Professional Documents

Culture Documents

CG-03-215 Surface Dressing

Uploaded by

Lucky TraderOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CG-03-215 Surface Dressing

Uploaded by

Lucky TraderCopyright:

Available Formats

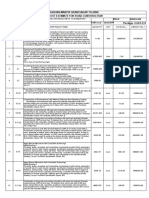

Bill of Quantity

PIU Name & No:- Project Implementation Unit 01,PRADHAN MANTRI GRAM SADAK YOJNA DANTEWADA

Name of Road :- PALNAAR ARMPURA TO LEKHAMPARA ROAD 100-249

Package No.:-CG-03-200 (I)

PALNAAR ARMPURA TO

Name of Road

Item LEKHAMPARA ROAD

S.No. Description

NO.

UOM RATE QTY Amount

Setting Out Setting Out work complete with construction of

bench mark (Min 1 per km) working benchmark (Min 4 per km)

and near all bridges and cross - drainage works made of

bricks/stone masonary or concrete and reference pillars made of

precast concrete poles/concrete filled100mm dia A.C. pipe @

100 m interval of as required on both sides of the formation

1 2.1 km 20955.00 1.20 25146

width, marking on central line, setting out curves and recording

of central line levels and other required levels and distances etc.

levels and other required levels and distances etc. including

setting out of cross- drainge structures & bridges with required

reference pillars and marking etc. as directed by engineer-in-

Charge.

Clearing Grass and Removal of Rubbish Clearing grass and

removal of rubbish up to a distance of 30 m outside the

2 2.2 sqm 1 7200.0 7200

periphery of the area as per Technical Specification Clause 201.

By Manual Means

Loosening, Levelling and Compacting original ground/existing

embankment/supporting embankment to facilitate placement of

first layer of embankment, scarified to a depth of 150 mm, mixed

3 3.2 with water at OMC and then compacted by rolling so as to cum 29.00 1080 31320

achieve minimum dry density as given in Tables 300.1 and 300.2

for embankment construction as per Technical Specification

Clause 301.4.1.

Surface Drains in Soil Construction of unlined surface drains

4 3.8 (i) of average cross-sectional area 0.40 sqm in soil to specified M 88.00 252.00 22176

lines, grades, levels and dimensions. Excavated material to be

used in embankment with a lift upto 3m and lead of 50 m

(average lead 25 m) as per Technical Specification Clause 307.

Excavation in Cutting in Soil by manual means with lead upto 50

5 3.5 (I) mExcavation for roadway in soil for carrying of cut earth to cum 91.00 0.00 0

embankment site with a lift upto 1.5 m and lead upto 50 m as per

Technical Specification Clause 302.3

Construction of Embankment with Material Obtained from

Roadway Cutting Construction of embankment with approved

6 3.3 (I) materials deposited at site from roadway cutting and excavation CUM 77 265.73 20461.518

from drain and foundation of other structures graded and

compacted to meet requirement of Tables 300.1 and 300.2 as per

Technical Specification Clause 301.5

Construction of Embankment with Material Obtained from Pits

7 3.4 (ll) Construction of embankment with approved material obtained cum 246 2921.176 718609.296

from borrow pits, transporting to site, spreading, grading to

required slope and compacting to meet requirement of Tables

300.1 and 300.2 (Beyond 250m)with all leads as per Technical

Specification Clause 301.5(Having CBR more than 5)

Construction of Subgrade and Earthen Shoulders Construction of

subgrade and earthen shoulders with approved material

(Granular material having CBR more than 7) obtained from

8 3.12 (A) borrow pits with all lifts and leads, transporting to site, cum 252 765.38 192874.752

spreading, grading to required slope and compacted to meet

requirement of Table 300.2 as per Technical Specification

Clause 303.1.

Construction of Subgrade and Earthen Shoulders Construction of

subgrade and earthen shoulders with approved material

9 3.12 (B) (Granular material having CBR more than 7) obtained from cum 280 298.01 83444.13

borrow pits with all lifts and leads, transporting to site,

spreading, grading to required slope and compacted to meet

requirement of Table 300.2 as per Technical Specification

Clause 303.1.

Construction of 1st layer of Bio enzyme based soil stabilized

layer to a required thickness as per manufacturer design with

local soil material/gravel/muroom having CBR greater than 6%

and treating it with TerraZyme 11x in the ratio for 26 cum soil

spreading in uniform layer with motor grader on prepared surface

mixing by mix in place method with rotavator at OMC and

compacting with smooth wheel roller to achieve the desired

density complete as per technical specification incl all labour,

equipment etc. Complete as per the direction of engineer in-

10 4.17 charge of the work except material like soil and metal. The soil CUM 1508.00 425.24 641255.888

will have PI between 7 & 12 % and clay % by hydrometery

should be more than 20% and less than 40%

Construction of 2st layer of Bio enzyme based soil stabilized

layer to a required thickness as per manufacture design with

local soil material/gravel/muroom having CBR greater than 6%

and treating it with TerraZyme 11x concentrate in the ratio 1lt for

28.0 cum soil with 30% 40mm crusher broken metal in design

mix, spreading in uniform layer with motor grader on prepared

surface mixing by mix in place method with rotavator at OMC

and compacting with smooth wheel roller to achieve the desired

density complete as per technical specification incl all labour,

11 4.18 material, soil, metal & equipment etc. Complete as per the cum 1576.00 317.60 500529.72

direction of engineer in-charge of the work. The soil will have PI

between 7 & 10 % and clay % by hydrometery should be more

than 20% and less than 30%

Granular Sub-base with Well Grded Material ( CBR 20 or more )

(Table 400.1)Construction of granular sub-base by providing

well graded material having CBR 20 or more, spreading in

uniform layers with motor grader on prepared surface, mixing by

12 4.1 (a) mix in place method with rotavator at OMC, and compacting CUM 910 0.00 0

with vibratory rollers of 80 to 100KN static weight to achieve

the desired density, complete as per Technical Specification

Clause 401. For Grading mentioned in table 400.1 (Grading III)

(b) Crushed Stone Materials

WBM Grade -2Providing, laying, spreading and compacting

mechanically crushed stone aggregates of specific sizes to water

bound macadam specification including spreading in uniform

thickness, hand packing, rolling with three wheel 80-100 kN

13 4.7 (2) cum 1981 0.00 0

static roller in stages to proper grade and camber, applying and

brooming, crushable screening to fill-up the interstices of coarse

aggregate, watering and compacting to the required density

Grading 2 as per Technical Specification Clause 405.

WBM Grade -3 Providing, laying, spreading and compacting

mechanically crushed stone aggregates of specific sizes to water

14 bound macadam specification including spreading in uniform cum 2118 317.60 672666.21

thickness, hand packing, rolling with three wheel 80-100 kN

static roller in stages to proper grade and camber, applying and

brooming, crushable screening to fill-up the interstices of coarse

aggregate, watering and compacting to the required density

4.7 (3) Grading 3 as per Technical Specification Clause 405.

Prime Coat Providing and applying primer coat with bitumen

15 5.1 emulsion (SS-1) on prepared surface of granular base including sqm 60.00 3813.04 228782.4

cleaning of road surface and spraying primer at the rate of 0.70-

1.0 kg/sqm using mechanical means as per Technical

Specification Clause 502

5.10 Surface Dressing using Bituminous (Penetrations grade /

modified bitumen) Binder

Case – I: Nominal chipping size 13.2 mm

16 5.1 (I) Bitumen (VG-10) sqm 85.00 0 0

(II) Bitumen (VG-30)

20mm thick Open-Graded Premix Carpet using Bituminous

( VG/modified bitumen ) Binder Providing, laying and rolling of

open-graded premix carpet of 20 mm thickness composed of

aggregate 13.2mm size (passing 22.4mm size sieve & retained

17 5.3 (ii) on 11.2mm sieve and 11.2mm size (passing 13.2mm sieve and sqm 171 3813.04 652029.84

retained on 5.6mm sieve) either using penetration grade/ VG

bitumen or emulsion to required line, grade and level to serve as

wearing course on a previously prepared base, including mixing

in a suitable plant, laying and rolling with a three wheel 80-100

kN static roller capacity, finished to required level and grades to

be followed by seal coat of either Type A or Type B or Type C

as per Technical Specification Clause 508., Viscocity grade

(VG) Bitumen specification as per IS 73:2006

Tack Coat Providing and applying tack coat with Bitumen

emulsion (RS-1) using emulsion distributor at the rate of 0.25

18 5.2 (iii) sqm 18 3813.04 68634.72

to 0.30 kg per sqm on the prepared granular surfaces treated with

primer & cleaned with Hydraulic broom as per Technical

Specification Clause 503.

Seal Coat Providing and laying seal coat sealing the voids in a

bituminous surface laid to the specified levels, grade and cross

19 5.5 (II) (ii) sqm 60 3813.04 228782.4

fall using Type A, Type B and Type C as per Technical

Specification Clause 510, Viscocity grade (VG) Bitumen

specification as per IS 73:2006

Semi-Reflective Traffic signs upto 0.90 sqm sign board

Providing and erecting direction and place identification of semi

reflective sign boards as per IRC-67 made of 2 mm thick M.S.

