Professional Documents

Culture Documents

), Surface Mount: Vishay Dale

Uploaded by

LeonardoMartinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

), Surface Mount: Vishay Dale

Uploaded by

LeonardoMartinCopyright:

Available Formats

WSR

www.vishay.com

Vishay Dale

Power Metal Strip® Resistors,

Low Value (down to 0.001 ), Surface Mount

FEATURES

• Molded high temperature encapsulation

• All welded construction of the Power Metal

Strip® resistors are ideal for all types of current

sensing, voltage division and pulse Available

applications

• Proprietary processing technique produces

extremely low resistance values (down to

0.001 ) Available

• Sulfur resistance by construction that is

unaffected by high sulfur environments Available

DESIGN SUPPORT TOOLS click logo to get started • Solid metal nickel-chrome or manganese-

copper alloy resistive element with low TCR Available

(< 20 ppm/°C)

Models Design Tools

Available Available • Very low inductance 0.5 nH to 5 nH

• Excellent frequency response to 50 MHz

• Low thermal EMF (< 3 μV/°C)

• AEC-Q200 qualified (1)

• Material categorization: for definitions of compliance

please see www.vishay.com/doc?99912

Notes

• This datasheet provides information about parts that are RoHS-compliant and / or parts that are non-RoHS-compliant. For example, parts

with lead (Pb) terminations are not RoHS-compliant. Please see the information / tables in this datasheet for details

• Follow link to Overview of Automotive Grade Products for more details: www.vishay.com/doc?49924

(1) Flame retardance test may not be applicable to some resistor technologies

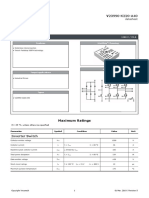

STANDARD ELECTRICAL SPECIFICATIONS

POWER RATING RESISTANCE VALUE RANGE WEIGHT

GLOBAL

SIZE P70 °C (typical)

MODEL

W Tol. ± 0.5 % Tol. ± 1.0 % g/1000 pieces

WSR2 4527 2.0 0.005 to 1.0 0.001 to 1.0 440

WSR3 4527 3.0 (1) 0.005 to 0.2 0.001 to 0.2 440

Notes

• Part marking: DALE, model, value, tolerance, date code

(1) The WSR3 requires a minimum of 1050 sq. mil. circuit traces connecting to the recommended solder pad

GLOBAL PART NUMBER INFORMATION

Global Part Numbering example: WSR25L000FEA (visit www.vishay.net Vishay Dale parts numbering manual for all options)

W S R 2 5 L 0 0 0 F E A

GLOBAL MODEL RESISTANCE VALUE (1) TOLERANCE CODE PACKAGING CODE (2) SPECIAL (3)

WSR2 L = m* D = ± 0.5 % EA = lead (Pb)-free, tape/reel (dash number)

WSR3 R = decimal F = ± 1.0 % EK = lead (Pb)-free, bulk (up to 2 digits)

5L000 = 0.005 J = ± 5.0 % TA = tin/lead, tape/reel (R86) from 1 to 99 as

R0100 = 0.01 BA = tin/lead, bulk (B43) applicable

* Use “L” for resistance

values < 0.01

Notes

(1) WSR Marking (www.vishay.com/doc?30327)

(2) Packaging code: EB (lead (Pb)-free) and TB (tin / lead) are non-standard packaging codes designating 1000 piece reels. These non-standard

packaging codes are identical to our standard EA (lead (Pb)-free) and TA (tin / lead), except that they have a package quantity of 1000 pieces

(3) Follow link for customization capabilities: www.vishay.com/doc?48163

Revision: 09-Jan-2019 1 Document Number: 30101

For technical questions, contact: ww2bresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

WSR

www.vishay.com

Vishay Dale

TECHNICAL SPECIFICATIONS

PARAMETER UNIT WSR2 AND WSR3 RESISTOR CHARACTERISTICS

± 75 for 0.010 to 1.0

± 110 for 0.005 to 0.0099

Temperature coefficient ± 300 for 0.004 to 0.0049

TCR measured from -55 °C to ppm/°C

150 °C ± 450 for 0.003 to 0.0039

± 600 for 0.002 to 0.0029

± 750 for 0.001 to 0.0019

Element TCR ppm/°C < 20

Dielectric withstanding voltage VAC > 500

Insulation resistance > 109

Operating temperature range °C -65 to +275

Maximum working voltage V (P x R)1/2

DIMENSIONS in inches (millimeters)

