Professional Documents

Culture Documents

1 - Mix Design - Chuan Lim - g40 s4 (160-210)

Uploaded by

ronel bayotOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 - Mix Design - Chuan Lim - g40 s4 (160-210)

Uploaded by

ronel bayotCopyright:

Available Formats

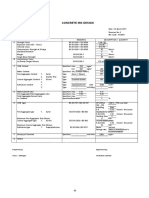

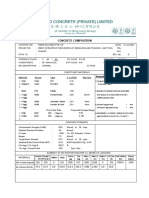

PAN-UNITED CONCRETE PTE LTD

CONCRETE MIX DESIGN COMPUTATION AND SUMMARY Date : 03-Apr-23

PROPOSED ADDITIONS AND ALTERATION WORKS INVOLVING NEW DROP- Concrete Type : Designed Concrete

OFF CANOPY AND ALL-DAY-DINING ON LEVEL 2 AND 3 OF THE EXISTING 8-

Project STOREY FESTIVE HOTEL ON LOT 02779W MK 34 AT 12 SENTOSA Concrete Family : CEM I - PUOPC

GATEWAY Concrete Grade : 40

Customer CHUAN LIM CONSTRUCTION PTE LTD Strength Class : C32/40

1. Specification SS EN 206 ; SS 544 - 1 & 2

1.1 Specific Characteristic Compressive Strength C32/40 N/mm² at 28 days

1.2 Designed Standard Deviation 4.6 N/mm²

1.3 Designed Margin 7.5 N/mm²

1.4 Target Mean Strength 47.50 N/mm²

1.5 Free Water / Cement Ratio 0.45

1.6 Design Chemical Class DC-4z

1.7 Chloride Content Class Cl 0.10

1.8 Workability S4 (160 - 210) mm (Slump)

1.9 Product Description GR 40 SL 160-210MM

1.10 Product Code EN4004

2. Cement SS EN 197-1

2.1 Cement Type Ordinary Portland Cement

2.2 Cement Content 410 kg/m³

3. Aggregates SS EN 12620

3.1 Aggregate Type : Coarse Crushed Granite

: Fine Crushed Granite Fine / Manufactured Sand / Sand

3.2 Relative Density of Aggregates 2.60 - 2.65

3.3 Coarse Agg lower (d) and upper (D) sieve Size d = 4 mm, D = 20 mm

3.4 Fine Agg lower (d) and upper (D) sieve Size d = 0 mm, D = 4 mm

3.5 Grading of Coarse Aggregate GC90/15

3.6 Grading of Fine Aggregate GF85

3.7 Coarse Aggregate Content : SSD 950 kg/m³

3.8 Fine Aggregate Content : SSD 785 kg/m³

4. Water

4.1 Free Water Content 185 kg/m³

5. Admixtures SS EN 934 – 2

5.1 Daratard P88. Water reducing, plasticising and set retarding. 500 ml per 100kg of cement (SG=1.13)

5.2 Daracem Super 21M - Non retarding superplasticizer 500 ml per 100kg of cement (SG=1.17)

6. Summary

Strength Class Slump Cement Coarse Agg Fine Agg Water Admix 1 Admix 2 A/C W/C Density

(mm) (kg/m³) (kg/m³) (kg/m³) (kg/m³) (L/m³) (%)[1] (L/m³) (%)[1] (kg/m³)

C32/40 160-210 410 950 785 185 2.05 0.57 2.05 0.59 4.23 0.45 2330

Note [1] : % = kg/100 kg of cement

Remarks : 1. The above mix design is subjected to be adjusted due to the availability and variability of the raw materials.

Pan-United Concrete Pte Ltd Co Reg No. 200106604K

12 Kaki Bukit Crescent, Kaki Bukit Techpark 1, Singapore 416243

T +65 6581 0777 F +65 6581 3777 www.panunited.com.sg

You might also like

- Credit Card Generator & Validator - Valid Visa Numbers - CardGuruDocument8 pagesCredit Card Generator & Validator - Valid Visa Numbers - CardGuruRahul Singh BhatiNo ratings yet

- Technical Interview Questions Active Directory and Networking - Part IDocument90 pagesTechnical Interview Questions Active Directory and Networking - Part Iajitskhot108100% (29)

- Pervious Concrete Mix Design PDFDocument12 pagesPervious Concrete Mix Design PDFZaher J. Yazeji100% (1)

- Design Mix of Concrete - Updated Is 10262-2019Document7 pagesDesign Mix of Concrete - Updated Is 10262-2019Raviteja MuralaNo ratings yet

