilling job hazard analysisDocument3 pagesBore well drilling job hazard analysissoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Jha RWFW Raft Cocrete JobDocument3 pagesJha RWFW Raft Cocrete JobsoubhagyaNo ratings yet

- Jha Batching Plant PlatformDocument5 pagesJha Batching Plant PlatformsoubhagyaNo ratings yet

- Revised Job Safety AnalysisDocument11 pagesRevised Job Safety AnalysisTigor GurningNo ratings yet

- Job Hazard Analysis for Interior FinishingDocument5 pagesJob Hazard Analysis for Interior FinishingsoubhagyaNo ratings yet

- All JsaDocument88 pagesAll JsaPankaj BhattNo ratings yet

- Electrical Safety Do - S - Dont - SDocument2 pagesElectrical Safety Do - S - Dont - SsoubhagyaNo ratings yet

- All JsaDocument88 pagesAll JsaPankaj BhattNo ratings yet

- Method Statement For Horizontal Tray Erection.Document5 pagesMethod Statement For Horizontal Tray Erection.soubhagyaNo ratings yet

- Revised Job Safety AnalysisDocument11 pagesRevised Job Safety AnalysisTigor GurningNo ratings yet

- Cuplocks Scaffolding JSA UtilityDocument4 pagesCuplocks Scaffolding JSA UtilitysoubhagyaNo ratings yet

- Tower Erection Method StatementDocument2 pagesTower Erection Method StatementsoubhagyaNo ratings yet

- Method Statement Bolero Shed: Purpose: Scope of WorkDocument2 pagesMethod Statement Bolero Shed: Purpose: Scope of WorksoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- METHOD STATMENT FORFIRE DETECTOR INSTALATIONDocument2 pagesMETHOD STATMENT FORFIRE DETECTOR INSTALATIONsoubhagyaNo ratings yet

- Method Statement - Bus DuctDocument2 pagesMethod Statement - Bus Ductsoubhagya100% (1)

- SAFE ERECTION OF ALL WORKSDocument4 pagesSAFE ERECTION OF ALL WORKSsoubhagyaNo ratings yet

- CONCRETING OF BOLERO SHEDDocument1 pageCONCRETING OF BOLERO SHEDsoubhagyaNo ratings yet

- Excavation Bolero ShedDocument1 pageExcavation Bolero ShedsoubhagyaNo ratings yet

- Method Statement Mrs Building: Purpose: Scope of WorkDocument1 pageMethod Statement Mrs Building: Purpose: Scope of WorksoubhagyaNo ratings yet

- Method Statement Staircase (Process Plant) LocationDocument4 pagesMethod Statement Staircase (Process Plant) LocationsoubhagyaNo ratings yet

- Method Statement Mrs Building: Purpose: Scope of WorkDocument1 pageMethod Statement Mrs Building: Purpose: Scope of WorksoubhagyaNo ratings yet

- Method Statement Staircase (Process Plant) LocationDocument4 pagesMethod Statement Staircase (Process Plant) LocationsoubhagyaNo ratings yet

- METHOD Errection CanopyDocument1 pageMETHOD Errection CanopysoubhagyaNo ratings yet

- Mining Raasm USA - Brochure PDFDocument10 pagesMining Raasm USA - Brochure PDFHector Robinson Prieto WilchesNo ratings yet

- Chevrolet Silverado 2010 Vin 0 y Vin 3Document12 pagesChevrolet Silverado 2010 Vin 0 y Vin 3Felix Velasquez100% (1)

- For New Equipment Sales, Call: Digger DerrickDocument2 pagesFor New Equipment Sales, Call: Digger DerrickSeguridadLaboralNo ratings yet

- AASHTO 07 - Minimum Designs For Truck and Bus TurnsDocument13 pagesAASHTO 07 - Minimum Designs For Truck and Bus TurnsValentínNo ratings yet

- Rough Terrain Vehicle Using Rocker Bogie MechanismDocument7 pagesRough Terrain Vehicle Using Rocker Bogie MechanismKalai SelvanNo ratings yet

