Professional Documents

Culture Documents

Cutthroat Flume: User's Manual

Uploaded by

Phạm LinhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cutthroat Flume: User's Manual

Uploaded by

Phạm LinhCopyright:

Available Formats

CUTTHROAT

FLUME

User’s Manual

i Cutthroat Flume User’s Manual

TABLE OF

CONTENTS

Introduction to the Cutthroat Flume ..................................................... 1

Development ................................................................................ 1

Function ...................................................................................... 2

Design ........................................................................................ 3

Standards .................................................................................... 4

Accuracy ..................................................................................... 4

Dimensions .................................................................................. 5

Dimensional Tolerances ................................................................... 5

Points of Measurement .................................................................... 7

Flow Equations .............................................................................. 7

Submerged Flow............................................................................ 9

Submergence Transition ................................................................... 9

Where to Install a Cutthroat Flume .................................................... 10

Upstream of the Flume .................................................................. 10

Flume Location ............................................................................ 11

Downstream of the Flume ............................................................... 11

How to Install a Cutthroat Flume ....................................................... 12

Dimensional Bracing ..................................................................... 13

Connection Joints ........................................................................ 14

How to Maintain a Cutthroat Flume ................................................... 14

Channel Inspection ....................................................................... 14

Flow Inspection ........................................................................... 15

Flume Inspection ......................................................................... 15

INTRODUCTION TO THE CUTTHROAT FLUME

In the 1960’s researchers at the Utah Water Research Laboratory at Utah State

University began investigations into what would become the Cutthroat flume. The goal

of the researchers was to develop a flume that overcame the limitations of the Parshall

flume in flat gradient applications.

Although originally developed to measure irrigation flow, Cutthroat flumes are now

used to for:

• Cooling water discharge

• Dam seepage

• Industrial effluent

• Irrigation / water rights

• Mine discharge / dewatering

• Sanitary sewage (piped and treatment plant)

• Spring discharge

• Storm water

In addition to these flow measurement applications, Cutthroat flume are frequently

used in wastewater treatment plants for proportional flow splitting.

DEVELOPMENT

Prior to the development of the Cutthroat flume, flow on flat gradients presented a

problem. The drop though the Parshall flume mean that the flume had to either be

elevated above the floor of the channel – creating upstream ponding and overtopping

issues – or using that the flume had to be used in a submerged manner (creating

measurement and accuracy issues).

Funded by the U.S. Department of the Interior, Office of Water Resources Research,

Drs. Skogerboe, Hyatt, Anderson, and Eggleston at the Utah Water Research

Laboratory extensively researched issues related to the problem:

1 Cutthroat Flume User’s Manual

• Flow conditions in flat-bodied Trapezoidal flumes (Robinson et al 1960), (Hyatt

1965)

• Inlet convergence ratios (Ackers and Harrison 1963)

• Submerged flow in open channel flow measurement structures (Skogerboe,

Hyatt, Eggleston 1967)

• Flume discharge in flat-bodied Trapezoidal flumes (Hyatt 1965)

Ultimately this research lead to the development of two different styles of Cutthroat

flumes: Rectangular (with flat, vertical sidewalls like a Parshall flume) and Trapezoidal

(with outward sloping sidewalls like a Trapezoidal flume). Of the two, the Rectangular

Cutthroat flume is most commonly used.

Rectangular Cutthroat flumes are available in four different lengths (18, 36, 54, and

108-inches L) and four throat widths for each length. Trapezoidal Cutthroat flumes

come in three different throat widths.

Rectangular Cutthroat flumes have a distinct advantage over similar flumes in that, for a

given length, intermediate throat widths can be developed without the need to

laboratory or field rate the new flume size.

Trapezoidal Cutthroat flumes have one given length and three different throat widths

(V, 6-inch, and 12-inch).

For the purposes of this User’s Manual, the discussion below will be for Rectangular

Cutthroat flumes unless otherwise indicated.

FUNCTION

Sub-critical flumes like the Cutthroat flume operate by accelerating slow, sub-critical

flow (Fr<1) to a supercritical state (Fr>1) by restricting the flow as it passes through the

flume. The Cutthroat flume accomplishes this restriction by contracting the side walls

of the – while keeping a constant floor elevation.

