Professional Documents

Culture Documents

7 Study of Mechanical and Durability Properties of SIFCON by Partial Replacement

Uploaded by

msheer hasanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Study of Mechanical and Durability Properties of SIFCON by Partial Replacement

Uploaded by

msheer hasanCopyright:

Available Formats

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 5, May 2016

Study of Mechanical and Durability

Properties of SIFCON by Partial Replacement

of Cement with Fly Ash as Defined By an

Experimental Based Approach

Patil Deepesh1, Kanase Jayant2

P.G. Student, Department of Civil Engineering, Trinity College of Engineering, Pune, Maharashtra, India1

Associate Professor, Department of Civil Engineering, Trinity College of Engineering, Pune, Maharashtra, India2

ABSTRACT: In this experimental investigation testing of mechanical and durability properties of Slurry Infiltrated

Fibrous Concrete (SIFCON) using hooked ended steel fibers is carried out. Similarly the replacement of cement with

fly ash in three different proportions as 5%, 10%, 15%, and replacement of fine aggregate with bottom ash in three

different proportions of 10%, 20% and 30% was done. The main goal is to improve the tensile strength and flexural

strength of concrete. To optimize this serious defect partial incorporation of fibers is practiced. In this study we have

induced 2% and 3% fibers of the total volume of the specimen. For the study of durability of concrete, the cubes were

kept immersed in MgSO4 for 28 days and the attack of chemical on concrete was studied. Mechanical tests such as

compression test, flexural test, split tensile test were carried out on standard size of cubes, beams and cylinder

respectively at the age of 7, 28, 56 days.

In this investigation it was observed that the mechanical as well as the durability properties of SIFCON were

severely affected in a positive manner by using the substitute as fly ash and by adding steel fiber reinforcement in

defined percentage.

KEYWORDS: SIFCON, Steel hooked end fibres, Mechanical properties, Durability properties, Fly Ash, Bottom Ash.

I. INTRODUCTION

SIFCON is unique construction material possessing high strength as well as large ductility and far excellent potential

for structural applications when accidental (or) abnormal loads are encountered during services SIFCON also exhibit

new behavioural phenomenon, that of ”Fiber lock” which believed to be responsible for its outstanding stress-strain

properties. The matrix in SIFCON has no coarse aggregates, but a high cementitious content. However, it may contain

fine (or) coarse sand and additives such as fly ash, micro silica and latex emulsions. The matrix fineness must be

designed so as to properly infiltrate the fiber network placed in moulds, since otherwise, large pores may form leading

to substantial reduction in properties. A controlled quantity of high range water reducing admixtures (super plasticizer)

may be used for improving flowing characteristics of SIFCON. All steel fiber types namely straight, hooked and

crimped can be used. The fibers are subjected to frictional and mechanical interlock in addition to the bond with the

matrix. The matrix plays the role of transferring the forces between fibers by shear, but also acts as bearing to keep

fibers interlock. Slurry-infiltrated fibrous concrete or mortar (SIFCON) is a relatively new material that can be

considered as a special type of fiber-reinforced concrete (FRC). In two aspects, however namely, fiber content and the

method of production of SIFCON is different from normal FRC. The fiber content of FRC generally varies from 1 to 3

percent by volume, but the fiber content of SIFCON varies between 5 and 20 percent. Again, the matrix of SIFCON

consists of cement paste or flowing cement mortar as opposed to regular concrete used in FRC. These make the

production of SIFCON far different from FRC. Unlike FRC, for which the fibers are added to the wet or dry concrete

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0505278 8568

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 5, May 2016

mix, SIFCON is prepared by infiltrating cement slurry into a bed of fibers preplaced and packed tightly in the molds. In

spite of their relatively high cost, high performance fiber reinforced cement-based composites are used more widely all

over the world especially in seismic retrofit design and in the structures under explosive and impact effects. High or

ultrahigh strength concrete with very high compressive strength values remains basically a brittle material. The

inclusion of adequate fibers improves tensile strength and provides ductility.

II. RELATED WORK

In literature survey of last 15 years different research has been carried out to develop the high performance fiber

Reinforced in different country under different climatic conditions, assumptions, and materials, etc. The technique of

infiltrated layers of steel fibers with Portland cement based materials was first proposed by Haynes (1968).Lankard

(1979) modified the method used by Haynes and proved that if percentage of steel fibres in cement matrix could be

increased, one could get a material with very high strength properties which he christened as SIFCON. He presented

the basic properties of SIFCON such as load-deflection curve, ultimate compressive and flexural strengths, impact and

abrasion resistance.

SundarsanaRao and Ramana tested the SIFCON slab elements under flexure and compared the results with FRC and

PCC slabs and concluded that SIFCON slabs exhibit superior performance in flexure when compared to FRC and PCC

slabs. He investigated the response of SIFCON two way slabs under impact loading and concluded that the SIFCON

slabs with 12% fibre volume fraction exhibit excellent performance in strength and energy-absorption characteristics.

He presented the behavior of SIFCON two way slabs in punching shear and show that the SIFCON slabs with 12%

fibre volume fraction exhibits excellent performance in punching shear among other slabs. However, literature review

reveals that a very little work has been carried out on SIFCON to determine the durability characteristics.

