Professional Documents

Culture Documents

d1 1 Wps 675 070 05 Digital Form

Uploaded by

Asep DadanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

d1 1 Wps 675 070 05 Digital Form

Uploaded by

Asep DadanCopyright:

Available Formats

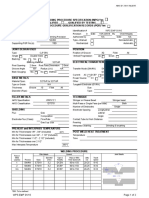

STATE OF FLORIDA DEPARTMENT OF TRANSPORTATION AWS D1.

1 WPS

Form # 675-070-05

WELDING PROCEDURE SPECIFICATION (WPS) April 2019

(D1.1) PREQUALIFIED QUALIFIED BY TESTING

Contractor/Organization: Identification #:

Welding Process(es): Revision: Date: By:

Supporting: PQR No.(s): FWST No.(s): Authorized By: Date:

JOINT DESIGN USED Manual Mechanized

Type:

Groove Type: Fillet: Semiautomatic Automatic

Backing: Yes No ELECTRICAL CHARACTERISTICS

Backing Mat’l: Transfer Mode (GMAW): Short-Circuiting

Root Opening: Root Face Dimension: Globular Spray

Groove Angle: Radius (J-U): Current: AC DCEP DCEN Pulsed

Backgouging: Yes No Method: Power Source: CC CV

Root Treatment: Other:

POSITION Tungsten Electrode (GTAW):

Position of Groove: Fillet: Size: Type:

Vertical Progression: Up Down TECHNIQUE

BASE METALS Stringer or Weave Bead:

Material Spec: Multi-Pass or Single Pass (per side):

Type or Grade: Number of Electrodes:

Thickness: Groove: Fillet: Electrode Spacing: Longitudinal:

Diameter (Pipe): Lateral: Angle:

FILLER METALS Electrical Stick Out:

AWS Specification: Peening: Interpass Cleaning:

AWS Classification: PREHEAT AND INTERPASS TEMPERATURE CHART

Mfg. Trade Name: Base Metal Thickness Min Preheat & Interpass Max Preheat & Interpass

SHIELDING Range (°F) (°F)

Flux:

Electrode Flux Class:

Gas: Composition:

Flow Rate: Gas Cup Size:

POSTWELD HEAT TREATMENT

Temp: Time:

WELDING PROCESS FABRICATOR’S CWI DIGITAL SIGNATURE

Pass or Weld Filler Metal Travel Speed AWS CWI #: CWI Exp. Date:

Current Volts

Layer(s) Diam. IPM

UPLOAD FDOT CONSULTANT STAMP

Joint Designation: UPLOAD JOINT DETAILS

Date:

Notes:

UPLOAD FDOT STAMP

Date:

Comments:

E-Mail the completed digital form to SM-StructuresCI@dot.state.fl.us, FDOT State Materials Office

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- d1 1 Wps 675 070 05 Digital FormDocument1 paged1 1 Wps 675 070 05 Digital FormYeisson VillamizarNo ratings yet

- d1 1 Wps 675 070 05 Digital FormDocument1 paged1 1 Wps 675 070 05 Digital FormGovind RaoNo ratings yet

- FDOT WPS for AWS D1.3 Sheet SteelDocument1 pageFDOT WPS for AWS D1.3 Sheet SteelaNKURNo ratings yet

- d1 4 Wps 675 070 12 Digital FormDocument1 paged1 4 Wps 675 070 12 Digital FormAamer MohammedNo ratings yet

- d1 6 PQR 675 070 13 Digital FormDocument2 pagesd1 6 PQR 675 070 13 Digital FormJimmy MyNo ratings yet

- Wps Smaw3g Smaw B-U2 (Vacio)Document1 pageWps Smaw3g Smaw B-U2 (Vacio)Richard Gonzales CapchiNo ratings yet

- PROCEDURE QUALIFICATION RECORD (PQRDocument2 pagesPROCEDURE QUALIFICATION RECORD (PQRBalkishan DyavanapellyNo ratings yet

- Document Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Document1 pageDocument Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Ed FangNo ratings yet

- Quality Control Form: Pocedure Qualification Record Wps No: Date: PQR No: PreheatDocument3 pagesQuality Control Form: Pocedure Qualification Record Wps No: Date: PQR No: PreheatAlesol EquipmentNo ratings yet

