Professional Documents

Culture Documents

B737NG - 49 00 A3 02 PDF

B737NG - 49 00 A3 02 PDF

Uploaded by

Muhammed MudassirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B737NG - 49 00 A3 02 PDF

B737NG - 49 00 A3 02 PDF

Uploaded by

Muhammed MudassirCopyright:

Available Formats

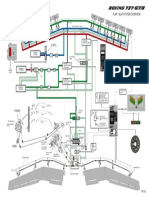

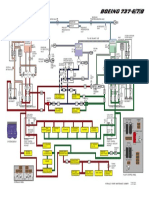

SCU control logic:

Min. 10 PSI to ’OPEN’

- DP

BAV opens when: BAV closes when: - PT

- Bleed sw. ’ON’ - Bleed sw. ’OFF’ T/M current

- T2

ALLIED SIGNAL 131-9(B) APU OVERVIEW Iso. valve switch pos. - N above 95% - Protective S/D occurs LVDT - IGV position

Eng bleed sw. pos. - Alt. < 17.000 ft. - APU underspeed - Bleed mode

- Alt. > 17.000 ft. - Air/gnd logic

I NI T / REF I NDEX Starter mode: 0 - 70%

< I DENT

< POS

NAV DATA>

Exciter field Dual bleed - P8 Fire sw. pulled Open when N < 95%

< PERF logic DUAL

- P28 Remote fire sw.

P5

BLEED

< T AKEOF F

PMG - Fire detected

< APPROACH

< OF F SET MAI NT > Open/close signal SCV (fuel operated)

Bite Variable VAC BAV - Reverse flow (for 1 sec.)

Pos. sw.

Rotor pos. (pneumatic operated) - Loss of both EGT probes

SCU causes’loss of EGT S/D’

115 V enable

115 VAC avb.

Starter generator (S/G)

270 VDC

- Overtemperature S/D (APU start) logic

is a function of speed adjusted for T2 and P2.

Air data S/D if corrected T5 is exceeded for 2 sec.

MCDU - APU total operating hours DP PT T5

(calculated by ECU) - Overtemperature S/D (on speed) logic

(through FMC/DEU) is a function of T4 calculated from highest EGT

- IGV offset (from test cell)

probe. T4 (1204C) is exceeded for 1 sec.

- APU health data P2 T2

N above 95% - APU serial number PS

(RTL) 115 VAC (AC transfer bus 1) - APU turbine life used

- Start numbers and data

28 VDC (Aircraft batteries) DMM - Shutdown (S/D) data

- Air/gnd logic EGT probes (2)

SPU - Eng start sw. (MES)

Start signal & SCU Bite - Bite power up

P5 AC system

- AGCU (generator load)

module

ECU - Airplane model (bleed demand)

- Fire detection module (S/D)

- DEU’s (17000 ft. signal)

EGT & lights - 28 vdc(S/D if lostfor more

OFF - ON - START than 50 msec and N>7%

A - BPCU (RTL when N>95%)

- BPCU (load shed)

- AGCU (RTL when N>95%)

- DFDAU

- DEU’s (Bite)

P5 APU module Speed sensor (2)

(S/D if both speed circuit fails or N>106%)

- Start inhibit if not ’OPEN’

after 30 sec (start up)

- Fuel - S/D if N>7% and pos.

Solenoid signal is lost for 0.2 sec.

- 40 sec. closing time

- Fuel metering Whole APU 8,7 qts after the 60 sec. ’cool

valve (T/M) - Oil (>5,7 qts) "FULL" on MCDU down’ cycle.

- APU bleed sw. Lube module - Oil (<4,8 qts) "ADD" on MCDU

- Pack sw. pos. - Oil (<3,8 qts) "LOW" on MCDU

+ "MAINT Lt on P5 panel

P5 Air conditioning - LOP switch

module Pos. sw.

- Fuel temp (RTD) (S/D if N > 95 % and

- Fuel flow P > 35 PSID for 20 sec)

Ignition unit

(energized during starting Air inlet door actuator

FMV control logic: - N (DC motor)

between 0-60%, and if a

- P2 ’speed droop’ below 95%

- Oil temp.

P8 Fire switch - T2 Oil level sensor occurs during APU run)

FCU (fuel control unit) (S/D if N > 95% and T > 143 °C for 10 sec.)

