Professional Documents

Culture Documents

BR/BD 65/80 W Service Manual

Uploaded by

szerelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR/BD 65/80 W Service Manual

Uploaded by

szerelCopyright:

Available Formats

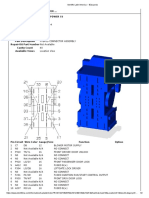

BR/BD 65/80 W (B80W)

Service Manual

English 5.906-468.0 Rev. 00 (02/09) 1

Downloaded from www.Manualslib.com manuals search engine

Contents

1 Preface 4

2 Safety instructions 4

2.1 Safety Devices 4

3 Technical Features 4

3.1 Drive 4

3.2 Brush system 4

3.3 Water System 4

3.4 Suction system 4

3.5 Electrical system 4

4 Setup and function 5

4.1 Front view 5

4.2 Rear view 6

4.3 Control terminal 8

4.3.1 Operating elements and displays 8

4.3.2 Operating panel from below 8

4.3.3 Drive control 8

4.4 Display controls 9

4.4.1 Open the operator menu 9

4.4.2 Open the setup menu 10

4.4.3 Open the debug mode 11

4.5 Circuit board (A1) 12

4.6 Water filling system (option) 13

4.7 Water filter 13

4.8 Drain tap for fresh water 13

4.9 parking brake 13

4.10 Vacuum bar 14

4.11 Cover opened. 14

4.12 Battery 15

4.13 Water stop valve 15

4.14 Detergent dosing pump (DOSE) 16

4.15 Raise/lower brush head 17

4.16 Water pump 18

4.17 Discharge flag against static electricity 18

3.1 Drive 4

4.19 Suction turbine 18

4.20 Brush head (BD model) 19

4.21 Brush head, BR model 19

5 Basic settings and service procedures 20

5.1 Replace filling system 20

5.2 Setting the vacuum Bar 20

5.3 Clean/replace the vacuum lips 21

5.4 Check/replace the support roller on the vacuum bar. 21

5.5 Removing the suction turbine 21

2 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

5.6 Remove the drive unit 22

5.7 Remove the BD brush head 22

5.8 Replace the disc brushes on the BD brush head 23

5.9 Remove the BR brush head 23

5.10 Replace the brush rollers on the BR brush head 24

5.11 Replace the drive belt 24

5.12 Remove the brush drive on the BR brush head 25

5.13 Clean water filter. 25

5.14 Adjust drive control 25

6 Circuit diagram 26

6.1 Circuit diagram 0.089-050.0 BAT models 26

6.2 Circuit diagram 0.089-051.0 BAT PACK models 27

6.3 Legend of the electrical components 28

7 Troubleshooting 29

7.1 Troubleshooting without display 29

7.2 Troubleshooting with display 29

8 Specifications 30

9 Special tools 30

English 5.906-468.0 Rev. 00 (02/09) 3

Downloaded from www.Manualslib.com manuals search engine

1 Preface 3.2 Brush system

Good service work requires extensive and practice-oriented train- – Brush head with 2 brush rollers (BR model) or 2 disc brushes

ing as well as well-structured training materials. (BD model).

Hence we offer regular basic and advanced training programmes

covering the entire product range for all service engineers.

In addition to this, we also prepare service manuals for important

appliances - these can be initially used as instruction guides and

later on as reference guides.

Apart from this, we also regular information about product en-

hancements and their servicing.

If you should require supplements, have corrections or questions

regarding this document, please address these citing the following – Brush speed adjustable in three steps (FACT).

subject to: – Brush head is lowered by means of pedal, brush drive is

international-service@de.kaercher.com switched on simultaneously. By pressing the pedal down, the

brush head is lifted and the brush drive is switched off. If the

Subject: Fall 106533 travel drive is shut off when the appliance is operated (brush

head lowered and brushes are rotating), the brushes will run

The responsible product specialist will take care of your issue. another 2 to 5 seconds until they are switched off automatically

(trailing time adjustable).

Copying and duplication of texts and diagrams as well as – The brush contact pressure can be adjusted at the lever.

third-party access to this information is permitted only with

– Brush replacement is possible without tools.

the explicit permission of the company:

Alfred Kärcher GmbH & Co. KG 3.3 Water System

P O Box 160

– Install fresh water reservoir and waste water reservoir in appli-

D - 71349 Winnenden

ance (tank-in-tank system).

www.kaercher.com

– The electrical swimmer in the wastewater reservoir shuts off

the suction turbine once the maxium fill level is reached (time

2 Safety instructions delay approx. 5 seconds).

– Mechanical swimmer closes the suction opening in the lid, if the

2.1 Safety Devices wastewater foams excessively.

Safety devices serve to protect the user and must not be rendered – Water pump to feed fresh water to the brush head.

inoperational or their functions bypassed. – The fresh water amount can be regulated with a dosing valve

2.1.1 Emergency-stop button according to the contamination level.

To put all functions out of operation immediately. – When the appliance stands still, a water stop valve interrupts

the supply flow of fresh water to the brush head.

– Detergent dosing via detergent dosing pump (DOSE).

2.2 Hazard levels

Note 3.4 Suction system

Indicates useful tips and important information about the product.

– The vacuum bar is lowered with a lever, the suction turbine is

switched on simultaneously. If the vacuum bar is raised, the

3 Technical Features suction turbine will switch back off (trailing time approx. 10 sec-

onds).

The appliance is used for the wet cleaning of level floors. It can be

– Longlife suction turbine, without carbon brushes.

easily adjusted to suit the required cleaning task by adjusting the

water quantity, the contact pressure of the brushes and the waste – Operation possible with straight and bent vacuum bar.

water suction. – The vacuum bar can be adjusted in horizontal position and tilt-

A working width of 650 mm and a capacity of 80 l each of the fresh ed without tools.

and dirt water reservoirs enable an effective cleaning even when – The vacuum lips can be replaced without the use of tools.

the machine is used for long duration.

The device is self-moving; the drive motor is powered by four bat- 3.5 Electrical system

teries.

The batteries can be charged using a charger connected to a 230 – The electrical assemblies are located easily accessible behind

V socket. the charger and below the operating panel.

A charger is already integrated in the "Pack" model. – The appliance comes to a sudden halt when you press the

emergency stop button.

– Standby function after 30 minutes break in operation.

3.1 Drive

– Voltage supplied by 4 maintenance-free, 6 volt batteries (180

Ah).

– Two front wheels driven by DC motor with differential drive.

– 2 rear swivel casters.

