Professional Documents

Culture Documents

(Vertical and Deviated Wells) : Casing (Last Set) Data

Uploaded by

c PjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Vertical and Deviated Wells) : Casing (Last Set) Data

Uploaded by

c PjCopyright:

Available Formats

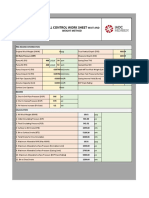

PRERECORDED WELL DATA

KEEP THIS DATA SHEET CURRENT AT ALL TIMES

(Vertical and Deviated Wells)

Well Name Field Rig

HOLE DATA Size(actual) 8.5000 Hole MD 8,000 ft. Hole TVD 8,000 ft.

*Use

DP PUMP DATA Liners (in.) Stroke(in.) Rod(in. ) % Eff. bbl./stk For Kill?

CSG

No. 1 X

No. 2

* X if used, empty if not

CASING (LAST SET) DATA

by Shoe MD Shoe TVD

(in. OD) (in. Avg ID) (feet) (feet)

WELLHEAD OR CASING PRESSURE LIMITATION

The lessor of: 100% BOP Rating 5,000 psi.

100% Wellhead Rating 5,000 psi. Limitation = 5000

80% Casing Burst psi. psi.

LINER CASING DATA

by Top @ ft. Shoe @

(in. OD) (in. Avg ID) MD(feet) MD(feet) TVD(feet)

DRILL STRING DATA DRILL COLLARS

Drill Pipe 1 4.5000 in. (OD) 16.6 lb./ft. OD(in.) ID(in.)

Drill Pipe 2 in. (OD) lb./ft. 6.75 by 2.8125

HW Drill Pipe 4.5000 in. (OD) 41.5 lb./ft. by

INTERNAL CAPACITIES

Drill Pipe 1 7,220 ft. x 0.0141 bbl./ft. = 101.8 bbl.

Drill Pipe 2 ft. x bbl./ft. = bbl.

HW Drill Pipe 330 ft. x 0.0074 bbl./ft. = 2.4 bbl.

Drill Collars 450 ft. x 0.0077 bbl./ft. = 3.5 bbl.

Drill Collars ft. x bbl./ft. = bbl.

Msrd Depth(bit) 8,000 ft. Total Internal = 107.7 bbl. = Strokes

ANNULUS CAPACITIES (Note: Use other side for subsea)

DP1 x Csg. ft. x -0.0197 bbl./ft. = bbl.

DP1 x Liner ft. x bbl./ft. = bbl.

DP1 x Hole 7,220 ft. x 0.0505 bbl./ft. = 364.9 bbl.

DP2 x Csg. ft. x bbl./ft. = bbl.

DP2 x Liner ft. x bbl./ft. = bbl.

DP2 x Hole ft. x bbl./ft. = bbl.

HW DP 330 ft. x 0.0505 bbl./ft. = 16.7 bbl.

DC x Hole 450 ft. x 0.0259 bbl./ft. = 11.7 bbl.

DC x Hole ft. x bbl./ft. = bbl.

Msrd Depth(bit) 8,000 ft. Total Annulus = 393.2 bbl. = Strokes

System Volume (Internal + Annulus) = 500.9 bbl. = Strokes

Volume from Bit to Shoe = 393.2 bbl. = Strokes

Active Pit Volume 500 bbl.

MAX INITIAL SICP TO FRACTURE SHOE

[ pcf EMW - pcf MW] x 0.007 x ft. = psi.

(Shoe Test) (Present Mud Weight) (Shoe TVD) Version 2.0 (4/15/00)

PRERECORDED WELL DATA

SUBSEA USE ONLY

(page 2)

INTERNAL CAPACITIES

(from other side)

DP

CSG

Total Internal Capacity 107.7 bbl. = strokes

Choke Line

Kill Line ANNULUS CAPACITIES (replaces other side)

Choke Line ft. x bbl./ft. = bbl.

RKB to ML ft.

DP1 x Csg. ft. x -0.0197 bbl./ft. = bbl.

DP1 x Liner ft. x bbl./ft. = bbl.

DP1 x Hole 7,220 ft. x 0.0505 bbl./ft. = 364.9 bbl.