2 Cutthroat Flume User’s Manual

DESIGN

When viewed from above, the Cutthroat flume has an hourglass shape.

As flow enters the flume it is accelerated in the short, uniformly converging (inlet)

section. Upon reaching the throat – the narrowest portion of the flume – the flow

immediately expands into the diverging (outlet) section. Unlike many other flumes, the

Cutthroat flume lacks an extended throat – hence the name “Cutthroat”.

The converging (inlet) section of a Cutthroat flume is 1/3 the length of the flume, with

the flat sidewalls contracting at a uniform 3:1 ratio.

The diverging (outlet) section of a Cutthroat flume is 2/3 the length of the flume, with

the flat sidewalls expanding at a uniform 6:1 ratio.

The floor of a Cutthroat flume is flat from inlet to outlet, making the flume well suited

for low gradient installations.

3 Cutthroat Flume User’s Manual

This layout is the same for both Rectangular and Trapezoidal Cutthroat flumes.

STANDARDS

Like the Trapezoidal flume, the dimensions for the Cutthroat flume are not subject to a

national standard, but are instead presented in various academic journals.

• Skogerboe, G., Bennett, R., Walker, W., Generalized Discharge Relations for

Cutthroat Flumes, Journal of the Irrigation and Drainage Division, Vol. 98, No.

IR4, December 1972

• Bennett, R., Cutthroat Flume Discharge Relations, Water Management Technical

Paper No. 16, Colorado State University, AER71-72RSB6, March 1972

ACCURACY

The Cutthroat flume was developed to provide accurate flow measurement with a

precision of +/-3% under free-flow conditions

This accuracy is to be expected when the ratio of flow depth (at the point of

measurement) to flume length.

4 Cutthroat Flume User’s Manual

For greatest accuracy, the ratio of flow depth to flume length should be 0.1 and 0.4.

Above 0.4 and higher approach velocities and rapid changes in the water surface

introduce inaccuracies.

DIMENSIONS

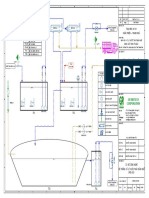

The master dimensions for Rectangular Cutthroat flumes are found in Figure 1.

DIMENSIONAL TOLERANCES

In general, the dimensions of a Cutthroat flume must be within +/-2% of nominal.

Wider than that and the equation for the actual dimensions should be developed

(assuming the deviations are constant and the throat width is between two standard

sizes).

5 Cutthroat Flume User’s Manual

Figure 1 – Rectangular Cutthroat Flume Master Dimensions

6 Cutthroat Flume User’s Manual

POINTS OF MEASUREMENT

The primary, free-flow, point of measurement, Ha, is located in the converging section

of the flume a distance of 2L/9 upstream of the throat (L = flume length).

The secondary point of measurement, Hb, used to determine the submergence of a

Cutthroat flume is located in near the outlet of the flume, 5L/9 downstream of the

throat.

As the floor of the Cutthroat flume is flat, there is no need to adjust the Hb elevation

when calculating the submergence ratio.

FLOW EQUATIONS

For free-flow conditions, the level-to-flow equation for the Cutthroat flume can be

expressed as:

Equation 1 – Cutthroat Flume Free-Flow Equation

A unique advantage of the Cutthroat flume over other short-throated flumes is the

ability to develop flow equations for intermediate throat widths. So long as the flume

is of a standard length and converges / diverges as the stand ratios, the rating can be

developed without the need for laboratory investigation.