Sheet duly stove enameled paint white colour in front and grey

20 9.2 A colour on back with reflective border of 70 mm width and SQM 6621 0.54 3575.34

required message, letters, figures with reflective tape of

engineering grade as per MORD specifications of required shade

and colour. Supported and welded on two nos. 47 mm x 47 mm

of 12 SWG square tube of 3050 mm height duly strengthened by

25 mm x 5 mm MS flat iron on edges on back firmly fixed to the

ground by means of properly designed foundations with M-15

grade cement concrete 450 mm x 450 mm x 600 mm, 600 mm

below ground level as per approved drawing and Technical

Specification Clause 1701

Semi-Reflective Traffic signs

more than 0.90 sqm sign board Providing and erecting direction

and place identification of semi reflective sign boards as per

IRC-67 made of 2 mm thick M.S. Sheet duly stove enameled

paint white colour in front and grey colour on back with

21 9.2 B reflective border of 70 mm width and required message, letters, SQM 6534 1.00 6534

figures with reflective tape of engineering grade as per MORD

specifications of required shade and colour. Supported and

welded on two nos. 47 mm x 47 mm of 12 SWG square tube of

3050 mm height duly strengthened by 25 mm x 5 mm MS flat

iron on edges on back firmly fixed to the ground by means of

properly designed foundations with M-15 grade cement concrete

450 mm x 450 mm x 600 mm, 600 mm below ground level as

per approved drawing and Technical Specification Clause 1701

Providing and Fixing of PMGSY 'Logo' Board Providing and

22 9.16 Fixing of typical PMGSY logo board as per MoRD specification EACH 9276.00 1 9276

and drawings

Providing and fixing 'Citizen Information Board' of PMGSY

Project (A) Providing and fixing of typical " PMGSY Citizen

23 9.15 (A) Information Board" with Logo as per MoRD specifications & EACH 19621.00 1 19621

drawings, made of 75 mm square or 75 mm dia circular steel

tube of 12 SWG 3.2 m height and cross member 2 nos 1m long,

fixed with angle iron 50x50x5 mm MS angle on the back

Kilometre Stones & Boundary Pillar Reinforced cement concrete

24 9.8

M15 grade kilometre stone/local stone of standard design as per

IRC:8 fixing in position including painting and printing, etc as

per drawing and Technical Specification Clause 1703

25 (i) 5th Kilometre Stone (precast) EACH 5180.00 0 0

26 (ii) Ordinary Kilometer Stone (Precast) EACH 3072.00 3 9216

27 (iii) 200 m stone (precast) EACH 648.00 5 3240

9.9 Boundary Pillar

Reinforced cement concrete M15 grade boundary pillars/local

stone of standard design as per IRC:25, fixed in position

28 EACH 724.00 0.00 0

including finishing and lettering but excluding painting as per

drawing and Technical Specification Clause 1704

Providing & Laying Cement Concrete Pipe NP3 on first class

bedding of granular material including fixing collar with cement

29 7.6 (A)

sand mortar 1:2 but excluding excavation, protection works, RM 4099.00 40 163960

backfilling, concrete and masonary work in head wall and

parapets as per clause 1106 .(A) 600 mm Dia.

Providing & Laying Cement Concrete Pipe NP3 on first class

bedding of granular material including fixing collar with cement

30 7.6 (D) sand mortar 1:2 but excluding excavation, protection works, RM 1581.00 0 0

backfilling, concrete and masonary work in head wall and

parapets as per clause 1106 .(A) 300 mm Dia.

Excavation for Structure as per drawing and technical

specifications Clause 305.1 including setting out, construction of

31 7.1 shoring and bracing, removal of stumps and other deleterious cum 354.00 0 0

material and disposal upto a lead of 50 m, dressing of sides and

bottom and backfilling in trenches with excavated suitable

material.

Construction of Plain Cement Concrete Drain with P.C.C.

grade M-15 including all shuttering/form work etc. complete

32 6.5 Cum 5335 0.00 0

as per drawings/technical specification and direction of

engineer in charge.

Providing and laying reinforced cement concrete in

33 7.27 I superstructure as per drawing and technical specifications Cum 6839 0 0

Clauses 800, 1205.4 and 1205.5 R.C.C. grade M 20 1:2:4

Supplying, fitting, and placing HYSD bar reinforcement in

34 7.28 superstructure complete as per drawing and technical mt 76384.00 0.000 0

specifications Clauses 1002, 1010 and 1202

Road marking with Hot Applied Thermoplastic Compound with

Reflectorizing Glass Beads on Bituminous Surface (Providing

and laying of hot applied thermoplastic compound 2.5 mm thick

35 9.18 including reflectorizing glass beads @ 250 gms per sqm area, sqm 1266.00 0 0

thickness of 2.5 mm is exclusive of surface applied glass beads

as per IRC: 35. The finished surface to be level, uniform and free

from streaks and holes.)

Road Work Total Amount 4309335.214

Excavation for Structure as per drawing and technical

specifications Clause 305.1 including setting out, construction of

36 7.1 shoring and bracing, removal of stumps and other deleterious cum 354.0 82.890 29343.06

material and disposal upto a lead of 50 m, dressing of sides and

bottom and backfilling in trenches with excavated suitable

material.

Providing concrete for plain/reinforced concrete in open

foundations complete as per drawings and technical specification

37 7.1 O(I) Clause 802,803,1202 & 1203 cum 5,107.0 49.800 254328.6

I. P.C.C grade M 10 (Nominal mix 1:3:6)

Providing concrete for plain/reinforced concrete in open

foundations complete as per drawings and technical specification

38 7.1 O(III) Clause 802,803,1202 & 1203 cum 5,713.0 35.000 199955

III. P.C.C grade M 20(Nominal mix (1:2:4)

Providing concrete for plain/reinforced concrete in substructure

complete as per drawings and technical specification Clause

39 7.18(II) cum 6,042.0 36.400 219928.8

802,804,805,806,807,1202 & 1204,

For height upto 5 m

II. P.C.C. grade M 20 (Nominal mix (1:2:4

Providing and laying concrete for reinforced cement concrete in

40 7.27(II) superstructure as per drawing and technical specification Clause cum 7,312.0 4.09 29906.08

800,1205.4 & 1205.5

R.C.C. grade M 25 (Design Mix)

Providing and laying cement concrete wearing course M-30

41 7.31 grade including reinforcement complete as per drawing and cum 12,727.0 0 0

technical specification.

Supplying, fitting, and placing HYSD bar reinforcement in

42 7.28 superstructure complete as per drawing and technical MT 76,384.0 0.301 22979.36256

specifications Clauses 1002, 1010 and 1202

Providing weepholes in brick masonry/stone masonry, plain/

reinforced concrete abutment, wing wall, return wall with 100

43 7.22 mm dia AC pipe extending through the full width of the NOS 335.0 18 6030

structures with slope of 1(V):20(H) towards drawing face

complete as per drawing and technical specification Clauses 614,

709, 1204.3.7

Providing and laying filter media with granular crushed

aggregates as per specification to a thickness of not less than 600

44 7.24 mm with smaller size towards the soil and bigger size towards cum 1,807.0 6.04 10914.28

the wall and providing over the entire surface behind abutment,

wing wall, return wall to the full height, compacted to firm

condition complete as per drawing and technical specification

Clause 1204.3.8

Filler Joint

(II) Providing and fixing 20 mm thick compressible fibre board

45 7.41 in expansion joint complete as per drawing and technical RM 431.0 12 5172

specifications

Backfilling behind abutment, wing wall and return wall complete

46 7.23 as per drawings & technical specification Clause 1204.3.8 I) cum 1,025.0 12.12 12423

Granular material

CD Work Total Amount 790980.18256

TOTAL AMOUNT 5100315

47 1st Year Routine maintenance km 30000.00 1.20 36000

48 2nd Year Routine maintenance km 40000.00 1.20 48000

49 3rd Year Routine maintenance km 70000.00 1.20 84000

50 4th Year Routine maintenance km 110000.00 1.20 132000

51 5th Year Routine maintenance km 150000.00 1.20 180000

Routine Maintenance Total Amount 480000

Grand TOTAL AMOUNT 5580315

TOTAL AMOUNT Say in lakh 55.80

Sub Engineer Assistant Engineer Exe. Engineer

PIU CGRRDA PIU CGRRDA PIU CGRRDA

Dantewada Dantewada Dantewada

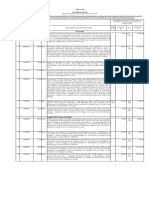

Bill of Quantity

PIU Name & No:- Project Implementation Unit 01,PRADHAN MANTRI GRAM SADAK YOJNA DANTEWADA

Name of Road :- BURGUM TO DORAPARA ROAD 100-249

Package No.:-CG-03-200 (II)

Name of Road BURGUM TO DORAPARA

S.N Item

Description

o. NO.

