Professional Documents

Culture Documents

Deaerator Operation

Uploaded by

Muhammad luqmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deaerator Operation

Uploaded by

Muhammad luqmanCopyright:

Available Formats

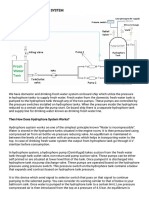

Deaerator operation steps

After the low pressure heater passes the flushing (Fe < 50ug / L), feed water to the deaerator

through the condensate pump or demineralized water pump to the normal water level.

Open the manual drain valve of the deaerator, wash the deaerator until it is qualified, adjust the

water level of the deaerator to be normal, and start a steam pump booster pump for recycling.

Open the auxiliary steam to the deaerator before and after the isolation valve of adjustable valve.

Slowly open the auxiliary steam to the deaerator adjustable valve, put into the deaerator heating,

pay attention to the pipeline drain system , and control deaerator feed water temperature is not

greater than 1.5℃/min.

When the deaerator water temperature reaches 80 ℃, put the auxiliary steam to the deaerator

regulating valve into automatic mode, check that the temperature rise rate of deaerator is not

more than 1.5 ℃ / min, and the deaerator pressure gradually rises to 0.147mpa.

In the process of auxiliary steam heating, the water level of deaerator can be controlled by

opening the overflow of deaerator.

When the fourth extraction pressure is greater than 0.2MPa, open the fourth extraction electric

valve, each check valve, slowly open the four extraction to the deaerator electric valve, close the

auxiliary steam to the deaerator regulating valve, and the deaerator will change from constant

pressure operation to sliding pressure operation, and check that the deaerator pressure and water

level are normal.

The dissolved oxygen at the outlet of deaerator is qualified. Close the start up electric exhaust

valve of deaerator and slightly open 8 manual normal exhaust valves.

You might also like

- HydraulicsDocument69 pagesHydraulicsRamesh SahniNo ratings yet

- Hydrophore SystemDocument4 pagesHydrophore SystemSWASTIK MISHRA50% (2)

- Fresh Water Generator On ShipsDocument11 pagesFresh Water Generator On ShipsGuruNo ratings yet

- Different Control Strategies For Chiller PlantDocument19 pagesDifferent Control Strategies For Chiller PlantAnkit AbhinavNo ratings yet

- Deaerator Working Principle: What Is Deaeration?Document4 pagesDeaerator Working Principle: What Is Deaeration?Freddy Mendoza CoronelNo ratings yet

- Fresh Water Generator GME 37Document30 pagesFresh Water Generator GME 37srinidhi246100% (2)

- Steam Turbine and Its Auxiliary Systems: Course PurposeDocument19 pagesSteam Turbine and Its Auxiliary Systems: Course PurposeMuhammad luqmanNo ratings yet

- Turbine Start UpDocument15 pagesTurbine Start UprobiansahNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Boiler OperationDocument97 pagesBoiler Operationdeeli1100% (2)

- Steam Turbine Maintenance Manual-1Document244 pagesSteam Turbine Maintenance Manual-1Trie Wahyudi100% (4)

- Unit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemDocument13 pagesUnit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemMuhammad luqman100% (1)

- FWG Explained (Autosaved)Document21 pagesFWG Explained (Autosaved)Junehenry YalduaNo ratings yet

- Boiler Startup ProcedureDocument5 pagesBoiler Startup ProcedureBrijesh Srivastav0% (1)

- 02B HRSGDocument50 pages02B HRSGrseclen100% (2)

- Turbine Startup ProcedureDocument8 pagesTurbine Startup ProcedureBrijesh Srivastav0% (1)

- Marine Fresh Water GeneratorDocument6 pagesMarine Fresh Water Generatorazeezur100% (2)

- Boiler Operation and ControlDocument99 pagesBoiler Operation and Controlwassli100% (1)

- LP Heaters Operation: 1. Operation While Unit Start Up Water Side OperationDocument2 pagesLP Heaters Operation: 1. Operation While Unit Start Up Water Side OperationMuhammad luqmanNo ratings yet

- HP Heaters Operation During Start Up of UnitDocument1 pageHP Heaters Operation During Start Up of UnitMuhammad luqman100% (1)

