Professional Documents

Culture Documents

ISO 17025 Risk Management Example: December 2019

Uploaded by

paeg65120 ratings0% found this document useful (0 votes)

191 views6 pagesOriginal Title

ISO_17025riskmanagementexample_-2-6

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

191 views6 pagesISO 17025 Risk Management Example: December 2019

Uploaded by

paeg6512Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/337951559

ISO 17025 risk management example

Presentation · December 2019

DOI: 10.13140/RG.2.2.31682.94409

CITATIONS READS

0 629

1 author:

Shodlik Masharipovich Masharipov

Tashkent State Technical University

70 PUBLICATIONS 5 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Metrology and measurement uncertainty View project

метрология и стандартизация View project

All content following this page was uploaded by Shodlik Masharipovich Masharipov on 16 December 2019.

The user has requested enhancement of the downloaded file.

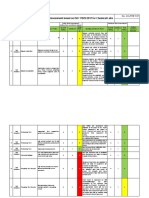

Doc. QCL/FRM 10.01

Lab Risk Assessment based on ISO 17025:2017 for Chemical Labs

Initial Risk Assessment Residual Risk Assessment

(without any controls in place)

Risk Further

Sr Severity Severity Likelihoo Risk

Area Activities / Process Quality Concerns / Risks Likelihood Ratin Existing Controls in Place Controls

# Rating Rating d Rating

g Required

Sample receiving person from lab

verify name & identification Criteria.

Furthermore, as sample received in

Lab Misidentification of

1 Sample collection 3 3 9 lab it is entered in Sample Log and 3 1 3

Activities sample/specimen

batch number/code is also alotted

otherwise he will return sample to

customer for proper identification

All sample are stored in designated

location of lab and environment

Lab Samples received in lab is not

2 Sample collection 4 2 8 conditions of lab is recorded on daily 4 1 4

Activities placed in controlled environment

basis. Lab Incharge also verified

environment record.

Weighing balance are calibrated and

placed on flat surface. Furthermore

rubber pad under weighing balance

to reduce vibrations and it is place in

designated position.

Inaccurate process parameters Volume measurement is done

Lab (e.g. Temp. Pressure, weighing through calibrated flask.

3 Sample preparation 4 2 8 4 1 4

Activities error), expire reagents used in Chemist are properly trained on

preparation testing activities.

Reagents lists are available used in

testing activities, expiry of reagents

are recorded in this list. Before using

reagents Chemist verify its expiry

Lab STMs are developed and

available at the place of use. Active

testing parameters are saved in

Lab Inaccurate test parameters HPLC. Chemist just select the test

4 Performing Test 4 2 8 4 1 4

Activities wABC e performing test parameter from equipment for

testing.

To ensure accuracy of test results lab

run standard with sample

Lab environment is controlled and its

Lab person perform test in lab

Lab conditions is recorded on daily basis.

5 Performing Test without considering environment 4 2 8 4 1 4

Activities Lab Incharge also verify evironment

conditions

record.

Lab Instruments are calibrated from

Lab

6 Performing Test Inaccurate measurements 4 1 4 accredited lab for accurate 4 1 4

Activities

measurements

Lab QC Lab Staff health & work risk, Lab has chemical spill kit available

Activities Lab environment condtion and and Emergency eye wash is placed

7 Chemical Spillage 3 4 12 3 1 3

result error may occur to avoid serious injury.

Equipment log books are available in

which all data of equipment are

recorded on daily basis.

Lab Person prepare test report

Lab Chromatrograph results of actives

8 Preparing Test Results without performing test on 5 2 10 4 1 4

Activities are attached with final report to

specimen

ensure the integrity and these

chromatrographs have date and time

mention on it

Final report is approved by GM

Technical/Manager QC after

verification of test evidence and

Miscalculation Data entry reviewed by Chemist. If evidence is

Lab

9 Preparing Test Results mistakes wABC e preparing 5 2 10 not appropriate report will not be 5 1 5

Activities

results approved. All test results from raw

data and from equipment data. If it is

not match with raw or machine data

then Chemist correct typo error

Lab Staff has implemented

Staff of QC lab leaks

Confidenti Confidentiality Policy

10 Lab Information Leakage confidential information of test 4 2 8 4 1 4

ality Furthermore all confidential

results and equipment’s

information is under control condition

Lab has signed NDC agreement from

Personnel other than lab having

Confidenti all authorized person. In case of any

11 Lab Information Leakage authorization of lab data (IT etc.) 2 5 10 2 2 4

ality violation legal action can be taken

leak confidential data

against person

PCs are password protected and

hard form documents are under lock

Confidenti Lab confidential data theft in

12 Lab Information Leakage 2 5 10 & key. Authorized person have 2 2 4

ality electronic or hard form

signed Non-Disclosure (NDC)

