Professional Documents

Culture Documents

Department of Civil Engineering: Materials of Construction and Testing

Uploaded by

John MarkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Department of Civil Engineering: Materials of Construction and Testing

Uploaded by

John MarkCopyright:

Available Formats

DEPARTMENT OF CIVIL ENGINEERING

Materials of Construction and Testing

EXPERIMENT 16: TENSILE STRENGTH OF REINFORCING STEEL BARS

16.1. Program Outcomes (POs) Addressed by the Experiment

b) Ability to design and conduct experiments, as well as to analyze and interpret data.

d) Ability to function on multidisciplinary teams.

16.2. Experiment’s Intended Learning Outcomes (EILOs)

At the end of this experiment the student shall be able to:

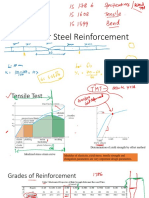

a) Classify the grade of reinforcing steel bars.

b) Apply appropriate ASTM/AASHTO standards for tension testing of reinforcing steel

bars.

c) Compute the tensile strength, yield strength and elongation of reinforcing steel bars.

16.3. Objectives of the Experiment

The objective of this experiment is to determine the yield point, tensile strength and

elongation of the reinforcing steel bar.

16.4. Principle of the Experiment

Tensile strength can be calculated by dividing the maximum load the specimen sustains

during test with the nominal cross – sectional area of the specimen.

Yield strength by dividing the load sustained by the specimen at the sudden halt of the load

indicating pointer by the nominal cross – sectional area of the specimen.

Elongation evaluates the ductility of the steel. It can be expressed as the increase in length of

the gage length as a percentage of the original gage length.

16.5. Materials / Equipment

Universal Testing Machine

Testing Grips

Micrometer Caliper / Scale

Balance

Measuring Tape

Labelling Devices

16.6. Procedure

1. Prepare approximately one meter of reinforcing steel bar and measure its length.

2. Determine the average diameter of the reinforcing steel bar and determine its weight.

3. Mark in the center of the test specimen a 200 mm (8 inches) gage length. Set suitable

grips in the testing to hold the specimens and apply the load until rupture at a uniform

rate.

4. Note the load at the sudden halt of the load indicating pointer and record the

corresponding stress as yield point as well as the maximum load attained by the

material until rupture.

Wednesday, October 21, 2020 2

5. After fracture, fit the ends of the fractured specimen together carefully and measure

the distance between the gage marks for the determination of its percent elongation.

16.7. Activity Report

Course: BSCE Experiment No.: 16

Group No.: 1 Section: V134A

Group Members: AGUILAR, RICO RHEN Date Performed:

AZORES, TRISTAN JANUS Date Submitted:

BALDO, MICHEAL Instructor: ENGR.ALMIENDA

BARCELO, IAN FREDRICK

CAGURUNGAN, JOHN MARK

16.7.1. Data and Results

Mass of the specimen = ______________________

Initial Length = _____49.3m / 493mm____

Final Length = _____55.6m / 566mm____

Specimen Diameter (mm)

1 11.15

2 12.55

3 12.5

4 11.6

5 11.45

6 12.6

Mean Diameter 11.975

16.7.2. Calculation

Wednesday, October 21, 2020 3

16.7.3. Observation

AGUILAR, RICO RHEN

I observed from this experiment is we should determine the yield point, tensile strength

and elongation of the reinforcing steel bar. Tensile strength can be calculated by dividing

the maximum load the specimen sustains during test with the nominal cross – sectional

area of the specimen. Yield strength by dividing the load sustained by the specimen at the

sudden halt of the load indicating pointer by the nominal cross – sectional area of the

specimen. While the Elongation evaluates the ductility of the steel. It can be expressed as

the increase in length of the gage length as a percentage of the original gage length.

AZORES, TRISTAN JANUS

BALDO, MICHEAL

BARCELO, IAN FREDRICK

CAGURUNGAN, JOHN MARK

I observed that in this experiment , tensile strength of reinforcing steel bar is use to

determine the yield point, tensile strength and elongation off the reinforcing steel bar,

also Testing the concrete-rebar bond strength is a more involved process because

reinforced concrete samples must be poured and cured, ensuring a consistent bond length

between samples. The concrete specimens are then secured and a tensile load applied by

clamping and pulling on the exposed rebar end, using a test machine

16.7.4. Conclusion/s

AGUILAR, RICO RHEN

It is extremely important for any tensile testing program to make sure there is

compliance with required standards and that standards being followed are up to date. To

further reduce the risk of incorrectly passing or failing product, it is also essential to

regularly evaluate all aspects of the testing process and take corrective actions as

necessary. Evaluation should include:

* Equipment (machine, grips, extensometers)

Wednesday, October 21, 2020 4

* Specimen Preparation

* Setup (software and hardware)

* Test Control (automatic or manual)

* Calculation of Results (automatic or manual)

With these evaluation, we are able to gather our data. Our speciman has the diameter of

11.15, 12.55, 12.5, 11.6, 11.45 & 12.6 with the mean diameter of 11.975. Our steel bar

has 49.3m initial length while it's final length is 55.6m.