UOM RATE QTY Amount

Setting Out Setting Out work complete with construction of

bench mark (Min 1 per km) working benchmark (Min 4 per km)

and near all bridges and cross - drainage works made of

bricks/stone masonary or concrete and reference pillars made of

precast concrete poles/concrete filled100mm dia A.C. pipe @

100 m interval of as required on both sides of the formation

1 2.1 km 20955.00 2.240 46939.2

width, marking on central line, setting out curves and recording

of central line levels and other required levels and distances etc.

levels and other required levels and distances etc. including

setting out of cross- drainge structures & bridges with required

reference pillars and marking etc. as directed by engineer-in-

Charge.

Clearing Grass and Removal of Rubbish Clearing grass and

removal of rubbish up to a distance of 30 m outside the

2 2.2 sqm 1 13440.0 13440

periphery of the area as per Technical Specification Clause 201.

By Manual Means

Loosening, Levelling and Compacting original ground/existing

embankment/supporting embankment to facilitate placement of

first layer of embankment, scarified to a depth of 150 mm, mixed

3 3.2 with water at OMC and then compacted by rolling so as to cum 29.00 2016 58464

achieve minimum dry density as given in Tables 300.1 and 300.2

for embankment construction as per Technical Specification

Clause 301.4.1.

Surface Drains in Soil Construction of unlined surface drains

4 3.8 (i) of average cross-sectional area 0.40 sqm in soil to specified M 88.00 590 51920

lines, grades, levels and dimensions. Excavated material to be

used in embankment with a lift upto 3m and lead of 50 m

(average lead 25 m) as per Technical Specification Clause 307.

Excavation in Cutting in Soil by manual means with lead upto 50

5 3.5 (I) mExcavation for roadway in soil for carrying of cut earth to cum 91.00 0 0

embankment site with a lift upto 1.5 m and lead upto 50 m as per

Technical Specification Clause 302.3

Construction of Embankment with Material Obtained from

6 3.3 (I) Roadway Cutting Construction of embankment with approved CUM 77 828.048 63759.696

materials deposited at site from roadway cutting and excavation

from drain and foundation of other structures graded and

compacted to meet requirement of Tables 300.1 and 300.2 as per

Technical Specification Clause 301.5

Construction of Embankment with Material Obtained from Pits

7 3.4 (ll) Construction of embankment with approved material obtained cum 246 8334.4541 2050275.7135143

from borrow pits, transporting to site, spreading, grading to

required slope and compacting to meet requirement of Tables

300.1 and 300.2 (Beyond 250m)with all leads as per Technical

Specification Clause 301.5(Having CBR more than 5)

Construction of Subgrade and Earthen Shoulders Construction of

subgrade and earthen shoulders with approved material

(Granular material having CBR more than 7) obtained from

8 3.12 (A) borrow pits with all lifts and leads, transporting to site, cum 252 0 0

spreading, grading to required slope and compacted to meet

requirement of Table 300.2 as per Technical Specification

Clause 303.1.

Construction of Subgrade and Earthen Shoulders Construction of

subgrade and earthen shoulders with approved material

9 3.12 (B) (Granular material having CBR more than 7) obtained from cum 280 3418.7563 957251.75

borrow pits with all lifts and leads, transporting to site,

spreading, grading to required slope and compacted to meet

requirement of Table 300.2 as per Technical Specification

Clause 303.1.

Construction of 1st layer of Bio enzyme based soil stabilized

layer to a required thickness as per manufacturer design with

local soil material/gravel/muroom having CBR greater than 6%

and treating it with TerraZyme 11x in the ratio for 26 cum soil

spreading in uniform layer with motor grader on prepared surface

mixing by mix in place method with rotavator at OMC and

compacting with smooth wheel roller to achieve the desired

density complete as per technical specification incl all labour,

equipment etc. Complete as per the direction of engineer in-

10 4.17 charge of the work except material like soil and metal. The soil CUM 1508.00 0 0

will have PI between 7 & 12 % and clay % by hydrometery

should be more than 20% and less than 40%

Construction of 2st layer of Bio enzyme based soil stabilized

layer to a required thickness as per manufacture design with

local soil material/gravel/muroom having CBR greater than 6%

and treating it with TerraZyme 11x concentrate in the ratio 1lt for

28.0 cum soil with 30% 40mm crusher broken metal in design

mix, spreading in uniform layer with motor grader on prepared

surface mixing by mix in place method with rotavator at OMC

and compacting with smooth wheel roller to achieve the desired

density complete as per technical specification incl all labour,

11 4.18 material, soil, metal & equipment etc. Complete as per the cum 1576.00 0 0

direction of engineer in-charge of the work. The soil will have PI

between 7 & 10 % and clay % by hydrometery should be more

than 20% and less than 30%

Granular Sub-base with Well Grded Material ( CBR 20 or more )

(Table 400.1)Construction of granular sub-base by providing

well graded material having CBR 20 or more, spreading in

uniform layers with motor grader on prepared surface, mixing by

12 4.1 (b) mix in place method with rotavator at OMC, and compacting CUM 910 2609.3985 2374552.635

with vibratory rollers of 80 to 100KN static weight to achieve

the desired density, complete as per Technical Specification

Clause 401. For Grading mentioned in table 400.1 (Grading III)

(b) Crushed Stone Materials

WBM Grade -2Providing, laying, spreading and compacting

mechanically crushed stone aggregates of specific sizes to water

bound macadam specification including spreading in uniform

thickness, hand packing, rolling with three wheel 80-100 kN

13 4.7 (2) cum 1981 0.95 1881.95

static roller in stages to proper grade and camber, applying and

brooming, crushable screening to fill-up the interstices of coarse

aggregate, watering and compacting to the required density

Grading 2 as per Technical Specification Clause 405.

WBM Grade -3 Providing, laying, spreading and compacting

mechanically crushed stone aggregates of specific sizes to water

14 bound macadam specification including spreading in uniform cum 2118 555.5475 1176649.605

thickness, hand packing, rolling with three wheel 80-100 kN

static roller in stages to proper grade and camber, applying and

brooming, crushable screening to fill-up the interstices of coarse

aggregate, watering and compacting to the required density

4.7 (3) Grading 3 as per Technical Specification Clause 405.

Prime Coat Providing and applying primer coat with bitumen

15 5.1 emulsion (SS-1) on prepared surface of granular base including sqm 60.00 6951.2 417072

cleaning of road surface and spraying primer at the rate of 0.70-

1.0 kg/sqm using mechanical means as per Technical

Specification Clause 502

5.10 Surface Dressing using Bituminous (Penetrations grade /

modified bitumen) Binder

Case – I: Nominal chipping size 13.2 mm

16 5.1 (I) Bitumen (VG-10) sqm 85.00 7006.4 595544

(II) Bitumen (VG-30)

20mm thick Open-Graded Premix Carpet using Bituminous

( VG/modified bitumen ) Binder Providing, laying and rolling of

open-graded premix carpet of 20 mm thickness composed of

aggregate 13.2mm size (passing 22.4mm size sieve & retained

17 5.3 (ii) on 11.2mm sieve and 11.2mm size (passing 13.2mm sieve and sqm 171 0 0

retained on 5.6mm sieve) either using penetration grade/ VG

bitumen or emulsion to required line, grade and level to serve as

wearing course on a previously prepared base, including mixing

in a suitable plant, laying and rolling with a three wheel 80-100

kN static roller capacity, finished to required level and grades to

be followed by seal coat of either Type A or Type B or Type C

as per Technical Specification Clause 508., Viscocity grade

(VG) Bitumen specification as per IS 73:2006

Tack Coat Providing and applying tack coat with Bitumen

emulsion (RS-1) using emulsion distributor at the rate of 0.25

18 5.2 (iii) sqm 18 6951.2 125121.6

to 0.30 kg per sqm on the prepared granular surfaces treated with

primer & cleaned with Hydraulic broom as per Technical

Specification Clause 503.

Seal Coat Providing and laying seal coat sealing the voids in a

bituminous surface laid to the specified levels, grade and cross

19 5.5 (II) (ii) sqm 60 0 0

fall using Type A, Type B and Type C as per Technical

Specification Clause 510, Viscocity grade (VG) Bitumen

specification as per IS 73:2006

Semi-Reflective Traffic signs upto 0.90 sqm sign board

Providing and erecting direction and place identification of semi

reflective sign boards as per IRC-67 made of 2 mm thick M.S.

