Professional Documents

Culture Documents

Oil and Gas Industry Megaprojects-Our Recent Track Record - Merrow 2012 PDF

Uploaded by

Fernando Jimenez ChillonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil and Gas Industry Megaprojects-Our Recent Track Record - Merrow 2012 PDF

Uploaded by

Fernando Jimenez ChillonCopyright:

Available Formats

Oil and Gas Industry Megaprojects:

Our Recent Track Record

Edward W. Merrow, Independent Project Analysis, Inc.

Summary with 33% real cost overruns, cost indices* that averaged 1.37, and

In a recent major study of industrial megaprojects, the author finds execution schedule slip of 30%. More importantly, a disappointing

that oil and gas industry megaprojects fared very poorly. Earlier 64% of these projects experienced serious and enduring production

studies showed that the results of oil and gas megaprojects were attainment problems in the first 2 years after first oil or gas.** The

quite similar to the results from megaprojects in other industrial issue this paper addresses is why the relative performance of oil and

sectors. With this much larger and more recent set of megaprojects, gas megaprojects dropped so precipitously in the first decade of the

we find that upstream megaprojects are more fragile than their non- twenty-first century.

oil and gas industry cousins. The author attributes this finding to

the poor functional integration that characterizes upstream project Database and Methodology

organizations, which makes these complex projects much more For the larger study of which this paper is a small part (Merrow

sensitive to poor preparation, schedule aggressiveness, and loss of 2011), the author employed detailed project information from three

continuity in project leadership. IPA databases:

The Onshore Processing Facilities database, which contains

Introduction data for minerals, petroleum processing† and refining/upgrading,

Projects throughout the process industries—oil and gas, chemicals, and chemicals megaprojects.

and minerals—have become significantly larger and more complex • The Offshore Oil and Gas Production database, which in-

over the past decade or so. The underlying reasons for increasing cludes information on the facilities and wells programs for offshore

project size and difficulty are understood—we are developing nat- reservoirs.

ural resources in progressively more difficult circumstances simply • The Onshore Upstream database, which contains the equiva-

because we have to. Moreover, the choice of oil and gas develop- lent information for onshore field developments.

ments is influenced by the decisions of some large resource-holding Because so many megaprojects have been completed during the

countries to restrict or delay the development of some more easily past decade, the resulting database is much more robust than the

accessible reservoirs. database used to support IPA’s earlier studies. The average project

Eight years ago at the Offshore Technology Conference, the in the database is approximately USD 3 billion measured in start-

author reported on a distressing pattern that Independent Project of-2009 terms. The largest project, a large field development, was

Analysis (IPA) was seeing in offshore projects: Success, mea- USD 18 billion. The median authorization date is 2003. The com-

sured by how well we meet promises made at the time of the finan- position of the database is described in Table 1.

cial investment decision (FID), declines rapidly with project size Oil and gas production projects dominate the sample, followed by

(Merrow 2003). (Note: IPA benchmarks projects before FID and petroleum processing facilities of one kind or another (refinery proj-

project systems in the oil and gas and other capital-intensive indus- ects, heavy oil upgraders, and standalone gas plant projects) and min-

trial sectors.) While projects in the USD 300- to USD 600-million erals mining and processing complexes. All other types of projects

range were largely successful, the success rate for the megaproj- constitute less than a quarter of the sample. The oil and gas projects

ects—defined as exceeding USD 1 billion measured in constant were executed by 33 companies acting as lead operator. Those opera-

start-of-2003 terms—was approximately 50%. Interestingly, mega- tors were almost evenly divided among large integrated international

projects in other industrial sectors, such as downstream oil and gas, oil companies, national companies, and the so-called independents.

minerals, and chemicals, had approximately the same rates of suc- The projects are distributed around the world in many of the

cess and failure. major producing provinces. Table 2 shows the worldwide distribu-

In this updated analysis with a much larger sample of both oil tion of the projects.

and gas and other process industry megaprojects, our conclusion

is quite different for oil and gas projects. While non-oil and gas Methods

development projects increased in size and difficulty, they main- To help understand the patterns in the data, a number of very stan-

tained a success rate of approximately 50%. This rate of success is dard statistical techniques are employed, including ordinary least-

certainly not good, but at least it had not declined despite the much squares regression, logit and probit regression, and frequency

more difficult projects market. Meanwhile, the performance of oil tables tested with Pearson’s chi-square for statistical significance.

and gas megaprojects collapsed; only 22% of these projects could We report statistical significance using the conventions shown in

reasonably be called successful. While the successful projects were Table 3. [“Statistical significance” indicates that a result is unlikely

spectacularly successful, the other 78% were equally unimpressive to have been generated very often if repeated draws of random data

*The IPA cost index measures the competitiveness of facilities cost relative to industry

Copyright © 2012 Society of Petroleum Engineers norms for like developments.