- EGT (T5)

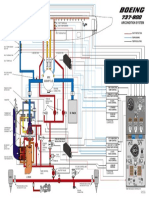

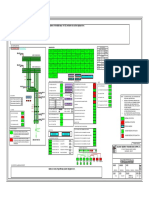

FIRE & OVERHEAT DETECTION

- S/G filter bypass switch

FAULT AREA

ENGINE 1

A B

LOOP

A

ENGINE 2

LOOP

B

- FF (S/D if N > 95%, P > 35 PSID for 5 sec,

SEE F.I.M. FOR

A

oil temp > 35 °C, both ENG off for > 95 sec

MULTIPLE FAULTS

Fuel panel logic

APU

FAULT CODE INFO.

FAULT DISPLAY

WIRING OPEN or

DETECTOR(S) FAULT and on ‘GND’.

Flow divider

WIRING SHORT TO

LOOP POWER

- P2

LOW DET. RESISTA

DETECTOR FAULT FOR

737-600/700/800 ONLY

ENGINE

control logic: - T2

Solenoid: energized

CORE LEFT

CORE RIGHT

FAN UPPER

IGVA control logic:

Closed between 7-30% -N LVDT - T2

And alt. > 25.000 ft. - Alt. - P2 Open/close

APU

- Calculated T4

Engine and APU Primary T/M current - Deterioration factor

FIRE

CONTROL

fire detection

1.PULL HANDLE DOWN

2.DISCHARGE BOTTLE

BOTTLE DISCHARGE

control module Secondary (max. 10.000 hr.)

- Air/gnd Pos. sw.

- MES (1 or 2)

BOTTLE HORN

- APU bleed valve pos.

Flow divider (open when P>120 psi)

DISCHARGE CUTOUT

IGVA (fuel operated) - Pack valve pos. APU Fuel Shutoff valve

APU Fuel pump (DC) P5 Fuel panel

(S/D if not closed

29 sec. after commanded)

P28 Remote

control switch CPHTH VER # 5 980922

You might also like

- B737NG - 27 50 A3 01 PDFDocument1 pageB737NG - 27 50 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 27 50 A3 01 PDFDocument1 pageB737NG - 27 50 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 27 50 A3 01 PDFDocument1 pageB737NG - 27 50 A3 01 PDFMuhammed MudassirNo ratings yet

- CAT Engine Timing CalibrationDocument8 pagesCAT Engine Timing Calibrationkamaleon dorado100% (3)

- B737NG - 49 00 A3 01 PDFDocument1 pageB737NG - 49 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 28 00 A3 01 PDFDocument1 pageB737NG - 28 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 32 40 A3 01 PDFDocument1 pageB737NG - 32 40 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 32 40 A3 01 PDFDocument1 pageB737NG - 32 40 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 32 40 A3 01 PDFDocument1 pageB737NG - 32 40 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 24 00 A3 01 PDFDocument1 pageB737NG - 24 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 24 00 A3 01 PDFDocument1 pageB737NG - 24 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 29 00 A3 01 PDFDocument1 pageB737NG - 29 00 A3 01 PDFMuhammed MudassirNo ratings yet

- ATA-26 Et 28Document566 pagesATA-26 Et 28Wilson BenincoreNo ratings yet

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDocument46 pagesVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức HuyNo ratings yet

- LCD LED Display Device TrainingDocument36 pagesLCD LED Display Device TrainingOakkar OrgNo ratings yet

- B737NG - 78 00 A3 01 PDFDocument1 pageB737NG - 78 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 78 00 A3 01 PDFDocument1 pageB737NG - 78 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 21 00 A3 02 - 8 9Document1 pageB737NG - 21 00 A3 02 - 8 9Muhammed MudassirNo ratings yet

- B737NG - 27 60 A3 01 PDFDocument1 pageB737NG - 27 60 A3 01 PDFMuhammed MudassirNo ratings yet

- Typical 400kV TRF (HV) Bay View (GIS MODULE)Document1 pageTypical 400kV TRF (HV) Bay View (GIS MODULE)Amarjit KulkarniNo ratings yet

- B737NG - 73 00 A3 01 PDFDocument1 pageB737NG - 73 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 73 00 A3 01 PDFDocument1 pageB737NG - 73 00 A3 01 PDFMuhammed MudassirNo ratings yet

- Cargo Fire Detection / Extinguishing: P7 PanelDocument1 pageCargo Fire Detection / Extinguishing: P7 PanelMuhammed MudassirNo ratings yet

