Professional Documents

Culture Documents

Series 10 Versasteer™: Parts and Repair Information

Uploaded by

Ridha AbbassiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 10 Versasteer™: Parts and Repair Information

Uploaded by

Ridha AbbassiCopyright:

Available Formats

Series 10 VersaSteer™

Parts and Repair Information

Series 10

VersaSteer

Table of Contents

Introduction

ID Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Parts

Assembly Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Gerotor parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-16

Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-12

Introduction

This manual provides service • Plug the control unit • Lubricate new rubber

information for Char-Lynn® ports and cover open seals with a petroleum

Series 10 VersaSteer™ hydraulic lines jelly before installation.

Steering Control Units. Step immediately after they • Torque all bolts over

by step instructions for have been gasketed joints, then

complete disassembly, disconnected. repeat the torquing

inspection and • Drain the oil and clean sequence to make up for

reassembly of the control the exterior of the gasket compression.

unit are given. control unit before

The following making repairs.

recommendations should be After all repairs are

• Wash all metal parts in complete it is essential to

followed to insure clean solvent.

successful repairs. verify the accuracy of control

• Use filtered, moisture- unit repairs on an

• Most repairs require the free compressed air to authorized test stand.

removal of the control dry the parts.

unit from the vehicle.

Do not wipe them dry

• Cleanliness is extremely with paper towels or

important. cloth – lint in a hydraulic

• Clean the port areas system will cause

thoroughly before damage.

disconnecting the • Always use new seals

hydraulic lines. when reassembling

hydraulic control units.

2 EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004

ID Tag

Ordering Parts

How to Order Each order must include the following:

Replacement Parts 1. Product Number

2. Date Code

3. Part Name

4. Part Number Bar Code Label — Launch Date June, 1999

5. Quantity of Parts

Refer to specific part listings

for your Char-Lynn® VersaSteer™

Steering Control Unit when ordering

replacement parts. Listings Customer part number

are available from Eaton. or base unit number if it

Sample tag shows identification. has a column or valve

When ordering replacement assembled Eaton Corp. Hydraulics Div.

Eden Prairie, MN 55344

parts, you must include the

following information: Month / Day / Year

For additional literature contact

Eaton Part Number

Eaton Hydraulics at

14615 Lone Oak Road,

Eden Prairie, MN 55344

http://hydraulics.eaton.com

Port Face

Tools Tools Required For Disassembly and Assembly

• Screwdriver (102-152 mm [4 in. - 6 in.] long, x 3 mm [118 in.]

thin flat blade).

• 1/2 inch socket for current hex head cap screws.

• Breaker bar wrench.

• Torque wrench (30 Nm [300 lb-in] capacity).

• 11/16 inch wrench.

Special Tools:

• Plunger and Sleeve Tool No. 600792-001*

*Tools available—by special order—through our service department.

EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004 3

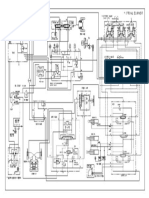

Parts

Assembly

Drawing

Low

10, 11

or

6

Medium

or

3 Standard

52

3

Manual Steering

Check Valve

3 18

8b

5 19

8a

7

9

12 60 15

13

14

1 * 13

16

Hex Head Screw

21

2

22

3

56 86a

86

3

55

48 3

85

49

89

86a

21

86

21 22

or

88

23

25 or 53

22

24

23

22

*Anti-cavitation valve parts will vary

according to configuration.

4 EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004

Parts

Table 1.0 Parts

List

Series 10

VersaSteer

ITEM REFERENCE

NO. PART NO. QTY. DESCRIPTION PAGE

1 See Table 1.0 7 Cap Screw, Hex Head 6

2 23901-000 1 Cap, End

3 5776-000 6 Seal, 72,6 mm [2.86 in.] ID

5 113094-000 1 Plate, Spacer

6 4998212-001 1 Drive

7 204107-XXX 1 Housing, Valve

8a 1 Control Sleeve

8b 1 Control Spool

9 15-000 1 Pin, Centering

10 112714-000 2 or 3 Spring, Spacer

11 113599-000 4 or 6 Spring, Centering

12 112737-000 1 Retainer Spring

13 14880-000 2 Bearing Race

14 5544-000 1 Bearing, Needle Thrust

15 9332-000 1 Seal – 24,9 mm [.98 in.] ID

16 844-000 1 Dust Seal

18 16026-422P 1 Pin, Roll– 34,92 mm [1.375 in.] Length

19 285020-080 1 Ball – 6,35 mm [.25 in.] OD

21 16026-436 2 Pin, Roll – 40,00 mm [1.575 in.] Length

22 18015-000 2 Ball, Check – 6,35 mm [.250 in.] OD

23 230400-000 2 Compression Spring

or 4999516-000 2 Compression Spring (See main parts assembly drawing)

