Professional Documents

Culture Documents

Trane air handling unit proposal and price list

Uploaded by

hanamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trane air handling unit proposal and price list

Uploaded by

hanamanCopyright:

Available Formats

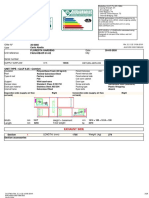

Offer N° 19-0022 Rel. 3.3.1.

30 12-02-2018-

User HC1 AHU1050/1000/1789.384

Client CHAM PALACE Date 10-09-2019

Project City

Serial number

This proposal is subject to the application of Trane’s General Conditions of Sale, attached hereafter. Any order or agreement, based on

or resulting from this proposal, or subsequent versions of this proposal, will be governed by these Trane’s General Con

However, this proposal is based upon the following project specific terms:

- Delivery: To be agreed

- Validity of Offer: 30 days

- Payment conditions: To be agreed

- Warranty: Standard Trane

- Supply: Ex factory

- Start up: on request

- Documentation: Standard Trane

- VAT and other taxes: not included

- What not explicitely mentioned: excluded

In case of conflict between the project’s specific terms and Trane’s General Conditions of Sale, the specific terms shall prevail.

CLCFWin Rel. 3.3.1.30 12-02-2018- 1/37

AHU1050/1000/1789.384

Unit reference Model Qty Unitary price Total list price

AHU-1 CLCF 6 1

AHU-2 CLCF 3.5 1

AHU-3 CLCF 2.5 1

AHU-4 CLCF 1.5 1

AHU-5 CLCF 5 1

AHU-6 CLCF 6 1

Total price 6

Your contacts for any question regarding this proposal:

Sales Engineer Customer Support Commercial Manager

CLCFWin Rel. 3.3.1.30 12-02-2018- 2/37

AHU1050/1000/1789.384

Modelbox CLCF PU50 (EN 1886)

- Casing Strength: D1

- Air Leakage: L1

- Filter Bypass: F9

- Thermal Transmittance: T2

- Thermal Bridging: TB2

TRANE participates in the ECC programme for

Air Handling Units (AHU); check ongoing validity

of certificate online

www.eurovent-certification.com or using

www.certiflash.com.

SFP 1.7 W/l/s = 1.7 kW/m3/s calculated using

EN BS 13779 standards.

Designed at mid-point filter status, wet coil

condition.

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/414.425

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-1 City

Project

Serial number

SUPPLY AIRFLOW m³/h 16000 RETURN AIRFLOW // m³/h

UNIT TYPE - CLCF 6 - Comfort

Insulation Polyurethane Foam (40 kg/m3) Panel thickness mm: 50

Roof Absent Panel internal side Galvanised Steel

Type of roof Absent Panel external side Painted Galvanised Steel

Absent/No Roof Coil conn cabinet Absent

Support With baseframe Door type With hinges

Damper class Standard: Class 2 EN1751 Screw and bolts Galvanised Steel (standard)

Drain pan material Galvanised Steel Packing type: Hygienic packing

Internal frame Galvanised Steel Eyes bolts Absent

Inspection side (supply air flow Right Connection side (supply air flow Right

on back) on back)

Width mm 1923 Height + basement mm 1314 + 100

Length mm 3395 Total weight kg 1190

SUPPLY SIDE

Section 1 LENGTH: (mm) 2005 Weight :(kg) 813

Section accessories

CLCFWin Rel. 3.3.1.30 12-02-2018- 3/37

AHU1050/1000/414.425

Mixing Box ALUMINIUM PROFILE DAMPERS

Fresh air damper - 1 off insp.side shaft dimensions 410x1813 mm.

Airflow 16000 m³/h

Motorisable (linkage not incl.)

Actuator absent

With blade gasket (Leakage Class 2 according to EN1751)

Return damper - 1 off insp.side shaft dimensions 410x1813 mm.

Airflow 16000 m³/h

Motorisable (linkage kit not included)

Actuator absent

With blade gasket (Leakage Class 2 according to EN1751)

Ricirculation factor % : 85

Total pressure drop section 22 Pa

MATERIAL DIMENSIONS N. EFFICIENCY

Soft Bag Filter Synthetic fiber 592 x 592 x 48 mm 6 class G4 EN779 DP CL(Pa) 68+180

class F9 EN779 (E) DP MP(Pa) 101+270

Synthetic fiber 592 x 592 x 535 mm 6 Des. Temp. 16.6 °C DP DT(Pa) 135+359

Vtunnel 2.01 m/s

Filter frame Galvanised Steel

Side removal

TUBES Cu/0.4 TYPE 60x30 CAPAC. (kW) 134.0 FLUID Water

Cooling coil FINS Al/0.11 DIM (mm) 1140x1570 EAT/RH (°C-%) 27.0-56 FLOW. (Kg/h) 22983

