Professional Documents

Culture Documents

SCC Class A G40 Concrete Mix

Uploaded by

WunNaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCC Class A G40 Concrete Mix

Uploaded by

WunNaCopyright:

Available Formats

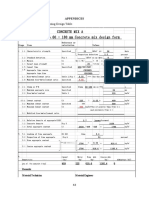

PAN-UNITED CONCRETE PTE LTD

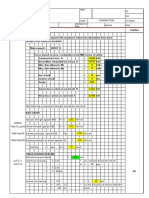

CONCRETE MIX DESIGN COMPUTATION AND SUMMARY Date : 28-Jun-19

Project PROJECT SGA (FACEBOOK) Concrete Type : Designed Concrete

Concrete Family : IIIB - PUPBFC

Concrete Grade : 40

Customer WAH LOON ENGINEERING PTE. LTD.

Strength Class : C32/40

SCC CLASS A

1. Specification SS EN 206 : 2014 ; SS 544 - 1 & 2 : 2014

1.1 Specific Characteristic Compressive Strength C32/40 N/mm² at 28 days

1.2 Designed Standard Deviation 4.6 N/mm²

1.3 Designed Margin 7.5 N/mm²

1.4 Target Mean Strength 47.50 N/mm²

1.5 Free Water / Cement Ratio 0.35

1.6 Design Chemical Class DC-4z

1.7 Chloride Content Class Cl 0.10

1.8 Workability 675±50 mm (Slump Flow)

1.9 Product Description GR 40 PBFC CHIP FL 675V50MM SCC CLASSA

2. Cement SS EN 197 - 1 : 2014, SS 544 : PART 2 : 2014 (Table-1)

2.1 Cement Type Portland Blast Furnace Cement IIIB, 42.5N

2.2 Cement Content 460 kg/m³

2.3 Silica Fume 20 kg/m³

3. Aggregates SS EN 12620 : 2008 + A1 2009

3.1 Aggregate Type : Coarse Crushed Granite

: Fine Natural Sand / Manufactured Sand

3.2 Relative Density of Aggregates 2.60 - 2.65

3.3 Coarse Agg lower (d) and upper (D) sieve Size d = 4 mm, D = 10 mm

3.4 Fine Agg lower (d) and upper (D) sieve Size d = 0 mm, D = 4 mm

3.5 Grading of Coarse Aggregate GC80/20

3.6 Grading of Fine Aggregate GF85

3.7 Coarse Aggregate Content : SSD 750 kg/m³

3.8 Fine Aggregate Content : SSD 935 kg/m³

4. Water

4.1 Free Water Content 170 kg/m³

5. Admixtures SS EN 934 – 2 : 2008

5.1 Admixture Type 1 ADVA 181 - Retarding Comb Polymer Superplasticizer

5.2 Dosage 300 ml per 100kg of cement (SG=1.115)

5.3 Admixture Type 2 ADVA 181N - Superplasticizer

5.4 Dosage 1350 ml per 100kg of cement (SG=1.09)

5.5 Admixture Type 3 V-MAR 10P

5.6 Dosage 0.2 kg/m³

6. Summary

Strength Slump Flow Cement Silica Fume Coarse Agg Fine Agg Water Admix 1 Admix 2 Admix 3 A/C W/C Density

Class

(mm) (kg/m³) (kg/m³) (kg/m³) (kg/m³) (kg/m³) (L/m³) (%)[1] (L/m³) (%)[1] (kg/m³) (kg/m³)

C32/40 675±50 460 20 750 935 170 1.38 0.33 6.21 1.47 0.20 3.51 0.35 2335

Remarks : The above mix design is subjected to be adjusted due to the availability and variability of the raw materials.

IIIB contains GGBS ranged from 66%-80%.

Note: [1] % = kg/100 kg of cement

Pan-United Concrete Pte Ltd Co Reg No. 200106604K

12 Kaki Bukit Crescent, Kaki Bukit Techpark 1, Singapore 416243

T +65 6581 0777 F +65 6581 3777 www.panunited.com.sg

You might also like

- MS 1314 Part 3 2004Document19 pagesMS 1314 Part 3 2004Wei Han NgNo ratings yet

- Esteem Plus 130404Document244 pagesEsteem Plus 130404tanaimharunNo ratings yet

- Release Notes 9.5.169.0 (27 April 2017)Document124 pagesRelease Notes 9.5.169.0 (27 April 2017)Nurmuliana Abdul WahabNo ratings yet