24 113598-000 2 Anti-cav plug retainer

25 230313-000 2 Compression Spring

48 202038-000 1 Ring, Seal

49 16101-322 1 Ring, Back-up

52 4999016-001 1 Plate, Valve

53 4999092-001 1 Valve S/A

55 4999015-000 1 Plate Valve

56 See Table 1.0 1 Gerotor Sub-assembly 6

60 4999651-001 1 O-ring

85 230397-000 1 Spring, Compression

86 112114-010 2 Fitting

86a 250003-906 2 O-Ring

88 4998914-001 1 Piston

89 4992809-001 1 Piston, Guide Spring

EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004 5

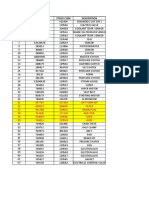

Parts

Gerotor

Table 1.0

ACTUAL

DISPL. REF. NO. 4 REF. NO. 29

cm3/r GEROTOR CAP SCREW

[in3/r] PART NO. Width mm[in] PART NO. LENGTH mm[in]

60 [3.6] 201234-023 10,2 [.40] 16336-530 76,2 [3.00]

75 [4.5] 201234-024 10,2 [.40] 16336-530 76,2 [3.00]

95 [5.9] 201234-003 13,2 [.52] 16336-531 79,5 [3.13]

120 [7.3] 201234-009 16,5 [.65] 16336-532 82,6 [3.25]

145 [8.9] 201234-020 20,1 [.79] 16336-533 85,9 [3.38]

160 [9.7] 201234-004 21,9 [.86] 16336-534 88,9 [3.50]

185 [11.3] 201234-005 25,4 [1.00] 16336-534 88,9 [3.50]

230 [14.1] 201234-031 31,7 [1.25] 16336-537 98,6 [3.88]

295 [17.9] 201234-035 40,4 [1.59] 16336-541 104,9 [4.13]

370 [22.6] 201234-008 50,8 [2.00] 16336-545 117,6 [4.63]

460 [28.2] 201234-033 63,5 [2.50] 16336-551 133,4 [5.25]

590 [35.9] 201234-036 80,8 [3.18] 16336-556 146,1 [5.75]

740 [45.1] 8618-034 101,6[4.00] 16336-564 165,1 [6.50]

Disassembly

Cleanliness is extremely 1. Clamp unit in vise,

important when repairing a Gerotor (Meter) End

meter end up. Clamp

steering control unit. Work lightly on edges of port

in a clean area. Before dis- face sides (see figure1). 25 mm

connecting lines, clean port Use protective material [1 inch]

area of unit thoroughly. Use on vise jaws. Housing Max.

a wire brush to remove distortion could result if

foreign material and debris jaws are overtightened.

from around exterior joints

of the unit.

We recommend that you

keep the unit in a vise during

disassembly. Follow the

clamping procedures

explained throughout the

manual.

Figure 1

6 EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004

Disassembly

Screw, Cap, Hex Head

2. Remove 5/16 in. cap

screws.

3. Remove end cap. Cap, End

4. Remove seal. Seal

Note: All Series 10

VersaSteer™ steering Low Slip

Sealed Seal, Ring

control units have a low

Gerotor Ring, Back-up

slip sealed gerotor Star Only

star, this unit inculdes a

ring seal and a back-up

ring. Gerotor

Figure 2

Gerotor

5. Remove gerotor (meter). (Meter)

Be careful not to drop star.

6. Remove seal from Seal

valve plate.

7. Remove valve plate.

Valve Plate

8. Remove seal from

valve S/A. Seal

Valve S/A

Figure 3

EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004 7

Disassembly

Valve S/A

Seal

9. Remove valve Sub-

assembly

10. Remove seal from Valve Plate

valve plate.

Seal

11. Remove valve plate

Drive

Figure 4

12. Remove seal from spacer Seal

plate.

13. Remove spacer plate. Plate, Spacer

14. Remove seal from housing.

Seal

15. Pull drive and twist to

remove SP/SL drive

assembly from housing. Attention: Do not bind

16. Remove housing from vise. spool and sleeve in housing.

Drive Rotate spool and sleeve

assembly slowly when

removing it from housing.