- Quality Control Form: Pocedure Qualification Record Wps No: Date: PQR No: PreheatDocument3 pagesQuality Control Form: Pocedure Qualification Record Wps No: Date: PQR No: PreheatAlesol EquipmentNo ratings yet

- Wps TempelateDocument2 pagesWps TempelatemohammedetaNo ratings yet

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- Annex Form J2 D1.1 D1.1M 2020 PDFDocument3 pagesAnnex Form J2 D1.1 D1.1M 2020 PDFDarioNo ratings yet

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Form UT, MT, PT, RTDocument5 pagesForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Welding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified or Procedure Qualification Records (PQR) YesRuben Purca0% (1)

- Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)rabacet23No ratings yet

- Aluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Document1 pageAluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Amin ThabetNo ratings yet

- Blank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document1 pageBlank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)GMNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- ESSAR Welding Data SheetDocument2 pagesESSAR Welding Data SheetmanojkumarmurlidharaNo ratings yet

- WPS SAW D1.1 2015 FormDocument1 pageWPS SAW D1.1 2015 FormHoque AnamulNo ratings yet

- Blank Sample WPS Form (SAW) Welding Procedure Specification (WPS)Document1 pageBlank Sample WPS Form (SAW) Welding Procedure Specification (WPS)GMNo ratings yet

- AWS D1.1/D1.1M:2020 Annex J Blank Sample WPS FormsDocument3 pagesAWS D1.1/D1.1M:2020 Annex J Blank Sample WPS FormsWegig WijanaNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNielNo ratings yet

- M 2 SAW D1.1 2015 Form PDFDocument1 pageM 2 SAW D1.1 2015 Form PDFyounessNo ratings yet

- Welding Procedure Specification KLPK 2Document2 pagesWelding Procedure Specification KLPK 2Zans 2001No ratings yet

- Aws D1.1Document1 pageAws D1.1พันธุ์เทพ คําพองNo ratings yet

- WPS Format For AWS D1.1 - WPS - SAWDocument1 pageWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNo ratings yet

- Form Run SheetDocument1 pageForm Run SheetRizaldi Akhmad SungkawaNo ratings yet

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- Contact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Document4 pagesContact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Maulik PatelNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- QW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToDocument2 pagesQW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToattaullaNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Main - Sample Welding Procedure Specification Wps FormDocument2 pagesMain - Sample Welding Procedure Specification Wps FormmuhammaddanishafandiNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- WPS GMAW FCAW D1.1 2015 Form PDFDocument1 pageWPS GMAW FCAW D1.1 2015 Form PDFHoque AnamulNo ratings yet

- Asirusa WPS-P-002 1FDocument5 pagesAsirusa WPS-P-002 1FWalter RuedaNo ratings yet

- FRM-Welder Performance Qualification RecordDocument1 pageFRM-Welder Performance Qualification RecordraofrhanNo ratings yet

- Wps Blank Form 2sheetDocument4 pagesWps Blank Form 2sheetdidi sudiNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- WPS SMAW Fillet Welding ProcedureDocument2 pagesWPS SMAW Fillet Welding ProcedurecrysNo ratings yet

- Welding Procedure Data Sheet for Steel Groups 1-3Document1 pageWelding Procedure Data Sheet for Steel Groups 1-3suronocaturatmojoNo ratings yet

- Cable: Length (Feet) 0.80 Bolt On DischargeDocument1 pageCable: Length (Feet) 0.80 Bolt On DischargeMohamedShafieNo ratings yet

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- Magnetic Particle Testing ReporDocument2 pagesMagnetic Particle Testing ReporGabriela MotaNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)AZaiNo ratings yet

- M 2 GTAW SMAW D1.1 2015 FormWPS PDFDocument1 pageM 2 GTAW SMAW D1.1 2015 FormWPS PDFUmi MaryanaNo ratings yet

- AWS D1.1/D1.1M:2015 ANNEX M WPS Form (GTAW & SMAWDocument1 pageAWS D1.1/D1.1M:2015 ANNEX M WPS Form (GTAW & SMAWRameshBaskaranNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Umi MaryanaNo ratings yet

- 48 Earthquake Safe Construction of Masonry BuildingDocument4 pages48 Earthquake Safe Construction of Masonry Buildingpramod_kNo ratings yet

- Guide-To Visual InspectionDocument25 pagesGuide-To Visual InspectionMatthew ShieldsNo ratings yet