Mr. Bryan Thane Wood from of North Carolina State University, Raleigh worked on "Use of Slurry Infiltrated Fiber

Concrete (SIFCON) in Hinge Regions for Earthquake Resistant Structures" In this paper the researcher demonstrated

that reinforced SIFCON hinges can exhibit superior performance as compared to reinforced concrete hinges. Many

problems encountered with reinforced concrete hinges do not occur when using SIFCON hinges. There are three

primary advantages of using reinforced SIFCON flexural hinges in place of reinforced concrete hinges.

1. Greater shear strength and toughness prevent shear sliding on through-depth flexural cracks in reinforced SIFCON.

In contrast, reinforced concrete hinges develop a through-depth flexural crack. As loading progresses, sliding occurs on

this plane, quickly degrading structural integrity. However, the SIFCON hinges tested in this program rarely developed

any through-depth cracks. If a through-depth flexural crack developed, it never opened enough to degrade the shear

capacity of the section.

2. Although SIFCON enables the reinforcing to undergo cyclic yielding withoutbuckling, minimal confining steel may

be required. Reinforced concrete hinges require longitudinal and transverse confining steel to not only confine the

flexural.

Mr.HalitYazici and others from Turkey has developed the practical technique of Development of “Autoclaved SIFCON

with high volume Class C fly ash binder phase”. In his work Cement was replaced with up to 60% FA (fly ash) in

SIFCON compositions and three different steel fiber volumes (2%, 6% and 10%) were used. Test results were

presented in comparison with the control mix (0% FA and 0% fiber). Mechanical properties were positively affected

almost at every FA replacement. Moreover, by increasing the fibre volume, flexural strength and toughness were

remarkably increased. This behaviour was more pronounced at 10% fibre volume. At this fibre volume ratio, flexural

strength of 55 MPa could be achieved with 60% FA replacement.

Mr. D. Elavarasi& others from India has developed and worked on “Behavior of fly Ash based slurry Infiltrated

Fibrous”. In this work the author has explained the use of high content of Fly ash with replacement to cement in

making of SIFCON so as to overcome the problems such as greater heat of hydration, higher shrinkage & high

production cost. The author studied the effect of fly ash and fiber content on mechanical properties of SIFCON. In this

course of work the author replaced cement with 10, 20, 30 % of fly ash. Fibre content in SIFCON varied with 6, 8, and

10%.

. Mr.Bhushan L. Karihaloo from Cardiff University, U.K and others worked on "Effect of Casting Direction on the

Mechanical Properties of CARDIFRC”. In this study tests were performed to investigate the effect of fiber orientation

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0505278 8569

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 5, May 2016

and any unintentional grading over the specimen size of CARDIFRC® on its mechanical properties. CARDIFRC® is

an UHPC reinforced with steel fibres of two differentlengths and a compressive strength of about 200 MPa. Tests were

performed to investigate the effect of fibre orientation and the unintentional grading over the specimen size of

CARDIFRC.

III. OBJECTIVES AND SCOPE OF RESEARCH

As stated above, being a relatively new construction material, very little information on SIFCON durability

characteristics is known from published previous researches. In light of this, the objectives of this study are to

investigate and provide information about various aspects of SIFCON durability, mainly permeability, resistance to

chloride penetration, freezing and thawing and drying shrinkage. This information will help in providing the necessary

database and knowledge about the ability of SIFCON to withstand the conditions for which it has been designed

without deterioration, especially when it is intended to be used in aggressive environments like the cases of marine

structures or bridges subjected to freeze-thaw damage and de-icing salts in cold regions. The understanding of SIFCON

behaviour related to durability will help in achieving a rational design of structure using.

1. To determine the compressive strength of SIFCON as a replacement of cement with fly ash and replacement

of fine aggregate with bottom ash separately.

2. To determine the flexural strength of SIFCON as a replacement of cement with fly ash and replacement of fine

aggregate with bottom ash separately.

3. To determine the split tensile strength of SIFCON as a replacement of cement with fly ash and replacement of

fine aggregate with bottom ash separately.

4. To study the influence of magnesium sulphate attack on SIFCON specimen and to determine its compressive

strength after the sulphate attack under 28 days chemical water curing.

5. To determine the Dynamic Modulus of elasticity of SIFCON as a replacement of cement with fly ash and

replacement of fine aggregate with bottom ash separately

IV. PREPARATION OF SIFCON

Analogous to preplaced aggregate concrete, SIFCON is preplaced fiber concrete with the placement of steel fibers in a

mold or form, or on a substrate, as the initial construction step. Fiber placement is accomplished by hand or through the

use of commercial fiber dispersing units. As stated before, the amount of fibers that can be incorporated depends on

fiber dimensions, especially aspect ratio (l/d), fiber geometry. The fiber density at the edges of the mold can be much

less, compared to the interior. Once the steel fibers have been placed on a substrate or in a mold, then they are

infiltrated with a fine-grained cement-based slurry. The slurry must be flow able and liquid enough and have sufficient

fineness to infiltrate thoroughly the dense matrix in the fiber-filled forms. As the slurry is self-compacted, it does not

need any external vibrations

V. MATERIALS AND MIX PROPORTION

The primary constituent materials of SIFCON are steel fibers and cement based slurry. The matrix can contain:

1. Only cement (slurry or cement paste)

2. Cement and sand mortar

3. Cement and other additives (mainly fly ash or silica fumes )

4. Bottom ash

STEEL FIBERS

A large variety of steel fibers have been investigated for use in SIFCON. To develop better mechanical anchorage and

bond between the fibers and the matrix, the fibers can be modified along its length by inducing mechanical

deformations or by roughening its surface. The most widely used types are hooked and crimped fibers. Surface

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0505278 8570

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 5, May 2016

deformed and straight fibers are used also, but they are less popular. In most cases, the cross section of steel fibers is

circular. It can be also rectangular, square, triangular or flat. In this case Hooked end steel fiber of diameter 1. 00 mm

and length of 30 mm giving aspect ratio of 30 was used. Fibers were oriented in the form in random manner.