Drive, Spool, and Sleeve

17. Carefully remove bearing

and races, anti-cavitation

valves and manual

Housing

steering check valve

(roll pin and ball) from bolt

holes by tipping housing

Gerotor side down.

(see figure 6).

Figure 5

8 EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004

Disassembly

18. Do not remove any Manual Steering Dust Seal

valves other than Check Valve

manual steering check

valve assembly and Ball

anti-cavitation valve Roll Pin

assembly. All other

valves are factory preset

and are non-serviceable.

Seal

O-ring

Race

Bearing

19. Carefully Remove Seal with Race * Anti-Cavitation Valves

a thin-blade screw driver. for Cylinder Ports

Ball

Do not scratch seal groove Reference Page 4

with screw driver. Roll Pin

for other configurations

20. Use thin bladed screw

driver to pry dust seal

from housing. Do not

damage housing. Figure 6

21. Push pin from spool and

sleeve assembly.

22. Remove Drive

23. Push spool partially from

control end of sleeve,

then carefully remove

centering springs and Standard Input Torque

Spring/Spacer Package

retaining ring from spool

by hand (figure 7).

Medium Input Torque

*Note Spring/Spacer Package

Standard input torque unit

uses six centering springs Low Input Torque

and two spacers. Spring/Spacer Package

Medium input torque unit

uses four centering

springs and three spacers.

Low input torque unit

uses four centering

springs and two spacers.

Figure 7

EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004 9

Disassembly

Fitting 1/4” Hex Key

Piston

24. Disassemble valve sub-assembly as

shown in figure 8.

Valve S/A

O-ring

Piston, Guide Spring

Fitting

Spring, Compression

O-ring Figure 8

Assembly

Assembly Cleanliness

Recommendations

Check all mating surfaces. Replace any parts that have scratches or burrs that could cause leakage. Clean all metal parts in

clean solvent. Blow dry with air. Do not wipe dry with cloth or paper towel because lint or other matter can get into the

hydraulic system and cause damage. Do not use grit paper or file or grind these parts.

Note: Lubricate all seals with clean petroleum jelly. A good service policy is to replace all old seals with new seals. Do not

use excessive lubricant on seals for meter section.

Refer to parts lists covering your steering control unit when ordering replacement parts.

Fitting

1. Reassemble valve parts Piston

with new o-rings on

plugs (See figure 9). Valve S/A

O-ring

Piston, Guide Spring Torque Fittings to

31-45Nm [23-33 lb-ft]

Fitting

*Note: The fittings included in the

valve assembly are critical in

Spring, Compression

the operation of the valve,

and must not be switched

O-ring

with another style.

Figure 9

10 EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004

Assembly

2. Place housing on a flat

work area on a clean lint

free cloth.

Install press-fit

24,9 mm[.98 in.] ID seal

in housing with metal

suface of seal facing

toward housing (figure 10).

Figure 10

2-Piece Shaft Seal

Installation

For installation of

o-ring: 4999651-001

and

Seal 9332-000

1. Place housing on a flat

work area as shown in

figure 11.

2. Lubricate seal and o-ring

with hydraulic oil before

installation

3. Align sleeve with Figure 11 Tool No. 600792-001

housing bore (figure 11)

4. Insert sleeve into

housing bore (Figure 12)

5. Place o-ring on plunger

(Figure 13).

Figure 12

Figure 13

EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004 11

Assembly

2-Piece Shaft Seal

Installation

6. Align seal with plunger.

cross section "L" shape 12. Inspect seal

of seal should be upside installation. Seal

down (figure 14). and o-ring must

both be within

shaft seal counter

bore of housing

(figure 18).

Figure 14 Figure 18

7. Push seal onto plunger.

Lip of seal should be

between o-ring and

plunger. No gap should

exist between o-ring

and seal (figure 15). 25mm[1in]

13. Clamp housing in vice

(figure 19).

Figure 15

8. Align plunger with

sleeve (figure 16).

Figure 19

9. Push plunger into sleeve

until it bottoms out,

rotate 1/4 turn 14. Install two bearing races

(figure 17). and thrust bearing as

shown in figure 20.

10. While holding sleeve in Needle Thrust Bearing

housing, withdraw Bearing Race

plunger.

11. Withdraw sleeve. Figure 16

Figure 20

Figure 17

12 EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004

Assembly

Spring Slot

15. Assemble spool and

sleeve carefully so that

spring slots line up at the

same end. Rotate spool

while sliding parts

together. Test for free

rotation. Spool should

Control Sleeve

rotate smoothly in sleeve

with fingertip force Control Spool

applied at splined end.