- Mix Design DLC-DelDocument9 pagesMix Design DLC-DelSanjay Constructions100% (1)

- Orange Education Catalogue 2022 23Document16 pagesOrange Education Catalogue 2022 23Sourav SahaNo ratings yet

- Concrete Mix Design RC5001Document1 pageConcrete Mix Design RC5001shahrilzainul77No ratings yet

- 001-135-12-Design Report-Washout Chamber-R0Document43 pages001-135-12-Design Report-Washout Chamber-R0Anonymous 3kDy7eNo ratings yet

- Mix Design Testing Fresh and Hardened Concrfete PDFDocument168 pagesMix Design Testing Fresh and Hardened Concrfete PDFizharNo ratings yet

- Concrete Mix DesignDocument5 pagesConcrete Mix DesignGlyn A. Brinquez100% (2)

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document6 pagesConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- Rating Sheet FinalDocument7 pagesRating Sheet FinalJazelle FacunNo ratings yet

- (As Per IS: 10262 - 2019) Trial Mix Date: A-1) Design StipulationDocument8 pages(As Per IS: 10262 - 2019) Trial Mix Date: A-1) Design StipulationvamsiNo ratings yet

- Pe Mixed SDN BHD: G.MohanadassDocument1 pagePe Mixed SDN BHD: G.MohanadassAmi ShafiNo ratings yet

- 6.2.7 Lab Build A Sample Web App in A Docker ContainerDocument12 pages6.2.7 Lab Build A Sample Web App in A Docker Containerkacajim402No ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- DBM Mix DesignDocument22 pagesDBM Mix DesignImran Khan50% (10)

- (Merdeka PNB 118) C85 Mix DesignDocument1 page(Merdeka PNB 118) C85 Mix DesignUma Selladurai100% (1)

- EN9848Document1 pageEN9848Ali md YounusNo ratings yet

- SCC Class A G40 Concrete MixDocument1 pageSCC Class A G40 Concrete MixWunNaNo ratings yet

- Mix Composition Contractor: Project: Attn To: Thong Huat Brothers Pte LTDDocument1 pageMix Composition Contractor: Project: Attn To: Thong Huat Brothers Pte LTDKoh Jia JieNo ratings yet

- Trial Mix Isc300 -Ha-be - ٠٢٢١٣٧Document2 pagesTrial Mix Isc300 -Ha-be - ٠٢٢١٣٧Hosam FawziNo ratings yet

- Img 20200831 0005Document1 pageImg 20200831 0005Aung Naing Latt AungNo ratings yet

- Mix Design Details For 40 MPaDocument1 pageMix Design Details For 40 MPaTaposh PaulNo ratings yet

- Concrete Mixing DesignDocument15 pagesConcrete Mixing DesignChris ArtecoNo ratings yet

- 2.summary of Design MixDocument4 pages2.summary of Design MixBscpl Repalle to EeppurpalemNo ratings yet

- Mix Design Waterproof C32CylinderDocument1 pageMix Design Waterproof C32CylinderSrean VannsinhNo ratings yet

- Mix Design Report - C37-1Document11 pagesMix Design Report - C37-1mohamed nomanNo ratings yet

- Concrete Mixed Proportion: Kg/100kg of Cement Kg/100kg of CementDocument1 pageConcrete Mixed Proportion: Kg/100kg of Cement Kg/100kg of CementSrean VannsinhNo ratings yet

- M 30 SFRSDocument2 pagesM 30 SFRSSudarsanan KNo ratings yet

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- CLASS 25/20: Maximum Free-Water/ Cement RatioDocument4 pagesCLASS 25/20: Maximum Free-Water/ Cement RatioHema Chandra IndlaNo ratings yet

- A1 (Week 9) PDFDocument8 pagesA1 (Week 9) PDFHazarina AbdullahNo ratings yet

- Self-Compacting Concrete (SCC)Document17 pagesSelf-Compacting Concrete (SCC)Ritika BansalNo ratings yet

- Technical SPECIFICATION FOR PILESDocument13 pagesTechnical SPECIFICATION FOR PILESgopal sudhirNo ratings yet

- JMF Pak VidiDocument1 pageJMF Pak VidiLab. Teknik SipilNo ratings yet

- Design and Execution of Thin White Topping Road: MR - Shaikh Adil Nooruddin, MR - Samiullah, MR - Mohd SafiuddinDocument5 pagesDesign and Execution of Thin White Topping Road: MR - Shaikh Adil Nooruddin, MR - Samiullah, MR - Mohd SafiuddinVinay RajNo ratings yet

