Professional Documents

Culture Documents

M 35 PS Basf Ult

Uploaded by

Sudarsanan KOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M 35 PS Basf Ult

Uploaded by

Sudarsanan KCopyright:

Available Formats

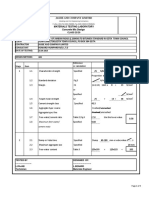

L&T CONSTRUCTION MUMBAI COASTAL ROAD PKG 04

Name of Project : Mumbai Coastal Road Project Package -IV

Client : Municipal Corporation of Greater Mumbai

General Consultant : AECOM Asia Company Limited

PMC : Yooshin Engineering Corporation & Tec Cuatro S.A

Contractor :L&T Construction

CONCRETE MIX DESIGN

GRADE - M35

Date: 04-02-2021

1 DESIGN STIPULATION :-

1.1 Grade of Concrete M 35

1.2 Type of cement : OPC 53 Grade

1.3 Nominal maximum Size of Aggregate : 20 mm

1.4 Type of exposure : Severe

1.5 Degree of Workability in terms of Slump

at Pouring Point : 150±25 mm

1.6 Degree of Quality Control : Good

As per IS456

1.7 Minimum Cementatious content : 360 kg/Cum. (As per vol4, ODS, Section 3, Cl. 2.5.5)

1.8 Maximum Water/Cement ratio : 0.45 (As per vol4, ODS, Section 3, Cl. 2.5.5)

1.9 Maximum cement content : 450 kg/cum

2.0 Mode of Placement at site : Pump/ Direct Pour

2.1 Type of Coarse aggregate : Crushed

2.2 Type of fine aggregate : Crushed sand

2.3 Type of Chemical admixture : Superplasticizer

2.4 Source of Ingredients -

a. Cement :OPC 53 grade Ultratech Cement.

b. GGBS :JSW

c. Coarse Aggregates :Uran

d. Crusher sand :Uran

e. Microsilica : Elkem

f. Water : Noor Mohammad Supplier

g. Superplasticizer : BASF Masterpolyheed

h. Corrosion inhibitor :BASF Masterlife CI 210

2 TEST DATA FOR MATERIALS :-

1.1 Sieve analysis of Coarse & Fine aggregate

& All - in - aggregate (As per IS:383 – 2016)

1.2 Specific Gravity of materials

a. OPC Cement 3.15

b. GGBS 2.90

c. Coarse Aggregates - 20 mm 2.73

d. Coarse Aggregates

Aggregates - 10 mm

mm 2.70

2.70

e. Crusher sand 2.68

f. Super plasticizer 1.120

g. Corrosion inhibitor 1.027

h. Microsilica 2.18

1.3 Water absorption

a. Coarse Aggregates - 20 mm 1.95%

b. Coarse Aggregates - 10 mm 2.15%

c. Crusher sand 3.80%

3 Target Mean Strength of Concrete :-

a. f'ck= fck+1.65*S

35+1.65*5 43.25 N/mm 2 (From IS 10262, 2019 table 2, Standard deviation, S = 5.0 N/mm )

2

b. f'ck= fck+X

35+6.5 41.50 N/mm 2

(From IS 10262, 2019 table 1, Standard deviation, X = 6.5 N/mm )

2

2 2

The higher value is to be adopted. Therefore,target strength will be 43.25 N/mm as 43.25 > 41.50 N/mm

4 Selection of Water/Cement ratio :-

Based on trials and experience, adopting water cementitious content ratio as 0.285

This is lower than the maximum value of 0.45 prescribed for severe exposure for reinforced concrete as per ODS vol 4, section 3, Clause 2.5.2

0.45 > 0.285, hence O.K.

Therefore Water/Cement ratio = 0.285

5 Selection of Water Content :-

From Table 4, water content = 186 kg (for 50mm slump ) for 20mm aggregate.

12*186

Estimated water content for 150 mm slump= 186+

100

= 208.32 kg

As superplasticizer is used, the water content may be reduced. Based on trial data,the water content reduction of 28.2 percent is considered while using plasticizer at the

rate 1.3 percentage by weight of cement.