**Productionattainment is the ratio of actual oil and gas production to forecast of production

This paper (SPE 153695) was accepted for presentation at the Offshore Technology

Conference, Houston, 2–5 May 2011, and revised for publication. Original manuscript levels made at FID. It is the largest single driver of return on investment.

received 24 January 2011. Revised manuscript received 20 July 2011. Paper peer approved †The term petroleum processing refers to standalone gas and oil processing facilities that

14 September 2011. are not an integral part of a new reservoir development.

38 Oil and Gas Facilities • April 2012

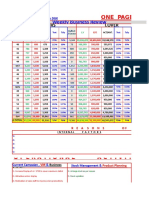

TABLE 1—CURRENT MEGAPROJECT DATABASE

Industrial Sector Number Percent of Sample

Oil and gas production 130 41

Petroleum processing and refining 66 21

Minerals and metals 47 15

Chemicals 31 10

Liquefied natural gas (LNG) 24 8

Power generation 8 3

Pipelines 7 2

Other 5 2

Totals 318 100*

*Does not add because of round-off error.

When a project suffers a major deviation from its FID prom-

TABLE 2—GEOGRAPHICAL DISTRIBUTION OF E&P

ises, it is classified as a failure. This does not necessarily mean that

MEGAPROJECTS

the project was unprofitable; rather, it means that the net present

Upstream Project Location Percent of Sample value (NPV) of the project was much lower—generally less than

half—than it would have been if the project had delivered on its

Europe 23

FID promises. Using the criteria for success and failure laid out in

South America 16 Merrow (2011), only 22% of oil and gas projects were successful

West Africa 14 versus half of non-E&P projects (Pr>|z|<.001).

United States 11 As seen in Table 4, the typical oil and gas megaproject was very

Middle East/North Africa 10 expensive, and a great deal more expensive than planned. It was

Central Asia 8 also nearly a year late. Worst of all, it was frequently quite disap-

Australia 8 pointing in terms of production. The failure to produce is by far the

Asia 7 most economically damaging result.

Canada 3 When we separate the small group of successful E&P megaproj-

ects, a much clearer picture emerges of the size of the economic

Total 100

disaster represented in the overall results. Fig. 1 shows the differ-

ence between the successful oil and gas megaprojects and the fail-

had been made. As a matter of convention, IPA generally uses a 5% ures. The 22% of E&P megaprojects that succeeded were truly

chance, but most of the results discussed in this paper are much brilliant projects: Their average cost was lower than budgeted and

stronger than that threshold. The statistical significance is indicated they were on time, they were very cost effective, they had average

by Pr<XX, which means the probability is less than the number schedules, and they all produced as promised. The successes were as

(XX) shown.] Unless otherwise noted, only results that are statisti- challenging technologically as the failures—there is no systematic

cally significant at a .05 probability or less are reported. Two-tailed difference in water depth, metocean conditions, or technical com-

tests are also employed. plexity. In fact, the successes were, on average, more innovative than

the failures, although the difference is not statistically significant.

Sample Bias By contrast, the failures were dismal projects: They were badly

There are two known biases in the data, both of which will tend to overrun, very expensive, and very late in delivery, and two-thirds

make the upstream project results look better than a fully random of them were production failures. The reader with good pattern rec-

sample of upstream megaprojects might. ognition skills, however, will have noted the anomaly in Fig. 1: the

• Europe is overrepresented, which provides a bit of positive schedule indices. Even though the failures slipped by 30%, their

bias to the sample. E&P megaprojects in the North Sea, Atlantic required execution time was just a few percent longer than that of

margin, and onshore were approximately twice as likely to be suc- the successes. Conversely, the successes were extraordinarily suc-

cessful as projects generally. Even then, they failed more often than cessful in every outcome dimension except schedule, in which they

non-E&P megaprojects. were merely average. That anomaly in the pattern allows us to begin

• At IPA, we know for a fact that our clients are less likely to to understand what separates successful and unsuccessful upstream

provide us the opportunity to collect final data for disaster proj- megaprojects: whether or not the projects set aggressive schedules.

ects than for normal projects. A variety of reasons is put forward, We have now established that upstream megaprojects fail more

ranging from the termination of involved personnel to pending liti- often than non-upstream megaprojects. We have established that

gation to a lack of knowledge of the actual costs. As a result, some the successes were very good projects indeed and that the failures

very poor projects escape the benchmarking process, which biases were very disappointing, except regarding schedule, in which they

the sample. were about average. Now, we explore the reasons for these results.