W H

I b

W1

T a

L

Notes

• 3D models available: www.vishay.com/doc?30336

• Surface mount solder profile recommendations: www.vishay.com/doc?31052

DIMENSIONS SOLDER PAD DIMENSIONS

MODEL

L H T W W1 a b l

0.455 ± 0.032

WSR2, 0.095 ± 0.005 0.100 ± 0.010 0.275 ± 0.005 0.215 ± 0.005 0.155 0.230 0.205

(11.56 ±

WSR3 (2.41 ± 0.127) (2.54 ± 0.254) (6.98 ± 0.127) (5.46 ± 0.127) (3.94) (5.84) (5.21)

0.813)

Note

• Sensing locations are based on the construction of the part; terminals are wrapped from the outside to underneath. These options place the

sensing location nearest the temperature stable resistance element, which minimizes contact resistance and optimizes TCR

TYPICAL SENSING LAYOUT

b c

l

a b c l

0.155 0.230 0.020 0.205

(3.94) (5.84) (0.51) (5.21)

Revision: 09-Jan-2019 2 Document Number: 30101

For technical questions, contact: ww2bresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

WSR

www.vishay.com

Vishay Dale

DERATING PULSE CAPABILITY

Rated Power in %

120

100 click to get started

LY

ON

ES

80

P OS

60 R

PU

E

40 IV

RAT

T

US

20

ILL

0

- 65 - 25 25 75 125 175 225 275

Ambient Temperature °C

70

www.vishay.com/resistors/power-metal-strip-calculator

PERFORMANCE

TEST LIMITS

TEST CONDITIONS OF TEST

WSR2 WSR3

Thermal shock -55 °C to +150 °C, 1000 cycles, 15 min at each extreme ± 0.5 % + 0.0005 ± 0.5 % + 0.0005

WSR2: 5x rated power for 5 s

Short time overload ± 0.5 % + 0.0005 ± 2.0 % + 0.0005

WSR3: 4x rated power for 5 s

Low temperature storage -65 °C for 24 h ± 0.5 % + 0.0005 ± 0.5 % + 0.0005

High temperature

1000 h at +275 °C ± 1.0 % + 0.0005 ± 1.0 % + 0.0005

exposure

Bias humidity +85 °C, 85 % RH, 10 % bias, 1000 h ± 0.5 % + 0.0005 ± 0.5 % + 0.0005

Mechanical shock 100 g’s for 6 ms, 5 pulses ± 0.5 % + 0.0005 ± 0.5 % + 0.0005

Vibration Frequency varied 10 Hz to 2000 Hz in 1 min, 3 directions, 12 h ± 0.5 % + 0.0005 ± 0.5 % + 0.0005

Load life 1000 h at rated power, +70 °C, 1.5 h “ON”, 0.5 h “OFF” ± 1.0 % + 0.0005 ± 2.0 % + 0.0005

Resistance to solder heat +260 °C solder, 10 s to 12 s dwell, 25 mm/s emergence ± 0.5 % + 0.0005 ± 0.5 % + 0.0005

MIL-STD-202, method 106, 0 % power, 7a and 7b not

Moisture resistance ± 0.5 % + 0.0005 ± 0.5 % + 0.0005

required

PACKAGING (1)

REEL

MODEL

TAPE WIDTH DIAMETER PIECES/REEL CODE

WSR2 and WSR3 24 mm/embossed plastic 330 mm/13" 1500 EA

Notes

• Embossed Carrier Tape per EIA-481

(1) Additional packaging details at www.vishay.com/doc?20051

Revision: 09-Jan-2019 3 Document Number: 30101

For technical questions, contact: ww2bresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of

typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding

statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a

particular product with the properties described in the product specification is suitable for use in a particular application.

Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over

time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk.

Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for

such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document

or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

© 2019 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 01-Jan-2019 1 Document Number: 91000

You might also like

- Ω), Surface Mount: Vishay DaleDocument3 pagesΩ), Surface Mount: Vishay DaleRodrigo BronzeriNo ratings yet

- Ω), Surface Mount: Vishay DaleDocument3 pagesΩ), Surface Mount: Vishay DaleGermánNo ratings yet

- WSL... 18 High Power: Ω), Surface-MountDocument4 pagesWSL... 18 High Power: Ω), Surface-MountMohendra PatiNo ratings yet

- WSL Power Metal Strip Resistors, Low Value (Down to 0.0005 Ω), Surface-MountDocument4 pagesWSL Power Metal Strip Resistors, Low Value (Down to 0.0005 Ω), Surface-MountGeorge ThomasNo ratings yet

- Info-R12s0000.015f VisDocument4 pagesInfo-R12s0000.015f Vised251No ratings yet

- WSL3921 Reistor de MedicionDocument5 pagesWSL3921 Reistor de Medicionluis.moralesNo ratings yet

- To 500 M ), Surface-Mount, High Power: Vishay DaleDocument5 pagesTo 500 M ), Surface-Mount, High Power: Vishay DaleCarlos ReisNo ratings yet

- WFC 2899679Document7 pagesWFC 2899679João JoséNo ratings yet

- HVR 2537Document7 pagesHVR 2537Damián PastreNo ratings yet

- VH Hermetic VH Hermetic: TCR of 1 Ppm/°c, Tolerance To 0.005% and Load-Life Stability of 0.005%Document6 pagesVH Hermetic VH Hermetic: TCR of 1 Ppm/°c, Tolerance To 0.005% and Load-Life Stability of 0.005%Daniel HubencuNo ratings yet

- 250rd Datasheet - 021753Document6 pages250rd Datasheet - 021753amr elnawamNo ratings yet

- Temd 6010Document5 pagesTemd 6010Ramulu VeesamNo ratings yet

- Resistor 1k - Vishay - 0.6wDocument3 pagesResistor 1k - Vishay - 0.6wLEDNo ratings yet

- Vishay Dale: FeaturesDocument4 pagesVishay Dale: FeaturesFouquetNo ratings yet

- S SeriesDocument6 pagesS SeriesshhNo ratings yet

- Smaj 530Document5 pagesSmaj 530EdgarNo ratings yet

- Low profile Schottky rectifiers for inverters and convertersDocument4 pagesLow profile Schottky rectifiers for inverters and convertersMantenimiento AsistelNo ratings yet

- Surface Mount - 200W SMF SeriesDocument6 pagesSurface Mount - 200W SMF Seriesm3y54mNo ratings yet

- SMB10 (8) J5.0 (C) A Thru SMB10 (8) J40 (C) A: Vishay General SemiconductorDocument6 pagesSMB10 (8) J5.0 (C) A Thru SMB10 (8) J40 (C) A: Vishay General SemiconductorStuxnetNo ratings yet

- CRCW0201 E3: VishayDocument5 pagesCRCW0201 E3: VishaycuperiniNo ratings yet

- Pr01, Pr02, Pr03: Vishay BccomponentsDocument19 pagesPr01, Pr02, Pr03: Vishay BccomponentsGabriel pedrosaNo ratings yet

- Common Mode SS Coils, 11VL Series: ApplicationsDocument10 pagesCommon Mode SS Coils, 11VL Series: ApplicationsGraner GranerNo ratings yet

- WFC Metal Foil Current Sense Resistors: Vishay DaleDocument7 pagesWFC Metal Foil Current Sense Resistors: Vishay DalezamphirjoNo ratings yet

- Vishay General Semiconductor: FeaturesDocument5 pagesVishay General Semiconductor: Featuresشعبان العواميNo ratings yet

- Compact Load Cell For Tension/Compression Applications: Main FeaturesDocument2 pagesCompact Load Cell For Tension/Compression Applications: Main FeaturesGopal HegdeNo ratings yet

- BZW04-5V8 Thru BZW04-376: Rans ORBDocument6 pagesBZW04-5V8 Thru BZW04-376: Rans ORBfaza1111No ratings yet

- SS32, SS33, SS34, SS35, SS36: Vishay General SemiconductorDocument4 pagesSS32, SS33, SS34, SS35, SS36: Vishay General SemiconductorHla Swe OoNo ratings yet

- MSP3V3, MSP5.0A: Rans ORBDocument5 pagesMSP3V3, MSP5.0A: Rans ORBsikeshkkNo ratings yet

- MSP3V3, MSP5.0A: Rans ORBDocument5 pagesMSP3V3, MSP5.0A: Rans ORBsikeshkkNo ratings yet

- Isb Datasheet enDocument3 pagesIsb Datasheet endiacochemicalsNo ratings yet

- Quadhifreq 1391243 PDFDocument17 pagesQuadhifreq 1391243 PDFDinu Racautanu MironNo ratings yet