Hence water content = 208.32 * 0.718

149.57 = 149.57 kg

# Sensitivity: LNT Construction Internal Use

6 Calculation of Cement content :-

149.6

Total Cementitious content : - = 524.820 kg

0.285

= 525 ( rounded off)

As per Vol 4, ODS, Section3, Cl:2.5.2 minimum cementatious content for severe exposure condition = 360kg/cum

525 kg/cum > 360 kg/cum , hence O.K.

Therefore total cementatious content is = 525 kg

Considering Cement as 34.28% of total cementitious content = 34.29% = 525*34.29

= 180 kg/cum

Considering GGBS as 60.95% of total cementitious content = 60.95% = 525*60.95

= 320 kg/cum

Considering Microsilica as 4.76 % of total cementatious = 4.76% = 525*4.76%

= 25 kg/cum

Total Cementitious Content :- = 525 kg/cum

7 Selection of Coarse & Fine aggregate :-

From Table 5 IS 10262, volume of coarse aggregate corresponding to 20mm MSA and fine aggregate (Zone-1) for water cement ratio of 0.50=0.6

In the present case water cement ratio is 0.285

Therefore, volume of coarse aggregate is required to be increased to decrease the fine aggregate content.

As water cement ratio is lower by 0.215, the proportion of volume of coarse aggregate is increased by 0.043

Therefore, corrected volume of coarse aggregate for the water-cementitious ratio of 0.285= 0.60+0.043 = 0.643

For the pumpable concrete the volume of Coarse aggregate is reduced to 2.5%

Therefore, volume of coarse aggregate = (0.643*0.975)

= 0.63

Therefore, volume of fine aggregate = 1-0.63

= 0.37

a. Volume of concrete = 1 cum Volume of entrapped air in concrete =0.01cum ( As per IS 10262, 2019)

Therefore Vol. of concrete = .99 cum

b. Volume of cement = (Mass of cement / Specific gravity of cement) * (1 / 1000)

= (180/3.15)*(1/1000) = 0.057 cum.

c. Volume of GGBS = (Mass of GGBS/ Specific gravity of GGBS) * (1 / 1000)

= (320/2.90)*(1/1000) = 0.110 cum.

d. Volume of water = (Mass of WATER / Specific gravity of WATER) * (1 / 1000)

= (149.6/ 1)*(1/1000) = 0.150 cum.

e. Volume of chemical admixture @1.30% by mass = (Mass of chemical admixture / Specific gravity of admixture)*(1 / 1000)

of Cementitious material = (6.83/1.12)*(1/1000) = 0.006 cum.

f. = (Mass of Corrosion inhibitor/Sp. gravity of Corrosion Inhib.)*(1 / 1000)

volume of Corrosion Inhibitor

= (2/1.027)*(1/1000) = 0.002 cum.

g. Volume of microsilica = (Mass of Microsilica/Sp. gravity of microsilica.)*(1 / 1000)

= (25/2.18)*(1/1000)

= 0.011 cum.

h. volume of all in aggregate = 0.99- (b+c+d+e+f+g)

= .99 - (0.057+.110+0.150+0.006+0.002+0.011)

= 0.653 cum.

i. Mass of coarse aggregate = Vol. of all in Agg* % of CA* Specific Gravity of Coarse Aggregate*1000

20 mm aggregate = 0.653*36.54 %*2.73*1000 = 651.502 = 652 kg/m 3

j. Mass of coarse aggregate = Vol. of all in Agg*% of CA*Specific Gravity of Coarse Aggregate*1000

10 mm aggregate = 0.653*26.46%*2.70*1000 = 466.516 = 467 kg/m 3

k. Mass of Fine Aggregate = Vol. of all in Agg. * % of FA * Specific Gravity of Fine Aggregate * 1000

