Professional Documents

Culture Documents

L&T Construction Mumbai Coastal Road PKG 04: 1 Design Stipulation

Uploaded by

Sudarsanan KOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L&T Construction Mumbai Coastal Road PKG 04: 1 Design Stipulation

Uploaded by

Sudarsanan KCopyright:

Available Formats

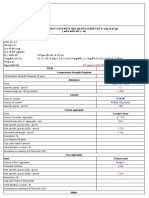

L&T CONSTRUCTION MUMBAI COASTAL ROAD PKG 04

Name of Project : Mumbai Coastal Road Package -04

Client : Municipal Corporation of Greater Mumbai

General Consultant : AECOM

PMC : YOOSHIN- Tech Curato S.A. (JV)

Contractor : L&T Heavy Civil Infrastructure.

CONCRETE MIX DESIGN

GRADE M - 25(OPC+GGBS)

Date: 02/04/2021

1 DESIGN STIPULATION :-

1.1 Grade of Concrete : M- 25

1.2 Type of cement : OPC 53 grade

1.3 Nominal maximum Size of Aggregate : 20 mm

1.4 Type of exposure : Severe

1.5 Degree of Workability in terms of Slump : 150 ± 25 mm

at Pouring Point

1.6 Degree of Quality Control : Good

1.7 Minimum Cementatious content : 360 kg/Cum. ( AS per, Vol 4, ODS, Sect 3, Cl: 2.5.2)

1.8 Maximum Water/Cement ratio : 0.45 ( AS per, Vol 4, ODS, Sect 3, Cl: 2.5.2)

1.9 Maximum cement content : 450 kg/cum

2.0 Mode of Placement at site : Pump/ Direct Pour

2.1 Type of Coarse aggregate : Crushed angular

2.2 Type of fine aggregate : Crusher sand

2.3 Type of Chemical admixture : Super plasticizer

2.4 Source of materials -

a. Cement :Ambuja OPC 53 grade Cement.

b. GGBS : JSW

c. Coarse Aggregates :ULWE HILL

d. Crushed Sand :ULWE HILL

e. Water :Devanshi Logistic Co.

f. Chemical Admixture :Chryso Optima K 940EMX

g. Corrosion inhibitor : BASF Masterlife Cl 210

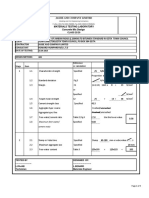

2 TEST DATA FOR MATERIALS :-

1.1 Sieve analysis of Coarse & Fine aggregate

& All - in - aggregate (As per IS:383 – 2016) (Reports attached )

1.2 Specific Gravity of materials

a. OPC Cement 3.15

b. GGBS 2.90

c. Coarse Aggregates - 20 mm 2.73

d. Coarse Aggregates - 10 mm 2.70

e. Crushed Sand 2.68

f. Super plasticizer 1.108

i. Corrosion Inhibitor 1.027

1.3 Water absorption

a. Coarse Aggregates - 20 mm 1.95%

b. Coarse Aggregates - 10 mm 2.15%

c. Crushed Sand 3.80%

3 Target Mean Strength of Concrete :-

a. f'ck= fck+1.65*S

= 25+1.65*4 31.6 N/mm2 ( From IS 10262, 2019 Table2, S = 4.0 Mpa)

b. f'ck= fck+X

f'ck= 25+5.5 30.5 N/mm2 ( From IS 10262, 2019 Table2, X = 5.5 Mpa)

2

The higher value is to be adopted thus, Target Mean Strength = 31.60 N/mm

4 Selection of Water/Cement ratio :-

From based on trials and experience, adopted water cementitious content ratio as 0.369

This is lower than the maximum value of 0.45 prescribed for severe exposure for reinforced concrete as per Vol4, ODS, Sect3, Cl:2.5.2

0.369 < 0.45, hence O.K.

Water/Cement ratio = 0.369

5 Selection of Water Content :-

From Table 4, IS 10262, 2019 water content = 186 kg (for 50mm slump ) for 20mm aggregate.