- B737NG - 21 00 A3 01 - 6 7 1Document1 pageB737NG - 21 00 A3 01 - 6 7 1wagdiNo ratings yet

- B737NG - 32 00 A3 01 PDFDocument1 pageB737NG - 32 00 A3 01 PDFMuhammed MudassirNo ratings yet

- Ac & DC Current Used in PhysiotherapyDocument11 pagesAc & DC Current Used in PhysiotherapyAniket67% (3)

- B737NG - 49 00 A3 01 PDFDocument1 pageB737NG - 49 00 A3 01 PDFMuhammed MudassirNo ratings yet

- Eng / Apu Fire Detection/ Extinguishing Wheelwell Fire DetectionDocument1 pageEng / Apu Fire Detection/ Extinguishing Wheelwell Fire DetectionMuhammed MudassirNo ratings yet

- Eng / Apu Fire Detection/ Extinguishing Wheelwell Fire DetectionDocument1 pageEng / Apu Fire Detection/ Extinguishing Wheelwell Fire DetectionMuhammed MudassirNo ratings yet

- Eng / Apu Fire Detection/ Extinguishing Wheelwell Fire DetectionDocument1 pageEng / Apu Fire Detection/ Extinguishing Wheelwell Fire DetectionMuhammed MudassirNo ratings yet

- Airbus A220 FamilyDocument1 pageAirbus A220 Familystrokeu02No ratings yet

- 29 Hydraulic PowerDocument234 pages29 Hydraulic PowerUcok BabaNo ratings yet

- ATA 79 ENG MCD Installation ProcedureDocument6 pagesATA 79 ENG MCD Installation Procedureanarko arsipelNo ratings yet

- Level III Ata 49 ApuDocument60 pagesLevel III Ata 49 ApuGuyNo ratings yet

- B737NG - 49 00 A3 01 PDFDocument1 pageB737NG - 49 00 A3 01 PDFMuhammed MudassirNo ratings yet

- B737NG - 49 00 A3 01 PDFDocument1 pageB737NG - 49 00 A3 01 PDFMuhammed MudassirNo ratings yet

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDocument108 pagesVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức HuyNo ratings yet

- Tech SpecDocument31 pagesTech SpecakhilNo ratings yet

- A330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APUDocument110 pagesA330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APULuiz Fernando MibachNo ratings yet

- 27 Flight ControlDocument221 pages27 Flight ControlHamidreza AhanzadehNo ratings yet

- B737NG - 49 00 A3 02 PDFDocument1 pageB737NG - 49 00 A3 02 PDFMuhammed MudassirNo ratings yet

- A380 LEVEL III ATA 46 Network Server System Onboard Informati PDFDocument52 pagesA380 LEVEL III ATA 46 Network Server System Onboard Informati PDFDharmeshNo ratings yet

- Convenience SystemDocument48 pagesConvenience Systemrobika79100% (1)

- Magnetism - Science Year 8Document15 pagesMagnetism - Science Year 8b_syiera100% (7)

- A321 Ata24 ELECTRICAL POWER SCHEMATIC PDFDocument1 pageA321 Ata24 ELECTRICAL POWER SCHEMATIC PDFkpilNo ratings yet

- ATA 36 PneumaticsDocument58 pagesATA 36 PneumaticsBao HuynhNo ratings yet

- Single Aisle Technical Training Manual T1+T2 (IAE V2500) (LVL 2&3) Auto FlightDocument106 pagesSingle Aisle Technical Training Manual T1+T2 (IAE V2500) (LVL 2&3) Auto Flight이용일No ratings yet

- A320fam Iae Ata80 Starting PDFDocument24 pagesA320fam Iae Ata80 Starting PDFshabbirjama103No ratings yet

- 06 - 0010 LED Anti-Collision Lighting System A320Document12 pages06 - 0010 LED Anti-Collision Lighting System A320premica100% (1)

- Ata25 AirbusDocument308 pagesAta25 AirbusOliver BarrientosNo ratings yet

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDocument36 pagesVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức HuyNo ratings yet

- Easa p66 Mod 1 Cat BDocument122 pagesEasa p66 Mod 1 Cat BQuân Nguyễn HoàngNo ratings yet

- Aerodynamics (Ameco)Document115 pagesAerodynamics (Ameco)July TadeNo ratings yet

- B737NG P5 Overhead-PanelDocument1 pageB737NG P5 Overhead-PanelMuhammed MudassirNo ratings yet