DP2 x Csg. ft. x bbl./ft. = bbl.

annular DP2 x Liner ft. x bbl./ft. = bbl.

DP2 x Hole ft. x bbl./ft. = bbl.

HW DP 330 ft. x 0.0505 bbl./ft. = 16.7 bbl.

DC x Hole 450 ft. x 0.0259 bbl./ft. = 11.7 bbl.

connector

DC x Hole ft. x bbl./ft. = bbl.

annular

M. Depth(bit) 8,000 ft.

blind/shear

pipe ram

Total Annulus = 393.2 bbl. = strokes

pipe ram

System Volume = 500.9 bbl. = strokes

pipe ram (Internal + Annulus)

connector Volume from Bit to Shoe = 393.2 bbl. = strokes

DP MUD LINE

RISER CAPACITY

(with no pipe in the hole)

Riser ID Capacity Fact. Length Capacity

inches bbl./ft. x ft. = bbls.

inches bbl./ft. x ft. = bbls.

Total Riser = bbl. = strokes

Notes:

1. Use slow pump rate through riser for calculations on Engineers Method Worksheet

2. All barite requirements and system volume calculations exclude riser capacity.

3. If monitoring static Kill Line pressure while adjusting pump rate, ignore Choke

Line friction.

CHOKE LINE FRICTION

Psys Psys Choke Line Change in

SPM BPM (Riser) (Choke) Friction Choke Friction

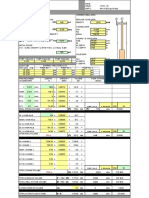

DRILLER'S METHOD WORKSHEET

(Vertical and Deviated Wells)

PRERECORDED INFORMATION SPM psi bbl/stk bbl/min

A. Slow Pump Rate Data Pump #1 30 350

( Use SPR Pressure through Riser for Subsea ) Pump #2 40 550

INFORMATION RECORDED WHEN WELL KICKS Time of Kick: 13:35

B. Old Mud Weight B pcf

C. Initial Shut-In Drill Pipe Pressure (SIDP) C 200 psi

D. Initial Shut-In Casing Pressure (SICP) D 300 psi

E. Initial Pit Volume Increase E 15 bbl

F. True Vertical Depth of Hole F 8,000 ft (TVD)

Measured Depth of Hole (for Capacity Calculations ONLY) 8,000 ft (MD)

FIRST CIRCULATION TO CLEAR WELL OF INFLUX

Bring Pumps up to Speed While Holding Casing Pressure Constant 30 SPM

{Account for Choke Line Friction if Subsea}

Read and Record Initial Circulating Pressure on Drill Pipe 550 psi

[Should Approximately = Slow Pump Rate Pressure (A) + SIDP (C)]

Maintain Constant DP Pressure Until Influx is Circulated Out. Then Shut Down

Pumps While Holding Casing Pressure Constant. {Remember CLF for Subsea}. If Drill

Pipe and Casing Shut-In Pressures are not Equal, Continue to Circulate Out Influx.

G. Increase in Mud Weight required to Balance Kick

Initial SIDP C

G= = = G 4 pcf

0.007 ´ TVD 0.007 ´ F

H. New Mud Weight H=B+G= H 4 pcf

I. Total Volume to Weight up I = Active Pit Vol + System Vol = I 1,001 bbl

J. Barite Required

J = I´

(30 ´ G ) =

(262 - H ) J 466 50#

sacks

SECOND CIRCULATION TO BALANCE WELL

Bring Pumps up to Speed While Holding

Casing Pressure Constant. {Account for » SIDP(C) Casing Pressure 200 psi

CLF if Subsea} Maintain Constant Casing

Pressure Until New Mud Reaches the Bit. Drill String Internal Capacity strokes

Read and Record Drill Pipe Pressure

KWM (H)

When New Mud Reaches the Bit » SPRP (A ) ´ Final Circulating Pressure psi

Old MW (B)

Maintain Constant Drill Pipe Pressure

Until the System is Displaced. System Volume strokes

Version 2.0 (4/15/00)

DRILLER'S METHOD WORKSHEET

(page 2)

RESERVOIR PRESSURE (Pr)