Align spring slots and

identification marks

(Figure 21) in spool and

sleeve and stand parts on

end of bench.

Identification Marks

Figure 21

2 Standard

4 Torque

Spring Spacer 6

16. Installation of spring 8

Springs 9

spacers and springs, hold 7

spring retainer at an angle 1

5

as shown (see figure 22 3

reference number 1),

insert spring spacers and

Spring Spacer

springs one at a time in

sequence noted by

reference numbers 2 - 9

(standard torque), 2 - 8 2 Medium

4

(medium torque), 2- 7 (low 6 Torque 2

torque), then position 8 Low

7 4

spring retainer correctly 5 6 Torque

over all these parts. 3 7

Adjust alignment of 5

3

spring parts with a

small screwdriver.

Figure 22

EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004 13

Assembly

17. Assemble drive and

spool/sleeve. Note: Check to insure that

spool and sleeve are flush or

slightly below 14 hole surface

18. Insert pin through spool of housing.

and sleeve assembly

through hole in drive, Pin Attention: Clean upper surface

until pin is flush at both of housing by wiping with palm

sides of sleeve. of clean hand. Clean each of

the flat surfaces of meter sec-

Figure 23 tion parts in a similar way just

before reassembly. Do not use

19. Position spool and sleeve cloth or paper to clean surfaces.

assembly so that splined

end of spool enters 14

hole end of housing first

(figure 23).

Attention: While inserting

spool and sleeve assembly

into housing, make sure parts

do not tilt out of position.

Push assembly gently into

place with slight rotating

action. Bring spool assembly

entirely within housing bore

until parts are flush at 14 hole

end of housing. With spool

assembly in this flush

position, check for free

rotation within housing by

turning assembly with

fingertip force at splined end.

Figure 24

Roll Pin (2)

20. Install 72,6 mm [2.86 in.] 40,00 mm

ID O-ring in housing [1.575 in.] L

(figure 25). * Anti-Cavitation Valves

for Cylinder Ports

See page 4 for other

21. Install anti-cavitation configurations

valves and manual

steering check valve (if Ball (2)

used) in holes, as shown 4,762 mm

in figure 25. After [.1875 in.] OD

Roll Pin (1)

installing balls, inspect 34,92 mm Manual Steering

holes to make sure they [1.375 in.] L Check Valve

are properly seated. Ball 6,35 mm

[.250 in.] OD

O-ring

Figure 25

14 EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004

Assembly

Seal

22. Install spacer plate.

Align bolt holes in spacer

Valve Plate

plate with tapped holes

in housing.

Seal

23. Lubricate and install 72,6

mm [2.86 in.] ID seal in

spacer plate. Valve S/A

24. Install valve plate.

Seal

25. Lubricate and install 72,6

mm [2.86 in.] ID seal in

valve plate. Valve Plate

26. Install valve S/A, Seal

see figure 26 for correct Alignment

position. Reference —

27. Lubricate and install 72,6 Spacer Plate Bolt Hole

on Center

mm [2.86 in.] ID seal in (Port Face

valve S/A. Side)

28. Install valve plate. Housing

29. Lubricate and install 72,6

mm [2.86 in.] ID seal in

valve plate.

30. Install gerotor, seal

groove up; note position

of star valleys in relation

to marked drive.

Figure 26

Timing Reference Data — Meter A

Align star valley (reference A) with (Gerotor

marked drive (reference B). Valley Star Valley

must align with pin. Note parallel Gerotor

relationship of reference lines A, B,

C, and D in figure 27. Align bolt

holes without disengaging gerotor Seal

(meter) from drive.

Valve Plate

B

Seal

Drive

(Marked)

C

Valve S/A

Pin

Figure 27

EATON Hydraulics Series 10 VersaSteer Parts and Repair October 2004 15

Assembly

31 Install back-up ring and seal

ring in gerotor star. Screw, Cap, Hex Head

32. Lubricate and install 72,6 mm

[2.86 in.] ID seal in gerotor

(meter). Cap, End

33. Install end cap on gerotor, Seal

aligning holes.

Low Slip

Sealed Seal, Ring (metal)

Gerotor Ring, Back-up (rubber)

Star

Gerotor

Groove cross section

w/ rings

Figure 28

34. Install 7 dry cap screws in

end cap. Pretighten cap 6 4

screws to 17Nm [150 lb-in],

then torque screws to

28-34 Nm [250-300 lb-in] in

sequence shown in

figure 29.