MATRIX

The matrix of SIFCON does not contain coarse aggregate which, of course, cannot infiltrate through the tiny spaces

between the steel fibers. In the given matrix composition fine aggregate is replaced by Bottom ash. The matrix is of 5%,

6%,7% with three different proportions of bottom ash- 1%, 2%, 3%.

MIX PROPORTION

The primary variables in the mix proportioning are fiber content and matrix composition. The fiber volume fraction is

commonly controlled by the placement technique and the fiber geometry. The recommended water-cement ratio for the

slurry (matrix) is 0.4 or less. As per the definition SIFCON is a self-compacted concrete, we need to improve the

workability of concrete. Super plasticizers (SP) can be used, if necessary, to improve the flow ability of the slurry,

which should be liquid enough to flow through the dense fiber bed without leaving honeycombs. Viscosity modifying

agent (VMA) can be used. Only fine sand should be used. Very fine sand of less than 0.5 mm in size is reported to use

in preparing mortar SIFCON.

VI. EXPERIMENTAL RESULTS

All the mechanical and durability properties were tested on different specimen. The compression test was carried out on

specimens cubical. The cube specimens are of the size 150 x 150 x 150 mm. The splitting tension test was performed

on cylindrical specimen of size 150 mmdiameter and 300mm length. The test consists of applying compressive line

load along the opposite generator of a concrete placed with its axis horizontal between the platen of a compression

testing machine.The flexural strength is determined by testing standard test specimen (prism) of size 500 mm x 100

mm x 100 mm under symmetrical two point loading according to IS : 516 – 1959.

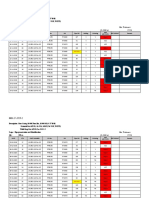

Sr. Compressive strength in MPa Compressive strength in MPa

No (2 % fibres) (3 % fibres)

Age of concrete in 7 days 28 days 56 days 7 days 28 days 56 days

days

1. C.S 36.72 53.12 56.09 42.25 56.28 59.05

2. FLY ASH (5%) 37.05 52.00 56.67 43.69 55.10 60.13

3. FLY ASH(10%) 39.12 51.67 58.00 45.36 54.67 62.00

4. FLY ASH (15%) 45.05 50.00 59.33 49.10 52.00 65.19

Table No. 1. Compression test result on cube specimen for 7, 28, 56 days with replacement of cement with Fly Ash 5%, 10%, 15%

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0505278 8571

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 5, May 2016

Figure No. 1. Compression test of 2% fibres with comparison of C.S & F.A (5%, 10%, and 15%)

Sr. Split Tensile strength in MPa Split Tensile strength in MPa

No (2 % fibres) (3 % fibres)

Age of concrete in 7 days 28 days 56 days 7 days 28 days 56 days

days

1. C.S 5.76 7.68 8.5 8.00 9.76 12.76

2. FLY ASH (5%) 6.05 8.050 9.10 8.515 10.113 13.00

3. FLY ASH (10%) 6.910 8.510 10.133 9.210 12.01 14.85

4. FLY ASH (15%) 8.610 11.67 13.67 12.85 14.133 15.833

Table No. 2. Split Tensile test result on cylindrical specimen for 7, 28, 56 dayswith replacementof cement with Fly Ash 5%, 10%, 15%

Figure No. 2. Split Tensile test of 2% fibres with comparison of C.S & F.A (5%, 10%, and 15%)

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0505278 8572

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 5, May 2016

Sr. Flexural testing strength in MPa Flexural testing strength in MPa

No (2 % fibres) (3 % fibres)

1 Age of concrete in 28 DAYS 28 DAYS

Days

2 C.S 13.75 16.5

3 FLY ASH (5%) 13.55 16.97

4 FLYASH (10%) 16.00 19.67

5 FLY ASH (15%) 19.33 24.67

Table No. 3. Flexural Testing test resultfor 28 days with replacement of cement with Fly Ash 5%, 10%, 15%

Figure No. 3. Flexural Test of 3% fibre with comparison of C.S & F.A (5%, 10%, 15%)

VII. CONCLUSION

In this experimental study various properties of SIFCON such as Compression test, Split tensile test, flexural test,

Impact test, water permeability/Sulphate attack test, and Ultra sonic pulse velocity test have been carried out. Hooked-

end steel fibers with two different volume percentages were considered for one type of concrete.