7 Cutthroat Flume User’s Manual

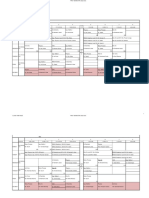

Size C (cfs) C (m3/s) N

18-inch x 1-inch 0.494 1479.9 2.15

18-inch x 2-inch 0.947 344.8 2.15

18-inch x 4-inch 1.975 719.2 2.15

18-inch x 8-inch 4.030 1,467 2.15

36-inch x 2-inch 0.719 181.2 1.84

36-inch x 4-inch 1.459 367.6 1.84

36-inch x 8-inch 2.970 748.3 1.84

36-inch x 16-inch 6.040 1,522 1.84

54-inch x 3-inch 0.96 209.7 1.72

54-inch x 6-inch 1.96 428.2 1.72

54-inch x 12-inch 3.980 869.5 1.72

54-inch x 24-inch 8.01 1,750 1.72

108-inch x 12-inch 3.50 632.2 1.56

108-inch x 24-inch 7.11 1,284 1.56

108-inch x 48-inch 14.49 2,618 1.56

108-inch x 72-inch 22.0 3,974 1.56

Table 1 – Rectangular Cutthroat Flume Free-Flow Discharge Values

8 Cutthroat Flume User’s Manual

SUBMERGED FLOW

As a Cutthroat flume becomes submerged – where downstream conditions reduce the

flow out of the flume – corrections must be made to the flow equation.

In order to determine when these corrections should be made (and the degree to

which the flume is submerged), the submergence ratio must be calculated.

The submergence ratio is the ratio of the downstream depth at the secondary point of

measurement, Hb, to the depth at the primary point of measurement, Ha.

Equation 2 – Submergence Ratio Equation

SUBMERGENCE TRANSITION

The transition from free, unrestricted flow to submerged to one of backwater / slowed

velocity discharge is known as the submergence transition (St). For Cutthroat flumes,

as the flume gets large, so does the submergence transition.

18-inches L 60%

36-inches L 65%

54-inches L 70%

108-inches L 80%

Table 2 – Submergence Transitions (St) Values for Rectangular Cutthroat Flumes

Above the submergence transitions for a given flume’s size, the flow must be corrected

for the effects of submergence.

9 Cutthroat Flume User’s Manual

WHERE TO INSTALL A CUTTHROAT FLUME

When selecting a site in which to install a Cutthroat flume, there are several points to

consider:

UPSTREAM OF THE FLUME

• Flow entering a Cutthroat flume MUST be sub-critical.

• The Froude number (Fr) for flow entering a flume should not exceed 0.5 and

should never exceed 0.99.

o Surface turbulence may be encountered for Froude numbers above 0.5.

o For a flume to accurately measure flow, that flow must be sub-critical

(Fr<0.99).

o If the approaching flow is critical (Fr = 1.0) or supercritical (Fr > 1.0), then

a hydraulic jump must be formed at least 30 times the maximum

anticipated head upstream of the entrance to the flume.

• The flow entering the flume should be smooth, tranquil, and well distributed

across the channel.

o ASTM D1941 indicates that 10 to 20 times the throat width will usually

meet the necessary inlet conditions.

• If the flow is super-critical approaching the flume a hydraulic jump must be

formed well upstream of the flume or upstream energy absorbers and

tranquilizing racks must be used).

• The approaching channel should be straight so that the velocity profile is

uniform. Surging, turbulent, or unbalanced flows must be conditioned before

the flow enters the flume.

• Any bends, dips, elbows, or flow junctions upstream of the flume must be

sufficiently far upstream so that the flow has is well distributed and non-

turbulent.

• While corrections can be made for improper installations or flume settlement,

they should be avoided where at all possible.

• Cutthroat flumes have been successfully used in applications where the flow

rises up a uniform vertical column and then enters the flume.

• Where the channel is wider than the inlet of the flume, wing walls should be

formed to smoothly direct the flow into the flume. The inlet wing walls should

be of a constant radius and should end tangent to the inlet walls of the flume.

10 Cutthroat Flume User’s Manual

• When connecting to inlet piping, observations have shown that the pipe should

be straight and without bends for at least 15 pipe diameters.

• The upstream channel should be clear of vegetative growth.

• Open channel (non-full pipe) flow must be present under all flow conditions.

FLUME LOCATION

• Cutthroat flumes must set so that the floor of the flume is level from front-to-

back and from side-to-side.

• The shorter converging section of the flume is set upstream.

• When Cutthroat flumes are installed in earthen channels and furrows, care

should be taken to ensure that a stable bottom elevation is present and that the

elevation does not change during dry / wet seasons or low-flow periods.

• The flume must be centered in the flow stream.

• Where a Parshall flume must be set above the floor of a channel, a 1:4 (rise:run)

slope should be formed into the flume. Slopes greater than this should be

avoided as they can cause turbulence as the flow separates at the junction of the

ramp and the inlet of the flume.