agreement

Staff of QC Lab should be

independent from the Lab Staff has implemented

production. Impartiality Policy.

13 Impartiality Impartiality 4 2 8 4 1 4

Lab is independent of external or

internal pressure and conflicts

Test report adultration is not possible

Lab Person adulterate the report in case of active because its result is

14 Impartiality Performing Test due to good relation with 4 2 8 automatically generate from system. 4 1 4

customer In case of weighing, volume, pH log

books are maintained. Furthermore

Lab Authorized persons and

management have signed non-

disclosure agreement with company

Due to per pressure from

in case of violation legal action can

company owner; top

15 Impartiality Ownership 2 5 10 be taken against person.

management interfere to change

ABC has good repute in market so

test results

top management/ owner can't force

to adultrate results to avoid minimal

loss as compare to company repute

ABC lab has dedicated equipment in

Due to un-availability of some

labs that is not available in other

desire equipment; Lab use

16 Impartiality Shared Equipment 3 5 15 department. Other than this 1 2 2

production or store department

supporting equipments like monitors

equipment for its activities

etc. back up are available in lab

Lab facility is dedicated for testing

Lab facility is used by production

activities only and persons are

17 Impartiality Shared facility or store department for its 4 5 20 2 2 4

authorized for this. Unauthorized

activties

persons are not allowed in lab

RISK MATRIX

Risk Assessment Matrix Value Probability Definition

Level of Risk 5 Very High At least once in a Day

IMPACT 4 High At least once in week

Very

PROBABILITY Very Low Low Medium High 3 Medium At least once in a month

High

1 2 3 4 5 2 Low At least once in 6 months

Very High (5) 5 10 15 20 25 1 Very Low At least once in a year or Rarely Occurs

High (4) 4 8 12 16 20

Medium (3) 3 6 9 12 15 Value Impact Description

Little/No impact on testing activities or the

Low (2) 2 4 6 8 10 1 Very Low

personnel performing the activity

Low Impact due to changes in work

Very Low (1) 1 2 3 4 5 2 Low environment which may create delays in

testing activity

Medium Impact due to changes in work

3 Medium environment (or equipment) which may

lead to ambiguous testing results

High Impact due to personal grievances or

pressure on the personnel performing the

4 High test which may lead to compromised test

results or falsified report ultimately lead to

high financial loss > 500000

Very high Impact due to illegal activity /

5 Very High Bribery case / compromise/change in

report for personal gains

View publication stats

You might also like

- Lab Risk Assessment Based On ISO 17025:2017 For Chemical LabsDocument5 pagesLab Risk Assessment Based On ISO 17025:2017 For Chemical Labsgristy100% (1)

- KKHL C4 SE 03 SOP For Measurement of Uncertianity FINAL 1Document10 pagesKKHL C4 SE 03 SOP For Measurement of Uncertianity FINAL 1GABULA MIKENo ratings yet

- Using A Fume Hood: RiskwareDocument7 pagesUsing A Fume Hood: RiskwaretafouzeltNo ratings yet

- Handling OOS Investigations Regulatry Expectn India 2023Document55 pagesHandling OOS Investigations Regulatry Expectn India 2023Saili DixitNo ratings yet

- RISK ASSESSMENT REPORT NO. 0001Document6 pagesRISK ASSESSMENT REPORT NO. 0001dsadasNo ratings yet

- Log Monitoring & Security StandardsDocument12 pagesLog Monitoring & Security StandardssharadNo ratings yet

- Tahmina-Zebin-General Risk Assessment FormDocument6 pagesTahmina-Zebin-General Risk Assessment FormTahmina L. ZebinNo ratings yet