- AUX Steam HeaderDocument14 pagesAUX Steam HeaderMuhammad luqmanNo ratings yet

- Navien CleaningDocument3 pagesNavien CleaningKyle HarasymNo ratings yet

- Training Material of Boiler Operation: Drum and Internal DevicesDocument8 pagesTraining Material of Boiler Operation: Drum and Internal DevicesandreNo ratings yet

- The Gland Seal Heater Is Running NormallyDocument1 pageThe Gland Seal Heater Is Running NormallyMuhammad luqmanNo ratings yet

- Boiler Maintenance On ShipsDocument7 pagesBoiler Maintenance On ShipsRobert LuuNo ratings yet

- Fresh Water Generato1Document12 pagesFresh Water Generato1YanaNo ratings yet

- Fresh Water GeneratorDocument22 pagesFresh Water GeneratorCungkringNo ratings yet

- Steam Boiler Basic OperationDocument1 pageSteam Boiler Basic OperationAdrian StephesonNo ratings yet

- Starting The Fresh Water GeneratorDocument4 pagesStarting The Fresh Water GeneratorVILLANUEVA, Marvin L.No ratings yet

- De-Crystallization ProcessDocument2 pagesDe-Crystallization Processwira triswandiNo ratings yet

- Alfa LavalDocument29 pagesAlfa LavallipovanychNo ratings yet

- Automatic Operation of BoilerDocument23 pagesAutomatic Operation of BoilerSuhas KassaNo ratings yet

- Coal Power Unit StartDocument8 pagesCoal Power Unit StartansudasinghaNo ratings yet

- Feed Water Pump and Deaerator SystemDocument34 pagesFeed Water Pump and Deaerator SystemAhmadNo ratings yet

- FreshWater Generator On ShipsDocument22 pagesFreshWater Generator On Shipschristian pope100% (1)

- 12.boiler System ComponentsDocument4 pages12.boiler System Componentskcp19860% (1)

- Bank QuestionDocument3 pagesBank Questionsiaboy97No ratings yet

- HydrogenDocument10 pagesHydrogennuzulNo ratings yet

- Control Philosophy of DearatorDocument2 pagesControl Philosophy of DearatorHEMANTNo ratings yet

- Cip CleaningDocument2 pagesCip CleaningAjai PSNo ratings yet

- Collin Test and Commissioning ProcedureDocument7 pagesCollin Test and Commissioning ProcedureSamuelJrManatadNo ratings yet

- Operation & Manual L200GVFM-150kW (SEPCO) - CompressedDocument11 pagesOperation & Manual L200GVFM-150kW (SEPCO) - CompressedWASSIM SUNNANo ratings yet

- Ninh Binh Rua Hoa ChatDocument3 pagesNinh Binh Rua Hoa Chathuy LuongNo ratings yet

- Boiler Filling and Cold FlushingDocument15 pagesBoiler Filling and Cold FlushingMuhammad luqmanNo ratings yet

- FAMIX Manual #1711+1713Document27 pagesFAMIX Manual #1711+1713JerickNo ratings yet

- Air Conditioning TechnologyDocument3 pagesAir Conditioning TechnologyAhmed AzadNo ratings yet

- WWE Filter Press OperationDocument4 pagesWWE Filter Press OperationMf LuiNo ratings yet

- Sop MeeDocument5 pagesSop MeeYogesh Dhekale100% (4)

- To Study About Closing Up, and Then Raising Steam On A Water Tube BoilerDocument2 pagesTo Study About Closing Up, and Then Raising Steam On A Water Tube BoilerAayush AgrawalNo ratings yet

- Hydropneumatic Tank Control Systems: Drinking Water Tech TipsDocument2 pagesHydropneumatic Tank Control Systems: Drinking Water Tech TipsBlancaNo ratings yet

- Teps of Standard Operating Procedure (Sops) of The Steam TurbineDocument6 pagesTeps of Standard Operating Procedure (Sops) of The Steam TurbineAKSHAY AGALAVENo ratings yet

- Sop 1Document2 pagesSop 1AnnuNo ratings yet

- 2004-07 Care & Maintenance of Water HeatersDocument2 pages2004-07 Care & Maintenance of Water HeatersMike PerryNo ratings yet