Because the direction of the biases is understood and reinforces

rather than undermines our conclusions, the presence of the biases Understanding the Poorer Outcomes

is not a major concern. There are three major factors that, taken together, explain the poorer

outcomes of upstream megaprojects. All three are manifestations of

Oil and Gas Outcomes Are Poorer the industry’s struggle to effectively integrate the functions that are

As stated in the Introduction, upstream megaprojects are not faring needed to produce excellent upstream projects. The three factors are:

as well as other industrial megaprojects. Table 4 provides some ev- • Front-End loading (FEL) is much more important for oil and

idence of this. gas megaprojects. FEL is the owner work process that prepares a

April 2012 • Oil and Gas Facilities 39

TABLE 3—METHODS

Technique Test Statistic Notation

Least squares or t-test t-ratios/t-test Pr>|t|<.0X

Logit or probit regression z-ratio Pr>|z|<0X

Pearson correlation r Pr>|r|<.0X

2 2

Cross tabulation Chi-square (χ ) Pr>| χ |<.0X

TABLE 4—COMPARING E&P AND NON-E&P MEGAPROJECT OUTCOMES

Measure of Merit Upstream Megaprojects Other Megaprojects

Cost overrun (%)* 25 15

Cost competitiveness % of industry average capex** 127 1.11

Slip in execution schedules (%)† 22 15

Severe and continuing production shortfalls†† 45 32

* Cost overruns are measured as the final actual capital cost, including Phase 1 well construction, divided by the FID estimate, with both adjusted to the same

currency and time base (escalation removed).

** Competitiveness is measured as the relationship between project cost per unit of capacity vs. industry average cost, with all adjusted to the same currency and time

base.

†

Slip is measured as the actual time from FID to first production divided by the time promised at FID.

††

A project is considered a production attainment failure if the project suffers extended shut-ins of production into the second year after first oil. E&P projects in this

category averaged less than 50% of first-year planned production, even after adjusting for slips in execution schedule.

project for FID. FEL is usually formatted into three stages: busi- The Effects of Turnover in Project Leadership

ness case development and appraisal, scope development, and Like poor FEL, turnover in the leadership positions, especially

front-end engineering design (FEED), which also includes execu- the project director position, damages project outcomes. This has

tion planning. been established quantitatively for many years. For smaller proj-

• Continuity of the project leadership is almost essential to ects, turnover in the project-manager position usually drives a delay

project success and much more important for oil and gas projects in execution and a modest amount of cost growth** because minor

than for those from other industrial sectors. changes to the project scope are made by the functions that were

• The strong tendency of upstream businesses to establish ag- not getting all they wanted from the prior project manager.

gressive schedules is different from non-upstream asset devel- For megaprojects, the turnover of the project director is asso-

opments, and exacerbates and accentuates the effects of the two ciated with substantially poorer project outcomes. Some, but only

previously described factors. some, of the association is created by decisions to replace the

We will discuss each factor in turn, showing the data that sup- project directors of failing projects. It is actually unusual to replace

port the conclusions. project directors because a project is not doing well. That is a fate

usually reserved for the contractor project managers.

FEL The turnover of the project director for an average upstream

For new field development projects, FEL includes the appraisal and project is associated with a 30% decline in the probability of

definition of the reservoir, definition of the facilities, and defini- achieving a successful project even after first controlling for the

tion of the well construction program. There are entirely analogous effects of FEL (Pr>|z|.004). If the sample is restricted to oil and

processes in other industrial areas. IPA measures FEL on a numer- gas projects that achieved a Good or Best Practical level of FEL,

ical index that runs from 3.00, which is the best possible, to 12.00, those without a turnover in the project leadership were successful

which indicates that no work has been done at all.* We divide the nearly two-thirds of the time, approximately as often as the equiva-

scale into descriptive categories as shown on the abscissa of Fig. 2. lent non-E&P project. If the project director turned over, however,

All projects and all outcome areas of projects are responsive to the the success rate plummeted to less than one in three. By contrast,

completeness of FEL. if the project director was replaced on a non-E&P project that was

As shown in Fig. 2, however, oil and gas megaproject outcomes equally well front-end loaded, there was a mere 5% decline in the

are particularly sensitive to the completeness of the front-end work. success rate that was not statistically significant.†

As FEL degrades, megaproject cost overruns mount quickly.* Two key conclusions can be drawn:

The average oil and gas megaproject was defined to a level in the • Turnover of the project director is quite devastating for oil and

middle of the Fair range. The typical non-upstream megaproject gas megaprojects, even if the team has properly prepared for and

was defined in the upper half of the Good range. Given the differ- developed the project.

ence in the slopes of the regression lines, that difference translates • The effects of turnover are more severe for oil and gas mega-

into significantly more cost growth for oil and gas projects. projects than for other industrial megaprojects.