• All of the flow must go through the flume – there should be no bypass.

DOWNSTREAM OF THE FLUME

• For a Cutthroat flume to operate under free-flow conditions, the downstream

channel must be of a sufficient size / configuration so that flow does not back up

into the flume – slowing discharge out of the flume.

• When flow out of the Cutthroat flume is returning to a channel or pipe, the EPA

recommends that the channel be straight and unobstructed for 5-20 throat

widths – although flow spilling freely off the end of the flume can eliminate this

requirement.

• To transition the flow out of a Cutthroat flume, wing walls should be used.

These walls can be flat or perpendicular to the flume (to save space or money)

or they can extend from the flume’s discharge at some angle or radius sufficient

to transition the flow as desired. Transitions to earthen or natural channels

should be as gradual as practical to minimize downstream scour.

• The downstream channel should be armored (riprap) or otherwise protected so

that scour does not occur.

• The downstream channel must be clear of vegetative growth or the collection of

debris so that flow does not back up in to the flume.

11 Cutthroat Flume User’s Manual

HOW TO INSTALL A CUTTHROAT FLUME

Once a site has been selected, the flume must then be installed correctly:

• The flume should be set so that it is centered in the flow stream.

• The floor of the flume should be set high enough so that the flume does not

operate under submerged flow conditions.

• The outlet of the flume should be set at or above (ideally) the invert of the outlet

channel / pipe to help transition solids out of the flume.

• The shorter section of the flume must be set upstream.

• The floor must be level from front-to-back and from side-to-side (using a level

on the floor - not the top - of the flume)

• The flume must be braced internally (plywood and lumber are typically used)

during installation to ensure that distortion does not occur.

• The flume must not float out of its intended final position during installation.

12 Cutthroat Flume User’s Manual

DIMENSIONAL BRACING

Most Cutthroat flumes ship with dimensional bracing (angle or tube) at the top of the

flume. The bracing should be left on the flume until the installation has been

completed.

If the flume is set in concrete, the bracing may be removed once the installation has

been completed.

For installations where the flume is free-standing or otherwise not set in concrete, the

bracing should be left in place.

If the bracing is removed, verify the dimensional accuracy of the flume after the

removal.

13 Cutthroat Flume User’s Manual

CONNECTION JOINTS

Cutthroat flumes supplied with bulkheads, or transition sections must remain sealed

between the joints.

While these joints may be sealed initially at the factory, a final visual inspection of all

joints should be done before installation.

Where required, apply one or two continuous beads of silicone on all seating surfaces

before proceeding with the installation.

HOW TO MAINTAIN A CUTTHROAT FLUME

For a Cutthroat flume to accurately measure flow, it must be periodically inspected and

maintained. This inspection should be done six (6) months after installation and each

following year.

The inspection should include the channel in which the flume is installed, the flow

entering / exiting the flume, and the flume itself.

CHANNEL INSPECTION

• The upstream channel banks should be clear of vegetation or debris that could

affect the flow profile entering the flume (upstream) or restrict flow out of the

flume (downstream).

• Inspect the upstream channel to make sure that flow is not bypassing the flume.

• Inspect the downstream channel to make sure that scouring is not occurring.

• Any hydraulic jump should be at least 30 times the maximum head (Hmax)

upstream of the flume.

14 Cutthroat Flume User’s Manual

FLOW INSPECTION

• Flow entering the flume should be tranquil and well distributed.

• Turbulence, poor velocity profile, or surging should not be present.

• The Froude (Fr) number should, ideally, be 0.5.

• As the Froude number increases so does surface turbulence.

• Flumes accelerate sub-critical flow (Fr < 1) to a supercritical state (Fr 1>) .

• Flumes experiencing flows greater than unit (Fr = 1) will not accurately

measure flow.

FLUME INSPECTION

• Flumes must be level from front-to-back and from side-to-side.

• Earthen installations are particularly susceptible to settling due to wet / dry

and freeze / thaw cycles.

• Flow surfaces are to be kept clean of surface buildup or algal

growth. Scrubbing or a mild detergent can be used.

• Galvanized flumes should be checked for corrosion.

• Any corrosion should be removed and then cold galvanization applied to the

area.