= 0.653*37.0%*2.68*1000 = 648.564824 = 649 kg/m 3

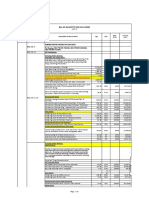

8 Mix design Calculation :-

3

Hence required quantity per m as given below :-

OPC Cement = 180 kg/m

3

3

GGBS = 320 kg/m

Microsilica = 25 kg/m3

3

Water = 150 kg/m

3

10 mm = 467 kg/m

3

20mm = 652 kg/m

3

Cr.Sand = 649 kg/m

3

Admixture = 6.83 kg/m

3

Corrosion Inhibitor = 2.00 kg/m

2450.00

Note :-

1. All the values for aggregates are for SSD conditions.

2. Adjustments to aggregate & water content shall be done based on the free moisture content in the aggregates.

3. Properties of materials may vary, conforming to specifications as per IS 4926

# Sensitivity: LNT Construction Internal Use

You might also like

- Progress in Nuclear Magnetic Resonance Spectroscopy: Volume 14From EverandProgress in Nuclear Magnetic Resonance Spectroscopy: Volume 14No ratings yet

- M20 PileDocument2 pagesM20 PileSudarsanan KNo ratings yet

- L&T Construction Mumbai Coastal Road PKG 04: 1 Design StipulationDocument2 pagesL&T Construction Mumbai Coastal Road PKG 04: 1 Design StipulationSudarsanan KNo ratings yet

- M 30 SFRSDocument2 pagesM 30 SFRSSudarsanan KNo ratings yet

- Concrete Mix Design For Grade M - 30Document8 pagesConcrete Mix Design For Grade M - 30AswIni PadhiNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument9 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- Trial Mix Isc300 -Ha-be - ٠٢٢١٣٧Document2 pagesTrial Mix Isc300 -Ha-be - ٠٢٢١٣٧Hosam FawziNo ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument61 pagesTest Report: M/S Abhi Engg Corporation PVT LTDimran khanNo ratings yet

- SCC Class A G40 Concrete MixDocument1 pageSCC Class A G40 Concrete MixWunNaNo ratings yet

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- Investigation On Strength Criteria and Cost Analysis of Self Compacting Concrete Using Ggbs Giriprasadgoud, Ashwin Kumar, Archanaa DongreDocument12 pagesInvestigation On Strength Criteria and Cost Analysis of Self Compacting Concrete Using Ggbs Giriprasadgoud, Ashwin Kumar, Archanaa DongreratnakarNo ratings yet

- CLASS 25/20: Maximum Free-Water/ Cement RatioDocument4 pagesCLASS 25/20: Maximum Free-Water/ Cement RatioHema Chandra IndlaNo ratings yet

- Grade 20 N PDFDocument1 pageGrade 20 N PDFSujithNo ratings yet

- DBM Mix DesignDocument22 pagesDBM Mix DesignImran Khan50% (10)

- 2.summary of Design MixDocument4 pages2.summary of Design MixBscpl Repalle to EeppurpalemNo ratings yet

- 1 - Mix Design - Chuan Lim - g40 s4 (160-210)Document1 page1 - Mix Design - Chuan Lim - g40 s4 (160-210)ronel bayotNo ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument6 pagesTest Report: M/S Abhi Engg Corporation PVT LTDImran Khan100% (1)

- Concrete Mix DesignDocument58 pagesConcrete Mix Designharikan chaturvediNo ratings yet

- Img 20200831 0005Document1 pageImg 20200831 0005Aung Naing Latt AungNo ratings yet

- Mix Design of Class C-24 (3500psi) ConcreteDocument3 pagesMix Design of Class C-24 (3500psi) ConcreteMd. Mahmudle HassanNo ratings yet

- Elongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and HousingDocument5 pagesElongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and Housingm8877223No ratings yet

- M-25 Mix Designs As Per Is-10262-2009Document3 pagesM-25 Mix Designs As Per Is-10262-2009burhan.kanjeta1988No ratings yet

- Mix Design For Poly Fiber Wet Shotcrete M-25: North and South PortalDocument1 pageMix Design For Poly Fiber Wet Shotcrete M-25: North and South Portalmp SinghNo ratings yet

- Concrete Mix Design C40/20-400 KG MSRC: Combined GradingDocument1 pageConcrete Mix Design C40/20-400 KG MSRC: Combined GradingkamakshiNo ratings yet

- M55 With GGBS and MicrosilicaDocument1 pageM55 With GGBS and MicrosilicaLegendary GamingNo ratings yet