AZORES, TRISTAN JANUS

BALDO, MICHEAL

BARCELO, IAN FREDRICK

CAGURUNGAN, JOHN MARK

Therefore i conclude that the experiment is calculating by dividing the maximum load,

load sustained and elongation evaluate the ductility of steel, in this experiment after we

measure the length of the steel and get the average diameter, we put the steel in the

machine to test, after the test we say that the initial length and final length is different,

final length is longer that initial, because in the test the steel was stretch by the machine.

16.7.5. Rating

16.8. References

ASTM A615/A615M. (2016). Standard Specification for Deformed and Plain Carbon Steel Bars

for Concrete Reinforcement. West Conshohocken, PA: ASTM International.

ASTM E8/E8M. (2009). Standard Test Methods for Tension Testing of Metallic Materials. West

Conshohocken, PA: ASTM International.

Bureau of Reserach and Standards. (2014). Laboratory Testing Procedures Manual:

Miscellaneous Construction Materials (Vol. V). Quezon City: Department of Public Works and

Highways.

Wednesday, October 21, 2020 5

You might also like

- Cec 204 PracticalDocument35 pagesCec 204 PracticalPratibha Singh50% (2)

- Tensile Test ReportDocument12 pagesTensile Test ReportMayowaNo ratings yet

- 002 Design Base Shear PDFDocument34 pages002 Design Base Shear PDFJohn Mark100% (1)

- Lab Report Bend Test UNIKL MFIDocument10 pagesLab Report Bend Test UNIKL MFINutmeg100% (1)

- Mechanical Behavior of Metals Lab ManualDocument33 pagesMechanical Behavior of Metals Lab ManualSaumya AgnihotriNo ratings yet

- Tensile Test Experiment Lab ReportDocument78 pagesTensile Test Experiment Lab ReportAmerul izwan Amiruddin88% (8)

- 5 Displacement and Force in Two Dimensions: 2 FrictionDocument5 pages5 Displacement and Force in Two Dimensions: 2 Frictionalex murker100% (1)

- Astm C 393Document4 pagesAstm C 393Arash Aghagol0% (1)

- Vector-Active Structure Systems PDFDocument35 pagesVector-Active Structure Systems PDFHaneen HamdonaNo ratings yet

- Dental BiomaterialsDocument491 pagesDental Biomaterialsaris100% (1)

- Sirius in Art and Astronomy of DogonDocument7 pagesSirius in Art and Astronomy of DogonKonstantinos MantasNo ratings yet

- ESC Marine Fenders Catalogue 2018 - 2019 PDFDocument46 pagesESC Marine Fenders Catalogue 2018 - 2019 PDFDiguinho PiresNo ratings yet

- Me136p Exp3 Bend Test of Reinforcing Steel BarsDocument14 pagesMe136p Exp3 Bend Test of Reinforcing Steel BarsJohn Henry SalvadoNo ratings yet

- Strength of Materials ReportDocument14 pagesStrength of Materials ReportRahul JohnsonNo ratings yet

- Som Lab Manual NnceDocument39 pagesSom Lab Manual Nncelogeshboy007No ratings yet

- Experiment 16: Tensile Strength of Reinforcing Steel Bars 16.1. Program Outcomes (Pos) Addressed by The ExperimentDocument4 pagesExperiment 16: Tensile Strength of Reinforcing Steel Bars 16.1. Program Outcomes (Pos) Addressed by The ExperimentJhanyn VivoNo ratings yet

- Postlab 1Document5 pagesPostlab 1Iana LeynoNo ratings yet

- Strength of MaterialDocument18 pagesStrength of MaterialMamta SinghNo ratings yet

- Broas CE152P-2 A71 Experiment6 Module2Document8 pagesBroas CE152P-2 A71 Experiment6 Module2Godwin BroasNo ratings yet

- Report3 Bending Test Steps.Document10 pagesReport3 Bending Test Steps.Lama AbdullahNo ratings yet