4 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

4 Setup and function

4.1 Front view

1 Guide handle

2 Drain hose for wastewater

3 Water reservoir

4 Vacuum bar

5 Drive wheel

6 Left scraper roller

7 Right scraper roller

8 Brush head (BD model only)

9 Brush head (BR model)

10 Cover

English 5.906-468.0 Rev. 00 (02/09) 5

Downloaded from www.Manualslib.com manuals search engine

4.2 Rear view

6 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

1 Operator console 14 Lever for adjusting the brush contact pressure

2 Driving lever 15 Pedal for raising/lowering the brush head

3 Guide handle 16 Waterfilter

4 Battery charger (U1) (BAT PACK model) 17 LED (red), fault on battery charger or battery

5 Suction hose 18 LED (green), battery fully charged

6 Vacuum bar 19 LED (yellow), batteries are being charged

7 Pedal for parking brake

8 Fresh water filling system

9 Drain hose for wastewater

10 Connection cable for battery charger (U1)

11 Fastening screws (2x), cover plate

12 Detergent reservoir (option)

13 LED indicator lamps on the battery charger (U1)

English 5.906-468.0 Rev. 00 (02/09) 7

Downloaded from www.Manualslib.com manuals search engine

1 Plug (X11)

4.3 Control terminal

2 Connection terminal (X10), magnetic sensor (B1)

4.3.1 Operating elements and displays 3 Operating panel board (A2)

4 Connection terminal (X9), microswitch suction turbine (M5) and

detergent pump (M6)

5 Plug (X7A), ground

6 Key switch (S1)

7 Emergency-stop button (S2)

8 Connection terminal (X7), circuit board (A1)

9 Connection terminal (X8), key switch (S1) and Emergency stop

button (S2)

10 Connection terminal (X13), safety sensor (option)

4.3.3 Drive control

Note

The indicator lamp brush overload blinks when the adjusted

I_MB_Max value is almost reached. When the set I_MB_Max val-

ue is reached or exceeded, the indicator lamp will be illuminated

permanently.

If the set I_MB_Max value is exceeded for more than 5 seconds,

there will be an automatic switch-off.

1 Shaft with magnet

1 Fastening screws (4x), operating panel

2 Side plate

2 Indicator lamps

3 Toothed gear segment

3 Display

4 Halting plate

4 Driving lever

5 Return spring

5 Emergency shut-off switch

6 Toothed gear

6 Key switch

7 Magnetic sensor (B1), drive control

7 Info button

8 microswitch (S3), suction turbine (M5)

8 Indicator lamp suction turbine ON (D1) (green)

9 Connection cable, magnetic sensor (B1)

9 Indicator lamp water pump ON (D2) (green)

10 Connection cables, microswitch (S6)

10 Indicator lamp "Wastewater tank full" (D4) (red)

11 Indicator lamp brush overload (D3) (red)

12 Indicator lamp parking brake (D5) (red)

13 Indicator lamp battery (D6) (red)

4.3.2 Operating panel from below

8 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

4.4 Display controls

4.4.1 Open the operator menu

The user can use the operator menu to query the basic settings of

the appliance.

Î Turn on the appliance using the key switch. The basic display

"battery" appears immediately.

Î The following information can be retrieved and partially

changed by using the info button:

Display on the moni- Explanations

tor

Batterie: Basic display for the current battery

charge. 8 fields = 100%

Water Basic display for the set water volume

1 - 10 fields.

CleanSpdFwd=60% Displays the set cleaning speed in for-

ward drive in % of the max. value.

If the option "Clean Speed edit“ is set

"ON" in the setup menu, this setting

can be changed by pressing the info

button in and turning it.

CleanSpdRev=60% Displays the set cleaning speed during

reverse drive in % of the max. value.

Changes to the setting are made as

with CleanSpdFwd.

FACT=Power Displays the set brush speed (FACT

system).

WDB-Function=OFF Displays the set WDB function (wall-

ceiling-floor nozzle).

RMDosierung=2,5% Displays the set dosing equipment for

detergent (DOSE).

Betr.st. 1h23m Displays the current operating hours in

hours (h) and minutes (m).

Geschw.:_ _km/h Displays the current drive speed in km/

h.

Bürste Displays the current brush contact

pressure. This is only displayed while

the brush motors are running.

Alfred Kärcher Displays the appliance manufacturer.

B80W 3.03 Displays the versions of the integrated

software.

English 5.906-468.0 Rev. 00 (02/09) 9

Downloaded from www.Manualslib.com manuals search engine

4.4.2 Open the setup menu

Î The display shows "B80W". Quickly tap the info button 3 x with-

in one second. The display shows "setup menu".

Î Browse through the setup menu using the rotating function of

the info button.

Î A menu point is modified by tapping the info button. The display

will blink. The setting is changed by rotating the info button and

it is saved by tapping the info button. Once the new setting is

saved, the display will no longer blink.

The user can use the setup menu to modify the basic settings of

Î Keep browsing via the rotating function until you reach the

the appliance.

menu item "SETUP EXIT“. The setup menu is saved and exited

Î Turn off the appliance using the key switch.

by retapping the info button.

Î Switch on the key switch.

Menu Settings Explanation Factory settings

the lan- German Displays the text in German. German english

guage English Displays the text in English.

Reverse On Driving possible with lowered vacuum bar. Suction turbine on during reverse On

clean Off drive.

Driving impossible with lowered vacuum bar. Suction turbine OFF during re-

verse drive.

Brush 0.5 to 5 seconds Switch-off delay to brush stop when machine is standing still. 2 seconds

delay 60 seconds 60 second setting cannot be saved. Only for service work.

Low 20.0 V - 22.8 V Deep discharge protection for low-maintenance and maintenance-free bat- 22.0 V for mainte-

Battery teries nance-free batter-

ies.

I MB 40 A - 80 A Overload protection of the brush motors. 68 A

MAX

FACT On Power, Whisper and Fine Clean can be selected from the operator menu. On with BR

Off Power, Whisper and Fine Clean are not displayed in the operator menu. OFF with BD

Clean On The cleaning speed can be changed in the operator menu. On

Speed edit Off The cleaning speed is not shown in the operator menu and can only be mod-

ified in the setup menu.

Clean 30 - 100 % Displays the cleaning speed during forward drive in % of the max. transport 70%

Speed Fwd speed (6 km/h).

"CleanSpeed Fwd" is only displayed if "Clean Speed Edit" – "Off" was select-

ed in the menu.

Clean 30 - 100 % Displays the cleaning speed during reverse drive in % of the max. transport 70 %

Speed Rev speed (4.5 km/h).

"CleanSpeed Rev" is only displayed if "Clean Speed Edit" – "Off" was select-

ed in the menu.

Water-Edit On The water volume can be changed in the operator menu. On

Off The water volume is not shown in the operator menu and can only be modi-

fied in the setup menu.