12*186

Estimated water content for 150 mm slump= 186+

100

= 208.32 kg

As superplasticizer is used, the water content may be reduced.Based on trial data,the water content reduction of 27.5 percent is

considered while using superplasticizer at the rate of 1.10 percentage by weight of cement.

Hence, water content is = 208.32 * 0.744

154.98 = 155 kg

# Sensitivity: LNT Construction Internal Use

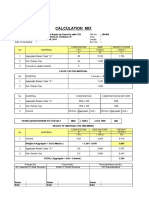

6 Calculation of Cement content :-

155

Total Cementitious content : - = 420 kg

0.369

From Vol.4, ODS, Sect3, Cl: 2.5.2,minimum cementatious content for severe exposure condition = 360 kg/cum

420 kg/cum > 360 kg/cum , hence O.K.

Considering GGBS @ 59.52% of total cementitious material content = 420*59.5% = 249.98

= 250 kg/cum (Rounded Off)

Therefore , OPC 53 grade cement = 420-250 = 170 kg/cum

OPC Cement = 170kg/cum

GGBS Content = 250 kg/cum

Total Cementitious Content :- = 420 kg/cum

7 Selection of Coarse & Fine aggregate :-

From Table 5 IS 10262, volume of coarse aggregate corresponding to 20 mm MSA and fine aggregate (Zone-1) for water cement

ratio of 0.50=0.60

In the present case water cement ratio is 0.37

Therefore, volume of coarse aggregate is required to be increased to decrease the fine aggregate content.

As water cement ratio is lower by 0.13, the proportion of volume of coarse aggregate is increased by 0.026

Therefore, corrected volume of coarse aggregate for the water-cementitious ratio of 0.37= 0.60+0.026

= 0.626

for pumpable concrete reducing the value by 9%

Therefore, volume of coarse aggregate = (0.626*0.91)

= 0.57

Therefore, volume of fine aggregate = 1-0.5

= 0.43

a. Volume of concrete = 1 cum Volume of air voids= 0.01 cum As per Table 3 of IS 10262, 2019

= 0.99 cum

b. Volume of cement = (Mass of cement / Specific gravity of cement) * (1 / 1000)

= (170/3.15)*(1/1000) = 0.0540 cum.

c. Volume of GGBS = (Mass of GGBS /Specific gravity of GGBS) * (1/1000)

= (250/2.90)*(1/1000) = 0.0862 cum.

d. Volume of water = (Mass of Water / Specific gravity of Water) * (1 / 1000)

= (155/ 1)*(1/1000) = 0.155 cum.

e. Volume of chemical admixture @ 1.10 % by = (Mass of chemical admixture / S.G of admixture)*(1 / 1000)

mass of Cementitious material = (4.62/1.108)*(1/1000) = 0.0042 cum.

f. Volume of Corrosion Inhibitor @ 2 kg/Cum = (Mass of Corrosion Inhibitor / S.G of Corrosion Inhibitor)*(1 / 1000)

= (2/1.027)*(1/1000) = 0.0019 cum.

g. Volume of all in aggregate = (a-(b+c+d+e+f+g+h+i))

= 0.99 - (0.054+0.086+0.155+0.004+0.002)

= 0.689 cum.

h. Mass of coarse aggregate = Vol. of all in Agg* % of CA* S.G of Coarse Aggregate*1000

20 mm aggregate = 0.689*35.40%*2.73*1000 = 665.86 = 666 kg/cm3

10 mm aggregate = 0.686*24.60%*2.70*1000 = 457.63 = 458 kg/cm3

i. Mass of Fine Aggregate = Vol. of all in Agg. * % of FA * S.G of Fine Aggregate * 1000

= 0.689*40%*2.68*1000 = 738.61 = 739 Kg/cm3

8 Mix design Calculation :-

3

Hence required quantity per m as given below :-

S.S.D.