K 224 psi

K. Pr = 0.007 ´ New MW ´ TVD = 0.007 ´ H´ F =

HEIGHT OF GAS BUBBLE AROUND DRILL PIPE (Kick Height(KH))

L. Annulus Capacity Factor (DP x Casing) Right Below Wellhead L -0.0197 bbls/ft

Initial Pit Vol Increase (E )

M. = M ft.

Annulus Capacity Factor (L )

MAXIMUM CASING PRESSURE (Pcmax) WHEN GAS GETS TO SURFACE

N. Mud Weight Gradient, psi/ft N psi/ft.

B x 0.007 =

O. Pc max , Part1 = SIDP ¸ 2 = ( C ) ¸ 2 = (Surface) O 100 psi

(Optional Correction for Subsea Wells)

O. (Subsea) A correction must be added to PCmax, Part 1 calculated above to

account for the choke line.

é Vol. Choke Line(bbl) ù N psi

Subsea Correction = êRKB to ML(ft) - ú´

ë L û 2

(Subsea) O = Subsea Correction + (Surface) O = (Subsea) O 100 psi

(Use this new O in Part Q. and Part R. below)

P. TZ= Compressibility and Temperature Effects (Figure 11P.5) P 1.97

or Tz = 4.03 - (0.38 ´ ln(Pr)) = 4.03 - (0.38 ´ ln(K))

Q. Pcmax, Part2 (Figure 11P.1)

= (O)2 + (K)(M)(N)(P)

Q 100 psi

R. Maximum Casing Pressure,

PcMAX = (PcMAX , Part 1 ) + (PcMAX , Part 2) = O + Q = R 200 psi

S. Does Pcmax Exceed the Wellhead or Casing Pressure Limitation?

YES NO X

VOLUME GAIN WHILE CIRCULATING OUT GAS BUBBLE

T. Volume of Gas at Surface (from Fig. 11P.4 or Formula below)

E´K ´P

T 33.2 bbl

Vg , Volume of gas at surface , bbl = =

R

U. Volume Gain While Circulating Out Gas Kick U= T-E = U 18.2 bbl

STROKES TO MAXIMUM CASING PRESSURE AND VOLUME

Maximum Casing Pressure and Excess Volume Occur When the Pumped Volume Equals

Total Annulus Capacity - Volume of Gas at Surface bbl strokes

= Annulus Cap {prerecorded } - T = 360.1

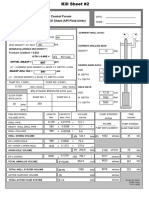

ENGINEER'S METHOD WORKSHEET

(Vertical and Deviated Wells)

PRERECORDED INFORMATION SPM psi bbl/stk bbl/min

A. Slow Pump Rate Data Pump #1 30 350

( Use SPR Pressure thru Riser for Subsea ) Pump #2 40 550

INFORMATION RECORDED WHEN WELL KICKS Time of Kick: 13:35

B. Old Mud Weight B pcf

C. Initial Shut-In Drill Pipe Pressure (SIDP) C 200 psi

D. Initial Shut-In Casing Pressure (SICP) D 300 psi

E. Initial Pit Volume Increase E 15 bbl

F. True Vertical Depth of Hole F 8000 ft (TVD)

Measured Depth of Hole (for Capacity Calculations ONLY) 8000 ft (MD)

MUD WEIGHT TO BALANCE KICK

G. Increase in Mud Weight required to Balance Kick

Initial SIDP C

G= = = G 4.0 pcf

0.007 ´ TVD 0.007 ´ F

H. New Mud Weight H=B+G= H 4.0 pcf

I. Total Volume to Weight up I = Active Pit Vol + System Vol = I 1001 bbl

J. Barite Required

J = I´

(30 ´ G ) =

(262 - H ) J 466 50# sacks

INITIAL CIRCULATING PRESSURE

K. Slow Pump Rate Pressure + SIDP K =A+C= K 550 psi

FINAL CIRCULATING PRESSURE

H

L. Slow Pump Rate Pressure X (New Mud Wt / Old Mud Wt) L=A´ = L psi

B

DRILL PIPE PRESSURE PROFILE strokes

M. Total Internal Capacity (from Prerecorded Well Data) M 107.7 bbl

N. Total Annulus Capacity (from Prerecorded Well Data) N 393.2 bbl

O. System Volume (from Prerecorded Well Data) O 500.9 bbl

Pres. Decline =

(I. Circ Pres.(K).-F. Circ Pres.(L))