- Etc - BD 28-87Document1 pageEtc - BD 28-87arun_angshuNo ratings yet

- Assignment 1 - RCCDocument7 pagesAssignment 1 - RCCRichard WestonyNo ratings yet

- Crack Width BS 8110Document2 pagesCrack Width BS 8110nhulugallaNo ratings yet

- PT Slab Vs RCC ComparisionDocument5 pagesPT Slab Vs RCC ComparisionaahtagoNo ratings yet

- 2013 - Kumkang Al-Form CatalogueDocument20 pages2013 - Kumkang Al-Form CataloguehungxdNo ratings yet

- Eastern Pretech Chart (HCS - EC2 - 2015)Document2 pagesEastern Pretech Chart (HCS - EC2 - 2015)LordM00nNo ratings yet

- Analysis and Design of A Combined Triangular Shaped Pile Cap Due To Pile EccentricityDocument7 pagesAnalysis and Design of A Combined Triangular Shaped Pile Cap Due To Pile Eccentricityazhar ahmad100% (1)

- BEM Form A3 2 Application Form ForDocument7 pagesBEM Form A3 2 Application Form ForINSTECH ConsultingNo ratings yet

- Appendix 16.a Example - Grass ChannelDocument4 pagesAppendix 16.a Example - Grass Channelkhoohuikiang100% (1)

- JKR Strip FootingDocument16 pagesJKR Strip FootingShazreel AmirNo ratings yet

- Continental Steel - Structural SteelDocument191 pagesContinental Steel - Structural SteelDesmond TongNo ratings yet

- Design MixDocument7 pagesDesign MixMohammad Hafiz MahadzirNo ratings yet

- IWK - Standardized Document For SCCDocument3 pagesIWK - Standardized Document For SCCazwarfahmi07100% (1)

- Mi TSDocument37 pagesMi TSwhoammeNo ratings yet

- Column Design - As Per BS CodeDocument16 pagesColumn Design - As Per BS CodeFar AwayNo ratings yet

- Ibs CalculationDocument5 pagesIbs CalculationSiongyung KongNo ratings yet

- Wind Load Bs 6399Document1 pageWind Load Bs 6399Kutty MansoorNo ratings yet

- Kelvin Pile Set CalculationDocument1 pageKelvin Pile Set CalculationKelvin Lau100% (1)

- Column Design - As Per BS8110Document16 pagesColumn Design - As Per BS8110Parthiban ArivazhaganNo ratings yet

- Uniform Building By-Laws 1984Document41 pagesUniform Building By-Laws 1984Azwani Abdullah0% (1)

- Design Parameters For Longitudinal Bars (Beams BS 8110)Document4 pagesDesign Parameters For Longitudinal Bars (Beams BS 8110)dhanya1995No ratings yet

- BRC Hand Book PDFDocument36 pagesBRC Hand Book PDFYang W OngNo ratings yet

- BEC 304 Steel and Timber DesignDocument18 pagesBEC 304 Steel and Timber DesignSeng Suen100% (1)

- Ruj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekDocument5 pagesRuj.: Kod: Subjek: No Helaian: Ruj. Lukisan: Disemak Tarikh: Direkabentuk Oleh: ProjekHafiz Budean RahmanNo ratings yet

- BS1881-202 1986Document13 pagesBS1881-202 1986venkateswara rao PothinaNo ratings yet

- EC2 Creep and Shrinkage LossesDocument9 pagesEC2 Creep and Shrinkage LossesSorin SavescuNo ratings yet

- Project: Date: Location: Job Ref: Column:: Column Design SUN - U, Phase1 Part 2 7-12-21 ACE.09.206Document15 pagesProject: Date: Location: Job Ref: Column:: Column Design SUN - U, Phase1 Part 2 7-12-21 ACE.09.206Lem TeohNo ratings yet

- Bond Strength Between Interfaces of ConcreteDocument21 pagesBond Strength Between Interfaces of ConcreteBhaskar AlapatiNo ratings yet

- Natural CoagulantsDocument18 pagesNatural CoagulantsNyamweya Momanyi JosephatNo ratings yet

- BS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesDocument19 pagesBS 5075-2-1982 - Concrete Admixtures - Specification For Air Entraining AdmixturesRaviranjan kumarNo ratings yet

- Effect of Cement Stabilization On Geotechnical Properties of Sandy Soils PDFDocument16 pagesEffect of Cement Stabilization On Geotechnical Properties of Sandy Soils PDFFahim KhanNo ratings yet