OPC Cement = 170 kg/m

3

GGBS = 250 kg/m

3

Water = 155 kg/m

3

20 mm = 666 kg/m

3

10 mm = 458 kg/m

3

C. Sand = 739 kg/m

3

Admixture = 4.62 kg/m

3

Corrosion inhibitor = 2.00 kg/m

3

Note :-

1. All the values for aggregates are for SSD conditions.

2. Adjustments to aggregate & water content shall be done based on the free moisture content in the aggregates.

3. Properties of materials may vary, conforming to specifications as per IS 4926.

# Sensitivity: LNT Construction Internal Use

You might also like

- CHCDIV002 Assessment 1Document17 pagesCHCDIV002 Assessment 1Anmol PoudelNo ratings yet

- DBM Mix DesignDocument22 pagesDBM Mix DesignImran Khan50% (10)

- Basic Ecological Concepts and PrinciplesDocument12 pagesBasic Ecological Concepts and PrinciplesShamira Yessa Lazaro Espinosa100% (3)

- Ann Charlton - Steamy DecemberDocument203 pagesAnn Charlton - Steamy Decembershrutigarodia95% (22)

- M20 PileDocument2 pagesM20 PileSudarsanan KNo ratings yet

- M 35 PS Basf UltDocument2 pagesM 35 PS Basf UltSudarsanan KNo ratings yet

- M 30 SFRSDocument2 pagesM 30 SFRSSudarsanan KNo ratings yet

- Trial Mix Isc300 -Ha-be - ٠٢٢١٣٧Document2 pagesTrial Mix Isc300 -Ha-be - ٠٢٢١٣٧Hosam FawziNo ratings yet

- SCC Class A G40 Concrete MixDocument1 pageSCC Class A G40 Concrete MixWunNaNo ratings yet

- Aparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Document5 pagesAparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Kumar gsNo ratings yet

- Concrete Mix Design For Grade M - 30Document8 pagesConcrete Mix Design For Grade M - 30AswIni PadhiNo ratings yet

- Investigation On Strength Criteria and Cost Analysis of Self Compacting Concrete Using Ggbs Giriprasadgoud, Ashwin Kumar, Archanaa DongreDocument12 pagesInvestigation On Strength Criteria and Cost Analysis of Self Compacting Concrete Using Ggbs Giriprasadgoud, Ashwin Kumar, Archanaa DongreratnakarNo ratings yet

- Concrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDocument13 pagesConcrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDzey IsorenaNo ratings yet

- Concrete Mix DesignDocument58 pagesConcrete Mix Designharikan chaturvediNo ratings yet

- 1 - Mix Design - Chuan Lim - g40 s4 (160-210)Document1 page1 - Mix Design - Chuan Lim - g40 s4 (160-210)ronel bayotNo ratings yet

- FFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodDocument4 pagesFFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodjaymarNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument9 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- L&T M30Document2 pagesL&T M30Kannan GnanaprakasamNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- M 35 With FlyashDocument54 pagesM 35 With FlyashCIVIL ENGINEERINGNo ratings yet

- M-30 Mix Designs As Per Is-10262-2009Document4 pagesM-30 Mix Designs As Per Is-10262-2009Vinod BabhaleNo ratings yet

- Grade 20 N PDFDocument1 pageGrade 20 N PDFSujithNo ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- Mix Design Details For 40 MPaDocument1 pageMix Design Details For 40 MPaTaposh PaulNo ratings yet

- TK ACI BASF 8735 Co So OK LY THUYETDocument42 pagesTK ACI BASF 8735 Co So OK LY THUYETDao Phuc LamNo ratings yet

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document6 pagesConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- Mix DesignDocument1 pageMix Designhitheshds1999No ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument61 pagesTest Report: M/S Abhi Engg Corporation PVT LTDimran khanNo ratings yet

- EN9848Document1 pageEN9848Ali md YounusNo ratings yet

- Mix Design For Poly Fiber Wet Shotcrete M-25: North and South PortalDocument1 pageMix Design For Poly Fiber Wet Shotcrete M-25: North and South Portalmp SinghNo ratings yet

- M-25 Mix Designs As Per Is-10262-2009Document3 pagesM-25 Mix Designs As Per Is-10262-2009burhan.kanjeta1988No ratings yet

- CLASS 25/20: Maximum Free-Water/ Cement RatioDocument4 pagesCLASS 25/20: Maximum Free-Water/ Cement RatioHema Chandra IndlaNo ratings yet