15 Cutthroat Flume User’s Manual

You might also like

- AIR BLOWERS Calculation-of-Air-Pipe-SizeDocument7 pagesAIR BLOWERS Calculation-of-Air-Pipe-SizeEngFaisal Alrai100% (3)

- AQA Physics: 5 Optics Exam-Style Mark SchemeDocument4 pagesAQA Physics: 5 Optics Exam-Style Mark SchemeAdrian Talukder HossainNo ratings yet

- Prevent Stuck Pipe with Proper Hole CleaningDocument23 pagesPrevent Stuck Pipe with Proper Hole CleaningddiazveNo ratings yet

- Montana (Short Parshall) Flume Users ManualDocument14 pagesMontana (Short Parshall) Flume Users ManualJabulani2010No ratings yet

- Pipeline ManifoldsDocument9 pagesPipeline ManifoldsElendu Emmanuel ChigozieNo ratings yet

- WeirsDocument11 pagesWeirsMansoob BukhariNo ratings yet

- Weirs for Measuring Open-Channel FlowDocument7 pagesWeirs for Measuring Open-Channel FlowthakurrmcplNo ratings yet

- ENGINEERING Estimating WaterFlowratesDocument4 pagesENGINEERING Estimating WaterFlowratesmohdnazirNo ratings yet

- Turf Irrigation DesignDocument7 pagesTurf Irrigation DesignfarhanNo ratings yet

- Turf Irrigation DesignDocument7 pagesTurf Irrigation DesignSamiYousifNo ratings yet

- Well Logging+ CaliperDocument11 pagesWell Logging+ Caliperginozky100% (1)

- How to Select and Design Efficient Bulk Solids FeedersDocument16 pagesHow to Select and Design Efficient Bulk Solids FeedersKalyani GangulianNo ratings yet

- W-3-4-Bar Rack-GC-Design-NML - 2023-10-21T104508.076Document56 pagesW-3-4-Bar Rack-GC-Design-NML - 2023-10-21T104508.076SALMANNo ratings yet

- Design Efficient FeedersDocument0 pagesDesign Efficient FeedersRajaram JayaramanNo ratings yet

- Tappi 0502-17 Papermaker FormulaDocument19 pagesTappi 0502-17 Papermaker FormulaMulyadi Moel86% (21)

- Venturi ReportDocument8 pagesVenturi Reportstephen kangereNo ratings yet

- Part 6 Mesin FluidaDocument19 pagesPart 6 Mesin FluidaARFAI020797No ratings yet

- Conversion Chart Manuals and Instructions in PDF Format Glossary Recommended Books Web LinksDocument12 pagesConversion Chart Manuals and Instructions in PDF Format Glossary Recommended Books Web LinksAziz Khan KakarNo ratings yet

- Applicational Design and Sizing of Decanter Centrifuges - American ...Document10 pagesApplicational Design and Sizing of Decanter Centrifuges - American ...Thang VuNo ratings yet

- Review: Turbine and Related Flowmeters: !. Industrial PracticeDocument15 pagesReview: Turbine and Related Flowmeters: !. Industrial PracticemohmehrNo ratings yet

- Flow Measurements New Mech (11407)Document13 pagesFlow Measurements New Mech (11407)Abood AshrafNo ratings yet

- Compressors Course-Chapter 4 PDFDocument11 pagesCompressors Course-Chapter 4 PDFMohamed TallyNo ratings yet

- Estimating Water Flow Rates EC1369 1994 PDFDocument0 pagesEstimating Water Flow Rates EC1369 1994 PDFwifiwaves3750No ratings yet

- CentrifugesDocument4 pagesCentrifugesdchyNo ratings yet

- P T T: S F E: HE RO Aper Echnique Haping The Uture of NdodonticsDocument4 pagesP T T: S F E: HE RO Aper Echnique Haping The Uture of NdodonticsFoysal SirazeeNo ratings yet

- Trapezoidal Flume Users ManualDocument16 pagesTrapezoidal Flume Users ManualAdriane Kelly CagampanNo ratings yet

- Centrifuges, Sediment IngDocument6 pagesCentrifuges, Sediment IngLatif Hasan Çite100% (2)