- Design Mix m40Document4 pagesDesign Mix m40SOIGNE ENGINEERING CONSULTANTSNo ratings yet

- M-30 Mix Designs As Per Is-10262-2009Document4 pagesM-30 Mix Designs As Per Is-10262-2009Vinod BabhaleNo ratings yet

- DBM Gupta ConstructionDocument24 pagesDBM Gupta Constructionimran khanNo ratings yet

- L&T M30Document2 pagesL&T M30Kannan GnanaprakasamNo ratings yet

- Mix Design Report - C37-1Document11 pagesMix Design Report - C37-1mohamed nomanNo ratings yet

- A. Design StipulationsDocument3 pagesA. Design StipulationsAnyam RambabuNo ratings yet

- EN9848Document1 pageEN9848Ali md YounusNo ratings yet

- M30 With Fly AshDocument1 pageM30 With Fly AshRishabhNo ratings yet

- Concrete Mix With CalculationsDocument12 pagesConcrete Mix With Calculationsarman malikNo ratings yet

- Package-9: From KM 390.445 To KM 444.845 Section:Village Bendiwada To Village Fatiyabad, District: AurangabadDocument6 pagesPackage-9: From KM 390.445 To KM 444.845 Section:Village Bendiwada To Village Fatiyabad, District: Aurangabadjay krishnaNo ratings yet

- M30 With GGBS Self Compacting ConcreteDocument1 pageM30 With GGBS Self Compacting ConcretePritha Das100% (1)

- Technical SPECIFICATION FOR PILESDocument13 pagesTechnical SPECIFICATION FOR PILESgopal sudhirNo ratings yet

- M 35 With FlyashDocument54 pagesM 35 With FlyashCIVIL ENGINEERINGNo ratings yet

- S.E.C M35 PIle Birla Gold Cement 1042 UDocument5 pagesS.E.C M35 PIle Birla Gold Cement 1042 UBIPL REPORTNo ratings yet

- Report For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)Document9 pagesReport For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)artiNo ratings yet

- Aparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Document5 pagesAparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Kumar gsNo ratings yet

- M-20 MIX DESIGN - PCC (Subject To - Confirmation at Aite) : DistrictDocument3 pagesM-20 MIX DESIGN - PCC (Subject To - Confirmation at Aite) : DistrictAnuraazNo ratings yet

- FFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodDocument4 pagesFFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodjaymarNo ratings yet

- Test Report: Shree Siddhivinayak ConstructionDocument2 pagesTest Report: Shree Siddhivinayak ConstructionrahulNo ratings yet

- Sheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportDocument2 pagesSheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportTejas MohanNo ratings yet

- Material Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFDocument117 pagesMaterial Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFBikasNo ratings yet

- M30 With Fly AshDocument1 pageM30 With Fly AsharuthyannathuraiNo ratings yet

- M30 For Concrete PavementDocument1 pageM30 For Concrete PavementR ARUNPANDIANNo ratings yet

- Tm-22 m35 RCCDocument19 pagesTm-22 m35 RCCVeera ManiNo ratings yet

- Mix DesignDocument4 pagesMix DesignraheelNo ratings yet

- Evaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSDocument14 pagesEvaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSumadevi rangaswamyNo ratings yet

- Mix DesignDocument1 pageMix Designhitheshds1999No ratings yet

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocument5 pagesDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNo ratings yet

- Mix Design Details For 40 MPaDocument1 pageMix Design Details For 40 MPaTaposh PaulNo ratings yet

- Concrete Mixed Proportion: Kg/100kg of Cement Kg/100kg of CementDocument1 pageConcrete Mixed Proportion: Kg/100kg of Cement Kg/100kg of CementSrean VannsinhNo ratings yet

- M40 With Fly AshDocument1 pageM40 With Fly Ashscribdfree anytimeNo ratings yet

- Concrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDocument13 pagesConcrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDzey IsorenaNo ratings yet

- Sheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportDocument2 pagesSheth Corrosion & Coating Pvt. LTD.: Surface Preparation & Painting Inspection ReportTejas MohanNo ratings yet