FRAME Zn/1.5 ROWS (n) 8 LAT/RH (°C-%) 12.0-100 EWT/LWT 7 12

(°C)

CONN.Ø. 2 1/2" F.SPACE (mm) 2 Vcoilface 2.48 DP (kPa) 50

VOL. (lt) 62.3 CIRCUITS (n) 19 DP tot/dry (Pa) 235/113

FTA (mm) 1775

Sens./Tot. 0.61

Cu-Al-FeZn P60AR 8R-19T-1570A-2.0pa 19C 2 1/2"

Total pressure drop section 235 Pa

TUBES Cu/0.4 TYPE 40x34.6 CAPAC. (kW) 67.0 FLUID Water

Heating coil FINS Al/0.11 DIM (mm) 1160x1570 EAT (°C) 16.6 FLOW. (Kg/h) 5769

FRAME Zn/1.5 ROWS (n) 1 LAT (°C) 28.9 EWT/LWT (°C) 80 70

CONN.Ø. 1 1/4" F.SPACE (mm) 3 Vcoilface 2.48 DP (kPa) 13.4

VOL. (lt) 13.0 CIRCUITS (n) 7 DP tot/dry (Pa) 21/21

FTA (mm) 1745

Cu-Al-FeZn P40AC 1R-29T-1570A-3.0pa 7C 1 1/4"

Total pressure drop section 21 Pa

Section 2 LENGTH: (mm) 1390 Weight :(kg) 378

Section accessories

CLCFWin Rel. 3.3.1.30 12-02-2018- 4/37

AHU1050/1000/414.425

FAN TYPE Forward curved AIRFLOW 16000 m³/h

Supply Fan SIZE TLZ450R EXTERNAL STATIC PRESSURE 200 Pa

MATERIAL Galvanised Steel TOTAL STATIC PRESSURE 849 Pa

PROTECTION Galvanised Steel RPM 1032 rpm

PULLEY - F35 ABSORBED POWER 6.3 kW

BELT DRIVE A EFFICIENCY STATIC/TOTAL 60/68 %

FAN DICHARGE VELOCITY: 13.73 m/s

FAN DICHARGE DIMENSION: L 569 mm - H 569 mm

In duct sound power: (dBA) 89.3

Octave in duct power level

F [Hz] 63 125 250 500 1000 2000 4000 8000

Supply [dB] 87 85 85 84 85 80 79 74

SL430*290-DM1170*660

GR2-1*5-1*6-1*6-1*6

Adjustable pitch pulley

Rubber insulators

With flexible connection on fan dicharge

PROTECTION IP 55 RPM 1440

Motor IE2 INSULATION CLASS F POWER SUPPLY 400V/3ph/50Hz

POLES N. 4 STARTING TYPE Star-Delta

INSTALLED POWER 7.5 kW RATED AMPS (A) 15.3

PULLEY VAR - F38 MAX AMPS (A) 107.1

MOTOR 50 Hz POWER INPUT: (kW) 7.67

SFPv (SFPe): (W/l/s) 1.7

CLCFWin Rel. 3.3.1.30 12-02-2018- 5/37

AHU1050/1000/414.425

AHU sound levels Octave band (dB/Hz)

Tot. dB(A) 63 125 250 500 1000 2000 4000 8000

Sound power level supply inlet 82 73 81 67 80 79 63 51 44

Sound power level supply outlet 89 83 87 89 84 85 79 76 72

Sound power level return inlet

Sound power level return outlet

Airborne sound power 65 66 60 65 59 55 38 34

- before installing the unit, read the IOM

- unit is designed at 0 m on sea level, and with air density 1,2 kg/m3

- make the electrical wiring following the drawing inside of the motor power box or on motor label

- to avoid electrical motors overload, do not start the unit without filters or other component or without ducts or with door open

- the unit has been designed with the required external static pressure and considering a status of filters: with plant pressure drop less

then the required, with different status of filters and without proper control, the airflow and the sound power will be more than the

indicated

- the cross flow recuperator has been designed in order to resist to the indicated differential pressure between the plates. Do not exceed

this value enslaving properly dampers or other interception devices. RHW and PHE are not airtight devices and leakage between flows

always occurs. Exact value can depends on static pressure and unit configuration; to avoid contamination, the pressures on the fresh air

side shall be higher than on the return air side

- performance data of the heat recuperator are considered for counterflow of air; in case both flows are in same direction, performance

data could be substantially different from those

-If footprint of PHE section or of other sections exceed 2300 mm x 2400 mm, a special transport could be necessary. Please contact the

factory

- unit is designed for a maximum air temperature of 55°C

- depending on supply air temperature and outdoor condition, condensate on profiles can occur