Sheet duly stove enameled paint white colour in front and grey

20 9.2 A colour on back with reflective border of 70 mm width and SQM 6621 1.08 7150.68

required message, letters, figures with reflective tape of

engineering grade as per MORD specifications of required shade

and colour. Supported and welded on two nos. 47 mm x 47 mm

of 12 SWG square tube of 3050 mm height duly strengthened by

25 mm x 5 mm MS flat iron on edges on back firmly fixed to the

ground by means of properly designed foundations with M-15

grade cement concrete 450 mm x 450 mm x 600 mm, 600 mm

below ground level as per approved drawing and Technical

Specification Clause 1701

Semi-Reflective Traffic signs

more than 0.90 sqm sign board Providing and erecting direction

and place identification of semi reflective sign boards as per

IRC-67 made of 2 mm thick M.S. Sheet duly stove enameled

paint white colour in front and grey colour on back with

21 9.2 B reflective border of 70 mm width and required message, letters, SQM 6534 0.36 2352.24

figures with reflective tape of engineering grade as per MORD

specifications of required shade and colour. Supported and

welded on two nos. 47 mm x 47 mm of 12 SWG square tube of

3050 mm height duly strengthened by 25 mm x 5 mm MS flat

iron on edges on back firmly fixed to the ground by means of

properly designed foundations with M-15 grade cement concrete

450 mm x 450 mm x 600 mm, 600 mm below ground level as

per approved drawing and Technical Specification Clause 1701

Providing and Fixing of PMGSY 'Logo' Board Providing and

22 9.16 Fixing of typical PMGSY logo board as per MoRD specification EACH 9276.00 1 9276

and drawings

Providing and fixing 'Citizen Information Board' of PMGSY

Project (A) Providing and fixing of typical " PMGSY Citizen

23 9.15 (A) Information Board" with Logo as per MoRD specifications & EACH 19621.00 1 19621

drawings, made of 75 mm square or 75 mm dia circular steel

tube of 12 SWG 3.2 m height and cross member 2 nos 1m long,

fixed with angle iron 50x50x5 mm MS angle on the back

Kilometre Stones & Boundary Pillar Reinforced cement concrete

24 9.8

M15 grade kilometre stone/local stone of standard design as per

IRC:8 fixing in position including painting and printing, etc as

per drawing and Technical Specification Clause 1703

25 (i) 5th Kilometre Stone (precast) EACH 5180.00 0 0

26 (ii) Ordinary Kilometer Stone (Precast) EACH 3072.00 4 12288

27 (iii) 200 m stone (precast) EACH 648.00 9 5832

9.9 Boundary Pillar

Reinforced cement concrete M15 grade boundary pillars/local

stone of standard design as per IRC:25, fixed in position

28 EACH 724.00 0 0

including finishing and lettering but excluding painting as per

drawing and Technical Specification Clause 1704

Providing & Laying Cement Concrete Pipe NP3 on first class

bedding of granular material including fixing collar with cement

29 7.6 (A)

sand mortar 1:2 but excluding excavation, protection works,

RM 4099.00 30 122970

backfilling, concrete and masonary work in head wall and

parapets as per clause 1106 .(A) 600 mm Dia.

Providing & Laying Cement Concrete Pipe NP3 on first class

bedding of granular material including fixing collar with cement

30 7.6 (D) sand mortar 1:2 but excluding excavation, protection works, RM 1581.00 0 0

backfilling, concrete and masonary work in head wall and

parapets as per clause 1106 .(A) 300 mm Dia.

Excavation for Structure as per drawing and technical

specifications Clause 305.1 including setting out, construction of

31 7.1 shoring and bracing, removal of stumps and other deleterious cum 354.00 88 31152

material and disposal upto a lead of 50 m, dressing of sides and

bottom and backfilling in trenches with excavated suitable

material.

Construction of Plain Cement Concrete Drain with P.C.C.

grade M-15 including all shuttering/form work etc. complete

32 6.5 Cum 5335 43.89 234153.15

as per drawings/technical specification and direction of

engineer in charge.

Providing and laying reinforced cement concrete in

33 7.27 I superstructure as per drawing and technical specifications Cum 6839 2.31 15798.09

Clauses 800, 1205.4 and 1205.5 R.C.C. grade M 20 1:2:4

Supplying, fitting, and placing HYSD bar reinforcement in

34 7.28 superstructure complete as per drawing and technical mt 76384.00 0.0693 5293.4112

specifications Clauses 1002, 1010 and 1202

Road marking with Hot Applied Thermoplastic Compound with

Reflectorizing Glass Beads on Bituminous Surface (Providing

and laying of hot applied thermoplastic compound 2.5 mm thick

35 9.18 including reflectorizing glass beads @ 250 gms per sqm area, sqm 1266.00 6 7596

thickness of 2.5 mm is exclusive of surface applied glass beads

as per IRC: 35. The finished surface to be level, uniform and free

from streaks and holes.)

Road Work Total Amount 8406354.7207143

Excavation for Structure as per drawing and technical

specifications Clause 305.1 including setting out, construction of

36 7.1 shoring and bracing, removal of stumps and other deleterious cum 354.0 466.6707 165,201.43

material and disposal upto a lead of 50 m, dressing of sides and

bottom and backfilling in trenches with excavated suitable

material.

Providing concrete for plain/reinforced concrete in open

foundations complete as per drawings and technical specification

37 7.1 O(I) Clause 802,803,1202 & 1203 cum 5,107.0 18.9731 96,895.62

I. P.C.C grade M 10 (Nominal mix 1:3:6)

Providing concrete for plain/reinforced concrete in open

foundations complete as per drawings and technical specification

38 7.1 O(III) Clause 802,803,1202 & 1203 cum 5,713.0 280.374 1,601,776.66

III. P.C.C grade M 20(Nominal mix (1:2:4)

Providing concrete for plain/reinforced concrete in substructure

complete as per drawings and technical specification Clause

39 7.18(II) cum 6,042.0 235.2 1,421,078.40

802,804,805,806,807,1202 & 1204,

For height upto 5 m

II. P.C.C. grade M 20 (Nominal mix (1:2:4

Providing and laying concrete for reinforced cement concrete in

40 7.27 superstructure as per drawing and technical specification Clause cum 7,312.0 23.0267 168,371.23

800,1205.4 & 1205.5

R.C.C. grade M 25 (Design Mix)

Providing and laying cement concrete wearing course M-30

41 7.31 grade including reinforcement complete as per drawing and cum 12,727.0 6.64903 84,622.20

technical specification.

Supplying, fitting, and placing HYSD bar reinforcement in

42 7.28 superstructure complete as per drawing and technical MT 76,384.0 1.6937292 129,373.81

specifications Clauses 1002, 1010 and 1202

Providing weepholes in brick masonry/stone masonry, plain/

reinforced concrete abutment, wing wall, return wall with 100

43 7.22 mm dia AC pipe extending through the full width of the NOS 335.0 101.34 33,948.90

structures with slope of 1(V):20(H) towards drawing face

complete as per drawing and technical specification Clauses 614,

709, 1204.3.7

Providing and laying filter media with granular crushed

aggregates as per specification to a thickness of not less than 600

44 7.24 mm with smaller size towards the soil and bigger size towards cum 1,807.0 34.0052 61,447.40

the wall and providing over the entire surface behind abutment,

wing wall, return wall to the full height, compacted to firm

condition complete as per drawing and technical specification

Clause 1204.3.8

Filler Joint

(II) Providing and fixing 20 mm thick compressible fibre board

45 7.41 in expansion joint complete as per drawing and technical RM 431.0 67.56 29,118.36

specifications

Backfilling behind abutment, wing wall and return wall complete

46 7.23 as per drawings & technical specification Clause 1204.3.8 I) cum 1,025.0 68.2356 69,941.49

Granular material

CD Work Total Amount 3861775.5043228

TOTAL AMOUNT 12268130

47 1st Year Routine maintenance km 30000.00 2.24 67200

48 2nd Year Routine maintenance km 40000.00 2.24 89600

49 3rd Year Routine maintenance km 70000.00 2.24 156800

50 4th Year Routine maintenance km 110000.00 2.24 246400

51 5th Year Routine maintenance km 150000.00 2.24 336000

Routine Maintenance Total Amount 896000

Grand TOTAL AMOUNT 13164130

TOTAL AMOUNT Say in lakh 131.64

Sub Engineer Assistant Engineer Exe. Engineer

PIU CGRRDA PIU CGRRDA PIU CGRRDA

Dantewada Dantewada Dantewada

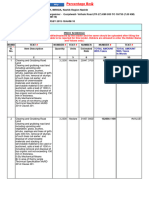

Bill of Quantity

PIU Name & No:- Project Implementation Unit 01,PRADHAN MANTRI GRAM SADAK YOJNA DANTEWADA

Name of Road :- KADMAPAL TO RIMANPARA ROAD 100-249

Package No.:-CG-03-200 (III)

KADMAPAL TO

Name of Road

S.N Item RIMANPARA ROAD

Description

o. NO.

UOM RATE QTY Amount

Setting Out Setting Out work complete with construction of

bench mark (Min 1 per km) working benchmark (Min 4 per km)

and near all bridges and cross - drainage works made of

bricks/stone masonary or concrete and reference pillars made of

precast concrete poles/concrete filled100mm dia A.C. pipe @

100 m interval of as required on both sides of the formation

1 2.1 km 20955.00 1.8 37719

width, marking on central line, setting out curves and recording

of central line levels and other required levels and distances etc.

levels and other required levels and distances etc. including

setting out of cross- drainge structures & bridges with required

reference pillars and marking etc. as directed by engineer-in-

Charge.

Clearing Grass and Removal of Rubbish Clearing grass and

removal of rubbish up to a distance of 30 m outside the

2 2.2 sqm 1 10800 10800

periphery of the area as per Technical Specification Clause 201.