- EFAS-4 Application Examples EN20130415TH08b - 2fpsDocument53 pagesEFAS-4 Application Examples EN20130415TH08b - 2fpsCostel CaramanNo ratings yet

- ΧΑΡΑΚΤΗΡΙΣΤΙΚΑ ΤΟΥΟΤΑDocument19 pagesΧΑΡΑΚΤΗΡΙΣΤΙΚΑ ΤΟΥΟΤΑjohn0% (1)

- Benny The Hero 9Document24 pagesBenny The Hero 9VictorNo ratings yet

- D375a-5eo Gen00054-02 PDFDocument167 pagesD375a-5eo Gen00054-02 PDFWill FrontNo ratings yet

- H5 Cargo Truck 6x2 260HP-1 PDFDocument2 pagesH5 Cargo Truck 6x2 260HP-1 PDFIbrahim Fadhl Kalajengking100% (2)

- JD 5075e 4WD Gearpro Lift Pro Ict Sign FTR UploadDocument14 pagesJD 5075e 4WD Gearpro Lift Pro Ict Sign FTR Uploadhugo fernandezNo ratings yet

- White Fork Lift Simplex Low Free Uprights Parts CatalogDocument2 pagesWhite Fork Lift Simplex Low Free Uprights Parts CatalogmaridhalaNo ratings yet

- PRICE LIST Consumer - Bridgestone Per 1 Oct 2022 - DistributorsDocument4 pagesPRICE LIST Consumer - Bridgestone Per 1 Oct 2022 - DistributorsBia Maya ViandhikaNo ratings yet

- Uperform - Pallet Truck PDFDocument52 pagesUperform - Pallet Truck PDFMohd Asrul Abu Harirah100% (2)

- Mobile B37Document2 pagesMobile B37Sheree PeoplesNo ratings yet

- Kubota Tracked Dumper: 45.5 PS 2700 KGDocument8 pagesKubota Tracked Dumper: 45.5 PS 2700 KGKeron TrotzNo ratings yet

- Operator Manual 2TD20Document47 pagesOperator Manual 2TD20Pandhari Shinde100% (1)

- Focus On Iveco TransmissionsDocument31 pagesFocus On Iveco TransmissionsBroCactus100% (1)

- Parts Catalog: Same Great Quality Parts at A Reduced CostDocument24 pagesParts Catalog: Same Great Quality Parts at A Reduced CostTIIFFDNo ratings yet

- Haward City Directory 23Document390 pagesHaward City Directory 23Mannu GoyatNo ratings yet

- Yard Ramps and Steel Platforms: Models SYS and SPDocument4 pagesYard Ramps and Steel Platforms: Models SYS and SPRoo VidNo ratings yet

- Nippon Piston Ring Co.,Ltd.: Gasoline-engine Automobiles ガソリン車Document4 pagesNippon Piston Ring Co.,Ltd.: Gasoline-engine Automobiles ガソリン車Edixo ReyesNo ratings yet

- The Hydraulic Steering System For Steered Axles On (Semi) Low LoadersDocument4 pagesThe Hydraulic Steering System For Steered Axles On (Semi) Low LoadersAdvenser GroupNo ratings yet

- Ford F-Series (Medium Duty Truck)Document9 pagesFord F-Series (Medium Duty Truck)roberto100% (1)

- Rod-Handler SchrammDocument2 pagesRod-Handler SchrammMarcelo CarNo ratings yet

- An Autobiography of BicycleDocument2 pagesAn Autobiography of Bicycle257sham74% (19)

- Vito Tourer 124 Cdi Vts eDocument4 pagesVito Tourer 124 Cdi Vts eCentrale Lemne LiepsneleNo ratings yet

- Life of Truck DriverDocument5 pagesLife of Truck DriverSahil BhasinNo ratings yet

- Contract of Sale of Motor VehicleDocument2 pagesContract of Sale of Motor VehicleRhea Mae A. SibalaNo ratings yet

- 50T Telescopic Rough Terrain Crane-GRIL 8500T-LOCATELLIDocument201 pages50T Telescopic Rough Terrain Crane-GRIL 8500T-LOCATELLIQUANG LÊ67% (3)