*IPA’s approach to measuring front-end definition of projects has been described in a

**Recall that cost growth is calculated after all effects of escalation have been removed.

number of prior publications and need not be repeated here. See Andrew F. Griffith,

“Improving Project System Performance Through Benchmarking,” Proceedings of the PMI †Another difference is that turnover in the project director in upstream projects is more likely

Global Congress 2006, Madrid, Spain and Andrew F. Griffith and Mary Ellen Yarossi, “Stage- when FEL is poorer, but the correlation coefficient is only 0.19. It is statistically significant,

Gated Process for Project Definition of Capital Projects,” 19th IPMA World Congress, New but not nearly colinear. In non-upstream megaprojects, there is no relationship at all

Delhi, India, 13–16 November 2005. between the two variables.

40 Oil and Gas Facilities • April 2012

COST INDEX

1.40

E&P Failures

1.30

E&P Successes

1.20

COST 1.10 PRODUCTION

GROWTH 40% 1.00 FAILURES

75%

30% 60%

20% 45%

0.90 30%

10% 15%

0% 0%

0.90 0%

1.00

10%

1.10

20%

1.20

30%

1.30

1.40 40%

SCHEDULE INDEX

SCHEDULE SLIP

Fig. 1—E&P megaproject successes and failures: striking differences in performance.

Another measure of schedule strategy is the relationship be-

Complete FEL Is More Important for tween the schedule established at FID and the schedule typically

Petroleum Development Megaprojects achieved by equivalent projects. We call this measure “schedule ag-

gressiveness.” The actual Schedule Aggressiveness Index for non-

80%

Pr<0.001 oil and gas megaprojects averages 1.05; that is, the schedule is 5%

70% longer than what is usually required. Upstream projects average a

60% Schedule Aggressiveness Index of 0.90 and the median index was

E&P Megaprojects even more heroic at 0.87. Oil and gas projects routinely establish

Cost Growth

50%

schedule targets for execution that cannot be met.

40% The drive for unobtainable speed to first oil is crippling the in-

30% dustry. It is driving up cost by many tens of billions of dollars in

Pr<0.01 CAPEX each year, and it is driving down production attainment

20%

Non-E&P Megaprojects after first oil is achieved. The cost index, a measure of CAPEX

10% competitiveness, for schedule-driven upstream projects was an as-

0% tounding 142% of the industry average. After slipping their aggres-

sive schedules, the projects ended up slower than average—and,

–10%

BEST GOOD FAIR POOR SCREENING after all the effort associated with executing a schedule-driven

Asset FEL Index

project, 59% of the projects suffered severe problems with produc-

tion attainment.. (Although the drive for speed is understandable in

an era of high oil prices, this result forfeits almost all of the gain

Fig. 2—FEL and the cost of E&P megaprojects. that the high prices might have brought the industry.)

When a project attempts to achieve unobtainable speed, the

quality of all work that goes into successful projects begins to

erode. This often starts with the completeness of the reservoir ap-

• Therefore, there is some feature of upstream projects that praisal, which explains many of the production attainment disap-

makes the project director position uniquely important. pointments. FEL for both facilities and wells is short-cut, which

sets the project up for many late changes during execution; then, in

The Drive for Speed a final twist, we are much more likely to turn over the project di-

The most important difference between upstream and other indus- rector position at least once if the project is schedule driven, a result

trial megaprojects is found in the schedule strategy. Outside E&P, that undermines the goal.* Seventy-seven percent of schedule-

the strategy is usually to set the project’s duration at or close to the driven upstream megaprojects suffered a turnover versus half of the

average speed achieved by equivalent projects executed in the past. non-schedule-driven projects, which is higher than the average for

Fifty-four percent of upstream projects were explicitly “schedule all non-upstream megaprojects.

driven.” This designator is given to a project when the business has

instructed the project team to minimize the time to first produc- What Makes Speed Unobtainable?

tion or set a schedule to first production that is much faster (15% I am sure we can all agree that rapid development of petroleum

or more) than industry average for equivalent projects; in these resources is, other things being equal, better than slower develop-

projects, the business is willing to increase the capital expenditure

(CAPEX) to achieve the schedule target. Only 32% of non-E&P

megaprojects were schedule driven. The difference is clearly statis- *It is difficult to understand why the industry turns over the project director position so much

more often on schedule-driven projects. In some cases, burnout was clearly the problem.

tically significant (Pr>|χ2|<.01). But overall, it is a perverse result.