Water 0 - 10 Water volume (electrical ball tap). Display appears if "Water Edit ON" is set 5

in the setup menu.

Water-Time 0.5 s - 4.0 s After the water is turned on, the ball tap is fully opened for this time period, 2.0 s

so that the empty hose can be filled as quickly as possible.

RM- On Detergent dosing exists. On

Function Off Detergent dosing does not exist.

RM-Edit On The detergent dose can be changed in the operator menu. On

Off The detergent dose is not shown in the operator menu and can only be set

in the setup menu.

RM- 0-3% Detergent dosing. Display appears if "RM Edit ON" is set in the setup menu. 1,0 %

Dosing

Flashlight On Beacon light (option) switched on during driving. Off

Off Beacon light (option) switched off.

Brake 1 to Appliance is immediately braked. 1

Ramp 4 Appliance is gently braked.

Debug On Access to debug mode during SETUP exit. Off

Mode Off No access to debug mode during SETUP exit.

Load Tap menu item once. Basic settings are saved again.

Defaults

Setup Exit The setup menu is saved and exited by tapping the info button.

10 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

4.4.3 Open the debug mode

+=xxx mV –=xxx mV Electronic information only

Dxxx Axxx Exxx Sxxx Dxxx = safety sensor distance

Axxx = max. speed at a distance of 150

cm (0...30...60) *0.1 km/h.

Exxx = max. speed at a distance of 30

cm (0...30...60) *0.1 km/h.

You can use the debug mode to call up additional information.

Î Call up the "debug mode" display in the setup menu. Sxxx = nominal value (0-60) *0.1 km/h

Î You can use the info button to set the debug mode to ON.

Î Keep turning the info button until "SETUP exit?" appears on the

display.

Î You can use the info button to confirm the settings.

Î The following information can now be retrieved by using the

info button:

Display on the moni- Explanations

tor

Battery: 26,0V Displays the current battery voltage.

Water Displays the current water volume.

CleanSpdFwd=60% Shows the set cleaning speed during

forward drive in % of the max. value (is

only shown in the display if "Clean

Speed Edit On“ is set up in the setup

menu).

CleanSpdRev=60% Shows the set cleaning speed during

reverse drive in % of the max. value (is

only shown in the display if "Clean

Speed Edit On“ is set up in the setup

menu).

FACT Displays the current brush speed.

WDB-Function=OFF Displays the set WDB function (wall-

ceiling-floor nozzle).

RM-Dosing Shows the set detergent volume (is

only shown in the display if "RM Edit

On“ is set up in the setup menu).

Operating hours 2 h Displays the current operating hours in

10 m hours (h) and minutes (m).

Speed:0.0km/h Displays the current drive speed in km/

h.

Alfred Kärcher Displays the appliance manufacturer.

B80W 3.03 Displays the versions of the integrated

software.

Pxxx Sxxx Vxxx Pxxx Display of additional electronic infor-

mation:

Pxxx = speed value (0-255) With max.

movement of driving lever, a value of

250-255 must be displayed.

Sxxx = nominal speed value 0-61 (*0.1

km/h)

Vxxx = actual speed value 0-61 (*0.1

km/h)

Pxxx = electronic information only 0-

250

Ixxx Bxxx Mxxx Pxxx Ixxx = current pickup drive motor in A

(0-50).

Bxxx = current pickup brush motor in A

(0-255).

Mxxx = electronic information only

Pxxx = electronic information only

English 5.906-468.0 Rev. 00 (02/09) 11

Downloaded from www.Manualslib.com manuals search engine

4.5 Circuit board (A1)

Î Unscrew the fastening screws (see Chapter 4.2, Item 11) and 15 Main relay (K1)

fold the cover plate back. 16 Connection terminal suction turbine (M5) (plus)

17 Plug (X4A), ground on performance circuit board (A2)

1 Connection terminal (X4) (covered), control board (A2) 18 Covering plate

2 Connection terminal (X3), microswitch (S7), detergent pump

(M6), water pump (M4), microswitch (S9), water stop valve (Y1)

3 Connection terminal (X2), main relay (K1) and power supply of

operating panel circuit board (A1)

4 Fuse 7.5 A (F3), water pump (M4)

5 Fuse 3 A (F2), control (A1)

6 Connection terminal (X1), battery charger (U1) (Bp pack only)

7 Circuit board (A1)

8 Fuse 30 A (F4), drive motor (M3)

9 Connection terminal of brush motors (M1 and M2) (plus)

10 Connection terminal 24 V (plus)

11 Connection terminal ground (minus)

12 Collection point ground (minus)

13 Connection terminal drive motor (M3) (plus)

14 Connection terminal drive motor (M3) (minus)

12 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

4.6 Water filling system (option) 4.8 Drain tap for fresh water

Î The stop valve on the fresh water reservoir must be opened in

order to empty the fresh water reservoir.

Note

Only open the stop valve once there is a suitable water drain under

the drain valve.

4.9 parking brake

The water filling system can be used to fill the fresh water reservoir.

The water hose is connected to the connection neck. Once the

maximum fill level is reached, the built-in floater valve will stop the

water inflow.

1 Connection nozzle

2 Fastening screws (4x), water filling system

3 Water outlet into the tank

4 Float

5 Swimmer valve

The parking brake is used to prevent the appliance from inadvert-

ent movements.

4.7 Water filter

Î Press the pedal for the parking brake down and let it lock.

Note

The stop valve must be closed before opening the water filter.

1 Water filter

2 Locking tap

The brake pushes against the drive wheel.

English 5.906-468.0 Rev. 00 (02/09) 13

Downloaded from www.Manualslib.com manuals search engine

4.11 Cover opened.

The microswitch is used and the indicator lamp for the parking

brake lights up on the operator panel.

1 Pedal for parking brake

2 Brake (on both sides of the appliance)

3 Microswitch (S9), parking brake

4.10 Vacuum bar

1 Plug for filling opening of fresh water

2 Cover

1 Winch, raise/lower vacuum bar 3 Swimmer for foam, mechanical

2 Pickup plate, vacuum bar 4 Dirt water reservoir

3 Wing screw (2x), setting of the inclination 5 Swimmer, electrical

4 Wing screw (2x), setting of the horizontal position 6 Fill opening for fresh water

5 Vacuum bar 7 Lint sieve, suction turbine

6 Support roller (2x) 8 Wastewater from the suction hose

7 Fastening screw (2x)

8 Scraper roller (2x)

9 vacuum lip (2x)

10 vacuum lip mounting (2x)

14 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

4.12 Battery 4.13 Water stop valve

The water stop valve is located under the tank.