1 2

3 7

5

Figure 29

Eaton Eaton Eaton

14615 Lone Oak Road 20 Rosamond Road Dr.-Reckeweg-Str. 1

Eden Prairie, MN 55344 Footscray D-76532 Baden-Baden

USA Victoria 3011 Germany

Tel: 952 937-9800 Australia Tel: (49) 7221 682-0

Fax: 952 974-7722 Tel: (61) 3 9319 8222 Fax: (49) 7221 682-788

www.hydraulics.eaton.com Fax: (61) 3 9318 5714

© 2005 Eaton Corporation

All Rights Reserved

Printed in USA

Document No. C-STCU-TS006-E

June 2005

You might also like

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Manual Servicio Eaton Serie 10 PDFDocument16 pagesManual Servicio Eaton Serie 10 PDFCesar MoraNo ratings yet

- Series 10 Dual Displacement: Parts and Repair InformationDocument20 pagesSeries 10 Dual Displacement: Parts and Repair InformationAлександрNo ratings yet

- Eaton Series 10 Char Lynn Power Steering Wide Angle Control Catalog C Stcu Ts008 e en UsDocument20 pagesEaton Series 10 Char Lynn Power Steering Wide Angle Control Catalog C Stcu Ts008 e en UsRicardo ArzolaNo ratings yet

- SM47576Document7 pagesSM47576Edison CorderoNo ratings yet

- H-4 Controlair Valve: Description of ModelsDocument12 pagesH-4 Controlair Valve: Description of Modelslucas ronaldo coronel mendoza100% (1)

- Orbitrol Repairing 2Document14 pagesOrbitrol Repairing 2Islam ShoukryNo ratings yet

- General Information: Section 1Document22 pagesGeneral Information: Section 1cunNo ratings yet

- Hydraulic System Initial Start-Up and MaintenanceDocument4 pagesHydraulic System Initial Start-Up and MaintenanceLuisNo ratings yet

- SM-800.6516 H4 ControlairDocument13 pagesSM-800.6516 H4 ControlairMuthia AstriNo ratings yet

- Use and Maintenance of Gear UnitDocument4 pagesUse and Maintenance of Gear UnitRaphael LinoNo ratings yet

- Calavar Condor 446q8 Operators Maintenance and Part ManualDocument20 pagesCalavar Condor 446q8 Operators Maintenance and Part ManualMichelle100% (55)

- Service and Maintenance Manual: ModelsDocument30 pagesService and Maintenance Manual: ModelsSebastian GeraciNo ratings yet

- Hayabusa Gen 3 Manual v1.0.0Document831 pagesHayabusa Gen 3 Manual v1.0.0Ronald AndradeNo ratings yet

- Idoc - Pub Maintenance and LubricationDocument34 pagesIdoc - Pub Maintenance and LubricationEric GarciaNo ratings yet

- JAC - Hfc4da12cDocument104 pagesJAC - Hfc4da12cLaibern JppdNo ratings yet

- CS76 Before OperationDocument4 pagesCS76 Before OperationJosé Carlos CarvalhoNo ratings yet

- Husco™ Main Control Valve: MaintenanceDocument22 pagesHusco™ Main Control Valve: MaintenanceAnonymous 7lirmoNo ratings yet

- PLL 1272Document28 pagesPLL 1272Steven LeeNo ratings yet

- Ex400-5, Ex400lc-5, Ex450lc-5 WMDocument598 pagesEx400-5, Ex400lc-5, Ex450lc-5 WMAnonymous vxpVVAcjJ8No ratings yet

- PC78US-8 General Information On TroubleshootingDocument50 pagesPC78US-8 General Information On TroubleshootingHai Van60% (5)

- Cartilla Mantenimiento Brazo ArtDocument9 pagesCartilla Mantenimiento Brazo ArtFabian Jara RodriguezNo ratings yet

- Snorkel Maintenimiento TB80 TB 86JDocument22 pagesSnorkel Maintenimiento TB80 TB 86Jcesar alejandro scavoNo ratings yet

- Series TZ Hydraulic CylindersDocument22 pagesSeries TZ Hydraulic CylindersOctavio VergaraNo ratings yet

- RM 8Document15 pagesRM 8Cristian CatalánNo ratings yet

- Engine Mechanical: Precautions and Preparations Timing ChainDocument88 pagesEngine Mechanical: Precautions and Preparations Timing ChainJames HavocNo ratings yet

- Timing Belt Clinic Peugeot 206 14 Hdi 8hx8hz PDFDocument1 pageTiming Belt Clinic Peugeot 206 14 Hdi 8hx8hz PDFDNo ratings yet