- Sokoine University of Agriculture: Department of Engineering Sciences and TechnologyDocument16 pagesSokoine University of Agriculture: Department of Engineering Sciences and TechnologyEngr.Hamid Ismail CheemaNo ratings yet

- Teopengco CE152P-2 E01 Experiment7 Module3Document8 pagesTeopengco CE152P-2 E01 Experiment7 Module3TEOPENGCO ALEC JOHNNo ratings yet

- Experiment 2: Tensile Test of Reinforcing Steel Bar: Feu Institute of Technology Department of Mechanical EngineeringDocument11 pagesExperiment 2: Tensile Test of Reinforcing Steel Bar: Feu Institute of Technology Department of Mechanical EngineeringMat Eugine Paul ComiaNo ratings yet

- INME-211 Eng. Material Technology. Done By: Moetassem Billah Saraya. ID:201902035. DATE:20-9-2019. Brinell Hardness TestDocument6 pagesINME-211 Eng. Material Technology. Done By: Moetassem Billah Saraya. ID:201902035. DATE:20-9-2019. Brinell Hardness TestMoetassem SarayaNo ratings yet

- Flexural Strength Test of ConreteDocument4 pagesFlexural Strength Test of ConreteKenghie Dela CruzNo ratings yet

- SOM Lab ManualDocument32 pagesSOM Lab ManualMuhammad Junaid100% (1)

- MT Lab ManualDocument29 pagesMT Lab Manualtarap11040No ratings yet

- Ce6411 Strength of Materials Laboratory (Civil)Document32 pagesCe6411 Strength of Materials Laboratory (Civil)Koleshwar Mahto KoleshwarNo ratings yet

- CE6411 Strength of MaterialsDocument38 pagesCE6411 Strength of Materialsamns99No ratings yet

- Engineering Materials Lab. No. (1) : Komar University of Science and TechnologyDocument8 pagesEngineering Materials Lab. No. (1) : Komar University of Science and TechnologyMuhamadMarufNo ratings yet

- Som Lab ManualDocument31 pagesSom Lab Manualmotiur rahman100% (2)

- Calculation of Measurement Uncertainty For Tensile Strength and Flexural Strength of ThermoplasticDocument11 pagesCalculation of Measurement Uncertainty For Tensile Strength and Flexural Strength of ThermoplasticHassam BashirNo ratings yet

- Engineering Material 1Document25 pagesEngineering Material 1essum belaNo ratings yet

- Material Testing Lab ManualDocument34 pagesMaterial Testing Lab ManualYogeswaranNo ratings yet

- Me136p Exp3 Bend Test of Reinforcing Steel BarsDocument14 pagesMe136p Exp3 Bend Test of Reinforcing Steel BarsJohn Henry SalvadoNo ratings yet

- LAB 1 - Tensile Test PolymerDocument10 pagesLAB 1 - Tensile Test PolymerAmilin HatiaraNo ratings yet

- Strength of Materials Lab-Ahmed AlsharaDocument24 pagesStrength of Materials Lab-Ahmed AlsharaMṜ ΛßßΛSNo ratings yet

- Me-302 Solid Mechanics-Ii - .Document68 pagesMe-302 Solid Mechanics-Ii - .Omar HameedNo ratings yet

- Final Tesile Testing ReportDocument12 pagesFinal Tesile Testing Reportismael hashiNo ratings yet

- MEC424 Content TensileDocument13 pagesMEC424 Content TensileHaFiy HaZim0% (1)

- Bendin Test On Mild SteelDocument20 pagesBendin Test On Mild SteelEriane Garcia100% (1)

- Discussion and ConclusionDocument16 pagesDiscussion and Conclusionzul hilmiNo ratings yet

- Material Testing Lab ManualDocument29 pagesMaterial Testing Lab ManualJithin Thomas ANo ratings yet

- LAB 1 STL261S TensileTestDocument9 pagesLAB 1 STL261S TensileTestMinister Peace ShalomNo ratings yet

- Experiment No. 9: Universal Tensile TestDocument9 pagesExperiment No. 9: Universal Tensile TestSyakirin IsmailNo ratings yet

- Material Lab 4Document6 pagesMaterial Lab 421pwind0685No ratings yet

- Design of Concrete Structures: Engineering 5706 Laboratory Instructions For Reinforced Concrete BeamsDocument5 pagesDesign of Concrete Structures: Engineering 5706 Laboratory Instructions For Reinforced Concrete BeamsmhwahebNo ratings yet