By Manual Means

Loosening, Levelling and Compacting original ground/existing

embankment/supporting embankment to facilitate placement of

first layer of embankment, scarified to a depth of 150 mm, mixed

3 3.2 with water at OMC and then compacted by rolling so as to cum 29.00 1620 46980

achieve minimum dry density as given in Tables 300.1 and 300.2

for embankment construction as per Technical Specification

Clause 301.4.1.

Surface Drains in Soil Construction of unlined surface drains

4 3.8 (i) of average cross-sectional area 0.40 sqm in soil to specified M 88.00 480 42240

lines, grades, levels and dimensions. Excavated material to be

used in embankment with a lift upto 3m and lead of 50 m

(average lead 25 m) as per Technical Specification Clause 307.

Excavation in Cutting in Soil by manual means with lead upto 50

5 3.5 (I) mExcavation for roadway in soil for carrying of cut earth to cum 91.00 0 0

embankment site with a lift upto 1.5 m and lead upto 50 m as per

Technical Specification Clause 302.3

Construction of Embankment with Material Obtained from

Roadway Cutting Construction of embankment with approved

6 3.3 (I) materials deposited at site from roadway cutting and excavation CUM 77 502.668 38705.436

from drain and foundation of other structures graded and

compacted to meet requirement of Tables 300.1 and 300.2 as per

Technical Specification Clause 301.5

Construction of Embankment with Material Obtained from Pits

7 3.4 (ll) Construction of embankment with approved material obtained cum 246 4924.38 1211398.587

from borrow pits, transporting to site, spreading, grading to

required slope and compacting to meet requirement of Tables

300.1 and 300.2 (Beyond 250m)with all leads as per Technical

Specification Clause 301.5(Having CBR more than 5)

Construction of Subgrade and Earthen Shoulders Construction of

subgrade and earthen shoulders with approved material

(Granular material having CBR more than 7) obtained from

8 3.12 (A) borrow pits with all lifts and leads, transporting to site, cum 252 0 0

spreading, grading to required slope and compacted to meet

requirement of Table 300.2 as per Technical Specification

Clause 303.1.

Construction of Subgrade and Earthen Shoulders Construction of

subgrade and earthen shoulders with approved material

9 3.12 (B) (Granular material having CBR more than 7) obtained from cum 280 2750.76 770213.78

borrow pits with all lifts and leads, transporting to site,

spreading, grading to required slope and compacted to meet

requirement of Table 300.2 as per Technical Specification

Clause 303.1.

Construction of 1st layer of Bio enzyme based soil stabilized

layer to a required thickness as per manufacturer design with

local soil material/gravel/muroom having CBR greater than 6%

and treating it with TerraZyme 11x in the ratio for 26 cum soil

spreading in uniform layer with motor grader on prepared surface

mixing by mix in place method with rotavator at OMC and

compacting with smooth wheel roller to achieve the desired

density complete as per technical specification incl all labour,

equipment etc. Complete as per the direction of engineer in-

10 4.17 charge of the work except material like soil and metal. The soil CUM 1508.00 0 0

will have PI between 7 & 12 % and clay % by hydrometery

should be more than 20% and less than 40%

Construction of 2st layer of Bio enzyme based soil stabilized

layer to a required thickness as per manufacture design with

local soil material/gravel/muroom having CBR greater than 6%

and treating it with TerraZyme 11x concentrate in the ratio 1lt for

28.0 cum soil with 30% 40mm crusher broken metal in design

mix, spreading in uniform layer with motor grader on prepared

surface mixing by mix in place method with rotavator at OMC

and compacting with smooth wheel roller to achieve the desired

density complete as per technical specification incl all labour,

11 4.18 material, soil, metal & equipment etc. Complete as per the cum 1576.00 0 0

direction of engineer in-charge of the work. The soil will have PI

between 7 & 10 % and clay % by hydrometery should be more

than 20% and less than 30%

Granular Sub-base with Well Grded Material ( CBR 20 or more )

(Table 400.1)Construction of granular sub-base by providing

well graded material having CBR 20 or more, spreading in

uniform layers with motor grader on prepared surface, mixing by

12 4.1 (b) mix in place method with rotavator at OMC, and compacting CUM 910 2096.5 1907815.91

with vibratory rollers of 80 to 100KN static weight to achieve

the desired density, complete as per Technical Specification

Clause 401. For Grading mentioned in table 400.1 (Grading III)

(b) Crushed Stone Materials

WBM Grade -2Providing, laying, spreading and compacting

mechanically crushed stone aggregates of specific sizes to water

bound macadam specification including spreading in uniform

thickness, hand packing, rolling with three wheel 80-100 kN

13 4.7 (2) cum 1981 0.95 1881.95

static roller in stages to proper grade and camber, applying and

brooming, crushable screening to fill-up the interstices of coarse

aggregate, watering and compacting to the required density

Grading 2 as per Technical Specification Clause 405.

WBM Grade -3 Providing, laying, spreading and compacting

mechanically crushed stone aggregates of specific sizes to water

14 bound macadam specification including spreading in uniform cum 2118 436.755 925047.09

thickness, hand packing, rolling with three wheel 80-100 kN

static roller in stages to proper grade and camber, applying and

brooming, crushable screening to fill-up the interstices of coarse

aggregate, watering and compacting to the required density

4.7 (3) Grading 3 as per Technical Specification Clause 405.

Prime Coat Providing and applying primer coat with bitumen

15 5.1 emulsion (SS-1) on prepared surface of granular base including sqm 60.00 5568.1 334086

cleaning of road surface and spraying primer at the rate of 0.70-

1.0 kg/sqm using mechanical means as per Technical

Specification Clause 502

5.10 Surface Dressing using Bituminous (Penetrations grade /

modified bitumen) Binder

Case – I: Nominal chipping size 13.2 mm

16 5.1 (I) Bitumen (VG-10) sqm 85.00 0 0

(II) Bitumen (VG-30)

20mm thick Open-Graded Premix Carpet using Bituminous

( VG/modified bitumen ) Binder Providing, laying and rolling of

open-graded premix carpet of 20 mm thickness composed of

aggregate 13.2mm size (passing 22.4mm size sieve & retained

17 5.3 (ii) on 11.2mm sieve and 11.2mm size (passing 13.2mm sieve and sqm 171 5623.3 961584.3

retained on 5.6mm sieve) either using penetration grade/ VG

bitumen or emulsion to required line, grade and level to serve as

wearing course on a previously prepared base, including mixing

in a suitable plant, laying and rolling with a three wheel 80-100

kN static roller capacity, finished to required level and grades to

be followed by seal coat of either Type A or Type B or Type C

as per Technical Specification Clause 508., Viscocity grade

(VG) Bitumen specification as per IS 73:2006

Tack Coat Providing and applying tack coat with Bitumen

emulsion (RS-1) using emulsion distributor at the rate of 0.25

18 5.2 (iii) sqm 18 5568.1 100225.8

to 0.30 kg per sqm on the prepared granular surfaces treated with

primer & cleaned with Hydraulic broom as per Technical

Specification Clause 503.

Seal Coat Providing and laying seal coat sealing the voids in a

bituminous surface laid to the specified levels, grade and cross

19 5.5 (II) (ii) sqm 60 5568.1 334086

fall using Type A, Type B and Type C as per Technical

Specification Clause 510, Viscocity grade (VG) Bitumen

specification as per IS 73:2006

Semi-Reflective Traffic signs upto 0.90 sqm sign board

Providing and erecting direction and place identification of semi

reflective sign boards as per IRC-67 made of 2 mm thick M.S.

Sheet duly stove enameled paint white colour in front and grey

20 9.2 A colour on back with reflective border of 70 mm width and SQM 6621 1.08 7150.68

required message, letters, figures with reflective tape of

engineering grade as per MORD specifications of required shade

and colour. Supported and welded on two nos. 47 mm x 47 mm

of 12 SWG square tube of 3050 mm height duly strengthened by

25 mm x 5 mm MS flat iron on edges on back firmly fixed to the

ground by means of properly designed foundations with M-15

grade cement concrete 450 mm x 450 mm x 600 mm, 600 mm

below ground level as per approved drawing and Technical

Specification Clause 1701

Semi-Reflective Traffic signs

more than 0.90 sqm sign board Providing and erecting direction

and place identification of semi reflective sign boards as per

IRC-67 made of 2 mm thick M.S. Sheet duly stove enameled

paint white colour in front and grey colour on back with

21 9.2 B reflective border of 70 mm width and required message, letters, SQM 6534 0.36 2352.24

figures with reflective tape of engineering grade as per MORD

specifications of required shade and colour. Supported and

welded on two nos. 47 mm x 47 mm of 12 SWG square tube of

3050 mm height duly strengthened by 25 mm x 5 mm MS flat

iron on edges on back firmly fixed to the ground by means of

properly designed foundations with M-15 grade cement concrete

450 mm x 450 mm x 600 mm, 600 mm below ground level as

per approved drawing and Technical Specification Clause 1701

Providing and Fixing of PMGSY 'Logo' Board Providing and

22 9.16 Fixing of typical PMGSY logo board as per MoRD specification EACH 9276.00 1 9276