- Parshall FlumesDocument6 pagesParshall FlumesSubhadip NandiNo ratings yet

- Astm - Thin Plate Weirs PDFDocument6 pagesAstm - Thin Plate Weirs PDFUSBR WaterNo ratings yet

- Pressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsDocument9 pagesPressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsJoseph Alexander BorgNo ratings yet

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- BN-EG-UE109 Guide For Vessel SizingDocument29 pagesBN-EG-UE109 Guide For Vessel SizingSachin ChavanNo ratings yet

- Vessel DesignDocument43 pagesVessel Designhomiez99No ratings yet

- Open Drain Separator SizingDocument23 pagesOpen Drain Separator SizingSuchart TarasapNo ratings yet

- Hydro Design & ConstructionDocument81 pagesHydro Design & ConstructionSamNo ratings yet

- BN-EG-UE109 Guide For Vessel SizingDocument28 pagesBN-EG-UE109 Guide For Vessel Sizingeulalio_méndezNo ratings yet

- How To Select A FlowmeterDocument8 pagesHow To Select A FlowmeterDave SchmittNo ratings yet

- Broad Crested Weir at OauDocument10 pagesBroad Crested Weir at OauEmmanuelNo ratings yet

- Flow Measurement in Pipes: BIE 5300/6300 Lectures 153 Gary P. MerkleyDocument8 pagesFlow Measurement in Pipes: BIE 5300/6300 Lectures 153 Gary P. MerkleyNAVASNo ratings yet

- Measure Propeller Taper SizesDocument2 pagesMeasure Propeller Taper SizesYoucefGMANo ratings yet

- Lecture 310 - Fluid Flow MetersDocument41 pagesLecture 310 - Fluid Flow Metersanonim 1178No ratings yet

- Measuring Instrument For Drilling MudDocument12 pagesMeasuring Instrument For Drilling Mudrony asmNo ratings yet

- 120719Document6 pages120719Jhuna Mae SubalaNo ratings yet

- Lab 3-2 - Venturi and Splits F20Document2 pagesLab 3-2 - Venturi and Splits F20hamzaNo ratings yet

- ApicalOneThird May2002Document10 pagesApicalOneThird May2002Mihaela TuculinaNo ratings yet

- Analysis of Pleated Air Filters Using CFDDocument100 pagesAnalysis of Pleated Air Filters Using CFDJorge Cuadros BlasNo ratings yet

- Organization's ISO 9001:2015 Certificate: Product Manual EIE - Notch Test ApparatusDocument14 pagesOrganization's ISO 9001:2015 Certificate: Product Manual EIE - Notch Test ApparatusRavi ParikhNo ratings yet

- The Effect of Outlet Weir Height On Sieve Tray PerformanceDocument25 pagesThe Effect of Outlet Weir Height On Sieve Tray PerformanceMasroorAbroNo ratings yet

- Sieve Tray ExtractorDocument12 pagesSieve Tray ExtractorCris-Anne Juangco III100% (2)

- The Internal Flow Investigation of A Centrifugal PumpDocument8 pagesThe Internal Flow Investigation of A Centrifugal Pumppreetham108No ratings yet

- Venturi LabDocument11 pagesVenturi LabKate MorrisNo ratings yet

- Three Phase Separator - Liquid InternalsDocument7 pagesThree Phase Separator - Liquid Internalsmehul10941No ratings yet

- D 5716 - 95 R00 - Rdu3mtyDocument4 pagesD 5716 - 95 R00 - Rdu3mtyRufo CascoNo ratings yet

- Halliburton: Rtts PackerDocument2 pagesHalliburton: Rtts PackermehrdadNo ratings yet

- C 107 Pulley Catalog 11 05 LowDocument42 pagesC 107 Pulley Catalog 11 05 LowMauricio MpintoNo ratings yet

- BN Eg UE109 Vessel SizingDocument40 pagesBN Eg UE109 Vessel Sizingbadelitamarius100% (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Ion Balance Water DBPDocument6 pagesIon Balance Water DBPPhạm LinhNo ratings yet

- Water Solutions: Unitank - Wastewater TreatmentDocument2 pagesWater Solutions: Unitank - Wastewater TreatmentPhạm LinhNo ratings yet