- SOM LabDocument22 pagesSOM LabVJ SharmaNo ratings yet

- Lab Manual 2019Document44 pagesLab Manual 2019se ruNo ratings yet

- Exp 2 ErianeDocument15 pagesExp 2 ErianeEriane GarciaNo ratings yet

- CVP243 Steel ReinforcementDocument9 pagesCVP243 Steel ReinforcementManikyaMayankNo ratings yet

- Laboratory Experiment 1.3Document6 pagesLaboratory Experiment 1.3Wes FerrerNo ratings yet

- Design of Composite Structures Containing Bolt Holes and Open Holes PDFDocument33 pagesDesign of Composite Structures Containing Bolt Holes and Open Holes PDFJizzPontesNo ratings yet

- Advanced SOM. LAB. Manual-2Document15 pagesAdvanced SOM. LAB. Manual-2Sudip LouhaNo ratings yet

- Lab Manual: International Islamic University Malaysia Department of Mechanical EngineeringDocument36 pagesLab Manual: International Islamic University Malaysia Department of Mechanical EngineeringMuhamad HilmiNo ratings yet

- EXP 7 - MaterialsDocument18 pagesEXP 7 - MaterialsLeslie CatindigNo ratings yet

- Marvil ME136P-2 E01 Experiment 3Document9 pagesMarvil ME136P-2 E01 Experiment 3Mitchell MarvilNo ratings yet

- Workability Study On Austempered AISI 1018Document8 pagesWorkability Study On Austempered AISI 1018MohanNo ratings yet

- 1.0 Compression TestDocument5 pages1.0 Compression TestmuuulNo ratings yet

- Som Manual-2013 RegDocument26 pagesSom Manual-2013 RegsugunavidiyadarNo ratings yet

- 2680-Article Text-8031-1-10-20240128Document5 pages2680-Article Text-8031-1-10-20240128Amira Nur Fadilah HendartoNo ratings yet

- Me136p Exp2 Tensile Test of Reinforcing Steel BarsDocument15 pagesMe136p Exp2 Tensile Test of Reinforcing Steel BarsJohn Henry SalvadoNo ratings yet

- Me136p Exp2 Tensile Test of Reinforcing Steel BarsDocument15 pagesMe136p Exp2 Tensile Test of Reinforcing Steel BarsJohn Henry SalvadoNo ratings yet

- Lab Sheet Tensile Test Steel BarDocument4 pagesLab Sheet Tensile Test Steel BarAbdul nurNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Load-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresFrom EverandLoad-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresNo ratings yet

- Experiment# 11Document9 pagesExperiment# 11John MarkNo ratings yet

- Expi. 2 GroupreportDocument2 pagesExpi. 2 GroupreportJohn MarkNo ratings yet

- 001 Introduction To Earthquake EngineeringDocument28 pages001 Introduction To Earthquake EngineeringJohn MarkNo ratings yet

- Experiment 6: Bulk Density (Unit Weight) and Voids in Aggregate 6.1. Program Outcomes (Pos) Addressed by The ExperimentDocument5 pagesExperiment 6: Bulk Density (Unit Weight) and Voids in Aggregate 6.1. Program Outcomes (Pos) Addressed by The ExperimentJohn MarkNo ratings yet

- Penetration Is Defined As The Consistency of A Bituminous Material Expressed As The DistanceDocument7 pagesPenetration Is Defined As The Consistency of A Bituminous Material Expressed As The DistanceJohn MarkNo ratings yet

- Expi. 5 GroupreportDocument3 pagesExpi. 5 GroupreportJohn MarkNo ratings yet

- 14 Making and Curing Concrete Test Specimens in The FieldDocument6 pages14 Making and Curing Concrete Test Specimens in The FieldJohn MarkNo ratings yet

- Experiment # 14Document7 pagesExperiment # 14John MarkNo ratings yet

- Penetration Is Defined As The Consistency of A Bituminous Material Expressed As The DistanceDocument7 pagesPenetration Is Defined As The Consistency of A Bituminous Material Expressed As The DistanceJohn MarkNo ratings yet

- Hydroelectric Powerplants & Water TurbinesDocument9 pagesHydroelectric Powerplants & Water TurbinesJohn MarkNo ratings yet

- Watershed Management: Pantabangan DamDocument14 pagesWatershed Management: Pantabangan DamJohn Mark0% (1)

- 14 Making and Curing Concrete Test Specimens in The FieldDocument6 pages14 Making and Curing Concrete Test Specimens in The FieldJohn MarkNo ratings yet