´ Stroke Increment =

psi/strk incr

(Internal Capacity Strokes(M))

Strokes Pressure (psi)

0 550 = Initial Circ. Press. (K)

100 550

Total Internal Cap (M) = = Final Circ. Press. (L)

Version 2.0 (4/15/00)

ENGINEER'S METHOD WORKSHEET (page 2)

RESERVOIR PRESSURE (Pr)

P. Pr = 0 . 007 ´ New MW ´ TVD = 0 . 007 ´ H ´ F =

P 224 psi

MAXIMUM CASING PRESSURE (Pcmax) WHEN GAS GETS TO SURFACE

Q. Drill String Capacity from Prerecorded Data Q 108 bbl

R. Annulus Capacity Factor (DP x Casing) Right Below Wellhead = R -0.0197 bbl/ft

S. Temperature and Compression Effects. (From Fig. 11P.5 or Formula Below)

[

S = TZ = 4 . 03 - 0 . 38 ´ ln (P ) = ] S 1.97

T. New Mud Weight Gradient

H x 0.007 = T 0.03 psi/ft

U. Pc MAX , Part 1 (from Fig. 11P.2 or Formula below)

(Surface) U psi

0 . 007 ´ G ´ Q

= =

2´R

(Optional Correction for Subsea Wells)

U. (Subsea) A correction must be added to PCmax, Part 1 calculated above to

account for the choke line.

é Vol. Choke Line(bbl) ù T

Subs ea correction = êRKB to ML(ft) - ú ´ psi

ë R û 2

(Subsea) U = Subsea Correction + (Surface) U = (Subsea) U psi

(use this new U in Part V. and Part W. below)

V. Pc MA X , Part 2 (from Fig. 11P.3 Formula below )

ö 2 æ P ´E ´ S ´ T ö

+ çç ÷÷ =

æ

= ç

ç

ç

ç

U ÷

÷

÷

÷

V psi

è R ø

è ø

W. Maximum Casing Pressure,

PcMAX = PcMAX , Part 1 + PcMAX , Part 2 = U + V = W psi

Does Pcmax Exceed the Wellhead or Casing Pressure Limitation?

YES NO

VOLUME GAIN WHILE CIRCULATING OUT GAS BUBBLE

X. Volume of Gas at Surface (From Formula Below)

E´P´S

Vg , Vol gas at surf, bbl = = X bbl

W

Y. Volume Gain While Circulating Out Gas Kick Y=X-E Y -15 bbl

J

Z. Volume Gain due to Barite Addition Z = = Z 16 bbl

30 sacks/bbl

Total Volume Gain While Circulating Out Gas Kick =Y+Z 1 bbl

STROKES TO MAXIMUM CASING PRESSURE AND VOLUME

Maximum Casing Pressure and Excess Volume Occur When the Pumped Volume Equals

bbl strokes

Total Annulus Capacity - Volume of Gas at Surface =N - X 393

KICK TOLERANCE CALCULATIONS

(Prerecorded sheet must be correctly filled in to make these calculations)

(This includes MISICP data at bottom of first page of Prerecorded Sheet)

Note: ECD is not considered in the calculations for circulating kick tolerance

DRILLING KICK TOLERANCE TRIPPING KICK TOLERANCE

Input maximum kick size and kick gradient. Input formation pressure of kick zone.

Calculates formation pressure Calculates swabbed kick size (bbls)

(in equivalent ppg) that will break down that will break down the shoe while

the shoe upon shut in and during stripping in and during circulation

circulation to kill well. to kill well.