- MohammadipaperDocument15 pagesMohammadipaperPhạm LinhNo ratings yet

- RoutledgeHandbooks 9781315368542 Chapter3Document51 pagesRoutledgeHandbooks 9781315368542 Chapter3Phạm LinhNo ratings yet

- Sewage PaperDocument19 pagesSewage PaperPhạm LinhNo ratings yet

- Categories and sub-categories documentDocument2 pagesCategories and sub-categories documentPhạm LinhNo ratings yet

- 21M010 - XT - PFD 0502Document3 pages21M010 - XT - PFD 0502Phạm LinhNo ratings yet

- Piping and Instrumentation Diagram (P&Id)Document64 pagesPiping and Instrumentation Diagram (P&Id)Quraisy AmriNo ratings yet

- Optimization of A2O BNR Processes Using PDFDocument16 pagesOptimization of A2O BNR Processes Using PDFPhạm LinhNo ratings yet

- Removal of Nitrogen A N D Phosphorus From Swine Wastewater by The Activated Sludge Units With The Intermittent Aeration ProcessDocument12 pagesRemoval of Nitrogen A N D Phosphorus From Swine Wastewater by The Activated Sludge Units With The Intermittent Aeration ProcessPhạm LinhNo ratings yet

- Biological Treatment of Wastewater Using PDFDocument9 pagesBiological Treatment of Wastewater Using PDFPhạm LinhNo ratings yet

- Three Simple Flumes For Flow Measurement in Open Channels: Zohrab SamaniDocument4 pagesThree Simple Flumes For Flow Measurement in Open Channels: Zohrab SamaniPhạm LinhNo ratings yet

- Planttools: Optimize Your Workflow For Autocad Plant 3DDocument34 pagesPlanttools: Optimize Your Workflow For Autocad Plant 3DPhạm LinhNo ratings yet

- Pressure Rating For PVC PipesDocument65 pagesPressure Rating For PVC PipesPhạm LinhNo ratings yet

- Cutthroat Flow Measuring Flumes For Flat Gradient ChannelsDocument17 pagesCutthroat Flow Measuring Flumes For Flat Gradient ChannelsPhạm LinhNo ratings yet

- Flow Measurement Venturi Flumes Polypropilene DesignsDocument2 pagesFlow Measurement Venturi Flumes Polypropilene DesignsPhạm LinhNo ratings yet

- Simplified Design of Flumes and WeirsDocument17 pagesSimplified Design of Flumes and WeirsSalman LSBUNo ratings yet

- Open Channel FlowsDocument16 pagesOpen Channel FlowsissamNo ratings yet

- Three Simple Flumes For Flow Measurement in Open Channels: Zohrab SamaniDocument4 pagesThree Simple Flumes For Flow Measurement in Open Channels: Zohrab SamaniPhạm LinhNo ratings yet

- Unified Equations For Cutthroat Flumes Derived From A Three-DimenDocument170 pagesUnified Equations For Cutthroat Flumes Derived From A Three-DimenPhạm LinhNo ratings yet

- De-Mystifying AutoCAD Plant 3D IsometricsDocument71 pagesDe-Mystifying AutoCAD Plant 3D IsometricsJorge Andrés PovedaNo ratings yet

- Plant 3D Orthographics Demystified: Learning ObjectivesDocument41 pagesPlant 3D Orthographics Demystified: Learning ObjectivesPhạm LinhNo ratings yet

- Plant 3D Orthographics Demystified: Learning ObjectivesDocument41 pagesPlant 3D Orthographics Demystified: Learning ObjectivesPhạm LinhNo ratings yet

- Biotechnology Vol 11a Waste Water TreatmentDocument592 pagesBiotechnology Vol 11a Waste Water TreatmentTTaddictNo ratings yet

- Lodos ActivadosDocument32 pagesLodos Activadosjvan migvelNo ratings yet

- World Cup 2018Document3 pagesWorld Cup 2018Phạm LinhNo ratings yet

- SCIENCE 10 Activity 2.2Document3 pagesSCIENCE 10 Activity 2.2sheila GepigaNo ratings yet

- Alphabet LinesDocument7 pagesAlphabet LinesCristy RiveraNo ratings yet

- Estimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemDocument13 pagesEstimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemAnand M VNo ratings yet