April 2012 • Oil and Gas Facilities 41

ment. The problem is that those “other things” are often not equal. dustries, the functions are better integrated at the outset, rendering

Shorter development cycle times to first oil followed by severe pro- the role of the project director less important.

duction attainment shortfalls is not a success. A huge overspend in

CAPEX means that some other project will not be funded. Conclusion

Yet, sometimes speed is achieved without losing excellence in Unless or until large E&P organizations find a way to achieve deep

other dimensions. This leads the financial analysts who track the in- functional integration, they need to stop listening to the siren song

dustry to bemoan the slow pace of developments, especially by the of speed for the sake of speed. Instead, they need to learn the virtues

large companies. However, what is essential for speed with excel- of patience and discipline, which are at least a little more common

lence is the one thing that the large petroleum companies absolutely in other industries.

have not figured out how to achieve: seamless functional integra-

tion. A functionally integrated team is one in which the reservoir References

functions, facilities engineers, and drillers work in harmony and Merrow, E. 2003. Reflections on 10 Years of Upstream Asset Development

mutual comprehension. Ironically, smaller companies, the indepen- Benchmarking. Paper Oral presentation presented at the Offshore

dents, are often able to achieve this ideal because of their small size Technology Conference, Houston, 5–8 May.

and because each function and subfunction has not (yet) evolved Merrow, Edward W. 2011. Industrial Megaprojects: Concepts, Strategies,

into an organization with turf to defend and walls to build. Given and Practices for Success. New Jersey, USA: John Wiley & Sons.

the way that large companies organize large developments, the fi-

nancial analysts who are pushing the businesses to drive for speed Ed Merrow is the founder and President of Independent Project Analysis

are actually doing the industry a massive disservice. (IPA), Inc. Established in 1987, IPA provides a unique project research

capability for the process and extraction industries. IPA has grown from a

Why Is the Project Director Position So Important? one-person organization to over 200 employees with offices in North and

At this point, I hope that the reader can answer this question im- South America, the United Kingdom, The Netherlands, Australia, Singa-

mediately: Because the project director position is the glue that pore, and China. After receiving degrees from Dartmouth College and

binds the functions together in large companies to provide some Princeton University, Merrow served as an Assistant Professor at UCLA,

semblance of good functional integration. The project director is where he taught mathematical economic modeling and industrial orga-

usually the only position that performs this vital function in most nization. He then joined the Rand Corporation, where he developed and

upstream megaprojects. directed Rand’s Energy Program and Research Program for the Chem-

The key organizational problem is our insistence on establishing ical Process Industries. After 14 years with Rand, he left in 1987 to form

separate reservoir, facilities, and wells teams and then trying to IPA. He received the 2007 Construction Industry Institute’s highest honor,

cobble them together into a coherent whole. Sometimes it works; the Carroll H. Dunn Award of Excellence, and the 2001 Engineering and

often, it does not. When it works, it is often because the project Construction Contracting (ECC) Division Award for Outstanding Contribu-

leadership has assumed the role of functional integrator for the de- tions to the Industry. Merrow has delivered hundreds of keynote speeches

velopment. That person becomes the glue that binds the entire de- for major companies and organizations regarding capital project manage-

velopment together. When we replace this person, we dissolve the ment and performance around the world, in addition to testifying before

glue and dis-integrate [sic] the effort. the U.S. Congress in matters pertaining to overruns in major capital proj-

In other industries, approaches to asset development have not ects. His years of analysis and research have culminated in the publica-

evolved with the degree of separation between functions that is so tion of his latest work, Industrial Megaprojects—Concepts, Strategies, and

prevalent in the petroleum industry. As a consequence, in those in- Practices for Success.

42 Oil and Gas Facilities • April 2012

You might also like

- Accelerating hydrogen deployment in the G7: Recommendations for the Hydrogen Action PactFrom EverandAccelerating hydrogen deployment in the G7: Recommendations for the Hydrogen Action PactNo ratings yet

- EY Spotlight On Oil and Gas Megaprojects 2014Document16 pagesEY Spotlight On Oil and Gas Megaprojects 2014gv360100% (2)

- Project Analysis ToolsDocument50 pagesProject Analysis ToolsChan Siew Chong100% (1)

- Frond-End Loading and Its Impact On Cost Overruns in The Norwegian Public SectorDocument96 pagesFrond-End Loading and Its Impact On Cost Overruns in The Norwegian Public SectorJoao VenancioNo ratings yet

- FEL Work ProcessDocument11 pagesFEL Work ProcessParijat MishraNo ratings yet

- Pages From Web Version Ei 1530 12.11.13Document16 pagesPages From Web Version Ei 1530 12.11.13Vaeco Đoàn Tncs Hcm100% (2)

- 1174 APS 1 CCS0521656666 001 - IPA - Gateway - Web1Document48 pages1174 APS 1 CCS0521656666 001 - IPA - Gateway - Web1PubuduNo ratings yet

- Research FEED, EPC and Engineering Contract in Oil, Gas and Petrochemicals - July 2013 Contract AwardsDocument2 pagesResearch FEED, EPC and Engineering Contract in Oil, Gas and Petrochemicals - July 2013 Contract AwardsSarwarzadEnergyPRNo ratings yet

- Principles For Project Success: V.1.0 - Government Project Delivery ProfessionDocument14 pagesPrinciples For Project Success: V.1.0 - Government Project Delivery ProfessionGary VNo ratings yet