- JLG 3394RT 4394RT Service Manual PDFDocument234 pagesJLG 3394RT 4394RT Service Manual PDFnelsonyNo ratings yet

- GE Fanuc 18i Maintenance ManualDocument44 pagesGE Fanuc 18i Maintenance Manualapi-377158450% (2)

- Grove Rt-880e-Service ManualDocument346 pagesGrove Rt-880e-Service Manualramiro serrano olliscoNo ratings yet

- 0 B1 RPMINo PAB3 RDJYT0 X TRL BYQkkDocument817 pages0 B1 RPMINo PAB3 RDJYT0 X TRL BYQkkLincoln Mansur CoelhoNo ratings yet

- Installation, Start-Up and Service Instructions: 38AH044-134 Air-Cooled Condensing Units 50/60 HZDocument56 pagesInstallation, Start-Up and Service Instructions: 38AH044-134 Air-Cooled Condensing Units 50/60 HZKumar sssssNo ratings yet

- Isuzu Trooper Workshop ManualDocument3,573 pagesIsuzu Trooper Workshop Manualvit otio89% (19)

- 15904746-Isuzu Engine 4lb1 4lc1 4le1 Workshop Service Repair ManualDocument210 pages15904746-Isuzu Engine 4lb1 4lc1 4le1 Workshop Service Repair Manual張家豪No ratings yet

- Operating & Maintenance Procedure For Air Cooler Heat ExchangerDocument10 pagesOperating & Maintenance Procedure For Air Cooler Heat Exchangerrahim_33516285675% (8)

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual Excerptanon_828943220No ratings yet

- Maintenance and Lubrication EN PDFDocument38 pagesMaintenance and Lubrication EN PDFDaniel Castillo PeñaNo ratings yet

- Mooney M20 100hour PDFDocument2 pagesMooney M20 100hour PDFsplyn100% (1)

- CR Injector Test and Repair: ManualDocument65 pagesCR Injector Test and Repair: ManualLuc Mutombo Mukulu100% (7)

- 73 Dit Power StrokeDocument78 pages73 Dit Power StrokeNic Price100% (1)

- 424B Disassembly and Assembly (Transmission) (RESM3578-02)Document102 pages424B Disassembly and Assembly (Transmission) (RESM3578-02)veeresh100% (3)

- Operation and Maintenance of HVAC Equipment for IT Server RoomDocument34 pagesOperation and Maintenance of HVAC Equipment for IT Server RoomNaushad HaiderNo ratings yet

- 6WG1 Engine Manual (Common RailDocument272 pages6WG1 Engine Manual (Common RailDick Gii100% (2)

- 2016 Vol-2 3 OCTDocument12 pages2016 Vol-2 3 OCTsppramNo ratings yet

- Manual Secador D12in-A - D950in-ADocument45 pagesManual Secador D12in-A - D950in-Aandrea garcia100% (6)

- Maintenance ScheduleDocument12 pagesMaintenance ScheduleyidigoNo ratings yet

- Steering SystemDocument28 pagesSteering SystemJahir FrutosNo ratings yet

- VRT200 Transmission Service ManualDocument160 pagesVRT200 Transmission Service Manualgerallazo29100% (3)

- W8L20DF Maintenance ScheduleDocument14 pagesW8L20DF Maintenance ScheduleJulien RichouNo ratings yet

- FlowMasterII - Rotary - Driven - 24 - V - DC - Electric - Pump - 85736 - 85737 - 85738 - 85739 - 85740 - 404517 - Version 2 PDFDocument20 pagesFlowMasterII - Rotary - Driven - 24 - V - DC - Electric - Pump - 85736 - 85737 - 85738 - 85739 - 85740 - 404517 - Version 2 PDFrd100% (1)

- Installation Instructions: Aquaforce 30XW150-400 Water-Cooled Liquid ChillersDocument44 pagesInstallation Instructions: Aquaforce 30XW150-400 Water-Cooled Liquid ChillersphlxuNo ratings yet

- Kalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io) (1) (051-100)Document50 pagesKalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io) (1) (051-100)ValeriNo ratings yet

- BGS OwnersManualDocument66 pagesBGS OwnersManualSoporte centralNo ratings yet

- Manual DL06S VEH R2 PDFDocument230 pagesManual DL06S VEH R2 PDFVu Truong100% (3)

- Manual Barredora CONEQTEC LPB1500Document29 pagesManual Barredora CONEQTEC LPB1500El AlemanNo ratings yet