- Solving Problems Using Central Angle-Intercepted Arc PostulateDocument18 pagesSolving Problems Using Central Angle-Intercepted Arc PostulateCedrick Nicolas ValeraNo ratings yet

- Cooling Tower DesignDocument4 pagesCooling Tower DesignRavi KasaudhanNo ratings yet

- 09 GasketCharacteristicValues PDFDocument3 pages09 GasketCharacteristicValues PDFdraj1875977No ratings yet

- UntitledDocument7 pagesUntitledKushank GuptaNo ratings yet

- Gravity MethodDocument38 pagesGravity Methodzain828No ratings yet

- Beginning Algebra 9th Edition Tobey Test Bank DownloadDocument49 pagesBeginning Algebra 9th Edition Tobey Test Bank DownloadMary Bumgarner100% (22)

- General Aptitude - Student'sDocument22 pagesGeneral Aptitude - Student'sAghaashNo ratings yet

- Entanglements in Filament Yarns by Needle Insertion: Standard Test Method ForDocument6 pagesEntanglements in Filament Yarns by Needle Insertion: Standard Test Method ForJuanNo ratings yet

- Openstax Physics Chapter 1 Lesson 5 3 Coordinate System of VectorsDocument16 pagesOpenstax Physics Chapter 1 Lesson 5 3 Coordinate System of VectorsWild RiftNo ratings yet

- An Intuitive Guide To Linear Algebra - BetterExplainedDocument25 pagesAn Intuitive Guide To Linear Algebra - BetterExplainedvkk intensiveNo ratings yet

- Unit - 4 Work SheetDocument6 pagesUnit - 4 Work SheetNathan GetachewNo ratings yet

- Tut3 OLET1640 Student NotesDocument4 pagesTut3 OLET1640 Student Notesdesheng wangNo ratings yet

- Lect 1 Limit State DesignDocument31 pagesLect 1 Limit State DesignWaleed Yahia100% (1)

- L15 Relieving PlatformDocument17 pagesL15 Relieving PlatformMohammed Al KhatibNo ratings yet

- Phyc2121 1ST Quarter ExamDocument35 pagesPhyc2121 1ST Quarter ExamRhea MIchaela Sto DomingoNo ratings yet

- Statics 213 Module 3.1 AND 3.2 HCCDocument12 pagesStatics 213 Module 3.1 AND 3.2 HCCMark MagcalasNo ratings yet

- I 11 292Document9 pagesI 11 292Rasheed YusufNo ratings yet

- Inform 7 Cheat SheetDocument6 pagesInform 7 Cheat SheetBrandon Curtis AugustineNo ratings yet

- 2201JB - Comparison 2:48PM 140FDocument5 pages2201JB - Comparison 2:48PM 140FBeantickNo ratings yet

- Manual Intended Use: Piinline Plus AQR/AQR Low PressureDocument5 pagesManual Intended Use: Piinline Plus AQR/AQR Low PressureMario PortillaNo ratings yet

- P008 Delgadillo FinalPaper SimultaneousPressureLevelControlDeaeratorDocument12 pagesP008 Delgadillo FinalPaper SimultaneousPressureLevelControlDeaeratorIgnacio RamirezNo ratings yet

- Muhammad Al-Karaji - A Mathematician Engineer From The Early 11th Century Muslim HeritageDocument18 pagesMuhammad Al-Karaji - A Mathematician Engineer From The Early 11th Century Muslim HeritageRaja AleeyaNo ratings yet

- Structural Balancing of Kohat Basin by Ahsan GardeziDocument22 pagesStructural Balancing of Kohat Basin by Ahsan GardeziAsad JahangirNo ratings yet

- Mukkkkk 2Document28 pagesMukkkkk 2Joshi ChumbaleNo ratings yet

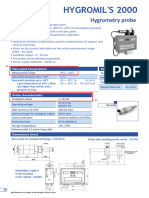

- En Hygromil'sDocument1 pageEn Hygromil'sYersson MesiasNo ratings yet

- Cell Type UR18650F: SpecificationsDocument5 pagesCell Type UR18650F: SpecificationsIskandar WirawanNo ratings yet