Maximum Kick Size 15 bbls Formation Pressure (pcf eq.) 78.00 pcf

Gradient of Kick (psi/ft) 0.1 psi/ft Gradient of Kick (psi/ft) 0.1 psi/ft

Kick Height 516 feet

SHUT-IN KICK TOLERANCE SHUT-IN KICK TOLERANCE

Max. Formation Press. (pcf eq.) 0.9 pcf (worst case-stripping in with kick across collars)

Kick Tolerance above current M.W. 0.9 pcf Kick Size to break shoe NA bbls

CIRCULATING KICK TOLERANCE CIRCULATING KICK TOLERANCE

Max. Formation Press. (pcf eq.) #DIV/0! pcf (back on bottom circulating, gas at shoe)

Kick Tolerance above current M.W. #DIV/0! pcf Kick Size to break shoe bbls

"NA" indicates a swabbed kick will not break the shoe down

You might also like

- PRE-RECORDED SHEET DATADocument7 pagesPRE-RECORDED SHEET DATASasan AbbasiNo ratings yet

- Kill Sheet Calculation Steps, Formulas & Calculators - Drilling ManualDocument7 pagesKill Sheet Calculation Steps, Formulas & Calculators - Drilling ManualGourav RanaNo ratings yet

- Swab and Surge Pressures SHBDocument1 pageSwab and Surge Pressures SHBstevebeardsleyNo ratings yet

- Drilling FormulaeDocument112 pagesDrilling FormulaeHunterNo ratings yet

- Petroleum Engineering Handbook For The Practicing Engineer Vol. 1 by M. A.Document5 pagesPetroleum Engineering Handbook For The Practicing Engineer Vol. 1 by M. A.ashishNo ratings yet

- IWCF Surface BOP: Kill SheetDocument6 pagesIWCF Surface BOP: Kill SheetMrSebollini0% (1)

- Deviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.Document7 pagesDeviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.yousef nNo ratings yet

- Kill Sheet IWCFDocument2 pagesKill Sheet IWCFMaria FernandaNo ratings yet

- Kill Sheet IWCFDocument2 pagesKill Sheet IWCFGourav RanaNo ratings yet

- Volume and StrokeDocument39 pagesVolume and StrokeHarpreetSinghNo ratings yet

- Surface Kill Sheet 1 AnswersDocument3 pagesSurface Kill Sheet 1 AnswersFarouq Eng100% (1)

- Kill sheet analysis and kick toleranceDocument1 pageKill sheet analysis and kick toleranceBaniNo ratings yet

- Spot Heavy MudDocument1 pageSpot Heavy MudstevebeardsleyNo ratings yet

- 31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodDocument1 page31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodJunaid MateenNo ratings yet

- Stimulation 4Document27 pagesStimulation 4DVScherbakovNo ratings yet

- 12 Casing Running Speed - QuartzDocument1 page12 Casing Running Speed - QuartzRebarNo ratings yet

- AVIARA ENERGY CORP Well Drilling ApplicationDocument1 pageAVIARA ENERGY CORP Well Drilling ApplicationstevebeardsleyNo ratings yet

- TVD & Kill Weight CalculationsDocument40 pagesTVD & Kill Weight Calculationsfrancisryan4519No ratings yet

- GOK-12 Wellbore Cementing ReportDocument5 pagesGOK-12 Wellbore Cementing Report-BloodSeeker-No ratings yet

- 14b-Kill Sheet PreparationDocument10 pages14b-Kill Sheet PreparationLorenaStămulescuNo ratings yet

- Drill String 1 DISDocument1 pageDrill String 1 DISpiies85No ratings yet

- Kill SheetDocument4 pagesKill SheetAnwar FauzenNo ratings yet

- Ilker Drilling ProgrammeDocument71 pagesIlker Drilling Programmerıdvan duranNo ratings yet

- WELL DATADocument3 pagesWELL DATAscrbdgharaviNo ratings yet

- Tutorial Sheet No.3: Leak Off Test and MAASPDocument14 pagesTutorial Sheet No.3: Leak Off Test and MAASPali jabbarNo ratings yet

- Optimize for 11-7/8Document1 pageOptimize for 11-7/8Vandear GoalcantaraNo ratings yet

- OVERPULLDocument3 pagesOVERPULLscrbdgharaviNo ratings yet

- Answers To WC - SIMULATOR KICK SHEET DATA DrillerlevelDocument4 pagesAnswers To WC - SIMULATOR KICK SHEET DATA DrillerlevelSilveira VictorinoNo ratings yet