- Group 7 - Block B (Up To 28 Floors) Building & Structural ElementDocument3 pagesGroup 7 - Block B (Up To 28 Floors) Building & Structural ElementChung ChanNo ratings yet

- Engineering SpecDocument304 pagesEngineering SpecSYifa ShuhaIliNo ratings yet

- 12.7 7 Wire Strand Proprieties VSLDocument1 page12.7 7 Wire Strand Proprieties VSLAbu BiduNo ratings yet

- Retaining Wall (BS8110)Document7 pagesRetaining Wall (BS8110)MAGED MOHMMED AHMED QASEMNo ratings yet

- Flexible Pavement Thickness Design JKR MethodDocument3 pagesFlexible Pavement Thickness Design JKR MethodMohamad Shahrizal AliasNo ratings yet

- Calculation PDFDocument126 pagesCalculation PDFmohammed almahrooqiNo ratings yet

- 01-Slides-D & C of Driven RC Piles-7 Aug 18-BriefDocument144 pages01-Slides-D & C of Driven RC Piles-7 Aug 18-BriefFreddie KooNo ratings yet

- Form SSA-PDC-1Document3 pagesForm SSA-PDC-1Lee LaiHaaNo ratings yet

- Design of An Industrial BuildingDocument7 pagesDesign of An Industrial BuildingAbhishek KaushikNo ratings yet

- HDB Requirements For A&a Work On HDB PremisesDocument16 pagesHDB Requirements For A&a Work On HDB PremiseschemicalbreadNo ratings yet

- BCA Circular Guide July 2019 - Guide in Format For Structural Plan SubmissionDocument23 pagesBCA Circular Guide July 2019 - Guide in Format For Structural Plan Submissionengrfrancis052993No ratings yet

- DOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsDocument42 pagesDOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsRebaz A. OthmanNo ratings yet

- Highway Engineering Notes - Chapter 5Document33 pagesHighway Engineering Notes - Chapter 5Muhammad Farhan GulNo ratings yet

- Esteem PlusDocument261 pagesEsteem PlusLun Ding50% (2)

- Dms 544 Part 2 - PC September 2015 PDFDocument48 pagesDms 544 Part 2 - PC September 2015 PDFaliNo ratings yet

- Soil Stabilization Practical Report Grp2Document18 pagesSoil Stabilization Practical Report Grp2Olowoniwa MarvellousNo ratings yet

- SFunmodDocument41 pagesSFunmodjaya_brbNo ratings yet

- Kamarul Ariffin Bin Mohd Mahpal COMPARISON OF SLAB DESIGN BETWEEN BS 8110 AND EUROCODE 2 BY USING MICROSOFT EXCELDocument24 pagesKamarul Ariffin Bin Mohd Mahpal COMPARISON OF SLAB DESIGN BETWEEN BS 8110 AND EUROCODE 2 BY USING MICROSOFT EXCELDzulkarnain B AhmadNo ratings yet

- SIRIM-Precast Pile 2019 PDFDocument15 pagesSIRIM-Precast Pile 2019 PDFTZeLOonNo ratings yet

- EN9848Document1 pageEN9848Ali md YounusNo ratings yet

- 1 - Mix Design - Chuan Lim - g40 s4 (160-210)Document1 page1 - Mix Design - Chuan Lim - g40 s4 (160-210)ronel bayotNo ratings yet

- Img 20200831 0005Document1 pageImg 20200831 0005Aung Naing Latt AungNo ratings yet

- Mix Composition Contractor: Project: Attn To: Thong Huat Brothers Pte LTDDocument1 pageMix Composition Contractor: Project: Attn To: Thong Huat Brothers Pte LTDKoh Jia JieNo ratings yet

- Concrete Mixing DesignDocument15 pagesConcrete Mixing DesignChris ArtecoNo ratings yet

- Pe Mixed SDN BHD: G.MohanadassDocument1 pagePe Mixed SDN BHD: G.MohanadassAmi ShafiNo ratings yet

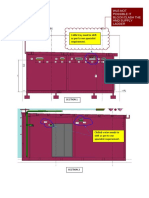

- Member of The Surbana Jurong GroupDocument1 pageMember of The Surbana Jurong GroupWunNaNo ratings yet

- Revit Pure BASICS RailingsDocument35 pagesRevit Pure BASICS RailingsWunNa100% (1)

- Wle:Possible To Shift: Cable Tray Need To Shift As Per To Our Specialist RequirementDocument3 pagesWle:Possible To Shift: Cable Tray Need To Shift As Per To Our Specialist RequirementWunNaNo ratings yet