The following conclusions were drawn out based on results obtained from this study:

a) In Compression test, SIFCON specimens of Fly ash (5%, 10%, and 15%) with 2 % and 3 % steel fiber showed

higher compressive strength in Comparison with controlled SIFCON specimen at the age of 56 days

curing.Similarly, when fine aggregate was replaced with bottom ash (10% 20% 30%) with 2% and 3% fibers,

compressive strength was decreased with respect t controlled SIFCON specimen at the age of 28 days curing.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0505278 8573

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 5, May 2016

b) In Split tensile test, SIFCON specimen of Fly ash (5%, 10%, and 15%) with 2% & 3% steel fibre showed

higher tensile strength in Comparison with Controlled SIFCON specimen at 28 & 56 days curing. It showed

tremendous increase in tensile strength for 3% steel fiber, with 10% fly ash replacement with cement. It might

be because of good bonding and less pores. The specimens added with fly ash with 2% steel fibres have

significantly improved results over the compressive strength for the specimens alsoSimilarly, when fine

aggregate was replaced with bottom ash tensile strength was increased due to the effect of steel fibers.

c) In Flexural test, SIFCON specimens of Fly ash (5%, 10%, and 15%) with 2 % and 3 % steel fiber showed

higher flexural strength in Comparison with Controlled SIFCON specimen. Similarly when Fine aggregates

were replaced with bottom ash with 2% steel fibers and 3% steel fibers showed significant improved results

over controlled SIFCON specimen under 28 days curing.

REFERENCES

[1] S.Balaji and G.S. Thirugnanam, “Flexural Strengtheningof reinforced concrete beams using precast SIFCONlaminates” Journal of structural

Engineering, Vol.40, Issue No. 3, pp.262-267, 2013.

[2] Lankard, D.R., “Preparation, Applications: Slurry Infiltrated FiberConcrete (SIFCON)”, Concrete International, Vol.6,Issue No.12, pp. 44-47,

1984.

[3] Naaman, A.E., Otter, D., and Najm, H., “Elastic Modulus of SIFCON in Tension and Compression”, ACI Materials Journal, Vol. 88, Issue

No.6, pp. 603-612, 1991.

[4] Naaman, A.E., and Baccouche, M.R., “Shear Response of Dowel Reinforced SIFCON”, ACI Structural Journal, Vol. 92, Issue No.5, pp. 587-

569, 1995.

[5] Naaman, A.E., Reinhardt, H.W., and Fritz, C., “Reinforced Concrete Beams with a SIFCON Matrix”, ACI Structural Journal, Vol. 89, Issue

No.1, pp. 79-88, 1992.

[6] Naaman, A.E., and Homrich, J.R., “Tensile Stress-Strain Properties of SIFCON”, ACI Materials Journal, Vol. 86, Issue No.3, pp. 244-251,

1989.

[7] Hamza, A.M., and Naaman, A.E., “Bond Characteristics of Deformed Reinforcing Steel Bars Embedded in SIFCON”, ACI Materials Journal,

Vol. 93, Issue No.6, pp. 578-588, 1996.

[8] Lankard, D.R., “Factors Affecting the Selection and Performance of Steel Fiber Reinforced Monolithic Refractories”, American Ceramic

Society Bulletin, Vol. 63, Issue No.7, pp. 919-925, 1984.

[9] Zhang, J., and Li, V.C., “Influences of Fibers on Drying Shrinkage of Fiber-reinfocedCementituous Composites”, ASCE Journal of Engineering

Mechanics, Vol. 127, Issue No. 1, pp. 37-44, 2001.

[10] V. S. Parameswaran, T. S. Krishnamoorthy, and K. Balasubramaman.“Behaviour of High Volume Fibre Cement Mortar in Flexure” ,Cement

and Concrete Composites, Vol. 12, pp. 293-301, 1990.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0505278 8574

You might also like

- Compressive Strength of WoodDocument6 pagesCompressive Strength of Woodatreu747100% (2)

- Design With Plastics. Focus - Injection MoldingDocument72 pagesDesign With Plastics. Focus - Injection MoldingPrithviraj Daga100% (6)

- Portland CementDocument46 pagesPortland Cementni putu diah untariningsihNo ratings yet

- Influence of Superplasticizers (Conplast Conplast SP 430) On Fresh Properties of Self-Compacting Concrete An Experimental InvestigationDocument6 pagesInfluence of Superplasticizers (Conplast Conplast SP 430) On Fresh Properties of Self-Compacting Concrete An Experimental InvestigationIJRASETPublicationsNo ratings yet

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- Role of Gypsum in Cement GrindingDocument13 pagesRole of Gypsum in Cement GrindingMinh Tien LeNo ratings yet

- Advantages and applications of steel fibre reinforced concrete (SFRCDocument213 pagesAdvantages and applications of steel fibre reinforced concrete (SFRChamsanram100% (3)

- IJRPR1049Document8 pagesIJRPR1049MUJEEB RAHMAN KNo ratings yet

- To Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesDocument6 pagesTo Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesIJRASETPublicationsNo ratings yet

- Pro118. Effect of Different Types of Steel Fibers OnDocument10 pagesPro118. Effect of Different Types of Steel Fibers OnMritunjay YadavNo ratings yet

- Sifcon Seminar ReportDocument27 pagesSifcon Seminar Reportshivukumar75% (4)

- Triple Blending Effect of Fly Ash, Silica Fume and Steel Fibers On Performance of High Strength ConcreteDocument8 pagesTriple Blending Effect of Fly Ash, Silica Fume and Steel Fibers On Performance of High Strength ConcreteIJRASETPublicationsNo ratings yet