- PETE 661: Drilling EngineeringDocument50 pagesPETE 661: Drilling Engineeringcmrig74No ratings yet

- Pressure Control CalculationsDocument4 pagesPressure Control Calculationsfisco4rilNo ratings yet

- Primary Cementing CalculationsDocument40 pagesPrimary Cementing CalculationsMostafa ElghifaryNo ratings yet

- Balance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsDocument2 pagesBalance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsRebarNo ratings yet

- Drill String DesignDocument1 pageDrill String DesignmalikshababNo ratings yet

- III. Basic CalculationDocument14 pagesIII. Basic Calculationdidin kenyalNo ratings yet

- Casing & Cementing ConventionalDocument1 pageCasing & Cementing ConventionalDeepak TandonNo ratings yet

- IWCF Surface BOP Kill Sheet DataDocument11 pagesIWCF Surface BOP Kill Sheet DataAnuranjanNo ratings yet

- Surface BOP Stack Operations API - Deviated Well Kill SheetDocument0 pagesSurface BOP Stack Operations API - Deviated Well Kill Sheetjosesito_amoroso2005No ratings yet

- Bit HydraulicsDocument11 pagesBit HydraulicstibismtxNo ratings yet

- Kick Tolerance CalculationDocument5 pagesKick Tolerance Calculationi oNo ratings yet

- Well Plan for TUT-126 Development WellDocument28 pagesWell Plan for TUT-126 Development Wellhamdi1000No ratings yet

- Example BHA Tally Directional Drilling 8.5 SectionDocument2 pagesExample BHA Tally Directional Drilling 8.5 Sectionfauzanhaq1602No ratings yet

- Drilling Fluid Calculations Archives - Drilling Formulas and Drilling Calculations PDFDocument10 pagesDrilling Fluid Calculations Archives - Drilling Formulas and Drilling Calculations PDFAmine MimoNo ratings yet

- 09 Spotting LCM Pill in The Annulus - QuartzDocument1 page09 Spotting LCM Pill in The Annulus - QuartzRebarNo ratings yet

- Exercise 4 AnswersDocument12 pagesExercise 4 AnswersadeelsnNo ratings yet

- Well Control ToolboxDocument8 pagesWell Control ToolboxAhmedNo ratings yet

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredDocument16 pagesKill Sheet: Prerecorded Infromation Pump Strokes RequiredAbdul Hameed OmarNo ratings yet

- CSG Design by AmrDocument19 pagesCSG Design by AmrSudish BhatNo ratings yet

- Mud Plan CalculationsDocument6 pagesMud Plan CalculationsHarjan Philipp C. GopaldasNo ratings yet

- Acid CalculationsDocument4 pagesAcid CalculationsjoensameNo ratings yet

- 12 - Hydraulic Calculations & MudpumpDocument1 page12 - Hydraulic Calculations & MudpumpJunaid MateenNo ratings yet

- 05 - SRB Hydraulic ProgramsDocument22 pages05 - SRB Hydraulic ProgramsnelsonhugoNo ratings yet

- Pilot Hole Hole OpenerDocument2 pagesPilot Hole Hole OpenerscrbdgharaviNo ratings yet

- Surface Kill Sheet Exercise 2Document3 pagesSurface Kill Sheet Exercise 2adeelsnNo ratings yet

- ( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Document5 pages( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Nitin GandhareNo ratings yet

- 04-LEK 1050 - 9.625 Casing & Cement Adjusted For HALL Stage ToolDocument5 pages04-LEK 1050 - 9.625 Casing & Cement Adjusted For HALL Stage ToolDrilling Engineering ChannelNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Kill Sheet #4Document2 pagesKill Sheet #4Ad AwsdNo ratings yet

- Simple Kill SheetDocument32 pagesSimple Kill SheetDiego AraqueNo ratings yet

- Flow DataDocument5 pagesFlow DataMiguel RodriguezNo ratings yet

- Kill Sheet #1Document2 pagesKill Sheet #1Ad AwsdNo ratings yet

- Kill Sheet #2Document2 pagesKill Sheet #2Ad AwsdNo ratings yet

- Spe-81573-Ms Water Injection Plant in Kuwait Oil FieldsDocument10 pagesSpe-81573-Ms Water Injection Plant in Kuwait Oil FieldsEvelynNo ratings yet