Î Drain the water from the fresh water and wastewater tank.

Î Open the tank cover screw.

Î Tilt the tank backwards.

The servo motor only opens the water stop valve, if the following

conditions are met:

– Water pump switched on.

– Brush head lowered.

Note – Drive operation forward or backward.

The insulation nut must be mounted so that the bottom edge fits ex- If one of the three conditions is not met, the servo motor will close

actly into the boring of the cable shoe of the connecting cable. If it the water stop valve.

is mounted incorrectly, the insulation nut can be damaged. The

fuse is bypassed and ineffective. Tighten the insulation nut finger- Note

tight using a wrench.

The water stop valve is used to avoid water damage by leaking wa-

ter. It is not as sensitive against contamination and leaks as a so-

1 Connection, battery plus terminal

lenoid valve.

2 Battery (G1), 4 x 6 Volts, 180 Ah

3 Central plug (X1)

4 Connection, battery minus terminal

5 Insulation nut

6 Fuse 125 A (F1), battery

English 5.906-468.0 Rev. 00 (02/09) 15

Downloaded from www.Manualslib.com manuals search engine

4.14 Detergent dosing pump (DOSE)

The detergent dosing pump is located behind the battery.

Î Drain the water from the fresh water and wastewater tank.

Î Open the tank cover screw.

Î Tilt the tank backwards.

Pin 1 Battery voltage 24 Volt (+).

Pin 2 24 Volts if the water pump is ON.

0 Volts if the water pump is OFF.

Pin 3 Ground 0 Volts.

Pin 4 Control voltage for servo motor:

1.7-1.9 volts = dosing valve opened to the max.

3.1-3.3 volts = dosing valve opened at min.

0 volts = dosing valve closed.

1 Water stop valve (Y1)

2 Hose for the water pump (M4)

3 Hose to the brush head

4 Connecting coupling

5 Potentiometer

6 Servo motor

7 Connection plug

16 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

While the brush head is raised, the press spring on the brush head

The flowmeter measures the set water volume, after that the cor- pickup is compressed.

responding volume of detergent is metered in by switching on the

detergent pump.

1 Detergent dosing pump (DOSE)

2 Cover, detergent pump

3 Cap, pump motor

4 Pump outlet

5 Pump input

6 Connection cables, detergent pump

7 Detergent pump (M6)

8 Transport rotor

9 Transport hose

10 Transport rolls

11 Flowmeter

12 Control cable, flowmeter

13 Motor, detergent pump

14 Control board

4.15 Raise/lower brush head If the brush head is lowered, the press spring is decompressed and

presses the brush head onto the floor.

The brush head is switched on and off by lowering and raising it.

Î Raise: Press the pedal downward and lock it towards the right. When the brush head is lowered, the microswitch switches on the

Î Lower: Press the pedal downwards; move it to the left and re- brush motors.

lease it upward. If the brush head is raised, the microswitch turns the brush motors

The brush head will automatically start up as soon as the appliance back off.

is driven forward/backwards.

The desired brush contact pressure is adjusted by means of the lever. 1 Foot lever for raising/lowering the brush head

The setting is adjusted in several detents. With each detent, by which 2 Lever for adjusting the brush contact pressure

the lever is pressed down, the brush contact pressure is reduced. 3 Press spring, compressed

4 Press spring, decompressed

Note 5 Microswitch (S7), brush motors (M1, M2) ON/OFF

Only use the lever while the brush head is lowered. When moving

the lever while the brush head is raised, there can be injuries by the

lever flying upwards.

English 5.906-468.0 Rev. 00 (02/09) 17

Downloaded from www.Manualslib.com manuals search engine

4.16 Water pump 4.18 Drive

The water pumps is located underneath the detergent dosing

pump (DOSE).

Î Drain the water from the fresh water and wastewater tank.

Î Tilt the tank backwards.

1 Hose from the water filter

2 Water pump (M4)

3 Hose to the flowmeter

4.17 Discharge flag against static electricity

1 Connection cable, drive motor (M3)

2 Drive motor (M3)

3 Differential gear

4.19 Suction turbine

The discharge flag prevents the buildup of static electricity, which

could interrupt or damage the control electronics. The suction turbine is located on the bottom of the folded open

tank.

Note

Î Drain the water from the fresh water and wastewater tank.

Distance between the discharge flag (arrow) and the floor: 5 mm

(0.197 in). Î Open the tank cover screw.

Î Tilt the tank backwards.

1 Exhaust air outlet

2 Suction turbine (M5)

18 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

4.20 Brush head (BD model) 4.21 Brush head, BR model

The water distribution bar can be pulled out of the front of the brush

head for cleaning.

1 Brush head

2 Cover, belt drive

3 Waste container

4 Lock, bearing lid, left

5 Bearing lid, left

6 Left scraper roller

1 Left mount

7 Water distribution bar

2 Connection terminal, brush motors (M1, M2)

3 Pedal for changing brushes, left

4 Left scraper roller

5 Right scraper roller

6 Top mount

7 Pedal for changing brushes, right

8 Connecting coupling

9 Right mount

10 Hose, distribution of detergent solution

11 Disc brush, right

12 Disc brush, left

13 Detergent outlet for right disc brush

14 Pickup, right disc brush

15 Bow to release the right disc brush

16 Bow to release the left disc brush

17 Pickup, left disc brush

18 Detergent outlet for left disc brush

English 5.906-468.0 Rev. 00 (02/09) 19

Downloaded from www.Manualslib.com manuals search engine

5 Basic settings and service procedures

5.1 Replace filling system 5.2 Setting the vacuum Bar

Î Unscrew locking screws.

Î Remove the filling system from the tank.

To improve the vacuuming result on tiled floors the vacuum bar can

be turned to an oblique position of up to 5°.

Î Release the wing screws.

Î Turn the vacuum bar into the respective horizontal position.

Î Retighten the wing screws.

If the vacuum result is unsatisfactory the inclination of the straight

vacuum bar can be modified.

Î Loosen the wing nuts.

Î Tilt the vacuum bar accordingly.

Î Retighten the wing screws.

1 Wing screws (2x), setting of the tilting position

2 Wing screws (2x), setting of the horizontal position

Î Grease the seal ring when installing the new filling system.

1 Filling system

2 Fastening screws (4x), filling system

3 Fresh water inlet into the fresh water reservoir

4 Float

5 Switch-off valve

20 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

5.3 Clean/replace the vacuum lips 5.4 Check/replace the support roller on the vacuum

bar.

The support roller is used to prevent the vacuum bar from sucking

itself to the floor and so that the vacuum lips do not bend too much.