- PCI - 9.0m-14-2.0kN (TNB)Document17 pagesPCI - 9.0m-14-2.0kN (TNB)Mohd Farmi Izudin Che RosNo ratings yet

- 0421 - 16 MS PT Meindo Elang EndahDocument1 page0421 - 16 MS PT Meindo Elang EndahJoel Alfonso ManurungNo ratings yet

- Circ05 - 2007 Ready Mix ConcreteDocument27 pagesCirc05 - 2007 Ready Mix ConcreteHaftom TekluNo ratings yet

- M-30 Mix Designs As Per Is-10262-2009Document4 pagesM-30 Mix Designs As Per Is-10262-2009Vinod BabhaleNo ratings yet

- Mix Design 2Document15 pagesMix Design 2partha_svnitNo ratings yet

- Design and Execution of Thin White Topping Road: MR - Shaikh Adil Nooruddin, MR - Samiullah, MR - Mohd SafiuddinDocument5 pagesDesign and Execution of Thin White Topping Road: MR - Shaikh Adil Nooruddin, MR - Samiullah, MR - Mohd SafiuddinLohith Kumar HPNo ratings yet

- Mix Design Specification Requirements (A) Class of Concrete C-30Document5 pagesMix Design Specification Requirements (A) Class of Concrete C-30Atm Tjah Radix LoegoeNo ratings yet

- International Journal of Chemtech Research: Baskara Sundararaj J, Dhinesh M, Revathi.T, Rajamane N.PDocument11 pagesInternational Journal of Chemtech Research: Baskara Sundararaj J, Dhinesh M, Revathi.T, Rajamane N.PheminNo ratings yet

- Grade 20 N PDFDocument1 pageGrade 20 N PDFSujithNo ratings yet

- Application of Fly Ash To Concrete Paving Block: Karasawa, A., Suda, S., Naito, H. and Fujiwara, HDocument9 pagesApplication of Fly Ash To Concrete Paving Block: Karasawa, A., Suda, S., Naito, H. and Fujiwara, HDarshan mNo ratings yet

- TDS VDSLDocument1 pageTDS VDSLAbdel Baziir EkongNo ratings yet

- Bentomat STDocument1 pageBentomat STDanilo Rojas MartinezNo ratings yet

- Influence of Specific Surface Area of Cement On Mechanical Properties of RCCDocument6 pagesInfluence of Specific Surface Area of Cement On Mechanical Properties of RCCJian-Tong DINGNo ratings yet

- Grdjev01i120050 PDFDocument6 pagesGrdjev01i120050 PDFRafael Obusan IINo ratings yet

- 133 Ijaema November 2020Document11 pages133 Ijaema November 2020Dharma banothuNo ratings yet

- Chapter Four: 4.0 Results and DiscussionsDocument10 pagesChapter Four: 4.0 Results and DiscussionsAyo OshoNo ratings yet

- Juno Bitumix Cold Mix Technology PresentationDocument58 pagesJuno Bitumix Cold Mix Technology PresentationAashishNo ratings yet

- EXAMPLE OF MIX DESIGN .R.s.Document11 pagesEXAMPLE OF MIX DESIGN .R.s.Ramkiran TalariNo ratings yet

- Concrete Mix Design K175 KGDocument1 pageConcrete Mix Design K175 KGWiditra Fetty PurbaNo ratings yet

- Swee Builders PL - r8201 Infrastructure Wks at Skang and Pung Light Rail Transit - 1mix - g50s2 - Lta - Pfac30 - 210621llDocument1 pageSwee Builders PL - r8201 Infrastructure Wks at Skang and Pung Light Rail Transit - 1mix - g50s2 - Lta - Pfac30 - 210621llmayoo1986No ratings yet

- Experimental Investigation of Self Compacting Concrete by Partially Replacing Fine Aggregate With Quartz Sand With Use of Recron FibreDocument6 pagesExperimental Investigation of Self Compacting Concrete by Partially Replacing Fine Aggregate With Quartz Sand With Use of Recron Fibreshivanand hippargaNo ratings yet

- m25 Mix DesignDocument7 pagesm25 Mix Design98675No ratings yet

- Evaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSDocument14 pagesEvaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSumadevi rangaswamyNo ratings yet

- Proposal PT Mutiara Indah ConstructionDocument38 pagesProposal PT Mutiara Indah ConstructionI Wayan PartamaNo ratings yet