- Effect of Manufactured Sand With Steel Fibre and Polypropylene On Strength Properties of ConcreteDocument12 pagesEffect of Manufactured Sand With Steel Fibre and Polypropylene On Strength Properties of ConcreteIJRASETPublicationsNo ratings yet

- 1 s2.0 S2352012421002605 MainDocument16 pages1 s2.0 S2352012421002605 MainVinkaNo ratings yet

- Comparative Study On Strength and Durability Properties of High Strength Self Compacting Concrete With and Without Steel FibresDocument15 pagesComparative Study On Strength and Durability Properties of High Strength Self Compacting Concrete With and Without Steel FibresIJRASETPublicationsNo ratings yet

- 27 Behaviour of Reinforced Concrete Beams With SIFCON at Various Locations in The BeamDocument6 pages27 Behaviour of Reinforced Concrete Beams With SIFCON at Various Locations in The Beammsheer hasanNo ratings yet

- Performance Optimization of Hybrid Fiber Concrete - Felxural - Compullout - High Temp.Document18 pagesPerformance Optimization of Hybrid Fiber Concrete - Felxural - Compullout - High Temp.Prasanth SekarNo ratings yet

- Sifcon 180Document5 pagesSifcon 180purvanchal instituteNo ratings yet

- Studies On High Performance Concrete Using Mineral AdmixturesDocument7 pagesStudies On High Performance Concrete Using Mineral AdmixturesIJRASETPublicationsNo ratings yet

- Performance of Slurry Infiltrated Fibrous Concrete Sifcon With Silica FumeDocument13 pagesPerformance of Slurry Infiltrated Fibrous Concrete Sifcon With Silica FumeMOHAN KUMARNo ratings yet

- Study The Variation of Properties of Concrete Mix Using Binding Material Portland CementDocument7 pagesStudy The Variation of Properties of Concrete Mix Using Binding Material Portland CementIJRASETPublicationsNo ratings yet

- Ferrado Et Al - Mec Comput 2016 BDocument13 pagesFerrado Et Al - Mec Comput 2016 Bingenauta7282No ratings yet

- Coir Fiber Reinforced Concrete-ReviewDocument6 pagesCoir Fiber Reinforced Concrete-ReviewIJRASETPublicationsNo ratings yet

- Effect of Recycled Coarse Aggregate On Workability and Shear Strength of Fibre Reinforced High Strength ConcreteDocument7 pagesEffect of Recycled Coarse Aggregate On Workability and Shear Strength of Fibre Reinforced High Strength ConcreteTyler WhiteNo ratings yet

- Behaviour of Crimped Steel Fiber in ConcreteDocument11 pagesBehaviour of Crimped Steel Fiber in ConcreteRainakNo ratings yet

- Waste Polyethylene and Tyre Fibres Are Industrial Waste As Well, and by Using Them, We May Slow Down The Deterioration of The EnvironmentDocument5 pagesWaste Polyethylene and Tyre Fibres Are Industrial Waste As Well, and by Using Them, We May Slow Down The Deterioration of The EnvironmentIJRASETPublicationsNo ratings yet

- Flexural Behavior of Self-Compacting Concrete Reinforced With Polypropylene FibersDocument6 pagesFlexural Behavior of Self-Compacting Concrete Reinforced With Polypropylene Fibersshubhamyadav7462No ratings yet

- 88 12 An PDFDocument13 pages88 12 An PDFHAJARA SULTHANANo ratings yet

- Jeas 1216 5411 PDFDocument6 pagesJeas 1216 5411 PDFHAJARA SULTHANANo ratings yet

- Harshad Seminar PPT FRCDocument16 pagesHarshad Seminar PPT FRCHarsh PuseNo ratings yet

- Review On Change The Properties of Concrete by Adding Rice Husk Ash and MetakaolinDocument7 pagesReview On Change The Properties of Concrete by Adding Rice Husk Ash and MetakaolinIJRASETPublicationsNo ratings yet

- Experimental Study On The Steel Fiber Reinforcement ConcreteDocument6 pagesExperimental Study On The Steel Fiber Reinforcement ConcreteIJRASETPublicationsNo ratings yet

- Comparative Study On Composite Stub Column: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument6 pagesComparative Study On Composite Stub Column: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologySyed Abdul RawoofNo ratings yet

- Experimental Investigation On The Ferrocement Slabs With A Sifcon MatrixDocument16 pagesExperimental Investigation On The Ferrocement Slabs With A Sifcon MatrixswathiNo ratings yet

- Effect of Steel Fibers On Strength of ConcreteDocument8 pagesEffect of Steel Fibers On Strength of ConcreteBlack KaiserNo ratings yet

- 91 Effect of Fiber Type On Freeze Thaw Durability of SifconDocument4 pages91 Effect of Fiber Type On Freeze Thaw Durability of SifconMsheer Hasan AliNo ratings yet

- F INALDocument19 pagesF INALBhushan JadhavNo ratings yet

- Assessing Mechanical Properties and Microstructure of Fire-Damaged Engineered Cementitious CompositesDocument8 pagesAssessing Mechanical Properties and Microstructure of Fire-Damaged Engineered Cementitious CompositesLarissa KirchhofNo ratings yet