Î Loosen the fastening screws.

Î Adjust the support roller in the elongated hole accordingly.

Clean the vacuum lips on the vacuum bar and check for damage/

wear. Turn over/replace if needed. 1 Fastening screw, support wheel

2 Support roller, vacuum bar

Î Loosen the fastening screw.

Î Pull the scraper roller with the metal bushing and the vacuum

5.5 Removing the suction turbine

lip mount off the vacuum bar on both sides.

Î Pull the vacuum lips out of the side of the guide grooves, install

the new vacuum lips in reverse sequence.

Note

The front and rear vacuum lip can also be rotated by 180°.

1 Vacuum lip mounting

2 Metal bushing

3 Scraper roller

4 Fastening screw

5 Vacuum lips (front and rear)

6 Vacuum bar

Î Loosen the hose clip and pull the exhaust air hose off the neck.

Î Disconnect the connecting cable at the connectors.

Î Unscrew locking screws.

Î Remove the suction turbine.

Î Install the new suction turbine in reverse sequence.

1 Hose clip

2 Fastening screws (3x), suction turbine

3 Suction turbine (M5)

4 Connectors on the connecting cables

English 5.906-468.0 Rev. 00 (02/09) 21

Downloaded from www.Manualslib.com manuals search engine

5.6 Remove the drive unit 5.7 Remove the BD brush head

The drive unit consists of a differential gear and an attached drive

motor.

Î Release the screw for locking the tank and swing up the tank.

Î Remove the lid of the connector cover on the brush head.

Î Disconnect the connection plug.

Î Disconnect the connecting coupling of the water supply.

Î Disconnect the connecting cable of the drive motor from the

power supply.

Î Support the drive unit and secure it against falling down.

Î Remove the fastening screws from the left and right bearing

block.

Î Remove the drive unit.

Î Assemble the drive unit in the reverse sequence.

1 Bearing blocks to attach the drive unit

2 Differential gear

3 Fastening screws (2x), left bearing block

4 Fastening screws (2x), right bearing block

22 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

5.9 Remove the BR brush head

Î Fold the safety locks on the brush head pickups on the left and

right of the brush head up and pull them out of the sides of the

pickups.

Î Fold the safety lock on the brush head pickup on top of the

brush head down and pull them out of the sides of the pickups.

Î The brush head is disconnected from the appliance and can be

removed.

Î Install the new brush head in reverse sequence.

Î To set the brush head, loosen the nuts on the adjusting screw

and align the brush head so that:

both brush heads touch the floor evenly on the BR head.

the brush head on the BD head is aligned parallel to the floor.

Î Retighten the nuts.

1 Connection plug

2 Adjusting screw

3 Nuts

4 Connection coupling, water supply

5 Safety lock, left

6 Safety lock, right

7 Safety lock, top

5.8 Replace the disc brushes on the BD brush head Î Release the screw for locking the tank and swing up the tank.

Î Unscrew the star handle screw of the connection plug cover

(see Chapter 4.20) on the brush head and pull the cover out.

Î Disconnect the connection plug.

Î Disconnect the connecting coupling of the water supply.

Î Fold the safety locks on the brush head pickups on the left and

right of the brush head up and pull them out of the sides of the

pickups.

Î Fold the safety lock on the brush head pickup on top of the

brush head down and pull them out of the sides of the pickups.

Î The brush head is disconnected from the appliance and can be

removed.

Î Install the new brush head in reverse sequence.

1 Safety lock, left

2 Safety lock, top

3 Safety lock, right

Î Raise the brush head.

Î Press the pedal for changing the brushes downward beyond its

resistance.

Î Pull the disc brush out of the side below the cleaning head.

Î Hold the new disc brush under the brush head, push upward

and lock.

1 Pedal for brush exchange (left and right on the brush head)

English 5.906-468.0 Rev. 00 (02/09) 23

Downloaded from www.Manualslib.com manuals search engine

5.10 Replace the brush rollers on the BR brush head 5.11 Replace the drive belt

Î Remove the bearing lid from the brush roller mount (see Chap-

ter 5.10).

Î Unscrew the fastening screws of the drive belt cover and re-

move the drive belt cover.

Î Raise the brush head.

Î Turn the lock of the bearing cover counter-clockwise.

Î Push the bearing lid down and remove.

Î Pull out the brush roller.

Î Loosen the fastening screws of the brush motor.

Î Remove the drive belt.

Î Insert the new brush roller and slide it onto the pickup mandrel. Î Install the new drive belt, tension it and tighten the fastening

Î Reassemble the bearing lid in the reverse sequence. screws on the motor. The V belt tension is determined via the

position of the motor shaft (tensioning by raising the motor, e.g.

1 Lock, bearing lid with a screwdriver, through the elongated hole beneath the mo-

2 Bearing lid tor shaft).

3 Pickup mandrel

Note

The drive belt must be tensioned so that it can be deflected by a

strong thumb press to a max. of 5 mm (arrow) between the motor

shaft and the driven pulley.

1 Fastening screws (9x), drive belt cover

2 Drive belt cover

3 Fastening screws (4x), brush motor

4 Drive belt

24 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

5.12 Remove the brush drive on the BR brush head 5.13 Clean water filter.

Î Close the stop valve.

Î Unscrew the filter cup.

Î Remove the sieve and rinse it.

Î Assemble in reverse order.

Î Remove the drive belt cover (see Chapter 5.11).

Î Unscrew the fastening screws (arrows) of the brush drive. 1 Filter pot

2 Locking tap

5.14 Adjust drive control

Î Pull the brush drive out of the brush head.

Î Disconnect the connecting cable of the brush motor.

Î Install the new brush drive in reverse sequence.

If the fault message "Gas>POTI_ZER_MAX" is displayed, the

drive control is not set correctly and the appliance will not run. In

Brush mirror adjustment this case, the positioning of the tooth segement and the toothed

Î Park the brush head on an even surface. gear is incorrect.

Î Install the new brush rollers.

Î Slightly shake the brush head so that the brush drive with the Î Unscrew the operating panel.

brush rollers can adapt to the even surface. Î Remove the right and left drive levers.

Î Tighten the fastening screws (arrows). Î Remove the entire drive control.

Î Unscrew the side plate and readjust the position of the tooth

1 Brush drive segment to the toothed wheel by one tooth forward/backwards.

Î Check the drive control and adjust by moving it by one more

tooth if necessary.