and drawings

Providing and fixing 'Citizen Information Board' of PMGSY

Project (A) Providing and fixing of typical " PMGSY Citizen

23 9.15 (A) Information Board" with Logo as per MoRD specifications & EACH 19621.00 1 19621

drawings, made of 75 mm square or 75 mm dia circular steel

tube of 12 SWG 3.2 m height and cross member 2 nos 1m long,

fixed with angle iron 50x50x5 mm MS angle on the back

Kilometre Stones & Boundary Pillar Reinforced cement concrete

24 9.8

M15 grade kilometre stone/local stone of standard design as per

IRC:8 fixing in position including painting and printing, etc as

per drawing and Technical Specification Clause 1703

25 (i) 5th Kilometre Stone (precast) EACH 5180.00 0 0

26 (ii) Ordinary Kilometer Stone (Precast) EACH 3072.00 3 9216

27 (iii) 200 m stone (precast) EACH 648.00 8 5184

9.9 Boundary Pillar

Reinforced cement concrete M15 grade boundary pillars/local

stone of standard design as per IRC:25, fixed in position

28 EACH 724.00 0 0

including finishing and lettering but excluding painting as per

drawing and Technical Specification Clause 1704

Providing & Laying Cement Concrete Pipe NP3 on first class

bedding of granular material including fixing collar with cement

29 7.6 (A)

sand mortar 1:2 but excluding excavation, protection works,

RM 4099.00 40 163960

backfilling, concrete and masonary work in head wall and

parapets as per clause 1106 .(A) 600 mm Dia.

Providing & Laying Cement Concrete Pipe NP3 on first class

bedding of granular material including fixing collar with cement

30 7.6 (D) sand mortar 1:2 but excluding excavation, protection works, RM 1581.00 0 0

backfilling, concrete and masonary work in head wall and

parapets as per clause 1106 .(A) 300 mm Dia.

Excavation for Structure as per drawing and technical

specifications Clause 305.1 including setting out, construction of

31 7.1 shoring and bracing, removal of stumps and other deleterious cum 354.00 32 11328

material and disposal upto a lead of 50 m, dressing of sides and

bottom and backfilling in trenches with excavated suitable

material.

Construction of Plain Cement Concrete Drain with P.C.C.

grade M-15 including all shuttering/form work etc. complete

32 6.5 Cum 5335 15.96 85146.6

as per drawings/technical specification and direction of

engineer in charge.

Providing and laying reinforced cement concrete in

33 7.27 I superstructure as per drawing and technical specifications Cum 6839 0.84 5744.76

Clauses 800, 1205.4 and 1205.5 R.C.C. grade M 20 1:2:4

Supplying, fitting, and placing HYSD bar reinforcement in

34 7.28 superstructure complete as per drawing and technical mt 76384.00 0.0252 1924.8768

specifications Clauses 1002, 1010 and 1202

Road marking with Hot Applied Thermoplastic Compound with

Reflectorizing Glass Beads on Bituminous Surface (Providing

and laying of hot applied thermoplastic compound 2.5 mm thick

35 9.18 including reflectorizing glass beads @ 250 gms per sqm area, sqm 1266.00 6 7596

thickness of 2.5 mm is exclusive of surface applied glass beads

as per IRC: 35. The finished surface to be level, uniform and free

from streaks and holes.)

Road Work Total Amount 7051284.0098

Excavation for Structure as per drawing and technical

specifications Clause 305.1 including setting out, construction of

36 7.1 shoring and bracing, removal of stumps and other deleterious cum 354.0 165.78 58,686.12

material and disposal upto a lead of 50 m, dressing of sides and

bottom and backfilling in trenches with excavated suitable

material.

Providing concrete for plain/reinforced concrete in open

foundations complete as per drawings and technical specification

37 7.1 O(I) Clause 802,803,1202 & 1203 cum 5,107.0 6.74 34,421.18

I. P.C.C grade M 10 (Nominal mix 1:3:6)

Providing concrete for plain/reinforced concrete in open

foundations complete as per drawings and technical specification

38 7.1 O(III) Clause 802,803,1202 & 1203 cum 5,713.0 99.6 569,014.80

III. P.C.C grade M 20(Nominal mix (1:2:4)

Providing concrete for plain/reinforced concrete in substructure

complete as per drawings and technical specification Clause

39 7.18(II) cum 6,042.0 70 422,940.00

802,804,805,806,807,1202 & 1204,

For height upto 5 m

II. P.C.C. grade M 20 (Nominal mix (1:2:4

Providing and laying concrete for reinforced cement concrete in

40 7.27 superstructure as per drawing and technical specification Clause cum 7,312.0 8.18 59,812.16

800,1205.4 & 1205.5

R.C.C. grade M 25 (Design Mix)

Providing and laying cement concrete wearing course M-30

41 7.31 grade including reinforcement complete as per drawing and cum 12,727.0 2.362 30,061.17

technical specification.

Supplying, fitting, and placing HYSD bar reinforcement in

42 7.28 superstructure complete as per drawing and technical MT 76,384.0 0.60168 45,958.73

specifications Clauses 1002, 1010 and 1202

Providing weepholes in brick masonry/stone masonry, plain/

reinforced concrete abutment, wing wall, return wall with 100

43 7.22 mm dia AC pipe extending through the full width of the NOS 335.0 36 12,060.00

structures with slope of 1(V):20(H) towards drawing face

complete as per drawing and technical specification Clauses 614,

709, 1204.3.7

Providing and laying filter media with granular crushed

aggregates as per specification to a thickness of not less than 600

44 7.24 mm with smaller size towards the soil and bigger size towards cum 1,807.0 12.08 21,828.56

the wall and providing over the entire surface behind abutment,

wing wall, return wall to the full height, compacted to firm

condition complete as per drawing and technical specification

Clause 1204.3.8

Filler Joint

(II) Providing and fixing 20 mm thick compressible fibre board

45 7.41 in expansion joint complete as per drawing and technical RM 431.0 24 10,344.00

specifications

Backfilling behind abutment, wing wall and return wall complete

46 7.23 as per drawings & technical specification Clause 1204.3.8 I) cum 1,025.0 24.24 24,846.00

Granular material

CD Work Total Amount 1289972.71912

TOTAL AMOUNT 8341257

47 1st Year Routine maintenance km 30000.00 2 60000

48 2nd Year Routine maintenance km 40000.00 2 80000

49 3rd Year Routine maintenance km 70000.00 2 140000

50 4th Year Routine maintenance km 110000.00 2 220000

51 5th Year Routine maintenance km 150000.00 2 300000

Routine Maintenance Total Amount 800000

Grand TOTAL AMOUNT 9141257

TOTAL AMOUNT Say in lakh 91.41

Sub Engineer Assistant Engineer Exe. Engineer

PIU CGRRDA PIU CGRRDA PIU CGRRDA

Dantewada Dantewada Dantewada

Bill of Quantity

PIU Name & No:- Project Implementation Unit 01,PRADHAN MANTRI GRAM SADAK YOJNA DANTEWADA

Name of Road :- NAKULNAR PALNAR TO DORIRAS ROAD 100-249

Package No.:-CG-03-200 (IV)

NAKULNAR

Name of Road PALNAR TO

S.N Item DORIRAS ROAD

Description

o. NO.

UOM RATE QTY Amount

Setting Out Setting Out work complete with construction of

bench mark (Min 1 per km) working benchmark (Min 4 per km)

and near all bridges and cross - drainage works made of

bricks/stone masonary or concrete and reference pillars made of

precast concrete poles/concrete filled100mm dia A.C. pipe @

100 m interval of as required on both sides of the formation

1 2.1 km 20955.00 0.85 17811.75

width, marking on central line, setting out curves and recording

of central line levels and other required levels and distances etc.

levels and other required levels and distances etc. including

setting out of cross- drainge structures & bridges with required

reference pillars and marking etc. as directed by engineer-in-

Charge.

Clearing Grass and Removal of Rubbish Clearing grass and

removal of rubbish up to a distance of 30 m outside the

2 2.2 sqm 1 5100 5100

periphery of the area as per Technical Specification Clause 201.

By Manual Means

Loosening, Levelling and Compacting original ground/existing

embankment/supporting embankment to facilitate placement of

first layer of embankment, scarified to a depth of 150 mm, mixed

3 3.2 with water at OMC and then compacted by rolling so as to cum 29.00 765 22185

achieve minimum dry density as given in Tables 300.1 and 300.2

for embankment construction as per Technical Specification

Clause 301.4.1.

Surface Drains in Soil Construction of unlined surface drains

4 3.8 (i) of average cross-sectional area 0.40 sqm in soil to specified M 88.00 660 58080

lines, grades, levels and dimensions. Excavated material to be

used in embankment with a lift upto 3m and lead of 50 m

(average lead 25 m) as per Technical Specification Clause 307.