- Investigate The Potential of Hypo Sludge and Steel Fiber, Which Can Be Partially Mixed Into The ConcreteDocument4 pagesInvestigate The Potential of Hypo Sludge and Steel Fiber, Which Can Be Partially Mixed Into The ConcreteResearch ParkNo ratings yet

- Thesis On Steel Fiber Reinforced ConcreteDocument5 pagesThesis On Steel Fiber Reinforced ConcreteBuyCustomEssayEverett100% (1)

- Effect of Polymeric Admixtures On Self-Compacting ConcreteDocument6 pagesEffect of Polymeric Admixtures On Self-Compacting ConcreteMichael GelongNo ratings yet

- Study The Behavior of Slurry Infiltrated Fibrous CDocument10 pagesStudy The Behavior of Slurry Infiltrated Fibrous CNedi GeremewNo ratings yet

- Pressive Strength and Flexural Behaviour of Foamed Concrete Slab Containing HybridFibresDocument8 pagesPressive Strength and Flexural Behaviour of Foamed Concrete Slab Containing HybridFibresPennarasiNo ratings yet

- Geopolymer Concrete To Reduce The Anthropogenic Greenhouse Gas Emissions Associated With The Concrete and Construction IndustryDocument3 pagesGeopolymer Concrete To Reduce The Anthropogenic Greenhouse Gas Emissions Associated With The Concrete and Construction IndustrylotushNo ratings yet

- Glass Fibre Concrete Strength and Fire PropertiesDocument5 pagesGlass Fibre Concrete Strength and Fire Propertiessushma chandrikaNo ratings yet

- Raghvendrapaper VJITDocument16 pagesRaghvendrapaper VJITKothuri KarunaNo ratings yet

- Literature Review On Carbon Fiber Reinforcement: GeneralDocument7 pagesLiterature Review On Carbon Fiber Reinforcement: GeneralIrfankhan OfficialNo ratings yet

- Ijciet 08 09 109Document10 pagesIjciet 08 09 109Snehal AbhyankarNo ratings yet

- Toughness Study On Fly Ash Based Fiber Reinforced Concrete: Originalresearch Open AccessDocument4 pagesToughness Study On Fly Ash Based Fiber Reinforced Concrete: Originalresearch Open AccessBenjaminLimonDuranNo ratings yet

- Studies On Metakaolin Based Coir Fibre Reinforced ConcreteDocument31 pagesStudies On Metakaolin Based Coir Fibre Reinforced ConcreteIAEME PublicationNo ratings yet

- Flexural Performance of SIFCON Composites at High TemperaturesDocument10 pagesFlexural Performance of SIFCON Composites at High Temperaturesmsheer hasanNo ratings yet

- Slurry Infiltrated Fibrous Concrete (Sifcon) : Research ArticleDocument2 pagesSlurry Infiltrated Fibrous Concrete (Sifcon) : Research ArticleMichael JeevaganNo ratings yet

- 80 Abrasion PDFDocument6 pages80 Abrasion PDFايات علي احمدNo ratings yet

- Research Paper ConcreteDocument8 pagesResearch Paper Concreteijsgpibkf100% (1)

- J Conbuildmat 2018 07 042Document8 pagesJ Conbuildmat 2018 07 042civilstructure.singhbrothersNo ratings yet

- Structural Glass Fiber Reinforced Concrete for Slabs on GroundDocument7 pagesStructural Glass Fiber Reinforced Concrete for Slabs on GroundJayanth RaviNo ratings yet

- Synthetic Fibers For Crack ControlDocument9 pagesSynthetic Fibers For Crack ControlourebooksNo ratings yet

- Rag H Vendra Paper VJ ItDocument16 pagesRag H Vendra Paper VJ ItSumit SahuNo ratings yet

- 1 s2.0 S2214509523009774 MainDocument18 pages1 s2.0 S2214509523009774 Maindileepkumarr538No ratings yet

- 207 - An ExperimentalDocument8 pages207 - An ExperimentalMhanel EdaNo ratings yet

- Flexural Behavior of Hollow RC Beam Using Glass FiberDocument10 pagesFlexural Behavior of Hollow RC Beam Using Glass FiberIJSTENo ratings yet

- Effects of Waste Polypropylene Fibers On The Mechanical Behavior of Fiber Reinforced Concrete An Experimental StudyDocument4 pagesEffects of Waste Polypropylene Fibers On The Mechanical Behavior of Fiber Reinforced Concrete An Experimental StudyEditor IJTSRDNo ratings yet

- Experimental Study On Steel Fiber Reinforced ConcreteDocument7 pagesExperimental Study On Steel Fiber Reinforced ConcreteIJRASETPublicationsNo ratings yet

- Steel Fiber ConcreteDocument16 pagesSteel Fiber ConcreteMagdy MakramNo ratings yet

- 10 1016@j Earscirev 2014 11 016Document73 pages10 1016@j Earscirev 2014 11 016Puspaidi PutraNo ratings yet

- 60 Effect of SIFRCCs With Varying Steel Fiber Volume Fractions On Flexural BehaviorDocument10 pages60 Effect of SIFRCCs With Varying Steel Fiber Volume Fractions On Flexural Behaviormsheer hasanNo ratings yet

- 58 Improvement On SIFCON Performance by Fiber Orientation and High-Volume Mineral AdmixturesDocument9 pages58 Improvement On SIFCON Performance by Fiber Orientation and High-Volume Mineral Admixturesmsheer hasanNo ratings yet