1 Shaft with magnet

2 Side plate

3 Toothed gear segment

4 Halting plate

5 Return spring

6 Toothed gear

7 Magnetic sensor for drive control (B1)

8 Microswitch (S6), suction turbine

9 Connection cable, magnetic sensor

10 Connection cables, microswitch (S6)

English 5.906-468.0 Rev. 00 (02/09) 25

Downloaded from www.Manualslib.com manuals search engine

6 Circuit diagram

6.1 Circuit diagram 0.089-050.0 BAT models

26 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

6.2 Circuit diagram 0.089-051.0 BAT PACK models

English 5.906-468.0 Rev. 00 (02/09) 27

Downloaded from www.Manualslib.com manuals search engine

6.3 Legend of the electrical components

A1 Control board

A2 Operating panel board

A3 Circuit Board, safety sensor (option)

B1 Magnetic sensor, drive control

B2/B3 Ultrasound sensors, transmitter/receiver (option)

D1 LED (green), suction turbine ON

D2 LED (green), water pump ON

D3 LED (red), brush overload

D4 LED (red), wastewater tank full

D5 LED (red), brake

D6 LED (red), battery

F1 Main switch (125 A)

F2 Fuse, control (3 A)

F3 Fuse, water pump (7.5 A)

F4 Fuse, travel drive (30 A)

G1 Battery (24 V / 180 Ah)

H1 Beacon lamp (option)

K1 Main relay

M1 Brush motor

M2 Brush motor

M3 Drive motor

M4 Water pump

M5 Suction turbine

M6 Detergent dosing pump (DOSE)

S1 Key switch

S2 Emergency-stop button

S6 Microswitch, suction turbine

S7 Microswitch, brush head

S8 Microswitch for detergent (option)

S9 Microswitch, brake

S10 Microswitch, wastewater tank

U1 Battery charger (BAT PACK model only)

V1 Protective diode

Y1 Water stop valve

EXT.X1 Central plug

28 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

7 Troubleshooting

7.1 Troubleshooting without display

Fault Remedy

Appliance cannot be started Stand-by, turn key switch to "0", then set it back to "1".

Check fuse F1 *, F2 *, replace if required. *

Check battery; charge it if required.

Machine does not move Check if the parking brake has been triggered.

Insufficient water quantity Check fresh water level, refill tank if necessary.

Check fresh water filter; clean if required.

(See "Maintenance Tasks").

Check hoses for blockages; clean if required.

Insufficient vacuum performance Clean the seals between dirt water reservoir and cover and check for tightness, replace if

required.

Clean the fluff filter.

Clean the vacuum lips on the vacuum bar, replace if required

Check suction hose for blockages; clean if required.

Check the suction hose for tightness; replace if required.

Check if the cover on the dirt water discharge hose is closed

Check the setting of the vacuum bar.

Insufficient cleaning result Set/ adjust contact pressure.

Check the brushes for wear, replace if required.

Use appropriate brush type for the type of dirt.

Set to "Power Clean" with appliances with brush rollers FACT.

Empty the waste container on the BR head.

Brushes do not turn Reduce contact pressure.

Check if foreign matters block the brushes; remove foreign matter if required.

If over-current switch in the electronics system has been triggered, turn key switch to "0",

then set it back to "1".

* Remove screws of the electronics system and tilt the electronics cover with charger downwards

7.2 Troubleshooting with display

Message Cause Remedy

Driving lever active! The driving lever is not in the centre position during Turn off the appliance, move the driving lever to the

switch on. centre position and turn on the appliance once

again.

Raise brush! Roller brush lowered and at a standstill. Raise the brush head.

Temperature !!! Overtemperature in the performance electronics Switch off appliance and let it cool down.

Gas pedal !!! Driving lever fault during operation. Release the driving lever, switch the appliance off

and back on again. Check the driving lever.

Brush overload! Max. brush power exceeded for more than 5 sec- Check/adjust the contact pressure at the brush

onds. head.

Battery depleted! Battery low voltage not reached for more than 60 Charge battery.

seconds.

Battery depleted!!! Battery power less than 18 V. Charge battery.

Refill detergent! Detergent container is empty. Install full detergent container.

Emergency-STOP! Emergency STOP button activated. Release emergency-stop button.

Gas>POTI_ZER_MAX Drive control not adjusted properly. Adjust drive control.

English 5.906-468.0 Rev. 00 (02/09) 29

Downloaded from www.Manualslib.com manuals search engine

8 Specifications

Appliance type Appliance no. Circuit diagram operating instruc- Spare parts list

tions

BR 65/80 W Bp *EU 1.259-120.0 0.089-050.0 5.962-445.0 5.962-558.0

BD 65/80 W Bp *EU 1.259-121.0 0.089-050.0 5.962-445.0 5.962-558.0

BR 65/80 W Bp Pack *EU 1.259-122.0 0.089-051.0 5.962-445.0 5.962-558.0

BD 65/80 W Bp Pack *EU 1.259-123.0 0.089-051.0 5.962-445.0 5.962-558.0

BR 65/80 W Bp DOSE *EU 1.259-124.0 0.089-050.0 5.962-445.0 5.962-558.0

BD 65/80 W Bp DOSE *EU 1.259-125.0 0.089-050.0 5.962-445.0 5.962-558.0

BR 65/80 W Bp Pack DOSE *EU 1.259-126.0 0.089-051.0 5.962-445.0 5.962-558.0

BD 65/80 W Bp Pack DOSE *EU 1.259-127.0 0.089-051.0 5.962-445.0 5.962-558.0

The technical specification sheet and the circuit diagram will be in- The operating instructions and the spare parts list can be request-

cluded in the next version of the spare parts CD (DISIS) and in the ed in paper form with the respective part numbers from our spare

Intranet. parts service department.

9 Special tools

Description Part number

Is not required.

30 English 5.906-468.0 Rev. 00 (02/09)

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Service Training CT CM CC PDFDocument112 pagesService Training CT CM CC PDFelucubraNo ratings yet

- Substation ComponentDocument62 pagesSubstation ComponentaangjaelaniNo ratings yet

- Vögele MT 1182 en CompleteDocument225 pagesVögele MT 1182 en CompleteMohamedSalah72% (18)

- Tipm C6 PDFDocument2 pagesTipm C6 PDFluis cañizales67% (3)

- 6sded We 0229TH PDFDocument319 pages6sded We 0229TH PDFAndres Miguel Cevallos Garcia100% (1)

- M47D20 VP44: Seminar Working MaterialDocument69 pagesM47D20 VP44: Seminar Working MaterialIongornistu67% (6)

- Service Manual BM 1300 30 VecchiolaDocument826 pagesService Manual BM 1300 30 VecchiolaHumberto ValenzuelaNo ratings yet

- FS110 Service Manual PDFDocument51 pagesFS110 Service Manual PDFAfton RobertNo ratings yet