- Stauf Content20230709060727Document2 pagesStauf Content20230709060727Mauricio Alejandro Bustos CuadraNo ratings yet

- 8-Pre-Engineered Steel BuildingsDocument188 pages8-Pre-Engineered Steel BuildingsBJ Swamy100% (1)

- Xypex Crystalline Coating SystemDocument3 pagesXypex Crystalline Coating SystemUcok DedyNo ratings yet

- Fisa Tehnica CelenitDocument44 pagesFisa Tehnica CelenitStuparu VictorNo ratings yet

- Astm D70Document2 pagesAstm D70FrengkiNo ratings yet

- Analysis of Cable Stayed BridgeDocument30 pagesAnalysis of Cable Stayed BridgeSijan ShresthaNo ratings yet

- Cempatch SDocument2 pagesCempatch Sjerry6670100% (1)

- MapesetDocument4 pagesMapesetdiv_bamaniaNo ratings yet

- Measurement of SubstructureDocument24 pagesMeasurement of SubstructureEngr MustansarNo ratings yet

- EcoQuip 2 EQ400T SystemDocument16 pagesEcoQuip 2 EQ400T SystemIliyan PetrovNo ratings yet

- The Use of Palm Kernel Shell and Ash For Concrete ProductionDocument9 pagesThe Use of Palm Kernel Shell and Ash For Concrete ProductionFolorunsho AyomideNo ratings yet

- Ref: MTCPL/SWSM/TPI-Cluster 17/2022-23/4435 Date: 30-05-2022Document5 pagesRef: MTCPL/SWSM/TPI-Cluster 17/2022-23/4435 Date: 30-05-2022dharmendraNo ratings yet

- Sans5862 2Document9 pagesSans5862 2Kyle MoolmanNo ratings yet

- Australian Shotcrete Guide V2.1Document84 pagesAustralian Shotcrete Guide V2.1Felipe TBNo ratings yet

- Boq Extend Workshop CH 22Document7 pagesBoq Extend Workshop CH 22mufqi fauziNo ratings yet

- Preco Mould Release QDDocument2 pagesPreco Mould Release QDtalatzahoorNo ratings yet

- Annexure I - Bill of Quantities - PricedDocument16 pagesAnnexure I - Bill of Quantities - PricedjatinNo ratings yet

- MasterGlenium ACE 8761 v1Document3 pagesMasterGlenium ACE 8761 v1Mohiuddin MuhinNo ratings yet

- Adhesive InstructionsDocument3 pagesAdhesive Instructionsyiel2003No ratings yet

- Chapter 5-Mix DesignDocument51 pagesChapter 5-Mix DesignJaphet LudovickNo ratings yet

- 2.2 Cements and Cement Replacement MaterialsDocument97 pages2.2 Cements and Cement Replacement MaterialsHassan FathiNo ratings yet

- Asphalt Pavement Repair ProceduresDocument173 pagesAsphalt Pavement Repair Proceduresshainojk100% (1)

- Finco GroutDocument2 pagesFinco GroutaselabollegalaNo ratings yet

- Now, Panel Tanks Are Made by Stainless Steel, Instead of FRP or ConcreteDocument6 pagesNow, Panel Tanks Are Made by Stainless Steel, Instead of FRP or ConcreteGooglNo ratings yet

- MasterFlow 936 ANDocument112 pagesMasterFlow 936 ANThet LinnNo ratings yet

- Test Report For Bricks - (B)Document16 pagesTest Report For Bricks - (B)AV ChavdaNo ratings yet

- Model GP Building EstimateDocument153 pagesModel GP Building Estimatekalyan_kolaNo ratings yet

- International Standard: Wind Energy Generation Systems - Part 6: Tower and Foundation Design RequirementsDocument13 pagesInternational Standard: Wind Energy Generation Systems - Part 6: Tower and Foundation Design RequirementsStenjevski100% (1)

- BRE Digest 330 pt3 Alkali-Silica Reaction in ConcreteDocument8 pagesBRE Digest 330 pt3 Alkali-Silica Reaction in ConcretehemendraengNo ratings yet

- Field Tests of Building MaterialsDocument4 pagesField Tests of Building Materialssmartman3550% (2)