Excavation in Cutting in Soil by manual means with lead upto 50

5 3.5 (I) mExcavation for roadway in soil for carrying of cut earth to cum 91.00 0 0

embankment site with a lift upto 1.5 m and lead upto 50 m as per

Technical Specification Clause 302.3

Construction of Embankment with Material Obtained from

Roadway Cutting Construction of embankment with approved

6 3.3 (I) materials deposited at site from roadway cutting and excavation CUM 77 701.202 53992.554

from drain and foundation of other structures graded and

compacted to meet requirement of Tables 300.1 and 300.2 as per

Technical Specification Clause 301.5

Construction of Embankment with Material Obtained from Pits

7 3.4 (ll) Construction of embankment with approved material obtained cum 246 2185.79 537703.848

from borrow pits, transporting to site, spreading, grading to

required slope and compacting to meet requirement of Tables

300.1 and 300.2 (Beyond 250m)with all leads as per Technical

Specification Clause 301.5(Having CBR more than 5)

Construction of Subgrade and Earthen Shoulders Construction of

subgrade and earthen shoulders with approved material

(Granular material having CBR more than 7) obtained from

8 3.12 (A) borrow pits with all lifts and leads, transporting to site, cum 252 0 0

spreading, grading to required slope and compacted to meet

requirement of Table 300.2 as per Technical Specification

Clause 303.1.

Construction of Subgrade and Earthen Shoulders Construction of

subgrade and earthen shoulders with approved material

9 3.12 (B) (Granular material having CBR more than 7) obtained from cum 280 1284.94 359783.27

borrow pits with all lifts and leads, transporting to site,

spreading, grading to required slope and compacted to meet

requirement of Table 300.2 as per Technical Specification

Clause 303.1.

Construction of 1st layer of Bio enzyme based soil stabilized

layer to a required thickness as per manufacturer design with

local soil material/gravel/muroom having CBR greater than 6%

and treating it with TerraZyme 11x in the ratio for 26 cum soil

spreading in uniform layer with motor grader on prepared surface

mixing by mix in place method with rotavator at OMC and

compacting with smooth wheel roller to achieve the desired

density complete as per technical specification incl all labour,

equipment etc. Complete as per the direction of engineer in-

10 4.17 charge of the work except material like soil and metal. The soil CUM 1508.00 0 0

will have PI between 7 & 12 % and clay % by hydrometery

should be more than 20% and less than 40%

Construction of 2st layer of Bio enzyme based soil stabilized

layer to a required thickness as per manufacture design with

local soil material/gravel/muroom having CBR greater than 6%

and treating it with TerraZyme 11x concentrate in the ratio 1lt for

28.0 cum soil with 30% 40mm crusher broken metal in design

mix, spreading in uniform layer with motor grader on prepared

surface mixing by mix in place method with rotavator at OMC

and compacting with smooth wheel roller to achieve the desired

density complete as per technical specification incl all labour,

11 4.18 material, soil, metal & equipment etc. Complete as per the cum 1576.00 0 0

direction of engineer in-charge of the work. The soil will have PI

between 7 & 10 % and clay % by hydrometery should be more

than 20% and less than 30%

Granular Sub-base with Well Grded Material ( CBR 20 or more )

(Table 400.1)Construction of granular sub-base by providing

well graded material having CBR 20 or more, spreading in

uniform layers with motor grader on prepared surface, mixing by

12 4.1 (b) mix in place method with rotavator at OMC, and compacting CUM 910 993.813 904369.375

with vibratory rollers of 80 to 100KN static weight to achieve

the desired density, complete as per Technical Specification

Clause 401. For Grading mentioned in table 400.1 (Grading III)

(b) Crushed Stone Materials

WBM Grade -2Providing, laying, spreading and compacting

mechanically crushed stone aggregates of specific sizes to water

bound macadam specification including spreading in uniform

thickness, hand packing, rolling with three wheel 80-100 kN

13 4.7 (2) cum 1981 0.95 1881.95

static roller in stages to proper grade and camber, applying and

brooming, crushable screening to fill-up the interstices of coarse

aggregate, watering and compacting to the required density

Grading 2 as per Technical Specification Clause 405.

WBM Grade -3 Providing, laying, spreading and compacting

mechanically crushed stone aggregates of specific sizes to water

14 bound macadam specification including spreading in uniform cum 2118 240.298 508950.105

thickness, hand packing, rolling with three wheel 80-100 kN

static roller in stages to proper grade and camber, applying and

brooming, crushable screening to fill-up the interstices of coarse

aggregate, watering and compacting to the required density

4.7 (3) Grading 3 as per Technical Specification Clause 405.

Prime Coat Providing and applying primer coat with bitumen

15 5.1 emulsion (SS-1) on prepared surface of granular base including sqm 60.00 2735.4 164124

cleaning of road surface and spraying primer at the rate of 0.70-

1.0 kg/sqm using mechanical means as per Technical

Specification Clause 502

5.10 Surface Dressing using Bituminous (Penetrations grade /

modified bitumen) Binder

Case – I: Nominal chipping size 13.2 mm

16 5.1 (I) Bitumen (VG-10) sqm 85.00 0 0

(II) Bitumen (VG-30)

20mm thick Open-Graded Premix Carpet using Bituminous

( VG/modified bitumen ) Binder Providing, laying and rolling of

open-graded premix carpet of 20 mm thickness composed of

aggregate 13.2mm size (passing 22.4mm size sieve & retained

17 5.3 (ii) on 11.2mm sieve and 11.2mm size (passing 13.2mm sieve and sqm 171 2790.6 477192.6

retained on 5.6mm sieve) either using penetration grade/ VG

bitumen or emulsion to required line, grade and level to serve as

wearing course on a previously prepared base, including mixing

in a suitable plant, laying and rolling with a three wheel 80-100

kN static roller capacity, finished to required level and grades to

be followed by seal coat of either Type A or Type B or Type C

as per Technical Specification Clause 508., Viscocity grade

(VG) Bitumen specification as per IS 73:2006

Tack Coat Providing and applying tack coat with Bitumen

emulsion (RS-1) using emulsion distributor at the rate of 0.25

18 5.2 (iii) sqm 18 2735.4 49237.2

to 0.30 kg per sqm on the prepared granular surfaces treated with

primer & cleaned with Hydraulic broom as per Technical

Specification Clause 503.

Seal Coat Providing and laying seal coat sealing the voids in a

bituminous surface laid to the specified levels, grade and cross

19 5.5 (II) (ii) sqm 60 2735.4 164124

fall using Type A, Type B and Type C as per Technical

Specification Clause 510, Viscocity grade (VG) Bitumen

specification as per IS 73:2006

Semi-Reflective Traffic signs upto 0.90 sqm sign board

Providing and erecting direction and place identification of semi

reflective sign boards as per IRC-67 made of 2 mm thick M.S.

Sheet duly stove enameled paint white colour in front and grey

20 9.2 A colour on back with reflective border of 70 mm width and SQM 6621 0.54 3575.34

required message, letters, figures with reflective tape of

engineering grade as per MORD specifications of required shade

and colour. Supported and welded on two nos. 47 mm x 47 mm

of 12 SWG square tube of 3050 mm height duly strengthened by

25 mm x 5 mm MS flat iron on edges on back firmly fixed to the

ground by means of properly designed foundations with M-15

grade cement concrete 450 mm x 450 mm x 600 mm, 600 mm

below ground level as per approved drawing and Technical

Specification Clause 1701

Semi-Reflective Traffic signs

more than 0.90 sqm sign board Providing and erecting direction

and place identification of semi reflective sign boards as per

IRC-67 made of 2 mm thick M.S. Sheet duly stove enameled

paint white colour in front and grey colour on back with

21 9.2 B reflective border of 70 mm width and required message, letters, SQM 6534 1 6534

figures with reflective tape of engineering grade as per MORD

specifications of required shade and colour. Supported and

welded on two nos. 47 mm x 47 mm of 12 SWG square tube of

3050 mm height duly strengthened by 25 mm x 5 mm MS flat

iron on edges on back firmly fixed to the ground by means of

properly designed foundations with M-15 grade cement concrete

450 mm x 450 mm x 600 mm, 600 mm below ground level as

per approved drawing and Technical Specification Clause 1701

Providing and Fixing of PMGSY 'Logo' Board Providing and

22 9.16 Fixing of typical PMGSY logo board as per MoRD specification EACH 9276.00 1 9276

and drawings

Providing and fixing 'Citizen Information Board' of PMGSY

Project (A) Providing and fixing of typical " PMGSY Citizen

23 9.15 (A) Information Board" with Logo as per MoRD specifications & EACH 19621.00 1 19621

drawings, made of 75 mm square or 75 mm dia circular steel

tube of 12 SWG 3.2 m height and cross member 2 nos 1m long,

fixed with angle iron 50x50x5 mm MS angle on the back

Kilometre Stones & Boundary Pillar Reinforced cement concrete

24 9.8

M15 grade kilometre stone/local stone of standard design as per

IRC:8 fixing in position including painting and printing, etc as

per drawing and Technical Specification Clause 1703

25 (i) 5th Kilometre Stone (precast) EACH 5180.00 0 0

26 (ii) Ordinary Kilometer Stone (Precast) EACH 3072.00 3 9216

27 (iii) 200 m stone (precast) EACH 648.00 8 5184

9.9 Boundary Pillar

Reinforced cement concrete M15 grade boundary pillars/local

stone of standard design as per IRC:25, fixed in position

28 EACH 724.00 0 0

including finishing and lettering but excluding painting as per

drawing and Technical Specification Clause 1704

Providing & Laying Cement Concrete Pipe NP3 on first class

bedding of granular material including fixing collar with cement

29 7.6 (A)

sand mortar 1:2 but excluding excavation, protection works,

RM 4099.00 90 368910

backfilling, concrete and masonary work in head wall and

parapets as per clause 1106 .(A) 600 mm Dia.