- ISO Guide 80 2014Document15 pagesISO Guide 80 2014Diego LunaNo ratings yet

- RE - BRC6 3.5.11, 3.5.1.2 Input Material Risk Assessment: SeverityDocument2 pagesRE - BRC6 3.5.11, 3.5.1.2 Input Material Risk Assessment: SeverityDutch CharmingNo ratings yet

- Gap Analysis - 17025 2017 PDFDocument20 pagesGap Analysis - 17025 2017 PDFmanojvattavilaNo ratings yet

- General Accreditation Criteria: Metrological Traceability PolicyDocument24 pagesGeneral Accreditation Criteria: Metrological Traceability Policyarli krisnandikaNo ratings yet

- Supplier File MatrixDocument4 pagesSupplier File MatrixSebastian LopezNo ratings yet

- Microbiologist Validation Protocol Protocol No: DNIL - AV.P.021.00 Page 1 of 7Document7 pagesMicrobiologist Validation Protocol Protocol No: DNIL - AV.P.021.00 Page 1 of 7HBNNo ratings yet

- AssgfgDocument34 pagesAssgfgashe zinabNo ratings yet

- Atharva Laboratories Biological Testing CapabilitiesDocument156 pagesAtharva Laboratories Biological Testing CapabilitiesSriram SubramanianNo ratings yet

- SOP For Preparation of TrendsDocument2 pagesSOP For Preparation of TrendsАнна ОрлеоглоNo ratings yet

- 4.4 Review of Requests, Tenders and ContractsDocument1 page4.4 Review of Requests, Tenders and ContractsGajaNand MallickNo ratings yet

- TP0602 0505Document8 pagesTP0602 0505nsk79in@gmail.comNo ratings yet

- Determine Critical Control Points (CCPsDocument5 pagesDetermine Critical Control Points (CCPsolotu_olaseindeNo ratings yet

- Gross Lab FailuresDocument9 pagesGross Lab FailuresNancy LonnrothNo ratings yet

- Risk Assessment On Temperature and Relative Humidity Deviation During On-Going Stability StudiesDocument2 pagesRisk Assessment On Temperature and Relative Humidity Deviation During On-Going Stability StudiesAAAAAAAAAAAAAAAAAAAA ANo ratings yet

- Health, Safety & Environmental Hazard IdentificationDocument6 pagesHealth, Safety & Environmental Hazard IdentificationImad ChaudharyNo ratings yet

- Cleaning Validation MACO Swab Rinse Ovais PDFDocument5 pagesCleaning Validation MACO Swab Rinse Ovais PDFAnonymous yBhOAi5UHNo ratings yet

- Laboratory Safety Chemical Fume HoodsDocument2 pagesLaboratory Safety Chemical Fume Hoodsacanis1016No ratings yet

- Verification of Compendial MethodsDocument52 pagesVerification of Compendial Methodsnsk79in@gmail.comNo ratings yet

- Quality Management System AuditDocument14 pagesQuality Management System AuditSpectro SinghNo ratings yet

- ISO 9001 Audit ChecklistDocument17 pagesISO 9001 Audit Checklistsaravanan ramkumar100% (1)

- Soil SamplingDocument10 pagesSoil SamplingLerry May del Rosario100% (1)

- Hazard Identification and Risk Assessment Form: Project ProcessDocument4 pagesHazard Identification and Risk Assessment Form: Project ProcessAli Al-GhamghamNo ratings yet

- 2.1.7. Balances For Analytical PurposesDocument3 pages2.1.7. Balances For Analytical PurposesTrung Dương Đức100% (1)

- Calibration, Validation, Qualification and System Suitability Tests in The ElectrochemistryDocument29 pagesCalibration, Validation, Qualification and System Suitability Tests in The ElectrochemistryVision2011100% (1)

- Risk Assessment - AHUDocument5 pagesRisk Assessment - AHUManzur AhmadNo ratings yet

- Humidity Effect On PharmaceuticalsDocument12 pagesHumidity Effect On PharmaceuticalsMohamedRefaatMohamed0% (1)

- G133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Document9 pagesG133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Alberto Garcia100% (1)

- Internal Quality Audit at Isuzu PlantDocument8 pagesInternal Quality Audit at Isuzu Plantgharba putraNo ratings yet