- Windows 7 Total Training: Chapter (4) Optimizing The Windows 7 User ExperienceDocument10 pagesWindows 7 Total Training: Chapter (4) Optimizing The Windows 7 User ExperienceWunNaNo ratings yet

- Windows 7 Total Training: Chapter (1) Getting Started Using Windows 7Document10 pagesWindows 7 Total Training: Chapter (1) Getting Started Using Windows 7WunNaNo ratings yet

- Tips To Understand Revit Railings: 1-Choose Between Sketch A Path or Place On HostDocument12 pagesTips To Understand Revit Railings: 1-Choose Between Sketch A Path or Place On HostWunNaNo ratings yet

- RP Pamphlet19 Railings Part 2Document33 pagesRP Pamphlet19 Railings Part 2WunNaNo ratings yet

- OPS0158 AKZ CodingDocument26 pagesOPS0158 AKZ CodingWunNaNo ratings yet

- Hetat Support RequirementDocument2 pagesHetat Support RequirementWunNaNo ratings yet

- Cable Tray Need To Shift As Per To Our Specialist RequirementDocument5 pagesCable Tray Need To Shift As Per To Our Specialist RequirementWunNaNo ratings yet

- Project Sga: Section 1 1 Section 2 2Document1 pageProject Sga: Section 1 1 Section 2 2WunNaNo ratings yet

- M&e Daily ReportDocument63 pagesM&e Daily ReportWunNaNo ratings yet

- L11 Chiller ATS PDFDocument1 pageL11 Chiller ATS PDFWunNaNo ratings yet

- Updated Temp - Substation - ChecklistDocument22 pagesUpdated Temp - Substation - ChecklistWunNaNo ratings yet

- Uts Handover CertDocument33 pagesUts Handover CertWunNaNo ratings yet

- TPN8C30 M&E Inspection FormDocument32 pagesTPN8C30 M&E Inspection FormWunNaNo ratings yet

- RoofDocument5 pagesRoofWunNaNo ratings yet

- Resignation and Offset of Annual LeaveDocument4 pagesResignation and Offset of Annual LeaveWunNaNo ratings yet

- KP Skc3n29 CSD b1 WipDocument4 pagesKP Skc3n29 CSD b1 WipWunNaNo ratings yet

- RevitPure3D ViewsDocument16 pagesRevitPure3D ViewsWunNaNo ratings yet

- Coordination Meeting 41 (24 Jun 14)Document6 pagesCoordination Meeting 41 (24 Jun 14)WunNaNo ratings yet

- CSD Check ListDocument1 pageCSD Check ListWunNaNo ratings yet

- Revit Pure BASICS Chapter1Document22 pagesRevit Pure BASICS Chapter1WunNa100% (1)

- Deck 1A 1 Deck 2A 2 Deck 3A 3: CL CLDocument3 pagesDeck 1A 1 Deck 2A 2 Deck 3A 3: CL CLWunNaNo ratings yet

- A B C D B.1 C.1: Unnamed Project Name Owner 01Document4 pagesA B C D B.1 C.1: Unnamed Project Name Owner 01WunNaNo ratings yet

- KubityDocument1 pageKubityWunNaNo ratings yet

- Epicsgpokemon (Iv:100% or Iv:99% or Iv:98% or Iv:97% or Iv:96% or Iv:95% or Unown)Document1 pageEpicsgpokemon (Iv:100% or Iv:99% or Iv:98% or Iv:97% or Iv:96% or Iv:95% or Unown)WunNaNo ratings yet

- SEAS RSRC 57bfe799620e0Document4 pagesSEAS RSRC 57bfe799620e0WunNaNo ratings yet

- Punjab Medical Faculty Registration Form: Personal DetailsDocument2 pagesPunjab Medical Faculty Registration Form: Personal DetailsAamir Khan PtiNo ratings yet

- Lyra Kate Mae P. Salvador BSA-1 MANSCI-446 Course Final RequirementDocument5 pagesLyra Kate Mae P. Salvador BSA-1 MANSCI-446 Course Final RequirementLyra Kate Mae SalvadorNo ratings yet

- Reference Book 2014 05 19Document84 pagesReference Book 2014 05 19leoNo ratings yet

- 4.0 Air Separators 4.1Document31 pages4.0 Air Separators 4.1Dilnesa Ejigu100% (1)

- Uplift With Moment CalculationDocument4 pagesUplift With Moment CalculationdennykvgNo ratings yet