- Mix Design of Class C-24 (3500psi) ConcreteDocument3 pagesMix Design of Class C-24 (3500psi) ConcreteMd. Mahmudle HassanNo ratings yet

- FFC-MBR-QC-CON-01 A Oct. 03, 2018: 3000 Psi at 28 Day 20 0.8 Good Mild 100 0.53 364Document4 pagesFFC-MBR-QC-CON-01 A Oct. 03, 2018: 3000 Psi at 28 Day 20 0.8 Good Mild 100 0.53 364jaymarNo ratings yet

- MIX DESIGN M15 To M50 PDFDocument8 pagesMIX DESIGN M15 To M50 PDFBabsal Work ConstructionNo ratings yet

- 2.summary of Design MixDocument4 pages2.summary of Design MixBscpl Repalle to EeppurpalemNo ratings yet

- Concrete and Its PropertiesDocument24 pagesConcrete and Its Propertiesabhijeet sahuNo ratings yet

- Img 20200831 0005Document1 pageImg 20200831 0005Aung Naing Latt AungNo ratings yet

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- Concrete and Asphalt Aggregate TestsDocument4 pagesConcrete and Asphalt Aggregate Testssaber2s22ahmadNo ratings yet

- (As Per IS 10262-2019) : 1.stipulations For ProportioningDocument10 pages(As Per IS 10262-2019) : 1.stipulations For Proportioningmahesh naikNo ratings yet

- (As Per IS: 10262 - 2019) Trial Mix Date: A-1) Design StipulationDocument8 pages(As Per IS: 10262 - 2019) Trial Mix Date: A-1) Design StipulationvamsiNo ratings yet

- UNIT-3: SP - GR Water Absorption Free (Surface-Moisture)Document2 pagesUNIT-3: SP - GR Water Absorption Free (Surface-Moisture)NmNo ratings yet

- Mix Design Report - C37-1Document11 pagesMix Design Report - C37-1mohamed nomanNo ratings yet

- Mix Design 2Document15 pagesMix Design 2partha_svnitNo ratings yet

- Concrete and Its PropertiesDocument24 pagesConcrete and Its PropertiesAmila LiyanaarachchiNo ratings yet

- Calculation of Design Mix: Fine Aggerates Coarse AggregatesDocument6 pagesCalculation of Design Mix: Fine Aggerates Coarse AggregatesVALIENT CANCERANNo ratings yet

- M35 Revised Mix Design SheetDocument2 pagesM35 Revised Mix Design Sheetamol awateNo ratings yet

- TM Concrete Mix Design M25PCCDocument11 pagesTM Concrete Mix Design M25PCCAnurag ChaturvediNo ratings yet

- Design Mix m40Document4 pagesDesign Mix m40SOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Report 3523 M40 08 12 2019Document20 pagesReport 3523 M40 08 12 2019Imran KhanNo ratings yet

- S.E.C M35 PIle Birla Gold Cement 1042 UDocument5 pagesS.E.C M35 PIle Birla Gold Cement 1042 UBIPL REPORTNo ratings yet

- Mix Design Calculations - DCIPL M40.Document14 pagesMix Design Calculations - DCIPL M40.AmirNo ratings yet

- Elongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and HousingDocument5 pagesElongation Test Bs. 812 Part (1) : Client: Ministry of Public Work and Housingm8877223No ratings yet

- Calculation of Design Mix: Fine Aggerates Coarse AggregatesDocument6 pagesCalculation of Design Mix: Fine Aggerates Coarse AggregatesVALIENT CANCERANNo ratings yet

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocument5 pagesDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNo ratings yet

- DBM Gupta ConstructionDocument24 pagesDBM Gupta Constructionimran khanNo ratings yet

- Group 3Document10 pagesGroup 3Shivam SharmaNo ratings yet

- Material Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFDocument117 pagesMaterial Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFBikasNo ratings yet

- Report For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)Document9 pagesReport For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)artiNo ratings yet

- Concrete Mixed Proportion: Kg/100kg of Cement Kg/100kg of CementDocument1 pageConcrete Mixed Proportion: Kg/100kg of Cement Kg/100kg of CementSrean VannsinhNo ratings yet