- Accutrim™ 1242 (QPL) : Vishay Foil ResistorsDocument5 pagesAccutrim™ 1242 (QPL) : Vishay Foil ResistorsDaniel HubencuNo ratings yet

- Vishay Foil Resistors: FeaturesDocument7 pagesVishay Foil Resistors: FeaturesMahemehr MehrNo ratings yet

- SSB 43 LDocument5 pagesSSB 43 LRomanoNo ratings yet

- 1.5smc27a TRTB FagorDocument8 pages1.5smc27a TRTB FagorFaulhaber AdrianNo ratings yet

- Axial Leaded - 500W SA SeriesDocument6 pagesAxial Leaded - 500W SA SeriesManuel RodriguezNo ratings yet

- 15smc100a-E357t VishayDocument6 pages15smc100a-E357t VishayFaulhaber AdrianNo ratings yet

- SS32, SS33, SS34, SS35, SS36: Vishay General SemiconductorDocument4 pagesSS32, SS33, SS34, SS35, SS36: Vishay General SemiconductorVinod kumarNo ratings yet

- SM6T Series: Rans ORBDocument5 pagesSM6T Series: Rans ORBАлексейNo ratings yet

- Littelfuse TVS Diode P6KE Datasheet PDFDocument6 pagesLittelfuse TVS Diode P6KE Datasheet PDFathinabebaNo ratings yet

- CAN4311153002451KDocument13 pagesCAN4311153002451KFrankxorNo ratings yet

- BPW34 and BPW34S PIN Photodiodes Spec SheetDocument5 pagesBPW34 and BPW34S PIN Photodiodes Spec SheetErwin RuizNo ratings yet

- Ss 29Document5 pagesSs 29Yasmin HasnaNo ratings yet

- Axial Leaded - 1500W 1.5KE SeriesDocument6 pagesAxial Leaded - 1500W 1.5KE SeriesdonpnchojrNo ratings yet

- Littelfuse TVS Diode 1 5KE Datasheet pdf-1761343Document7 pagesLittelfuse TVS Diode 1 5KE Datasheet pdf-1761343Giorgos GourgiotisNo ratings yet

- VSMB2000X01, VSMB2020X01: Vishay SemiconductorsDocument8 pagesVSMB2000X01, VSMB2020X01: Vishay SemiconductorsAnoop C PatilNo ratings yet

- BPW34, BPW34S: Vishay SemiconductorsDocument5 pagesBPW34, BPW34S: Vishay SemiconductorsWA Q ASNo ratings yet

- Sbyv26C: Vishay General SemiconductorDocument5 pagesSbyv26C: Vishay General SemiconductorSalomon ChoqueNo ratings yet

- TNPW E3-1761965Document15 pagesTNPW E3-1761965João JoséNo ratings yet

- Veml6035 1605016 PDFDocument16 pagesVeml6035 1605016 PDFMário FrançaNo ratings yet

- Analog Device Splitter ZX10Q-2-34-S+Document1 pageAnalog Device Splitter ZX10Q-2-34-S+Ib MotoNo ratings yet

- 1N4728A To 1N4761A Zener Diodes: Not Recommended For New Automotive DesignDocument4 pages1N4728A To 1N4761A Zener Diodes: Not Recommended For New Automotive Designsaif habibNo ratings yet

- SBSM Data SheetDocument4 pagesSBSM Data SheetAlex JonesNo ratings yet

- Bias TDocument2 pagesBias TkidusNo ratings yet

- Axial Leaded - 600W P6KE SeriesDocument6 pagesAxial Leaded - 600W P6KE SeriesJohnny BobyNo ratings yet

- S3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General SemiconductorDocument4 pagesS3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General Semiconductormahbub metulNo ratings yet

- Surface Mount - 600W SMBJ SeriesDocument6 pagesSurface Mount - 600W SMBJ SeriesViniciusNo ratings yet

- Littelfuse TVS Diode SMBJ Datasheet - pdf-1108540Document7 pagesLittelfuse TVS Diode SMBJ Datasheet - pdf-1108540Андрей МедведевNo ratings yet

- 1N4728A To 1N4764ADocument5 pages1N4728A To 1N4764AMarianovMarianNo ratings yet

- 225 PDFDocument2 pages225 PDFLeonardoMartinNo ratings yet

- Timer - Counter - Tachometer CTADocument2 pagesTimer - Counter - Tachometer CTALeonardoMartinNo ratings yet