- 63 Preliminary Assessment of The Influence of Accelerated Curing On Concrete QualityDocument10 pages63 Preliminary Assessment of The Influence of Accelerated Curing On Concrete Qualitymsheer hasanNo ratings yet

- 64 The Effectof Accelerated Curing On Compressive StrengthDocument21 pages64 The Effectof Accelerated Curing On Compressive Strengthmsheer hasanNo ratings yet

- 62 Curing Effets On Carbonation of Concrete Using A Phenolphthalein Indicator and Fourier-Transform Infrared SpectrosDocument8 pages62 Curing Effets On Carbonation of Concrete Using A Phenolphthalein Indicator and Fourier-Transform Infrared Spectrosmsheer hasanNo ratings yet

- 59 Experimental Investigation On Protection Methods of Slurry Infiltrated Fiber Concrete in Corrosive EnvironmentsDocument14 pages59 Experimental Investigation On Protection Methods of Slurry Infiltrated Fiber Concrete in Corrosive Environmentsmsheer hasanNo ratings yet

- 9 Effect of Impact Load On SIFCONDocument12 pages9 Effect of Impact Load On SIFCONmsheer hasanNo ratings yet

- 5 Fresh and Some Mechanical Properties of Sifcon Containing Silica FumeDocument8 pages5 Fresh and Some Mechanical Properties of Sifcon Containing Silica Fumemsheer hasanNo ratings yet

- 6 SIFCON Strengthening of Concrete Cylinders in Comparison With Conventional GFRP Confinement MethodDocument16 pages6 SIFCON Strengthening of Concrete Cylinders in Comparison With Conventional GFRP Confinement Methodmsheer hasanNo ratings yet

- 4 The Effect of Different Types of Fiber On Flexure Strength and Fracture Toughness in SIFCONDocument12 pages4 The Effect of Different Types of Fiber On Flexure Strength and Fracture Toughness in SIFCONmsheer hasanNo ratings yet

- 7 Study of Mechanical and Durability Properties of SIFCON by Partial ReplacementDocument7 pages7 Study of Mechanical and Durability Properties of SIFCON by Partial Replacementmsheer hasanNo ratings yet

- 1 s2.0 S0360128509000604 Main PDFDocument37 pages1 s2.0 S0360128509000604 Main PDFNurul AkmamNo ratings yet

- A Constant Dependent Upon Fiber VF The Volume Percent of FibersDocument10 pagesA Constant Dependent Upon Fiber VF The Volume Percent of Fibersmsheer hasanNo ratings yet

- 36 Blast Resistance of Slurry Infiltrated Fibre Concrete With Hybrid Fibre ReinforcementDocument8 pages36 Blast Resistance of Slurry Infiltrated Fibre Concrete With Hybrid Fibre Reinforcementmsheer hasanNo ratings yet

- 8 Behaviour of Slurry Infiltrated Fibre Concrete (SIFCON) Under Triaxial CompressionDocument11 pages8 Behaviour of Slurry Infiltrated Fibre Concrete (SIFCON) Under Triaxial Compressionmsheer hasanNo ratings yet

- Flexural Performance of SIFCON Composites at High TemperaturesDocument10 pagesFlexural Performance of SIFCON Composites at High Temperaturesmsheer hasanNo ratings yet

- 35 Structural Repair of Shear-Deficient Reinforced Concrete Beams Using SIFCONDocument13 pages35 Structural Repair of Shear-Deficient Reinforced Concrete Beams Using SIFCONmsheer hasanNo ratings yet

- 27 Behaviour of Reinforced Concrete Beams With SIFCON at Various Locations in The BeamDocument6 pages27 Behaviour of Reinforced Concrete Beams With SIFCON at Various Locations in The Beammsheer hasanNo ratings yet

- 3 Study On Strength Properties of Sifcon PDFDocument4 pages3 Study On Strength Properties of Sifcon PDFmsheer hasanNo ratings yet

- 34 Behaviour of Restrained Sifcon Two Way Slabs PART 1 FLEXUREDocument23 pages34 Behaviour of Restrained Sifcon Two Way Slabs PART 1 FLEXUREmsheer hasanNo ratings yet

- Shear Strength and Behavior of Ultra-High Performance Fiber Reinforced Concrete (Uhpc) Deep Beams Without Web ReinforcementDocument12 pagesShear Strength and Behavior of Ultra-High Performance Fiber Reinforced Concrete (Uhpc) Deep Beams Without Web Reinforcementmsheer hasanNo ratings yet

- Mechanical Properties and Spalling of High Performance Concrete with Reactive and Waste Powders at Elevated TemperaturesDocument6 pagesMechanical Properties and Spalling of High Performance Concrete with Reactive and Waste Powders at Elevated Temperaturesmsheer hasanNo ratings yet

- Experimental Study of CFRP Confined Low Strength R.C. Columns Under Concentric LoadsDocument10 pagesExperimental Study of CFRP Confined Low Strength R.C. Columns Under Concentric Loadsmsheer hasanNo ratings yet