- JMF CTB Rev1Document6 pagesJMF CTB Rev1Central NetNo ratings yet

- Progress in Nuclear Magnetic Resonance Spectroscopy: Volume 14From EverandProgress in Nuclear Magnetic Resonance Spectroscopy: Volume 14No ratings yet

- Pidgin - God's Simple PlanDocument3 pagesPidgin - God's Simple PlanAfrica BiblesNo ratings yet

- Fake ProfilingDocument18 pagesFake Profilingmohit moreNo ratings yet

- Field2014 TheJournalofAsianStudiesDocument18 pagesField2014 TheJournalofAsianStudiesRevathi SakthiNo ratings yet

- Philosophy in LifeDocument1 pagePhilosophy in LifeOuelle EvansNo ratings yet

- Estruturas Kerto LVLDocument12 pagesEstruturas Kerto LVLwilfredoNo ratings yet

- The Use of Aspirin During Pregnancy: Letters To EditorsDocument2 pagesThe Use of Aspirin During Pregnancy: Letters To EditorsIqbal Muhammad Yaa-BegitulahNo ratings yet

- Grep v1p5Document111 pagesGrep v1p5joseNo ratings yet

- Carbonation of Steel SlagDocument12 pagesCarbonation of Steel SlagTania Dealina SariNo ratings yet

- Lion Offficer Reporting Form PDFDocument2 pagesLion Offficer Reporting Form PDFMottobyte PonnurNo ratings yet

- Ronkonkoma Train ScheduleDocument1 pageRonkonkoma Train Scheduleanthonybottan0% (1)

- Chapter 6 Recursion PDFDocument16 pagesChapter 6 Recursion PDFBangtan gurlNo ratings yet

- Generating EquipmentDocument15 pagesGenerating EquipmentRajendra Lal ShresthaNo ratings yet

- 7 Problems - CompressorDocument2 pages7 Problems - CompressorBenedict TumlosNo ratings yet

- Sri Chaitanya Charitamrita PDFDocument3 pagesSri Chaitanya Charitamrita PDFAuther MerlinNo ratings yet

- Applied Geography: Marco VizzariDocument11 pagesApplied Geography: Marco Vizzarialexandra mp100% (1)

- NEVILLE Marking GenderDocument22 pagesNEVILLE Marking GenderThom EmNo ratings yet

- Bacteriological Test: It Is A Method of Analysing Water To Estimate The Numbers of Bacteria Present And, IfDocument18 pagesBacteriological Test: It Is A Method of Analysing Water To Estimate The Numbers of Bacteria Present And, IfAnamNo ratings yet

- B9 Main Ideas ML-1Document3 pagesB9 Main Ideas ML-1rd4tp5k25gNo ratings yet

- Assignment 1 302 Fall 2009. CorrectDocument2 pagesAssignment 1 302 Fall 2009. CorrectJohn HopkinsNo ratings yet

- Construction Issue: Qty. (Nos) AI DI AO DO Hvac System I Water Chilling Units 3Document11 pagesConstruction Issue: Qty. (Nos) AI DI AO DO Hvac System I Water Chilling Units 3Al Amin Hossain Srabon100% (1)

- DAFZA Security - User ManualDocument28 pagesDAFZA Security - User Manualzubeen RIZVINo ratings yet

- Extemporaneous RubricDocument2 pagesExtemporaneous RubricGeorge Kevin TomasNo ratings yet

- Composition of PetroleumDocument17 pagesComposition of PetroleumAleem Ahmed100% (1)

- PHP SQL AnywhereDocument7 pagesPHP SQL Anywherecool03No ratings yet

- Net 2018 11 1 - 12Document7 pagesNet 2018 11 1 - 12mirandasuryaprakash_No ratings yet

- Design of Composite Columns: The American Approach: Roberto T. LeonDocument18 pagesDesign of Composite Columns: The American Approach: Roberto T. LeonvardhangargNo ratings yet

- Analytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceDocument14 pagesAnalytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceAndres NaranjoNo ratings yet