- Manual w200 WartsillaDocument452 pagesManual w200 Wartsillanikolasthermosolutions100% (1)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- External Gear Motors: RE 14 026/01.05 Replaces: 1 987 760 101/01.99Document40 pagesExternal Gear Motors: RE 14 026/01.05 Replaces: 1 987 760 101/01.99Ridha AbbassiNo ratings yet

- Radial Piston Motor Technical ManualDocument48 pagesRadial Piston Motor Technical ManualElias80No ratings yet

- DoosanM300 HYDDocument1 pageDoosanM300 HYDRidha AbbassiNo ratings yet

- MT 16Document2 pagesMT 16Ridha AbbassiNo ratings yet

- Sauerdanfoss Series Osp Catalogue en 11007611Document80 pagesSauerdanfoss Series Osp Catalogue en 11007611Ridha AbbassiNo ratings yet

- Catalogue Vickers PumpiDocument35 pagesCatalogue Vickers PumpiRn SrtnNo ratings yet

- Service Manual: S/N 233311001 & Above S/N 233211001 & Above (D Series)Document6 pagesService Manual: S/N 233311001 & Above S/N 233211001 & Above (D Series)Ridha AbbassiNo ratings yet

- MVP 07 T A Edition: 07/03.2022 Replaces: MVP 06 T ADocument72 pagesMVP 07 T A Edition: 07/03.2022 Replaces: MVP 06 T ARidha AbbassiNo ratings yet

- Variable-Displacement Piston Pump: PP VB2V F8A3 EE B GDocument4 pagesVariable-Displacement Piston Pump: PP VB2V F8A3 EE B GRidha AbbassiNo ratings yet

- Specifications: Ackhoe OaderDocument4 pagesSpecifications: Ackhoe OaderRidha AbbassiNo ratings yet

- Industrial Training Template BasicsDocument65 pagesIndustrial Training Template BasicsFaiz IbrahimNo ratings yet

- Hydraulic Training Smiley PDFDocument100 pagesHydraulic Training Smiley PDFliu zhao liu zhaoNo ratings yet

- Vane Pump PDFDocument76 pagesVane Pump PDFHidroil Neuquen SrlNo ratings yet

- Eaton Vickers 20V 25V 35V 45VDocument35 pagesEaton Vickers 20V 25V 35V 45VRidha Abbassi100% (1)

- Bomba Sauer Partes m40-m46Document132 pagesBomba Sauer Partes m40-m46fercsl100% (3)

- PDF V10 V20 V2010 V2020 - Vickers PDFDocument27 pagesPDF V10 V20 V2010 V2020 - Vickers PDFAyoub RouissiNo ratings yet

- To Be Used For Pars Service Option Only in Bond: ExpressDocument4 pagesTo Be Used For Pars Service Option Only in Bond: ExpressRidha AbbassiNo ratings yet

- Variable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ADocument72 pagesVariable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ARidha AbbassiNo ratings yet

- To Be Used For Pars Service Option Only in Bond: ExpressDocument4 pagesTo Be Used For Pars Service Option Only in Bond: ExpressRidha AbbassiNo ratings yet

- Bomba Sauer Partes m40-m46Document132 pagesBomba Sauer Partes m40-m46fercsl100% (3)

- Series 20 Axial Piston Pumps Service ManualDocument36 pagesSeries 20 Axial Piston Pumps Service Manualvrosalio100% (1)

- Catalogue: Guns For GenerationsDocument38 pagesCatalogue: Guns For GenerationsRidha AbbassiNo ratings yet

- Service Training for 325D/320D Hydraulic Excavators Pump and Pump ControlsDocument13 pagesService Training for 325D/320D Hydraulic Excavators Pump and Pump Controlsمحمد يونس100% (1)

- PVC-CPVC-80 - PVC Plastic Pipe and Fittings 80Document12 pagesPVC-CPVC-80 - PVC Plastic Pipe and Fittings 80Ridha AbbassiNo ratings yet

- To Be Used For Pars Service Option Only in Bond: ExpressDocument4 pagesTo Be Used For Pars Service Option Only in Bond: ExpressRidha AbbassiNo ratings yet

- Variable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ADocument72 pagesVariable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ARidha AbbassiNo ratings yet

- Nexbraid Clear PVC Hose: Series 125 (Standard Wall) / Series 126 (Heavy Duty)Document2 pagesNexbraid Clear PVC Hose: Series 125 (Standard Wall) / Series 126 (Heavy Duty)Ridha AbbassiNo ratings yet

- Vane Motors High Performance Hydraulic Series M5B - M5BS - M5BFDocument11 pagesVane Motors High Performance Hydraulic Series M5B - M5BS - M5BFRidha AbbassiNo ratings yet