- Flexural Behavior of Reinforced Concrete Beams Made With Ordinary and High Strength Concretes Effect of Interfacial Roughness Between Old and New ConcretesDocument10 pagesFlexural Behavior of Reinforced Concrete Beams Made With Ordinary and High Strength Concretes Effect of Interfacial Roughness Between Old and New Concretesmsheer hasanNo ratings yet

- 6 SIFCON Strengthening of Concrete Cylinders in Comparison With Conventional GFRP Confinement MethodDocument16 pages6 SIFCON Strengthening of Concrete Cylinders in Comparison With Conventional GFRP Confinement Methodmsheer hasanNo ratings yet

- Steel PDFDocument5 pagesSteel PDFSamanAtrianNo ratings yet

- 5 Fresh and Some Mechanical Properties of Sifcon Containing Silica FumeDocument8 pages5 Fresh and Some Mechanical Properties of Sifcon Containing Silica Fumemsheer hasanNo ratings yet

- 4 The Effect of Different Types of Fiber On Flexure Strength and Fracture Toughness in SIFCONDocument12 pages4 The Effect of Different Types of Fiber On Flexure Strength and Fracture Toughness in SIFCONmsheer hasanNo ratings yet

- OS&Y Gate Valves - Flanged Ends: Schematic DrawingDocument1 pageOS&Y Gate Valves - Flanged Ends: Schematic Drawingbhima irabattiNo ratings yet

- Catalog Leoni CableDocument2 pagesCatalog Leoni CablesubodhNo ratings yet

- Tds - Tile Adhesive 711v1910Document2 pagesTds - Tile Adhesive 711v1910Susana KhoNo ratings yet

- Incoterms 2020 Transport Obligations Cost RisksDocument1 pageIncoterms 2020 Transport Obligations Cost Riskskuuku asmahNo ratings yet

- TDS BRIDGEDECK Waterproofing Agent 4pg 04-01-2023Document4 pagesTDS BRIDGEDECK Waterproofing Agent 4pg 04-01-2023q2jkbj4ptfNo ratings yet

- 2019 - Novel Gas Sensing Platform Based On A Stretchable Laser-Induced Graphene Pattern With Self-Heating CapabilitiesDocument15 pages2019 - Novel Gas Sensing Platform Based On A Stretchable Laser-Induced Graphene Pattern With Self-Heating CapabilitiesMARIA FERNANDA HERNANDEZ RODRIGUEZNo ratings yet

- 251-260 GregurekDocument10 pages251-260 GregurekAlexander SledzNo ratings yet

- ASME Symposium Proceedings on Creep Deformation of T/P92 SteelsDocument9 pagesASME Symposium Proceedings on Creep Deformation of T/P92 SteelsAntonioNo ratings yet

- Shape Memory Alloys (Smas) Are Family of Smart Materials. They HaveDocument21 pagesShape Memory Alloys (Smas) Are Family of Smart Materials. They HaveSubir DebNo ratings yet

- FAQ: What's The Difference Between Canvas Micarta and Linen Micarta? How Do They Compare To G-10?Document1 pageFAQ: What's The Difference Between Canvas Micarta and Linen Micarta? How Do They Compare To G-10?kayraNo ratings yet

- Tufnol Whale SRBF Material DataDocument3 pagesTufnol Whale SRBF Material DataRay FaiersNo ratings yet

- Waterproofing Comparison Table: Basf SikaDocument2 pagesWaterproofing Comparison Table: Basf SikaKhin Sandi KoNo ratings yet

- Nadeem GEO Tech 3rdDocument30 pagesNadeem GEO Tech 3rdYoung YouTuber (Naduu)No ratings yet

- Duct Tape: Technical Data June, 2005Document2 pagesDuct Tape: Technical Data June, 2005ismail mijasNo ratings yet

- Sacrificial Tooling Material: Mechanical Properties Test Method English MetricDocument2 pagesSacrificial Tooling Material: Mechanical Properties Test Method English MetrickaledioskoppNo ratings yet

- 7th Sem BE (MET) Elective ListDocument8 pages7th Sem BE (MET) Elective ListSumanthDattuVedaNo ratings yet

- Engr: Temoor Abbas Larik: QUCEST Larkana Campus Mechanical Engineering DepartmentDocument42 pagesEngr: Temoor Abbas Larik: QUCEST Larkana Campus Mechanical Engineering DepartmentTemoor AbbasNo ratings yet

- Paper On Curing Methods of GPCDocument17 pagesPaper On Curing Methods of GPCKUMAR RAJUNo ratings yet

- Epikote 828 Tech DataDocument2 pagesEpikote 828 Tech DataLê TiếnNo ratings yet

- Pipe Preservation Internal Job 2020Document169 pagesPipe Preservation Internal Job 2020Tri HeriNo ratings yet

- Mechanics of Composite Materials Course OverviewDocument119 pagesMechanics of Composite Materials Course OverviewArslan AhmedNo ratings yet

- Glenium - Ace - 6 - Suretec - v4Document2 pagesGlenium - Ace - 6 - Suretec - v4Kuldeep ChakerwartiNo ratings yet

- Sheel PilesDocument15 pagesSheel Pilesعصام ايادNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- Yield Criteria PDFDocument11 pagesYield Criteria PDFTarza Bayez100% (1)

- Nema Installation Guideline For Non Metallic Sheathed CableDocument23 pagesNema Installation Guideline For Non Metallic Sheathed Cablejun cortesNo ratings yet