- 15 Use and Misuse of Capital Cost Estimate ContingencyDocument8 pages15 Use and Misuse of Capital Cost Estimate ContingencylalitNo ratings yet

- Tririga and Managing Capital Projects-3Document7 pagesTririga and Managing Capital Projects-3April Angela Ilao TaggsNo ratings yet

- LNG Technology PortofolioDocument75 pagesLNG Technology PortofolioMoch FaridNo ratings yet

- 15 - Subsea Installation Duration vs. Number of WellsDocument6 pages15 - Subsea Installation Duration vs. Number of WellsHector AlfredoNo ratings yet

- 2018 EXXON Downstream SpotlightDocument39 pages2018 EXXON Downstream Spotlightswaggeroni yololo100% (1)

- 2 IpaDocument36 pages2 Ipaghostforever0No ratings yet

- 2011 Corporate Citizenship ReportDocument54 pages2011 Corporate Citizenship ReportIhda Arifin FaizNo ratings yet

- 1174 APS 2 CCS0521656666 001 - IPA - Gateway - Web1Document52 pages1174 APS 2 CCS0521656666 001 - IPA - Gateway - Web1PubuduNo ratings yet

- Nuts and Bolts of Project Management: Right Timing + Right Decision = SuccessFrom EverandNuts and Bolts of Project Management: Right Timing + Right Decision = SuccessRating: 5 out of 5 stars5/5 (1)

- FEL Stage GatedProcess Online 2023Document2 pagesFEL Stage GatedProcess Online 2023PabloNo ratings yet

- TEN Digital White PaperDocument7 pagesTEN Digital White PaperarjunguglaniNo ratings yet

- Suppliers Petroleum PHSE00MSFPetroleumHSECManagementSystemFrameworkDocument28 pagesSuppliers Petroleum PHSE00MSFPetroleumHSECManagementSystemFrameworkThanh NguyenNo ratings yet

- Business Process Framework The Ultimate Step-By-Step GuideFrom EverandBusiness Process Framework The Ultimate Step-By-Step GuideNo ratings yet

- Bharat Pertroleum StrategyDocument24 pagesBharat Pertroleum StrategySiddharth Sourav Padhee100% (1)

- Small Scale+Lng+in+Asia+PacificDocument75 pagesSmall Scale+Lng+in+Asia+Pacificrayan adboNo ratings yet

- Main Automation Contractor ServicesDocument4 pagesMain Automation Contractor Servicestkdrt2166No ratings yet

- Seven Deadly Sins in Industrial MegaprojectsDocument31 pagesSeven Deadly Sins in Industrial MegaprojectsXuxu Too100% (1)

- Oil and Gas Production An Introduction To Oil and Gas Production 2 ND Edition 2018Document8 pagesOil and Gas Production An Introduction To Oil and Gas Production 2 ND Edition 2018osamaNo ratings yet

- FEED Capabilities FlyerDocument4 pagesFEED Capabilities FlyerRuth Pauline HutapeaNo ratings yet

- Natural Gas Transmission Systems - CPADocument8 pagesNatural Gas Transmission Systems - CPAmike BarrazaNo ratings yet

- StrategyDocument43 pagesStrategyapi-3757629No ratings yet

- China National Petroleum CorporationDocument35 pagesChina National Petroleum CorporationMBA...KIDNo ratings yet

- Capital-Expenditures - Guide To Managing CapexDocument84 pagesCapital-Expenditures - Guide To Managing CapexEder Andres Rodriguez Cotua100% (1)

- OilandGasSlidePack PDFDocument18 pagesOilandGasSlidePack PDFbharathaninNo ratings yet

- Achieving Operational Excellence Through Digital TransformationDocument20 pagesAchieving Operational Excellence Through Digital TransformationTedyNo ratings yet

- Designing an Error Tolerant Workplace Through Human FactorsDocument6 pagesDesigning an Error Tolerant Workplace Through Human FactorsVan SotNo ratings yet

- Batam Island Infrastructure - ProjectsDocument21 pagesBatam Island Infrastructure - ProjectsafiqahshamsuriNo ratings yet

- Week 1a Business Strategy - Introduction To StrategyDocument21 pagesWeek 1a Business Strategy - Introduction To StrategyOnur SerbestNo ratings yet

- EP00 2 IntroductionDocument6 pagesEP00 2 Introductionfisco4rilNo ratings yet

- 7 Key Stages CAPEX ProcessDocument9 pages7 Key Stages CAPEX ProcessІрина ТурецькаNo ratings yet

- Long Intl Avoiding Project Failure by Defining RequirementsDocument18 pagesLong Intl Avoiding Project Failure by Defining RequirementsMario MendezNo ratings yet

- Accenture Strategy Oil Gas Capital Projects PoV 2019Document9 pagesAccenture Strategy Oil Gas Capital Projects PoV 2019Deepak SharmaNo ratings yet