- Manual Motor Yx 140cc Pit Bike EngineDocument4 pagesManual Motor Yx 140cc Pit Bike EngineDavidCM11% (9)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Turbocharger ABBDocument124 pagesTurbocharger ABBadi nurahmanNo ratings yet

- MicroSmart Single-pieceWirelineUnitDocument422 pagesMicroSmart Single-pieceWirelineUnitVictor Patiño100% (1)

- Schlumberger JET Manual 23 Fracturing Pump UnitsDocument68 pagesSchlumberger JET Manual 23 Fracturing Pump UnitsVladyslav67% (3)

- Maintenance (Edition 06.2015) PDFDocument134 pagesMaintenance (Edition 06.2015) PDFRADEKNo ratings yet

- Rend Att-Tpl69 A 77 A Dbad009490 e eDocument146 pagesRend Att-Tpl69 A 77 A Dbad009490 e eRupesh Tiwari100% (1)

- WMF PRESTO-1400-Service-Manual2 PDFDocument40 pagesWMF PRESTO-1400-Service-Manual2 PDFOlimpiu EnacheNo ratings yet

- HS300SR Service Manual R1 PDFDocument180 pagesHS300SR Service Manual R1 PDFluisoft88100% (1)

- Fs 55 PDFDocument62 pagesFs 55 PDFIonut Costache100% (1)

- Berthoud Major 35 Ops ManualDocument34 pagesBerthoud Major 35 Ops ManualGarreth Fitzsimon100% (1)

- SERVICE MANUAL HIGHLIGHTSDocument144 pagesSERVICE MANUAL HIGHLIGHTSszerelNo ratings yet

- SERVICE MANUAL HIGHLIGHTSDocument144 pagesSERVICE MANUAL HIGHLIGHTSszerelNo ratings yet

- SY16 Maintenance ManualDocument148 pagesSY16 Maintenance ManualAndres SorinNo ratings yet

- Hds 818 4cDocument87 pagesHds 818 4cGoshko JorkovNo ratings yet

- Manual Busch - Seco - SV - 1010 - 1040C - MRDocument16 pagesManual Busch - Seco - SV - 1010 - 1040C - MRignacio35127935No ratings yet

- Cutting Machine Inspection ChecklistDocument1 pageCutting Machine Inspection ChecklistThein Myint OoNo ratings yet

- National Crane 500E2 Operators ManualDocument94 pagesNational Crane 500E2 Operators ManualRoamir Alayon MalaveNo ratings yet

- Johnson Pump Horizontal Centrifugal Pump CombiBloc Instruction Manual PDFDocument60 pagesJohnson Pump Horizontal Centrifugal Pump CombiBloc Instruction Manual PDFseloNo ratings yet

- HDS 5/11 U/UX Service Manual: English 5.906-487.0 Rev. 00 (04/10)Document50 pagesHDS 5/11 U/UX Service Manual: English 5.906-487.0 Rev. 00 (04/10)Jose Maria Castro PazosNo ratings yet

- Merivaara Practico Operating Table - Service Manual PDFDocument32 pagesMerivaara Practico Operating Table - Service Manual PDFimran maaniNo ratings yet

- Oxygen Concentrator Service Manual: For Visionaire, Visionaire 2 & Visionaire 3 ModelsDocument37 pagesOxygen Concentrator Service Manual: For Visionaire, Visionaire 2 & Visionaire 3 ModelsSadegh ShebaniNo ratings yet

- Visionaire 2 3 Service Manual English PDFDocument47 pagesVisionaire 2 3 Service Manual English PDFQuarmina HesseNo ratings yet

- PRETREATmaker IV Instruction ManualDocument40 pagesPRETREATmaker IV Instruction ManualKrid CaralNo ratings yet

- Newlife-Intensity10 mn134-1 Service-Manual RevbDocument40 pagesNewlife-Intensity10 mn134-1 Service-Manual RevbSpero AgbomenouNo ratings yet

- Commander 750 875 1200 ManualDocument80 pagesCommander 750 875 1200 ManualCoco BangoNo ratings yet

- Airsep VisionAire Concentrator - Service Manual PDFDocument46 pagesAirsep VisionAire Concentrator - Service Manual PDFBoyke WinterbergNo ratings yet

- HD 10/25 S HD 13/18 S Service Manual: Downloaded From Manuals Search EngineDocument30 pagesHD 10/25 S HD 13/18 S Service Manual: Downloaded From Manuals Search Engineali83No ratings yet

- SSP Rotary Lobe Pump Databook PDFDocument94 pagesSSP Rotary Lobe Pump Databook PDFVishal SalveNo ratings yet

- B-191 Operationmanual en A LowresDocument28 pagesB-191 Operationmanual en A LowresDinhtrung TruongNo ratings yet

- Newlife Intensity 10 Oxygen Concentrator Service ManualDocument31 pagesNewlife Intensity 10 Oxygen Concentrator Service ManualDiego RebolledoNo ratings yet

- Air Dryer Manual PragDocument82 pagesAir Dryer Manual PragSSE DEMUNo ratings yet

- Ms MC 50 ADVDocument80 pagesMs MC 50 ADVequipetwowheelsNo ratings yet

- SC 2K TwinControl Finishing ENG 2339331Document108 pagesSC 2K TwinControl Finishing ENG 2339331Jaelani Painting n Powder Coating WagnerNo ratings yet

- Montaža Dautel RampiDocument61 pagesMontaža Dautel RampiLikNo ratings yet

- RepairManual DIWA.5Document172 pagesRepairManual DIWA.5Muhammet KınalıNo ratings yet

- Dishwasher Evo3: Service ManualDocument54 pagesDishwasher Evo3: Service ManualGaborNo ratings yet

- CH 6Document140 pagesCH 6Nibha PandeyNo ratings yet

- O, I - Z T W S 700 S R O U: Smonics NC YZA ECH Ater Ystems Eries Everse Smosis NITDocument92 pagesO, I - Z T W S 700 S R O U: Smonics NC YZA ECH Ater Ystems Eries Everse Smosis NITluis bazanNo ratings yet

- tt-tg-sp-manual-rev-f5_m-sp-001-enDocument106 pagestt-tg-sp-manual-rev-f5_m-sp-001-enWaltinegojiya CadondonNo ratings yet

- Drilling Audit Questionnaire ReviewDocument50 pagesDrilling Audit Questionnaire ReviewMM pHiveNo ratings yet

- LR Omegas GPL 5 6 8 Cil GBDocument48 pagesLR Omegas GPL 5 6 8 Cil GBYacine KhazeneNo ratings yet