- A Report On Boiler Feed WaterDocument11 pagesA Report On Boiler Feed WaterAustin UdofiaNo ratings yet

- SOP For BFPDocument2 pagesSOP For BFPsambhuNo ratings yet

- OSO OM 17RA Operation & MaintenanceDocument3 pagesOSO OM 17RA Operation & MaintenanceRomanPochinkovNo ratings yet

- Boiler Operation Made Easy: Procedure For Starting and Stopping A BoilerDocument24 pagesBoiler Operation Made Easy: Procedure For Starting and Stopping A BoilerBanshi Lal MaanNo ratings yet

- Tech Sheet 128Document1 pageTech Sheet 128Sriram RamanujamNo ratings yet

- Starting A Boiler From Dead Ship ConditionsDocument21 pagesStarting A Boiler From Dead Ship ConditionsrickNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Vacuum SystemDocument16 pagesVacuum SystemMuhammad luqmanNo ratings yet

- Boiler SH - RH SystemDocument12 pagesBoiler SH - RH SystemMuhammad luqmanNo ratings yet

- Closed Cooling Water System (CCCW)Document13 pagesClosed Cooling Water System (CCCW)Muhammad luqmanNo ratings yet

- Bottom Ash and GrateDocument19 pagesBottom Ash and GrateMuhammad luqmanNo ratings yet

- CW TrainingDocument23 pagesCW TrainingMuhammad luqmanNo ratings yet

- Q/ZDJGN-BD: Centralized Control Operation ProcedureDocument281 pagesQ/ZDJGN-BD: Centralized Control Operation ProcedureMuhammad luqmanNo ratings yet

- 仇中柱-pulvizer and pulverising systems-2016-6-3Document24 pages仇中柱-pulvizer and pulverising systems-2016-6-3Muhammad luqmanNo ratings yet

- Coal FeederDocument12 pagesCoal FeederMuhammad luqmanNo ratings yet

- Soot BlowerDocument11 pagesSoot BlowerMuhammad luqmanNo ratings yet

- 7-电站锅炉原理第7章-LV revised-burners-qiuDocument54 pages7-电站锅炉原理第7章-LV revised-burners-qiuMuhammad luqmanNo ratings yet

- Chapter 2 Heating Surfaces of A Boiler: 1 Prof&Dr Zhongzhu QiuDocument49 pagesChapter 2 Heating Surfaces of A Boiler: 1 Prof&Dr Zhongzhu QiuMuhammad luqmanNo ratings yet

- Turbine Rapid Cooling DeviceDocument3 pagesTurbine Rapid Cooling DeviceMuhammad luqmanNo ratings yet

- 12-need improvement电站锅炉原理第12章-revised by Lv-qiuDocument23 pages12-need improvement电站锅炉原理第12章-revised by Lv-qiuMuhammad luqmanNo ratings yet

- Feed Water Turbine Adjustment Recirculation Valve Control PrecautionsDocument5 pagesFeed Water Turbine Adjustment Recirculation Valve Control PrecautionsMuhammad luqmanNo ratings yet

- 10- 电站锅炉原理第10章-natural circulation+Document23 pages10- 电站锅炉原理第10章-natural circulation+Muhammad luqmanNo ratings yet

- The Gland Seal Heater Is Running NormallyDocument1 pageThe Gland Seal Heater Is Running NormallyMuhammad luqmanNo ratings yet

- Boiler Equipment and System: Prof & DR Zhongzhu Qiu Shanghai University of Electric Power 2016Document49 pagesBoiler Equipment and System: Prof & DR Zhongzhu Qiu Shanghai University of Electric Power 2016Muhammad luqmanNo ratings yet

- Sealing Oil System OperationDocument2 pagesSealing Oil System OperationMuhammad luqmanNo ratings yet

- Coal Feeder BlockageDocument1 pageCoal Feeder BlockageMuhammad luqmanNo ratings yet

- Coal Mill Trip AccidentDocument1 pageCoal Mill Trip AccidentMuhammad luqmanNo ratings yet

- Coal Feeder Trip AccidentDocument1 pageCoal Feeder Trip AccidentMuhammad luqmanNo ratings yet