- Practice Exam2Document2 pagesPractice Exam2liza davitadzeNo ratings yet

- UNIT-3 Illumination System: Lecture Videos On YoutubeDocument7 pagesUNIT-3 Illumination System: Lecture Videos On YoutubeLavanya LakshmiNo ratings yet

- Lesson Plan Mole ConceptDocument3 pagesLesson Plan Mole ConceptQueencess Ara TorresNo ratings yet

- Three Ways To Define The Poisson ProcessDocument23 pagesThree Ways To Define The Poisson ProcessMansi PanwarNo ratings yet

- Lab Services Materials CharacterizationDocument8 pagesLab Services Materials CharacterizationOwais MalikNo ratings yet

- Unit-IV. Design of Deep FoundationDocument91 pagesUnit-IV. Design of Deep FoundationRwagatare civilcontractorsNo ratings yet

- 300+ TOP Engineering Mechanics Objective Questions & AnswersDocument24 pages300+ TOP Engineering Mechanics Objective Questions & AnswersramkumarNo ratings yet

- 15.3 Integrating FactorDocument3 pages15.3 Integrating FactorHin Wa Leung100% (1)

- Amilan® CM1026: Toray Industries, IncDocument3 pagesAmilan® CM1026: Toray Industries, IncAgoenk KertawijayaNo ratings yet

- Design 2Document6 pagesDesign 2bmyertekinNo ratings yet

- Practice Paper For XII BDocument6 pagesPractice Paper For XII BvartikaagrawalaNo ratings yet

- Regional Subsidence Effects in Tunnel-Soil-Structure Seismic InteracionDocument7 pagesRegional Subsidence Effects in Tunnel-Soil-Structure Seismic Interacionmauricio perez diazNo ratings yet

- Institute of Geology and Petroleum Technologies of Kazan Federal University Master Degree Program Petroleum Engineering 1Document3 pagesInstitute of Geology and Petroleum Technologies of Kazan Federal University Master Degree Program Petroleum Engineering 1Fatima BenmohamedNo ratings yet

- 17-Dec - Kota - PNCF - IOQJS - ST Test-1 - Sub Mainbatch PaperDocument3 pages17-Dec - Kota - PNCF - IOQJS - ST Test-1 - Sub Mainbatch PaperAshrith0% (1)

- Introduction To Power Reactor Types: Prof. Jacopo BuongiornoDocument22 pagesIntroduction To Power Reactor Types: Prof. Jacopo BuongiornoHenriqueNo ratings yet

- Standard Specification For Lightweight Aggregates For Insulating Concrete PDFDocument3 pagesStandard Specification For Lightweight Aggregates For Insulating Concrete PDFAndy OliveraNo ratings yet

- Topics 11 and 21 HL Measurement and Data ProcessingDocument23 pagesTopics 11 and 21 HL Measurement and Data ProcessingDuddlie YuNo ratings yet

- OIML R 137-1&2: Nternational EcommendationDocument70 pagesOIML R 137-1&2: Nternational EcommendationNicole WilliamsNo ratings yet

- Preformed Expansion Joint Fillers For Concrete Construction (Nonextruding and Resilient Types)Document7 pagesPreformed Expansion Joint Fillers For Concrete Construction (Nonextruding and Resilient Types)Gregorio ToroNo ratings yet

- Experimental and Theoretical Analysis of A Heat Pipe Heat Exchanger Operating With A Low Global Warming Potential RefrigerantDocument8 pagesExperimental and Theoretical Analysis of A Heat Pipe Heat Exchanger Operating With A Low Global Warming Potential RefrigerantasalazarhNo ratings yet

- Sample LET Math QuestionsDocument5 pagesSample LET Math QuestionsAljon Tupas TevesNo ratings yet

- 9 Science NcertSolutions Chapter 10 ExercisesDocument12 pages9 Science NcertSolutions Chapter 10 Exercisestindutt life timeNo ratings yet

- AA Mury, SC Pont, JJ Koenderink - Structure of Light Fields in Natural Scenes (2009)Document10 pagesAA Mury, SC Pont, JJ Koenderink - Structure of Light Fields in Natural Scenes (2009)Joseph WhiteNo ratings yet

- Tiering SystemDocument14 pagesTiering SystemRichard R.IgnacioNo ratings yet

- 3x16 Rm+1x10 RM 2xRGY - DocxxDocument1 page3x16 Rm+1x10 RM 2xRGY - DocxxRasel AhmedNo ratings yet