- Img 0004Document3 pagesImg 0004Shruti BhatiaNo ratings yet

- PCP & FmeaDocument4 pagesPCP & FmeaDaniela AscolaniNo ratings yet

- GLP Test Facility Inspection ChecklistDocument33 pagesGLP Test Facility Inspection ChecklistOula Hatahet100% (1)

- Evaluation Reporting of Results Annex 1b Responsibilities of The Laboratory Supervisor PDFDocument3 pagesEvaluation Reporting of Results Annex 1b Responsibilities of The Laboratory Supervisor PDFParkhomyukNo ratings yet

- LabX Bro eDocument12 pagesLabX Bro eWalter BurtonNo ratings yet

- Controls:: Measuring Instruments in ImteDocument5 pagesControls:: Measuring Instruments in ImteDhinakaranNo ratings yet

- RA Installation of Earthing SystemDocument15 pagesRA Installation of Earthing Systemamal0% (1)

- (Pharma-Tech Assignment) : Fire Hazards IN Pharmaceutical IndustryDocument6 pages(Pharma-Tech Assignment) : Fire Hazards IN Pharmaceutical IndustryZulqarnain AslamNo ratings yet

- Health and Safety Procedure - Hazard Identification Risk Assessment and ControlDocument6 pagesHealth and Safety Procedure - Hazard Identification Risk Assessment and ControlMohamad Zakwan Zach ZakariaNo ratings yet

- Investigation of Out of Specification ResultsDocument75 pagesInvestigation of Out of Specification ResultsAmit MishraNo ratings yet

- QMS 1004255 SENSATA GSQM - Rev P No Markup BLACK PDFDocument54 pagesQMS 1004255 SENSATA GSQM - Rev P No Markup BLACK PDFJossie FuentesNo ratings yet

- Sample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7Document7 pagesSample Procedure For Method Validation 1.: Document Control: SAP - Approved 20161221 Page 1 of 7YAMA ENGINEERSNo ratings yet

- SOP Housekeeping&CleaningDocument3 pagesSOP Housekeeping&Cleaningmalik234everNo ratings yet

- Ba Tho 5000toce Full Calibration Sop en 58130094bDocument38 pagesBa Tho 5000toce Full Calibration Sop en 58130094bعبدالعزيز بدرNo ratings yet

- Operate and Report On A Water Treatment PlantDocument3 pagesOperate and Report On A Water Treatment PlantMziyanda Boet-Bhayi ShumîNo ratings yet

- QC 05 03 Oven VerificationDocument9 pagesQC 05 03 Oven Verificationahmad atsari sujudNo ratings yet

- Assay of Ammonium Chloride by Acid-Base TitrationDocument20 pagesAssay of Ammonium Chloride by Acid-Base TitrationBMohdIshaqNo ratings yet

- ORA Lab Measurement TraceabilityDocument7 pagesORA Lab Measurement TraceabilityOsman Aita100% (1)

- Preventive Action PlanDocument11 pagesPreventive Action PlanAniruddha Chatterjee100% (1)

- Internal Quality Control Practices in Coagulation LaboratoriesDocument10 pagesInternal Quality Control Practices in Coagulation LaboratoriesMy LeNo ratings yet

- Food Safety Auditing - Practice and PrinciplesDocument96 pagesFood Safety Auditing - Practice and PrinciplesmkrchgNo ratings yet

- GLP Framework for Lab StudiesDocument7 pagesGLP Framework for Lab Studiesaakash sahaNo ratings yet

- Detect Power Failures in Industries and HomesDocument3 pagesDetect Power Failures in Industries and HomesdileeppatraNo ratings yet

- ISO 17025riskmanagementexample - 2-6Document6 pagesISO 17025riskmanagementexample - 2-6Thusitha LakpriyaNo ratings yet

- ISO 17025 Lab Risk Assessment: September 2019Document6 pagesISO 17025 Lab Risk Assessment: September 2019Elena Iulia CucoleaNo ratings yet

- PurgingDocument10 pagesPurgingSai PrasathNo ratings yet

- BS5500 - 1994-1Document65 pagesBS5500 - 1994-1paeg6512100% (1)

- Section Three. Design: BS 5 5 0 0: 1994 Issue 2, January 1 9 9 5Document91 pagesSection Three. Design: BS 5 5 0 0: 1994 Issue 2, January 1 9 9 5paeg6512No ratings yet