- 2012 Expedition SSV2Document73 pages2012 Expedition SSV2atereñoneNo ratings yet

- Stage Gate Management GuideDocument36 pagesStage Gate Management GuideJesus vazquezNo ratings yet

- Project Cost-Time-Risk Diagram for Planning and Risk ManagementDocument8 pagesProject Cost-Time-Risk Diagram for Planning and Risk ManagementGuillermo BandaNo ratings yet

- Cost EstimationDocument69 pagesCost EstimationMr. KNo ratings yet

- EnvE Body of Knowledge FinalDocument82 pagesEnvE Body of Knowledge FinalhelardsNo ratings yet

- Of RISK MANAGEMENT OIL AND GAS CONSTRUCTION PROJECTS IN NIGERIADocument29 pagesOf RISK MANAGEMENT OIL AND GAS CONSTRUCTION PROJECTS IN NIGERIAPratick TibrewalaNo ratings yet

- Q4-One Page Recovery Plan-2017Document72 pagesQ4-One Page Recovery Plan-2017BilalAwanNo ratings yet

- The Microbanking Bulletin - Microfinance Information ExchangeDocument90 pagesThe Microbanking Bulletin - Microfinance Information ExchangeVICTOR TERAN100% (1)

- Job Description: Project EngineerDocument2 pagesJob Description: Project EngineerRichard GacitúaNo ratings yet

- Seplat Petroleum ProspectusDocument635 pagesSeplat Petroleum ProspectusAF Dowell MirinNo ratings yet

- NNPC Ms 2012 May Rev1Document79 pagesNNPC Ms 2012 May Rev1idristeekay100% (2)

- Kingdom of Saudi Arabia - The IPO ProcessDocument12 pagesKingdom of Saudi Arabia - The IPO ProcessCecil OwensNo ratings yet

- The BHP Shareholder Value Unlock Plan: April 10, 2017Document39 pagesThe BHP Shareholder Value Unlock Plan: April 10, 2017superinvestorbulletiNo ratings yet

- A Project Report ON: Ifrs (International Financial Reporting Standards) & It'S Convergence in IndiaDocument74 pagesA Project Report ON: Ifrs (International Financial Reporting Standards) & It'S Convergence in Indiaasheesh_aashuNo ratings yet

- Kerangka Kerja Imtermal AuditDocument5 pagesKerangka Kerja Imtermal AuditkaranziaNo ratings yet

- Solving Oil & Gas Megaproject FailuresDocument9 pagesSolving Oil & Gas Megaproject FailuresMiltonThitswaloNo ratings yet

- Risk Analysis For Prevention of Hazardous Situations in Petroleum Engineering - C1 - 2014 PDFDocument26 pagesRisk Analysis For Prevention of Hazardous Situations in Petroleum Engineering - C1 - 2014 PDFFernando Jimenez ChillonNo ratings yet

- Risk Analysis For Prevention of Hazardous Situations in Petroleum Engineering - C1 - 2014 PDFDocument26 pagesRisk Analysis For Prevention of Hazardous Situations in Petroleum Engineering - C1 - 2014 PDFFernando Jimenez ChillonNo ratings yet

- Member Certificate For 4549234 PDFDocument1 pageMember Certificate For 4549234 PDFFernando Jimenez ChillonNo ratings yet

- Member Certificate For 4549234 PDFDocument1 pageMember Certificate For 4549234 PDFFernando Jimenez ChillonNo ratings yet

- Member Certificate For 4549234 PDFDocument1 pageMember Certificate For 4549234 PDFFernando Jimenez ChillonNo ratings yet

- 0415 RiserPoster 032315 Final.5cf68e0c62dee PDFDocument1 page0415 RiserPoster 032315 Final.5cf68e0c62dee PDFFernando Jimenez ChillonNo ratings yet

- DHSG - The New Domain in Deepwater Drilling Applied Engineering and Organizational Impacts On Uncertainties and Risk - Pritchard - 2011 PDFDocument36 pagesDHSG - The New Domain in Deepwater Drilling Applied Engineering and Organizational Impacts On Uncertainties and Risk - Pritchard - 2011 PDFFernando Jimenez ChillonNo ratings yet

- Member Certificate For 4549234 PDFDocument1 pageMember Certificate For 4549234 PDFFernando Jimenez ChillonNo ratings yet

- 6.9 Bow Tie Analysis - 2016 PDFDocument10 pages6.9 Bow Tie Analysis - 2016 PDFFernando Jimenez ChillonNo ratings yet

- Keszei Chemical ThermodynamicsDocument361 pagesKeszei Chemical ThermodynamicsAndrés OchoaNo ratings yet

- 6.9 Bow Tie Analysis - 2016 PDFDocument10 pages6.9 Bow Tie Analysis - 2016 PDFFernando Jimenez ChillonNo ratings yet