- KD-213 TDSDocument3 pagesKD-213 TDSalpesh.samruddhigroupNo ratings yet

- Jenkins-Portella-Baweja-Austroads Final-WebDocument11 pagesJenkins-Portella-Baweja-Austroads Final-WebPhú Trịnh ĐìnhNo ratings yet

- M 35 PS Basf UltDocument2 pagesM 35 PS Basf UltSudarsanan KNo ratings yet

- Subaru EA 82 Service Manual Part 1Document200 pagesSubaru EA 82 Service Manual Part 1Philzip100% (2)

- Is AI Dangerous To Humans?Document2 pagesIs AI Dangerous To Humans?Kevin FungNo ratings yet

- October 2016 Question Paper 3 - tcm143 370635Document12 pagesOctober 2016 Question Paper 3 - tcm143 370635Mihaela Cristina LazarNo ratings yet

- Liam Devaney: ProfileDocument2 pagesLiam Devaney: Profileapi-25949163No ratings yet

- Niir Directory Database List Companies Sme Industries in Himachal Pradesh Uttarakhand 2nd EditionDocument2 pagesNiir Directory Database List Companies Sme Industries in Himachal Pradesh Uttarakhand 2nd EditionDeepak MoryaNo ratings yet

- ASI451141 User-Manual1Document1 pageASI451141 User-Manual1Sakthi VelayuthanNo ratings yet

- Alghamedi, Ahmad Ali ADocument101 pagesAlghamedi, Ahmad Ali AFakhriah AzmiNo ratings yet

- VT Map Minbu TSP Magway MIMU575v01 01dec10 A3Document1 pageVT Map Minbu TSP Magway MIMU575v01 01dec10 A3Z EntertainmentNo ratings yet

- The Courier Relic Runner Book 1 - Ernest DempseyDocument276 pagesThe Courier Relic Runner Book 1 - Ernest DempseyDirt Road CowboyNo ratings yet

- This Is A First-to-Market' Fraud Prevention Method Offered by FNBDocument2 pagesThis Is A First-to-Market' Fraud Prevention Method Offered by FNBSmile TimeNo ratings yet

- Configuring Network ConnectivityDocument26 pagesConfiguring Network ConnectivityangelitoNo ratings yet

- HiLCoE School of Computer Science and Technology Model Exit ExamDocument14 pagesHiLCoE School of Computer Science and Technology Model Exit ExamMahlet AregaNo ratings yet

- Volumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmDocument19 pagesVolumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmGreen FarmersNo ratings yet

- S. No. Name Test/Lab Onsite DateDocument11 pagesS. No. Name Test/Lab Onsite Daterajat.telecomNo ratings yet

- 2020 04 29T19 24 03 - R3dlogDocument9 pages2020 04 29T19 24 03 - R3dlogConfusTrefleNo ratings yet

- PowerPoint Slides To Chapter 10Document117 pagesPowerPoint Slides To Chapter 10Ashish SinghNo ratings yet

- Caillau Visa ToolDocument14 pagesCaillau Visa ToolLady MenaNo ratings yet

- RMC No. 122 2022 S1905 RUS 1kikay PDFDocument1 pageRMC No. 122 2022 S1905 RUS 1kikay PDFGloria Kikay KuderaNo ratings yet

- The Decision Tree Classifier: Design and Potential: Abstmct-Tiús Paper Presents The Basic Concepts of A MultistageDocument6 pagesThe Decision Tree Classifier: Design and Potential: Abstmct-Tiús Paper Presents The Basic Concepts of A MultistageKlissman Morales OlabarreraNo ratings yet

- Technical Specifications: Easy. Efficient. ReliableDocument2 pagesTechnical Specifications: Easy. Efficient. ReliableZahid RasoolNo ratings yet

- 500,000.00 GBP (Five Hundred Thousand Great British Pounds Only) Promotion 500,000.00 Great British PoundsDocument4 pages500,000.00 GBP (Five Hundred Thousand Great British Pounds Only) Promotion 500,000.00 Great British PoundstayyabNo ratings yet

- Computer AssignmentDocument4 pagesComputer AssignmentRichid1234No ratings yet

- Power Bi Interview QA WordDocument26 pagesPower Bi Interview QA WordBhagavan BangaloreNo ratings yet

- Gloucester MT Extra Condensed (TrueType)Document1 pageGloucester MT Extra Condensed (TrueType)dgw0512No ratings yet

- Geranioc GB1 PDFDocument4 pagesGeranioc GB1 PDFmaksimilNo ratings yet