- BakerDocument4 pagesBakerWilliam EvansNo ratings yet

- Spe 15835 PaDocument14 pagesSpe 15835 Pacamelion3100% (1)

- SPE 95760 MS Ppaper2 PDFDocument14 pagesSPE 95760 MS Ppaper2 PDFWALDO DAVID SILVA SANCHEZNo ratings yet

- LW-781 (Cg08) DRL PGM One Page RevDocument2 pagesLW-781 (Cg08) DRL PGM One Page Revmohamed elshemyNo ratings yet

- 1a Roles of Engineers in SocietyDocument37 pages1a Roles of Engineers in SocietydailaNo ratings yet

- Wellhead Operations and Maintenance CourseDocument65 pagesWellhead Operations and Maintenance CourseAbdelkhak KhallaNo ratings yet

- EquationsDocument9 pagesEquationstsar mitchelNo ratings yet

- MODU DefinitionsDocument5 pagesMODU Definitionsdani lopezNo ratings yet

- Unconventional ResourcesDocument8 pagesUnconventional ResourcesjuckyrNo ratings yet

- Well control worksheet drillers methodDocument1 pageWell control worksheet drillers methodTriana Priyo SunjoyoNo ratings yet

- MAWOP CalculationDocument28 pagesMAWOP Calculationsigit praNo ratings yet

- (Doi 10.2118 - 39727-MS) Harmony, Kunu - (Society of Petroleum Engineers SPE Asia Pacific Conference On Integrated Modelling For Asset Management - Kuala Lumpur, MalaysDocument13 pages(Doi 10.2118 - 39727-MS) Harmony, Kunu - (Society of Petroleum Engineers SPE Asia Pacific Conference On Integrated Modelling For Asset Management - Kuala Lumpur, MalaysTălmaciu BiancaNo ratings yet

- DR - Ramanand Singh - IIT Madras 2023Document4 pagesDR - Ramanand Singh - IIT Madras 2023Ravi ChandakNo ratings yet

- Cement Packer Experience in Java Sea Provides Cost-Effective Way to Access Bypassed ReservesDocument10 pagesCement Packer Experience in Java Sea Provides Cost-Effective Way to Access Bypassed ReservesKimberly LawrenceNo ratings yet

- B Shifting Tool PDFDocument1 pageB Shifting Tool PDFdont replyNo ratings yet

- Paper 1Document21 pagesPaper 1Barham Sabir MahmoodNo ratings yet

- M. Asim Khan: Education CertificatesDocument1 pageM. Asim Khan: Education CertificatesAsim khanNo ratings yet

- Subsea Intervension SystemDocument41 pagesSubsea Intervension SystemVignesh KuppurajNo ratings yet

- NS 1 Specification Numbers NS1 A4Document3 pagesNS 1 Specification Numbers NS1 A4islam atifNo ratings yet

- 10 Coiled Tubing OperationDocument51 pages10 Coiled Tubing Operationام فاطمة البطاط100% (2)

- Coiled Tubing Brochure PDFDocument20 pagesCoiled Tubing Brochure PDFBisne BisneNo ratings yet

- KEROI Well ServicesDocument13 pagesKEROI Well Servicesa_salehiNo ratings yet

- Well Completion - Baker Oil ToolsDocument39 pagesWell Completion - Baker Oil ToolsAnonymous wHpCOKNo ratings yet

- Well CompletionDocument28 pagesWell CompletionNouman AliNo ratings yet

- The Development and Implementation of A Drilling Database: A Case StudyDocument8 pagesThe Development and Implementation of A Drilling Database: A Case StudyAliNo ratings yet

- Lecture#01# Types Well CompletionDocument12 pagesLecture#01# Types Well CompletionSherif MohammedNo ratings yet

- Reservoir Engineer, Production EngineerDocument4 pagesReservoir Engineer, Production Engineerapi-77948689No ratings yet

- Diagnosis of Excessive Water Production in Horizontal Wells Using WOR PlotsDocument9 pagesDiagnosis of Excessive Water Production in Horizontal Wells Using WOR Plotsjefpri simanjuntakNo ratings yet