- Parts Information: Char-LynnDocument5 pagesParts Information: Char-LynnRidha AbbassiNo ratings yet

- Toshiba Main Pump Solar-V PDFDocument12 pagesToshiba Main Pump Solar-V PDFRonald AuquiNo ratings yet

- Calculating masonry costs for a residential structureDocument7 pagesCalculating masonry costs for a residential structureSean Franz VilardoNo ratings yet

- Rock Mass Classification SystemsDocument33 pagesRock Mass Classification Systemsmortaza7094No ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- Industrial Electrical or Maintenance RepairDocument2 pagesIndustrial Electrical or Maintenance Repairapi-78929944No ratings yet

- Technical Solutions For The Installation of High Voltage CablesDocument13 pagesTechnical Solutions For The Installation of High Voltage Cablesrrazak63No ratings yet

- DSM Arnite® B434 SE PBT-GF20 FRDocument2 pagesDSM Arnite® B434 SE PBT-GF20 FRcurioushoainamNo ratings yet

- Sand Drag and Mud Bog RulesDocument7 pagesSand Drag and Mud Bog RulesWhitney Michelle BillingNo ratings yet

- DebugDocument295 pagesDebugkarthikNo ratings yet

- AN2085Document9 pagesAN2085ahseerhsgNo ratings yet

- SJ-20100630164932-027-ZXSS10 SS1b (V2.0.1.07) SoftSwitch Control Equipment Data Configuration Guide Subscriber Allocation - 280443Document31 pagesSJ-20100630164932-027-ZXSS10 SS1b (V2.0.1.07) SoftSwitch Control Equipment Data Configuration Guide Subscriber Allocation - 280443منصورالمغربيNo ratings yet

- Olt Config CuyDocument21 pagesOlt Config CuyEron RamdanyNo ratings yet

- Traction Transformers From SiemensDocument10 pagesTraction Transformers From Siemenscosty_transNo ratings yet

- Harris 25GX 250 580Document2 pagesHarris 25GX 250 580Sadot GutierrezNo ratings yet

- Galaxy Y S5360 Android 2.3.6 Gingerbread Official FirmwareDocument23 pagesGalaxy Y S5360 Android 2.3.6 Gingerbread Official Firmwarekharishkhan0% (1)

- Linux Interview QuestionsDocument4 pagesLinux Interview QuestionsPaaventhan DharmarajanNo ratings yet

- AM8 Printer: A Metal Frame For Your Anet A8Document28 pagesAM8 Printer: A Metal Frame For Your Anet A8polococo6No ratings yet

- NM ENMR TeleCoop Fact Sheet 02-24-2010Document1 pageNM ENMR TeleCoop Fact Sheet 02-24-2010StimulatingBroadband.comNo ratings yet

- Compressor Tech May 2013Document89 pagesCompressor Tech May 2013H.a. UlicesNo ratings yet

- MBD J JNF9KC 1047 Manual PDFDocument51 pagesMBD J JNF9KC 1047 Manual PDFvin ruNo ratings yet

- Lte Epc Umts 3GPPDocument222 pagesLte Epc Umts 3GPPjbarriospNo ratings yet

- Chemistry PSPM 1 2008/2009Document3 pagesChemistry PSPM 1 2008/2009Viknish Arumugam50% (2)

- Medical Equipment MaintenanceDocument6 pagesMedical Equipment Maintenancever_at_workNo ratings yet

- Lossy Compression and Iterative Reconstruction For Encrypted ImageDocument22 pagesLossy Compression and Iterative Reconstruction For Encrypted ImageVanambhadi DeepuNo ratings yet

- AIR Modeller 2019-04-05 83Document68 pagesAIR Modeller 2019-04-05 83Tomeu Llompart100% (8)

- Sage X3 - User Guide - HTG-Printing CLOB Comments PDFDocument8 pagesSage X3 - User Guide - HTG-Printing CLOB Comments PDFcaplusinc100% (1)

- Print: 2Zr-Fe Engine Control Sfi System System DiagramDocument10 pagesPrint: 2Zr-Fe Engine Control Sfi System System DiagramAlfredo MedinaNo ratings yet

- CW MasterDocument80 pagesCW MasterArianta RianNo ratings yet

- Racing Boy Catalog - 2014Document117 pagesRacing Boy Catalog - 2014Eddie BoyzNo ratings yet

- Volvo Plane Ice ReportDocument18 pagesVolvo Plane Ice ReportAreebNo ratings yet