- HD 6/16-4 M / MX HD 7/18-4 M / MX HD 9/19 M / MX HD 9/20-4 M / MX Service ManualDocument32 pagesHD 6/16-4 M / MX HD 7/18-4 M / MX HD 9/19 M / MX HD 9/20-4 M / MX Service Manualali83No ratings yet

- Drilling Hse AuditDocument54 pagesDrilling Hse AuditQHSE ManagerNo ratings yet

- Limitorque - L120-85 ActuatorDocument52 pagesLimitorque - L120-85 ActuatorThiago RodriguesNo ratings yet

- Citytrac 4200Document112 pagesCitytrac 4200h45xlmNo ratings yet

- V30 PDFDocument84 pagesV30 PDFLuis SiuLNo ratings yet

- CyansmartDocument79 pagesCyansmartГ. АлтангадасNo ratings yet

- 1400 Presto Service ManualDocument40 pages1400 Presto Service ManualRustam MalyshevNo ratings yet

- Washing Machine 2000: Service ManualDocument56 pagesWashing Machine 2000: Service ManualАлександр ПетровNo ratings yet

- TESA-hite 400 / 700: Instruction ManualDocument52 pagesTESA-hite 400 / 700: Instruction ManualArmando RodríguezNo ratings yet

- HD 10/25 S and HD 13/18 S Service ManualDocument30 pagesHD 10/25 S and HD 13/18 S Service ManualFabri GutyNo ratings yet

- A-En MoviPol-5 IMDocument58 pagesA-En MoviPol-5 IMFabien CazesNo ratings yet

- Instructions For Repair: BW 213 DH / PDH - 4 BW 214 DH / PDH - 4Document838 pagesInstructions For Repair: BW 213 DH / PDH - 4 BW 214 DH / PDH - 4Hector Sacaca aliagaNo ratings yet

- Advantage Portable Chillers MG 5 40 TonsDocument90 pagesAdvantage Portable Chillers MG 5 40 TonsMauro Guardiola A.No ratings yet

- AB MaintenanceDocument46 pagesAB Maintenanceagung_wpNo ratings yet

- Components and Installation HandbookDocument52 pagesComponents and Installation HandbookOmar Enrique ContrerasNo ratings yet

- Airwell MQH12 IOM MQLH N 1GB InstallationDocument40 pagesAirwell MQH12 IOM MQLH N 1GB InstallationMohammad dadkhahNo ratings yet

- Neptune 3Document2 pagesNeptune 3szerelNo ratings yet

- Philips 42pf9731d 10+fj3.0e LaDocument261 pagesPhilips 42pf9731d 10+fj3.0e LaszerelNo ratings yet

- Kranzle 895 1165Document52 pagesKranzle 895 1165szerelNo ratings yet

- Operating Instructions for the Neptune 7 FA High Pressure CleanerDocument27 pagesOperating Instructions for the Neptune 7 FA High Pressure CleanerszerelNo ratings yet

- Schaumburg Vigilant ALPR Basic User GuideDocument4 pagesSchaumburg Vigilant ALPR Basic User GuideMike BureshNo ratings yet

- SBW & SBW II Actuator Re-Calibration InstructionsDocument13 pagesSBW & SBW II Actuator Re-Calibration InstructionsYaşar BaşerNo ratings yet

- A Review of Power Battery Thermal Energy Management PDFDocument18 pagesA Review of Power Battery Thermal Energy Management PDFHARSHIT KUMARNo ratings yet

- Future of Mobility - Preview Report-1Document25 pagesFuture of Mobility - Preview Report-1Andrés De FerariNo ratings yet

- GWM Haval Portfolio and List of Accessories and Merchandise Updated 1Document4 pagesGWM Haval Portfolio and List of Accessories and Merchandise Updated 1dboibreeNo ratings yet

- Fault Codes: STO U AndriivDocument7 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- Ce-20 Water Blaster Slim Line 500 Bar: 3X 220 V 60 HZDocument31 pagesCe-20 Water Blaster Slim Line 500 Bar: 3X 220 V 60 HZRusmansyah100% (1)

- Litreature Review 1. History of Water Pumping Technolgy: Water Pumps How Potable Water Is To The Top of The BuildingDocument6 pagesLitreature Review 1. History of Water Pumping Technolgy: Water Pumps How Potable Water Is To The Top of The BuildingAwanyo thomasNo ratings yet

- Ausa Mixers 500RX-X1100RH-ENG PDFDocument2 pagesAusa Mixers 500RX-X1100RH-ENG PDFAsad AijazNo ratings yet

- 02250245-493 (r00) enDocument100 pages02250245-493 (r00) enmukhtarahmadaNo ratings yet

- Forged Steel Gate Valve 800 15NB To 50NBDocument1 pageForged Steel Gate Valve 800 15NB To 50NBArsag Tech PharmaNo ratings yet

- 6300 3056Document1 page6300 3056vmg guindastesNo ratings yet

- Worm Gear Pair: K W G DL 2 - R1 KDocument56 pagesWorm Gear Pair: K W G DL 2 - R1 KShuvam ShuvamNo ratings yet

- RR Differential ComponentDocument3 pagesRR Differential ComponentirfanNo ratings yet

- Shop Logo Toyota Wish: Tokopedia Tokopedia TokopediaDocument1 pageShop Logo Toyota Wish: Tokopedia Tokopedia TokopediaFirmash HermawanNo ratings yet

- C Type Build Manual 2017 RFDocument68 pagesC Type Build Manual 2017 RFJoakim EkmanNo ratings yet

- Toyota BT Vector BrochureDocument7 pagesToyota BT Vector BrochurePingNo ratings yet

- My PPT On CVTDocument16 pagesMy PPT On CVTSaurabh Shekhar100% (1)

- DTC Codes and Fault Paths for Diesel EnginesDocument36 pagesDTC Codes and Fault Paths for Diesel EnginesSidali KilardjNo ratings yet

- Capacities (Refill) : Operation and Maintenance ManualDocument2 pagesCapacities (Refill) : Operation and Maintenance ManualJuanVelasquezHerreraNo ratings yet

- Wiring The Toyota Crown 1UZDocument11 pagesWiring The Toyota Crown 1UZLahiru MadusankaNo ratings yet

- New Holland E50B Hydraulic Excavator Service Repair ManualDocument21 pagesNew Holland E50B Hydraulic Excavator Service Repair ManualggjjjjotonesNo ratings yet

- Arm VOLVO 330 BDocument2 pagesArm VOLVO 330 BAR FAMILYNo ratings yet

- Samsung Motors - Case Study by Woonghee Lee and Nam S. LeeDocument17 pagesSamsung Motors - Case Study by Woonghee Lee and Nam S. Leenaikintu9818No ratings yet