- 123 ChemDocument4 pages123 Chemoperator daazNo ratings yet

- Engineering Fracture Mechanics: W. Bleck, W. Dahl, A. Nonn, L. Amlung, M. Feldmann, D. Schäfer, B. EichlerDocument17 pagesEngineering Fracture Mechanics: W. Bleck, W. Dahl, A. Nonn, L. Amlung, M. Feldmann, D. Schäfer, B. EichlerShubhom PaulNo ratings yet

- All 31 9amDocument134 pagesAll 31 9amSikha KaushikNo ratings yet

- Natural Gas ProcessingDocument41 pagesNatural Gas Processingjomafeba100% (2)

- NASA - Obtain Coordinates of NACADocument27 pagesNASA - Obtain Coordinates of NACATiago CandeiasNo ratings yet

- Transformer Test Report AnalysisDocument39 pagesTransformer Test Report AnalysisNguyễn Hoàng SơnNo ratings yet

- Safety Director EHS SH&E in Philadelphia PA Resume Dale JohnsonDocument2 pagesSafety Director EHS SH&E in Philadelphia PA Resume Dale JohnsonDale JohnsonNo ratings yet

- 106 TOP Control Systems - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsDocument18 pages106 TOP Control Systems - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsRian RiveraNo ratings yet

- Important Indian Standard Codes: Civil Booster (Civil Ki Goli Publication 9255624029)Document34 pagesImportant Indian Standard Codes: Civil Booster (Civil Ki Goli Publication 9255624029)AKYNo ratings yet

- Most Open Valve Concept WWTP EE AnalysisDocument29 pagesMost Open Valve Concept WWTP EE AnalysisRahmi ArslanNo ratings yet

- (Multi V Task) Technical Seminar - Multi V AHU Solution - FinalDocument36 pages(Multi V Task) Technical Seminar - Multi V AHU Solution - FinalPaulo Augusto GarayNo ratings yet

- Chapter 09 Flow Measurement Applications Aps Compatibility ModeDocument12 pagesChapter 09 Flow Measurement Applications Aps Compatibility ModeBig BangNo ratings yet

- Extension Springs Torsion Spring: Active Coils (N)Document9 pagesExtension Springs Torsion Spring: Active Coils (N)Pidathala Raghu Vamsi ReddyNo ratings yet

- Project Management Assignment 2 - Soichiro HondaDocument7 pagesProject Management Assignment 2 - Soichiro HondaGladwin SamuelNo ratings yet

- Data StructuresDocument41 pagesData StructuresSree Charan ReddyNo ratings yet

- Aquini: 3 Decades of ExcellenceDocument13 pagesAquini: 3 Decades of ExcellenceAnuj AggarwalNo ratings yet

- AVImark ReadMe Enhancements 2009.0.0Document33 pagesAVImark ReadMe Enhancements 2009.0.0William OglesbyNo ratings yet

- CN0125 PDFDocument4 pagesCN0125 PDFPuerco_EspinNo ratings yet

- Linde T20 /131 ManualDocument63 pagesLinde T20 /131 Manualalan mad100% (2)

- Implementation of Shortest Path in Packet Switching Network Using Genetic AlgorithmDocument6 pagesImplementation of Shortest Path in Packet Switching Network Using Genetic Algorithmeditor_ijarcsseNo ratings yet

- Reinforced Concrete DesignDocument3 pagesReinforced Concrete DesignRodel100% (2)

- Impedance, Angular Velocities & Frequencies of Oscillating CurrentsDocument32 pagesImpedance, Angular Velocities & Frequencies of Oscillating CurrentselectrosciNo ratings yet

- Eee342 hw2 Solution PDFDocument7 pagesEee342 hw2 Solution PDFRedion XhepaNo ratings yet

- LED TV Service ManualDocument54 pagesLED TV Service ManualJuan Jose100% (1)

- Release GuideDocument74 pagesRelease Guidelcalvo50No ratings yet

- Presentation On Gas Power PlantDocument82 pagesPresentation On Gas Power Plantakshay gupta100% (2)

- Ettus B100Document2 pagesEttus B100Philip GaddiNo ratings yet

- Sage X3 - User Guide - HTG-Printing CLOB Comments PDFDocument8 pagesSage X3 - User Guide - HTG-Printing CLOB Comments PDFcaplusinc100% (1)