- Wiring Instructions For Series It Itb and Its ConnectorsDocument52 pagesWiring Instructions For Series It Itb and Its ConnectorsРоман ДяченкоNo ratings yet

- ATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyDocument86 pagesATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyZbor ZborNo ratings yet

- 47 Fuel InertingDocument28 pages47 Fuel InertingTamara AntonyNo ratings yet

- Single Aisle Technical Training Manual Maintenance Course - T1 & T2 JackingDocument12 pagesSingle Aisle Technical Training Manual Maintenance Course - T1 & T2 JackingBintang LucioNo ratings yet

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Air ConditioningDocument130 pagesSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Air ConditioningHafyzzi AriffinNo ratings yet

- ATPG Flow DocumentDocument27 pagesATPG Flow DocumentNitish KumarNo ratings yet

- Ata 36 PneumaticDocument30 pagesAta 36 PneumaticSohaib Aslam ChaudharyNo ratings yet

- Ata 25Document78 pagesAta 25Sohaib Aslam ChaudharyNo ratings yet

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) APUDocument216 pagesSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) APUAnonymous 298xlo3uUNo ratings yet

- 06 - Corrosion Issues: A320 Wing Top Skin Corrosion A320 Gear Rib 5 Corrosion Cabin Floor StructureDocument64 pages06 - Corrosion Issues: A320 Wing Top Skin Corrosion A320 Gear Rib 5 Corrosion Cabin Floor StructureРоман ДяченкоNo ratings yet

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) LightsDocument36 pagesSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) LightsjuanNo ratings yet

- TTM Single Aisle Line & Base Ata 49 ApicDocument174 pagesTTM Single Aisle Line & Base Ata 49 Apic林至伟No ratings yet

- TTM Single Aisle Line & Base Ata 46Document82 pagesTTM Single Aisle Line & Base Ata 46林至伟No ratings yet

- AE 315 - Prelim - Learning Module No. 02 PDFDocument57 pagesAE 315 - Prelim - Learning Module No. 02 PDFhypertextNo ratings yet

- ID DCU IndustrialDocument4 pagesID DCU IndustrialRoozbeh BahmanyarNo ratings yet

- A320 Ramp and Transit Ata 28 - Fuel Metric UnitsDocument184 pagesA320 Ramp and Transit Ata 28 - Fuel Metric UnitsCassiano CapellassiNo ratings yet

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) PneumaticDocument60 pagesSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) PneumaticangeNo ratings yet

- TTM Single Aisle Line & Base Ata 23Document450 pagesTTM Single Aisle Line & Base Ata 23林至伟No ratings yet

- 50 Cargo and Accessory CompartmentsDocument40 pages50 Cargo and Accessory CompartmentsWilson BenincoreNo ratings yet

- A340-500/600 Airbus: Fuel 28Document202 pagesA340-500/600 Airbus: Fuel 28Navid Khalili SafaNo ratings yet

- A340-500/600 Airbus: Lights 33Document14 pagesA340-500/600 Airbus: Lights 33Navid Khalili SafaNo ratings yet

- Training Manual: 31 Indicating and Recor-Ding SystemsDocument13 pagesTraining Manual: 31 Indicating and Recor-Ding SystemsNavid Khalili SafaNo ratings yet

- A340-500/600 Airbus: Navigation 34Document6 pagesA340-500/600 Airbus: Navigation 34Navid Khalili SafaNo ratings yet

- Single Aisle Technical Training Manual Maintenance Course - M35 Line Mechanics (V2500-A5/ME) PneumaticDocument34 pagesSingle Aisle Technical Training Manual Maintenance Course - M35 Line Mechanics (V2500-A5/ME) PneumaticAnh NguyenXuanNo ratings yet

- A340-500/600 Airbus: Fire Protection 26Document56 pagesA340-500/600 Airbus: Fire Protection 26mamon113No ratings yet

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 09 TowingDocument10 pagesA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 09 TowingJia DuoduoNo ratings yet

- 7.04 UnEncryptedDocument26 pages7.04 UnEncryptedkpilNo ratings yet

- Introduction & ObjectivesDocument6 pagesIntroduction & ObjectivesРоман ДяченкоNo ratings yet

- A319/A320/A321 Technical Training Manual T1 & T2 30 Ice & Rain Protection CFM MetricDocument144 pagesA319/A320/A321 Technical Training Manual T1 & T2 30 Ice & Rain Protection CFM MetricSelcuk GuncanNo ratings yet