- Mathchapter 2Document12 pagesMathchapter 2gcu974No ratings yet

- Service Manual Omoda 5 Part4Document2,081 pagesService Manual Omoda 5 Part4Sina ArsaniNo ratings yet

- Technical DescriptionDocument6 pagesTechnical DescriptionJigar MehtaNo ratings yet

- PDF Kajaria Report Final - CompressDocument40 pagesPDF Kajaria Report Final - CompressMd Borhan Uddin 2035097660No ratings yet

- Understanding M-Values PDFDocument9 pagesUnderstanding M-Values PDFrolandoNo ratings yet

- Chapter 15.1.2.3 DC Drives PPT II Spring 2012Document56 pagesChapter 15.1.2.3 DC Drives PPT II Spring 2012Muhammad Saqib Noor Ul IslamNo ratings yet

- Data Sheets Bulletin Electric Actuators Model Epi 2 Keystone Us en 2721364Document16 pagesData Sheets Bulletin Electric Actuators Model Epi 2 Keystone Us en 2721364Nag RajNo ratings yet

- How To Disassemble Dell Inspiron 17R N7110 - Inside My LaptopDocument17 pagesHow To Disassemble Dell Inspiron 17R N7110 - Inside My LaptopAleksandar AntonijevicNo ratings yet

- Omni Bas Outdoor Product CatalogDocument70 pagesOmni Bas Outdoor Product CatalogVladislav GordeevNo ratings yet

- Hi Fi Audio Tone Control Circuit Using Low Noise TransistorsDocument8 pagesHi Fi Audio Tone Control Circuit Using Low Noise TransistorsMuhammad YousafNo ratings yet

- ITS US Special Edition 2017-18 - Volume 14 Issue 10Document15 pagesITS US Special Edition 2017-18 - Volume 14 Issue 10Leo Club of University of MoratuwaNo ratings yet

- Introduction To Device ManagementDocument72 pagesIntroduction To Device ManagementMOHAMMED SHEHBAAZNo ratings yet

- A User Guide For FORTRAN 90-95-0Document19 pagesA User Guide For FORTRAN 90-95-0Anonymous IF3H0X2vBeNo ratings yet

- MicroStructPy A Statistical Microstructure Mesh GeDocument6 pagesMicroStructPy A Statistical Microstructure Mesh GeMike JohanssenNo ratings yet

- IASDocument3 pagesIASankit sharmaNo ratings yet

- Using GPS, GIS, and Accelerometer Data To Predict Transportation ModesDocument7 pagesUsing GPS, GIS, and Accelerometer Data To Predict Transportation ModesAdanely Escudero BarrenecheaNo ratings yet

- Control 4Document17 pagesControl 4muhamed mahmoodNo ratings yet

- Final Examination SEMESTER 1, SESSION 2014/2015: SKAA 2722 1Document10 pagesFinal Examination SEMESTER 1, SESSION 2014/2015: SKAA 2722 1Hanis SyafiqNo ratings yet

- RiskWISE Import Template StorageTank 11-Aug-2018 145718412Document41 pagesRiskWISE Import Template StorageTank 11-Aug-2018 145718412irfanlarikhotmailcomNo ratings yet

- Name: Maturan, Renz Myko B. Date: November 28, 2022 Subject & Section: EE 330 AC/DC Machineries - CDocument7 pagesName: Maturan, Renz Myko B. Date: November 28, 2022 Subject & Section: EE 330 AC/DC Machineries - CRenz MykoNo ratings yet

- Environmental Accounting From The New Institutional Sociology Theory Lens: Branding or Responsibility?Document16 pagesEnvironmental Accounting From The New Institutional Sociology Theory Lens: Branding or Responsibility?abcdefghijklmnNo ratings yet

- Ampd Data Sheet Vacuum Casting Resin 8263Document2 pagesAmpd Data Sheet Vacuum Casting Resin 8263Lorenzo Guida0% (1)

- Apartments? Not in My Backyard. Stouffville & Affordable Housing. Presentation To Public HearingDocument14 pagesApartments? Not in My Backyard. Stouffville & Affordable Housing. Presentation To Public HearingArnold Neufeldt-FastNo ratings yet

- Earth and Life Science LAS UpdatedDocument7 pagesEarth and Life Science LAS UpdatedAnthony HawNo ratings yet

- Syncronex Single Copy 3.1 Users GuideDocument208 pagesSyncronex Single Copy 3.1 Users GuideTony BoscoNo ratings yet