- SS Ni LiteDocument114 pagesSS Ni Litepaeg6512No ratings yet

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- FVC Catalog - UnlockedDocument80 pagesFVC Catalog - UnlockedhumbubbleNo ratings yet

- HSE ElectricalDocument12 pagesHSE Electricalpaeg6512No ratings yet

- Safety EquipmentDocument20 pagesSafety Equipmentgrandad21No ratings yet

- Stainless DepDocument12 pagesStainless Deppaeg6512No ratings yet

- Simple Guide To The Lifting Operations and Lifting Equipment Regulations 1998Document8 pagesSimple Guide To The Lifting Operations and Lifting Equipment Regulations 1998salesgglsNo ratings yet

- Simple Guide To The Lifting Operations and Lifting Equipment Regulations 1998Document8 pagesSimple Guide To The Lifting Operations and Lifting Equipment Regulations 1998salesgglsNo ratings yet

- Safety Risk AssessmentDocument8 pagesSafety Risk Assessmentpaeg6512No ratings yet

- Din en 4288 1998 PDFDocument13 pagesDin en 4288 1998 PDFLjiljana Glisic100% (1)

- HSE TrainingDocument12 pagesHSE Trainingpaeg6512100% (1)

- Espaco Confinados FiocruzDocument12 pagesEspaco Confinados FiocruzVereador ExclusivoNo ratings yet

- Din en 4288 1998 PDFDocument13 pagesDin en 4288 1998 PDFLjiljana Glisic100% (1)

- 2.defects and RepairDocument9 pages2.defects and Repairpaeg6512No ratings yet

- Idiots Guide To CHIPDocument12 pagesIdiots Guide To CHIPbmckevittNo ratings yet

- Din en 4288 1998 PDFDocument13 pagesDin en 4288 1998 PDFLjiljana Glisic100% (1)

- Painting Defects - Cswip BgasDocument63 pagesPainting Defects - Cswip BgasLuan Nguyen86% (7)

- Din en 4288 1998 PDFDocument13 pagesDin en 4288 1998 PDFLjiljana Glisic100% (1)

- Welding Processes Welding Processes: Welding Inspection Welding InspectionDocument11 pagesWelding Processes Welding Processes: Welding Inspection Welding Inspectionpaeg6512No ratings yet

- Consumables: Welding Inspection Welding InspectionDocument5 pagesConsumables: Welding Inspection Welding Inspectionpaeg6512No ratings yet

- Weld Procedures: Welding Inspection Welding InspectionDocument4 pagesWeld Procedures: Welding Inspection Welding Inspectionpaeg6512No ratings yet

- Lab Quality Manual Rev 10 (031119)Document17 pagesLab Quality Manual Rev 10 (031119)paeg6512No ratings yet

- RiskISO 17025Document8 pagesRiskISO 17025paeg6512No ratings yet

- Heat Treatments: Welding Inspection Welding InspectionDocument3 pagesHeat Treatments: Welding Inspection Welding Inspectionpaeg6512No ratings yet

- Decision Rule ISO17025 PDFDocument43 pagesDecision Rule ISO17025 PDFpaeg6512No ratings yet

- Decision Rule ISO17025 PDFDocument43 pagesDecision Rule ISO17025 PDFpaeg6512No ratings yet

- Megahertz Internet Network Pvt. LTD.: Retail InvoiceDocument1 pageMegahertz Internet Network Pvt. LTD.: Retail InvoiceAyush ThapliyalNo ratings yet

- Action Plan Custodian SY 2018 FinalDocument2 pagesAction Plan Custodian SY 2018 FinalStarLord JedaxNo ratings yet

- LESSON 2 Roles of Educational Technology in LearningDocument14 pagesLESSON 2 Roles of Educational Technology in LearningJenny SamoranosNo ratings yet

- Unit 4 BiostatisticsDocument17 pagesUnit 4 BiostatisticsअभिषेकNo ratings yet

- Faizan Ur Rehman CVDocument3 pagesFaizan Ur Rehman CVHawabaz AwanNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie605Document4 pagesCaterpillar Performance Handbook 49 62020 Partie605ali alilouNo ratings yet