- B) DCAM PART 66 - Module 4 PDFDocument114 pagesB) DCAM PART 66 - Module 4 PDFwmfadzli7265100% (2)

- Basic Control Systems Equipment and Terms Used IT02 Curriculum ManualDocument1 pageBasic Control Systems Equipment and Terms Used IT02 Curriculum Manualbaboiu electricNo ratings yet

- Traffic Inductive Vehicle Loop Detector PD 132 SiDocument1 pageTraffic Inductive Vehicle Loop Detector PD 132 SiandyNo ratings yet

- Dmi Cal 10 003 A4 Line SizingDocument1 pageDmi Cal 10 003 A4 Line Sizingkemas biruNo ratings yet

- M01 Mathematics (B1+B2) Rev.00 Pages 9Document10 pagesM01 Mathematics (B1+B2) Rev.00 Pages 9Muhammed MudassirNo ratings yet

- Cortona CarbonCopier DocumentDocument1 pageCortona CarbonCopier DocumentMuhammed MudassirNo ratings yet

- B737NG P8 PedestalDocument1 pageB737NG P8 PedestalMuhammed MudassirNo ratings yet

- 351283010Document1 page351283010williamNo ratings yet

- Lab12-Ss-18bme (Design Iir Filters)Document7 pagesLab12-Ss-18bme (Design Iir Filters)saba rasheedNo ratings yet

- ETAP Product Overview 2012Document8 pagesETAP Product Overview 2012JoeDabidNo ratings yet

- Seatex MRU H PDFDocument2 pagesSeatex MRU H PDFCindy0% (1)

- 155513Document5 pages155513TecsloNo ratings yet

- A 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsDocument4 pagesA 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsRamanathanNo ratings yet

- Question Paper CodeDocument3 pagesQuestion Paper CodeDinesh SrinivasanNo ratings yet

- Pic pg3bDocument2 pagesPic pg3bnmanishnNo ratings yet

- WEEK 11 F TOPIC11 RADAR ARPA Different Signals 3Document7 pagesWEEK 11 F TOPIC11 RADAR ARPA Different Signals 3Daniel OrenaNo ratings yet

- Series 956: Steyning Way, Bognor Regis, Solartron Metrology, West Sussex, PO22 9ST UKDocument17 pagesSeries 956: Steyning Way, Bognor Regis, Solartron Metrology, West Sussex, PO22 9ST UKAndresNo ratings yet

- PT9 C-PROOF Product InfoDocument6 pagesPT9 C-PROOF Product Infomarine f.No ratings yet

- Mirrant 2002Document61 pagesMirrant 2002ME SAVRNo ratings yet

- SSP-5-1 Adaptive FilteringDocument88 pagesSSP-5-1 Adaptive FilteringGabor GerebNo ratings yet

- Quotation Estimate-Saeed CottonDocument1 pageQuotation Estimate-Saeed CottonMuhammad Asif RazaNo ratings yet

- Lightning Properties Derived From Lightning LocatiDocument6 pagesLightning Properties Derived From Lightning LocatiCarlos Alberto Avendaño AvendañoNo ratings yet

- PIT ModuleDocument7 pagesPIT ModuleAravindSomuNo ratings yet

- York Tecnologia Inverter MS Inverter RVCC09-24DSAADR - LDocument2 pagesYork Tecnologia Inverter MS Inverter RVCC09-24DSAADR - LYorgos J. Ramirez PNo ratings yet

- Process ControlDocument24 pagesProcess ControlEr Shubham RaksheNo ratings yet

- Flygt Ficha TecnicaDocument12 pagesFlygt Ficha Tecnicaomaralexei86No ratings yet

- BDSP Lecture 3Document79 pagesBDSP Lecture 3Mohammed FarisNo ratings yet

- Discrete-Time Fourier Methods: M. J. Roberts All Rights Reserved. Edited by Dr. Robert AklDocument72 pagesDiscrete-Time Fourier Methods: M. J. Roberts All Rights Reserved. Edited by Dr. Robert AklvenkatNo ratings yet

- WRCPDocument14 pagesWRCPagmarketing1959100% (1)

- 06 Industrial ApplicationDocument45 pages06 Industrial ApplicationshrirangjoshiNo ratings yet

- Diagram Kabel Sound SystemDocument3 pagesDiagram Kabel Sound SystemAnsgar ManurungNo ratings yet