- Mudmat Role in Offshore Drilling Operations: August 2015Document4 pagesMudmat Role in Offshore Drilling Operations: August 2015Dr R Panneer SelvamNo ratings yet

- Eetaa PDFDocument333 pagesEetaa PDFKyren GreiggNo ratings yet

- 69550-MS Non Conventional Sucker Rod Pumping For Slim Hole Wells PDFDocument5 pages69550-MS Non Conventional Sucker Rod Pumping For Slim Hole Wells PDFFernando Jimenez ChillonNo ratings yet

- Clemson Offense 2 2013 PDFDocument89 pagesClemson Offense 2 2013 PDFFernando Jimenez ChillonNo ratings yet

- Odoo Partnership Program EMEA AgendaDocument28 pagesOdoo Partnership Program EMEA AgendaEric Teo100% (2)

- Cbse Cost Accounting NotesDocument154 pagesCbse Cost Accounting NotesMANDHAPALLY MANISHANo ratings yet

- Management Skills For EntrepreneursDocument21 pagesManagement Skills For EntrepreneursDhruv ChaudharyNo ratings yet

- KALAMAZOO Case Study SolutionDocument13 pagesKALAMAZOO Case Study SolutionSanskriti sahuNo ratings yet

- TCPL Integrated Annual Report - FY2020-21Document288 pagesTCPL Integrated Annual Report - FY2020-21Mark LucasNo ratings yet

- Notice: Combined Graduate Level Examination, 2020Document63 pagesNotice: Combined Graduate Level Examination, 2020Abhay Pratap SharmaNo ratings yet

- Jawad Internship ReportDocument28 pagesJawad Internship Reportjunaidyaseen442No ratings yet

- Accounts PaperDocument2 pagesAccounts PaperRohan Ghadge-46No ratings yet

- SCM Furniture 027Document14 pagesSCM Furniture 027Mohaiminul IslamNo ratings yet

- Solved A Religious Organization Is Considering Spreading Its Message Into Illinois PDFDocument1 pageSolved A Religious Organization Is Considering Spreading Its Message Into Illinois PDFAnbu jaromiaNo ratings yet

- FSA Guide 20Document16 pagesFSA Guide 20David DangNo ratings yet

- Analysis of Competitiveness of The Agribusiness Sector Companies Using Porter'S Five ForcesDocument11 pagesAnalysis of Competitiveness of The Agribusiness Sector Companies Using Porter'S Five ForceseryNo ratings yet

- Free GameDocument1 pageFree GameSC AyuburiNo ratings yet

- FC102 Dea ShimizuDocument6 pagesFC102 Dea Shimizudr.afroza1875No ratings yet

- Commercial Space Lease LetterDocument1 pageCommercial Space Lease LetterBplo Caloocan100% (3)

- BioPharma Case StudyDocument4 pagesBioPharma Case StudyNaman Chhaya100% (3)

- BGC Internship Job Description On LetterheadDocument4 pagesBGC Internship Job Description On Letterheadgadija ishahNo ratings yet

- RBI's Credit Monitoring Arrangement and Tandon Committee recommendationsDocument4 pagesRBI's Credit Monitoring Arrangement and Tandon Committee recommendationsAbhi_IMK100% (1)

- Nepal Health Service Act 2053 BSDocument72 pagesNepal Health Service Act 2053 BSDinesh YadavNo ratings yet

- Ijcs 127281Document34 pagesIjcs 127281Faten bakloutiNo ratings yet

- Bni Organization ChartDocument1 pageBni Organization ChartVickyRahadianNo ratings yet

- Building Contruction Workers Regulation of Employment and Working Conditions Act 1996Document14 pagesBuilding Contruction Workers Regulation of Employment and Working Conditions Act 1996omarmhusainNo ratings yet

- CV Example (Dubal Avinash)Document3 pagesCV Example (Dubal Avinash)Rajkumar KhaseraoNo ratings yet

- Chapter 4 MCQsDocument3 pagesChapter 4 MCQsprince ahenkoraNo ratings yet

- 7 Eleven Store Nantun District - Google SearchDocument1 page7 Eleven Store Nantun District - Google SearchArleen MallillinNo ratings yet

- Urban MarketplaceDocument20 pagesUrban MarketplaceMae LafortezaNo ratings yet

- Final Ruckus ProposalDocument29 pagesFinal Ruckus Proposalapi-609740598No ratings yet

- Romania Pestel Analysis Comprehensive Country OutlookDocument6 pagesRomania Pestel Analysis Comprehensive Country OutlookAtharva UppalwarNo ratings yet

- MRB Approves Nonconforming PartsDocument3 pagesMRB Approves Nonconforming PartsMiguel RodriguezNo ratings yet

- Sample Paper Speaking BEC PreliminaryDocument2 pagesSample Paper Speaking BEC PreliminaryPham Van Khoa100% (1)