- BS en 12953-12-2003Document22 pagesBS en 12953-12-2003Tuấn ChuNo ratings yet

- SST Programming Guide for Gen4 SystemsDocument8 pagesSST Programming Guide for Gen4 SystemsdmaslachNo ratings yet

- Plantilla Powerpoint QuimicaDocument22 pagesPlantilla Powerpoint QuimicaMayra HernandezNo ratings yet

- Atswa: Study TextDocument479 pagesAtswa: Study TextBrittney JamesNo ratings yet

- Creating E-Portfolio As A Technology ToolDocument3 pagesCreating E-Portfolio As A Technology ToolGian Reyes100% (1)

- CES 2020 Summary: by Frank Egle, I/EZ-I (Slide 1-46), Dr. Harald Altinger I/EF-XS (Slide 47-50)Document50 pagesCES 2020 Summary: by Frank Egle, I/EZ-I (Slide 1-46), Dr. Harald Altinger I/EF-XS (Slide 47-50)mazuedNo ratings yet

- Lecture3-1 OSSS TreesDocument39 pagesLecture3-1 OSSS Treesahmezo100% (1)

- Lesson Plan in Random VariableDocument10 pagesLesson Plan in Random VariableJeson N. RondinaNo ratings yet

- Massey Ferguson 1155 TRACTOR Service Parts Catalogue ManualDocument14 pagesMassey Ferguson 1155 TRACTOR Service Parts Catalogue Manualzhuangfuqian31No ratings yet

- Guidelines For Safety in E O T Cranes: IPSS: 2-02-007-18 (First Revision)Document4 pagesGuidelines For Safety in E O T Cranes: IPSS: 2-02-007-18 (First Revision)Mohammad Safdar SadatNo ratings yet

- Thesis Paper On Mobile Banking in BangladeshDocument8 pagesThesis Paper On Mobile Banking in Bangladeshaflnzefdqbrevm100% (2)

- The Specifications of 151821-2010: Details PDFDocument1 pageThe Specifications of 151821-2010: Details PDFSaul UribeNo ratings yet

- Final Report For Research PaperDocument55 pagesFinal Report For Research PaperAnshu PandeyNo ratings yet

- STS New OBE SyllabusDocument14 pagesSTS New OBE Syllabusgalileo jr roma100% (4)

- Femi-Akala Omotola H Computer Science Group B 19/1509 Data Communications and Computer Networks-COSC 335Document3 pagesFemi-Akala Omotola H Computer Science Group B 19/1509 Data Communications and Computer Networks-COSC 335Femi-Akala Hamzat OmotolaNo ratings yet

- Earthing Calculation: A General Design DataDocument14 pagesEarthing Calculation: A General Design Dataمحمد الأمين سنوساوي100% (1)

- 6 Axis Breakout Board Wiring and SetupDocument5 pages6 Axis Breakout Board Wiring and SetupJalaj ChhalotreNo ratings yet

- Python Regular Expressions (RegEx) Cheat SheetDocument4 pagesPython Regular Expressions (RegEx) Cheat SheetbabjeereddyNo ratings yet

- Cockpit and Passenger Compartment Separation Solutions 1588230875Document14 pagesCockpit and Passenger Compartment Separation Solutions 1588230875rubenarisNo ratings yet

- HT Metal Frame AnchorDocument4 pagesHT Metal Frame AnchorChirag SharmaNo ratings yet

- SUNSTAR - Latest Philippine Community News, Cebuano Stories, Bisaya News and Information - SUNSTARDocument23 pagesSUNSTAR - Latest Philippine Community News, Cebuano Stories, Bisaya News and Information - SUNSTARJOHN LUKE VIANNEYNo ratings yet

- Vibrating ScreensDocument6 pagesVibrating Screensvarun_0512933No ratings yet

- + - OSDI2020-FIRM - An Intelligent Fine-Grained Resource Management Framework For SLO-Oriented MicroservicesDocument22 pages+ - OSDI2020-FIRM - An Intelligent Fine-Grained Resource Management Framework For SLO-Oriented MicroservicesBENKEMCHI OussamaNo ratings yet

- 2122 Mast M-Tech A2 Hoe Emship enDocument22 pages2122 Mast M-Tech A2 Hoe Emship enMohamed BoutmezoughetNo ratings yet