- PCF8574 Pcf8574aDocument33 pagesPCF8574 Pcf8574asilasroveriNo ratings yet

- MEMO TI-5000JX Testing 1Vpp Sine and Inductive Scanning GapDocument4 pagesMEMO TI-5000JX Testing 1Vpp Sine and Inductive Scanning GapLeonardoMartinNo ratings yet

- Nema 1Document8 pagesNema 1Liliana LeiroNo ratings yet

- BU208 BU208A High Voltage NPN Silicon Power Transistor DescriptionDocument2 pagesBU208 BU208A High Voltage NPN Silicon Power Transistor DescriptionLeonardoMartinNo ratings yet

- Doc1132 PDFDocument9 pagesDoc1132 PDFLeonardoMartinNo ratings yet

- NXP - Semiconductors PMMT491A DatasheetDocument7 pagesNXP - Semiconductors PMMT491A DatasheetLeonardoMartinNo ratings yet

- 863 867 Smeng0000Document101 pages863 867 Smeng0000BhaskarNo ratings yet

- ), Surface Mount: Vishay DaleDocument4 pages), Surface Mount: Vishay DaleLeonardoMartinNo ratings yet

- Fluke 702Document118 pagesFluke 702Beatriz Giraldo MejiaNo ratings yet

- 9100 Ogeng0000Document86 pages9100 Ogeng0000LeonardoMartinNo ratings yet

- 20x4 LCD Brief DataDocument7 pages20x4 LCD Brief Datavigneshwaranj87100% (1)

- 24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMDocument29 pages24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMSudhagarSubbiyanNo ratings yet

- Input Filter Design Example PDFDocument5 pagesInput Filter Design Example PDFLeonardoMartinNo ratings yet

- Vincotech V23990-K220-A40 FD-Rev 05Document30 pagesVincotech V23990-K220-A40 FD-Rev 05LeonardoMartinNo ratings yet

- Powermonitoring Quick Selection Guide EN - 202002131300274826Document2 pagesPowermonitoring Quick Selection Guide EN - 202002131300274826LeonardoMartinNo ratings yet

- RT SeriesDocument6 pagesRT SeriesLeonardoMartinNo ratings yet

- A Designers Guide To Instrumentation Amplifiers 3rd EdDocument130 pagesA Designers Guide To Instrumentation Amplifiers 3rd EdCL ManinhoNo ratings yet

- SENTRON LV10-PH06 Complete English 10-2015 201603161104047523Document32 pagesSENTRON LV10-PH06 Complete English 10-2015 201603161104047523LeonardoMartinNo ratings yet

- Three Phase Common Mode Active EMI Filters For Induction Motor Drive Applications Vuttipon Tarateeraseth JPE Vol18 No3 pp871 878 2018Document9 pagesThree Phase Common Mode Active EMI Filters For Induction Motor Drive Applications Vuttipon Tarateeraseth JPE Vol18 No3 pp871 878 2018LeonardoMartinNo ratings yet

- Common Mode Filters Design Guide (2007) (Coilcraft)Document4 pagesCommon Mode Filters Design Guide (2007) (Coilcraft)mapo mfaNo ratings yet

- Intel® Desktop Board DZ68BC Product Guide: Order Number: G41105-002Document88 pagesIntel® Desktop Board DZ68BC Product Guide: Order Number: G41105-002LeonardoMartinNo ratings yet

- Fluke PM6666Document8 pagesFluke PM6666LeonardoMartinNo ratings yet

- Getting Started: Function GeneratorsDocument6 pagesGetting Started: Function GeneratorsLeonardoMartinNo ratings yet

- Atomlux Modulo MA1000Document99 pagesAtomlux Modulo MA1000LeonardoMartinNo ratings yet

- EMI Filter Design PDFDocument28 pagesEMI Filter Design PDFidistiraNo ratings yet

- Atomlux Modulo MA1000Document1 pageAtomlux Modulo MA1000Serchu_29No ratings yet

- SMC HF 24V 30aDocument2 pagesSMC HF 24V 30aLeonardoMartinNo ratings yet

- Hydrogenated Amorphous SiliconDocument1 pageHydrogenated Amorphous SiliconRyan LizardoNo ratings yet

- Quint - PS - 100 - 240ac24 DC40Document15 pagesQuint - PS - 100 - 240ac24 DC40AndyNo ratings yet

- TLE-EIM ExamDocument4 pagesTLE-EIM ExamMark Dexter MejiaNo ratings yet

- Amplifier circuits exam questionsDocument4 pagesAmplifier circuits exam questionsjuber mullaNo ratings yet