Providing & Laying Cement Concrete Pipe NP3 on first class

bedding of granular material including fixing collar with cement

30 7.6 (D) sand mortar 1:2 but excluding excavation, protection works, RM 1581.00 0 0

backfilling, concrete and masonary work in head wall and

parapets as per clause 1106 .(A) 300 mm Dia.

Excavation for Structure as per drawing and technical

specifications Clause 305.1 including setting out, construction of

31 7.1 shoring and bracing, removal of stumps and other deleterious cum 354.00 40 14160

material and disposal upto a lead of 50 m, dressing of sides and

bottom and backfilling in trenches with excavated suitable

material.

Construction of Plain Cement Concrete Drain with P.C.C.

grade M-15 including all shuttering/form work etc. complete

32 6.5 Cum 5335 19.95 106433.25

as per drawings/technical specification and direction of

engineer in charge.

Providing and laying reinforced cement concrete in

33 7.27 I superstructure as per drawing and technical specifications Cum 6839 1.05 7180.95

Clauses 800, 1205.4 and 1205.5 R.C.C. grade M 20 1:2:4

Supplying, fitting, and placing HYSD bar reinforcement in

34 7.28 superstructure complete as per drawing and technical mt 76384.00 0.0315 2406.096

specifications Clauses 1002, 1010 and 1202

Road marking with Hot Applied Thermoplastic Compound with

Reflectorizing Glass Beads on Bituminous Surface (Providing

and laying of hot applied thermoplastic compound 2.5 mm thick

35 9.18 including reflectorizing glass beads @ 250 gms per sqm area, sqm 1266.00 6 7596

thickness of 2.5 mm is exclusive of surface applied glass beads

as per IRC: 35. The finished surface to be level, uniform and free

from streaks and holes.)

Road Work Total Amount 3884628.3

Excavation for Structure as per drawing and technical

specifications Clause 305.1 including setting out, construction of

36 7.1 shoring and bracing, removal of stumps and other deleterious cum 354.0 248.67 88029.18

material and disposal upto a lead of 50 m, dressing of sides and

bottom and backfilling in trenches with excavated suitable

material.

Providing concrete for plain/reinforced concrete in open

foundations complete as per drawings and technical specification

37 7.1 O(I) Clause 802,803,1202 & 1203 cum 5,107.0 10.11 51631.77

I. P.C.C grade M 10 (Nominal mix 1:3:6)

Providing concrete for plain/reinforced concrete in open

foundations complete as per drawings and technical specification

38 7.1 O(III) Clause 802,803,1202 & 1203 cum 5,713.0 149.4 853522.2

III. P.C.C grade M 20(Nominal mix (1:2:4)

Providing concrete for plain/reinforced concrete in substructure

complete as per drawings and technical specification Clause

39 7.18(II) cum 6,042.0 105 634410

802,804,805,806,807,1202 & 1204,

For height upto 5 m

II. P.C.C. grade M 20 (Nominal mix (1:2:4

Providing and laying concrete for reinforced cement concrete in

40 7.27 superstructure as per drawing and technical specification Clause cum 7,312.0 12.27 89718.24

800,1205.4 & 1205.5

R.C.C. grade M 25 (Design Mix)

Providing and laying cement concrete wearing course M-30

41 7.31 grade including reinforcement complete as per drawing and cum 12,727.0 0 0

technical specification.

Supplying, fitting, and placing HYSD bar reinforcement in

42 7.28 superstructure complete as per drawing and technical MT 76,384.0 0.90252 68938.08768

specifications Clauses 1002, 1010 and 1202

Providing weepholes in brick masonry/stone masonry, plain/

reinforced concrete abutment, wing wall, return wall with 100

43 7.22 mm dia AC pipe extending through the full width of the NOS 335.0 54 18090

structures with slope of 1(V):20(H) towards drawing face

complete as per drawing and technical specification Clauses 614,

709, 1204.3.7

Providing and laying filter media with granular crushed

aggregates as per specification to a thickness of not less than 600

44 7.24 mm with smaller size towards the soil and bigger size towards cum 1,807.0 18.12 32742.84

the wall and providing over the entire surface behind abutment,

wing wall, return wall to the full height, compacted to firm

condition complete as per drawing and technical specification

Clause 1204.3.8

Filler Joint

(II) Providing and fixing 20 mm thick compressible fibre board

45 7.41 in expansion joint complete as per drawing and technical RM 431.0 36 15516

specifications

Backfilling behind abutment, wing wall and return wall complete

46 7.23 as per drawings & technical specification Clause 1204.3.8 I) cum 1,025.0 36.36 37269

Granular material

CD Work Total Amount 1889867.3177

TOTAL AMOUNT 5774496

47 1st Year Routine maintenance km 30000.00 1.9 57000

48 2nd Year Routine maintenance km 40000.00 1.9 76000

49 3rd Year Routine maintenance km 70000.00 1.9 133000

50 4th Year Routine maintenance km 110000.00 1.9 209000

51 5th Year Routine maintenance km 150000.00 1.9 285000

Routine Maintenance Total Amount 760000

Grand TOTAL AMOUNT 6534496

TOTAL AMOUNT Say in lakh 65.34

Sub Engineer Assistant Engineer Exe. Engineer

PIU CGRRDA PIU CGRRDA PIU CGRRDA

Dantewada Dantewada Dantewada

Bill of Quantity

PIU Name & No:- Project Implementation Unit 01,PRADHAN MANTRI GRAM SADAK YOJNA DANTEWADA

Name of Road :-KIRANDUL KADAMPAL TO BOJIPARA ROAD 100-249

Package No.:-CG-03-200 (V)

KIRANDUL

Name of Road KADAMPAL TO

Item BOJIPARA ROAD

S.No. Description

NO.

UOM RATE QTY Amount

Setting Out Setting Out work complete with construction of

bench mark (Min 1 per km) working benchmark (Min 4 per km)

and near all bridges and cross - drainage works made of

bricks/stone masonary or concrete and reference pillars made of

precast concrete poles/concrete filled100mm dia A.C. pipe @

100 m interval of as required on both sides of the formation

1 2.1 km 20955.00 2.000 41910

width, marking on central line, setting out curves and recording

of central line levels and other required levels and distances etc.

levels and other required levels and distances etc. including

setting out of cross- drainge structures & bridges with required

reference pillars and marking etc. as directed by engineer-in-

Charge.

Clearing Grass and Removal of Rubbish Clearing grass and

removal of rubbish up to a distance of 30 m outside the

2 2.2 sqm 1 12000 12000

periphery of the area as per Technical Specification Clause 201.

By Manual Means

Loosening, Levelling and Compacting original ground/existing

embankment/supporting embankment to facilitate placement of

first layer of embankment, scarified to a depth of 150 mm, mixed

3 3.2 with water at OMC and then compacted by rolling so as to cum 29.00 1800 52200

achieve minimum dry density as given in Tables 300.1 and 300.2

for embankment construction as per Technical Specification

Clause 301.4.1.

Surface Drains in Soil Construction of unlined surface drains

4 3.8 (i) of average cross-sectional area 0.40 sqm in soil to specified M 88.00 939 82632

lines, grades, levels and dimensions. Excavated material to be

used in embankment with a lift upto 3m and lead of 50 m

(average lead 25 m) as per Technical Specification Clause 307.

Excavation in Cutting in Soil by manual means with lead upto 50

5 3.5 (I) mExcavation for roadway in soil for carrying of cut earth to cum 91.00 0 0

embankment site with a lift upto 1.5 m and lead upto 50 m as per

Technical Specification Clause 302.3

Construction of Embankment with Material Obtained from

Roadway Cutting Construction of embankment with approved

6 3.3 (I) materials deposited at site from roadway cutting and excavation CUM 77 817.734 62965.518

from drain and foundation of other structures graded and

compacted to meet requirement of Tables 300.1 and 300.2 as per

Technical Specification Clause 301.5

Construction of Embankment with Material Obtained from Pits

7 3.4 (ll) Construction of embankment with approved material obtained cum 246 4907.6923 1207292.2997

from borrow pits, transporting to site, spreading, grading to

required slope and compacting to meet requirement of Tables

300.1 and 300.2 (Beyond 250m)with all leads as per Technical

Specification Clause 301.5(Having CBR more than 5)

Construction of Subgrade and Earthen Shoulders Construction of

subgrade and earthen shoulders with approved material

(Granular material having CBR more than 7) obtained from

8 3.12 (A) borrow pits with all lifts and leads, transporting to site, cum 252 0 0

spreading, grading to required slope and compacted to meet

requirement of Table 300.2 as per Technical Specification

Clause 303.1.