- Cpac Puritan Bennet 420E PDFDocument56 pagesCpac Puritan Bennet 420E PDFEduardoNo ratings yet

- SEMIKRON DataSheet SKT 160 01238940 PDFDocument5 pagesSEMIKRON DataSheet SKT 160 01238940 PDFraviNo ratings yet

- User Manual: DSP Controlled Studio MonitorDocument5 pagesUser Manual: DSP Controlled Studio MonitorCarmelitas MensageirosNo ratings yet

- Huawei Y5 2019 Quick Start Guide (Amn-Lx9, Emui9.0 - 01, En)Document30 pagesHuawei Y5 2019 Quick Start Guide (Amn-Lx9, Emui9.0 - 01, En)Shoron Yosquy Aragon MedranoNo ratings yet

- Chemical EtchDocument18 pagesChemical EtchznpfgNo ratings yet

- QinetiQ certifies Japan Radio Co.'s ECDIS and Raster Chart Display SystemDocument4 pagesQinetiQ certifies Japan Radio Co.'s ECDIS and Raster Chart Display Systemcem100% (1)

- Random-Access MemoryDocument19 pagesRandom-Access MemorychahoubNo ratings yet

- Silex: Super Critical Cylindrical SilencersDocument1 pageSilex: Super Critical Cylindrical SilencersMaarij AnjumNo ratings yet

- Plastic Memory ReportDocument31 pagesPlastic Memory ReportAjit Padmarajan100% (2)

- 05 O&m V1.20Document38 pages05 O&m V1.20Krisstian SandateNo ratings yet

- alexia-v-owners-manualDocument54 pagesalexia-v-owners-manualHeritier NealNo ratings yet

- MSM 14 75109 - Statys 800A - 1000A - Fan ReplacementDocument17 pagesMSM 14 75109 - Statys 800A - 1000A - Fan ReplacementDoan DaiNo ratings yet

- Solid-State Timer H3T: Ordering InformationDocument8 pagesSolid-State Timer H3T: Ordering Informationheart prince0% (1)

- Mcqs Electrochemistry: Chemistry by Saad AnwarDocument5 pagesMcqs Electrochemistry: Chemistry by Saad AnwarPhoton Online Science Academy0% (1)

- Carlo Gavazzi Rev 10 2013Document252 pagesCarlo Gavazzi Rev 10 2013matoyNo ratings yet

- Technics - RS-TR 979Document34 pagesTechnics - RS-TR 979FernandoNo ratings yet

- Quadxs: Most Rugged Four Door/Eight Reader Access Controller To Ensure Unparalleled Physical SecurityDocument2 pagesQuadxs: Most Rugged Four Door/Eight Reader Access Controller To Ensure Unparalleled Physical SecurityMd Mansoor100% (1)

- Atv 61Document62 pagesAtv 61Сања БанковићNo ratings yet

- Description Mechanical Dimensions: 2.0 Amp Schottky Barrier RectifiersDocument2 pagesDescription Mechanical Dimensions: 2.0 Amp Schottky Barrier RectifiersStuxnetNo ratings yet

- A New Type Seismic Intensity MeterDocument6 pagesA New Type Seismic Intensity MeterSherling GanzNo ratings yet

- Guardians of Glxy - Awesome Mix, Volume I.logDocument4 pagesGuardians of Glxy - Awesome Mix, Volume I.logJesenko BurgićNo ratings yet

- Advances in Communication, Devices and Networking: Rabindranath Bera Subir Kumar Sarkar Swastika Chakraborty EditorsDocument923 pagesAdvances in Communication, Devices and Networking: Rabindranath Bera Subir Kumar Sarkar Swastika Chakraborty EditorsAshish JindalNo ratings yet

- 1097 DDRDocument39 pages1097 DDRapi-352243139No ratings yet

- High-Power Switching Applications Hammer Drive, Pulse Motor Drive ApplicationsDocument5 pagesHigh-Power Switching Applications Hammer Drive, Pulse Motor Drive ApplicationsVito LaudicinaNo ratings yet

- Client Call Report - Nov 29 2017 2pi, Amertron, DBCDocument3 pagesClient Call Report - Nov 29 2017 2pi, Amertron, DBCdexterbautistadecember161985No ratings yet

- LSLVG 100Document343 pagesLSLVG 100Yohanes TriatmojoNo ratings yet