- if water temperature entering the coil is below 1°C, freezing of coil fins can occur

- link the fan working to intercepting devices, as dampers or similar, avoiding fan working with those devices closed

- filter frame “side removable” could cause filter bypass due to not perfect airtight between filter cells

- if unit is provide of roof in kit, it will be provide separately, to mount on site by customer

- standard painted panel skin colour RAL9002

- if the door lenght is < 360 mm, also if selected, the inspection window will not be provided - in some cases

the inspection window could be partially occluded by components or components frame

- calculate sound pressure levels are indicative only. It corresponds to: free filed hemispheric sound radiation from the unit casing, the

inlet and outlet opening. Other sources, acoustic character of the room, air flow noise, duct connection and vibration can influence the

sound pressure in dependence. In practise, therefore measured values on site may be different from the calculation ones

- unit has been designed in wet condition

- unit weight does not include water/refrigerant and control (if provided)

- tolerance on sound levels are: - airborne level : +/-3 Db; duct level : +/-5 Db @ 63-125 Hz

and +/-3 Db @ 250-8000 Hz

- due to the gasket between sections, the total length of the unit will be around mm.5+ longer for each break point

- dimensions of CLCF unit could be increase by mm.4 due to the plastic profile

- in case unit is provided of flat roof, it will be mm.20 out all around the unit

- in case unit is provided of sloped roof, it will be mm.100 out all around the unit

- due to bigger heater and bends, the steam coil finned area will be light reduced respect what indicated, with consequent increase of

the air velocity thought it

-based on dimensions mentioned in datasheet, a special transport could be required

- for FC units, it's possible to install the inspection doors only at the bottom

This technical sheet and the attached drawing is the only document reporting the air handling unit construction features, also if not in

conformity with offer or other requests/documents sent to us, including mechanical specifications, technical description or similar.

For general construction features not indicated in it, refer to available documentation.

CLCFWin Rel. 3.3.1.30 12-02-2018- 6/37

AHU1050/1000/414.425

Ecodesign

Manufacturer TRANE

Unit model CLCF 6

Typology NRVU;UVU

SFPint / SFPint limit 2016 [W/(m³/s)]

SFPint / SFPint limit 2018 [W/(m³/s)] 199 / 230

Type of HRS -

Thermal efficiency of heat recovery [%] -

Class of casing leakage at -400 Pa / +400 Pa L1(M) / L1(M)

Maximum internal leakage rate [%] L1(M)

Supply

Nominal flow rate [m³/s] 4.44

Type of drive for var. speed scheduled inst. of var. speed drive

Effective electric power input [Kw] 8.1

Face velocity [m/s] 2.01

Nominal external pressure [Pa] 200

Internal pressure drop of ventilation components [Pa] 93

Static efficiency of fan [%] 46.7

Energy consumption of the filters (kWh/annum) D

Internet address for disassembly instructions

AHU doesn't fall under Ecodesign

CLCFWin Rel. 3.3.1.30 12-02-2018- 7/37

AHU1050/1000/414.425

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/414.425

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-1 City

Project

Serial number

Supply Fan

FAN TYPE Forward curved SIZE TLZ450R

P. Tot. [Pa]

66 63 58

11 67

7.5 52

66

1733 55 62

46 1500

5.5

1390

37

1367 [dB]

4 1280

30

3 1170

1000 22

18.5

2.2 1060

15

950

633 1.5 11

1.1 840

7.5

0.8 730

5.5

0.6 4

620

267 0.4 3

5102.2

0.2 0.6

[kW] 0.3 0.4 0.8 4001.1

1.1 9.2 17.4 25.5 33.6 41.8 49.9

Qx1000 [m3/h]

Airflow 16000 m³/h Fan efficiency 60/68 %

EXTERNAL STATIC PRESSURE 200 Pa RPM 1032 rpm

Internal pressure drops of AHU 649 Pa ABSORBED POWER 6.3 kW

Dynamic pressure 113 Pa Sound power level 89.3 db(A)

CLCFWin Rel. 3.3.1.30 12-02-2018- 8/37

AHU1050/1000/414.425

Modelbox CLCF PU50 (EN 1886)

- Casing Strength: D1

- Air Leakage: L1

- Filter Bypass: F9

- Thermal Transmittance: T2

- Thermal Bridging: TB2

TRANE participates in the ECC programme for

Air Handling Units (AHU); check ongoing validity

of certificate online

www.eurovent-certification.com or using

www.certiflash.com.

SFP 1.6 W/l/s = 1.6 kW/m3/s calculated using

EN BS 13779 standards.

Designed at mid-point filter status, wet coil

condition.

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/289.627

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-2 City

Project

Serial number

SUPPLY AIRFLOW m³/h 10000 RETURN AIRFLOW // m³/h

UNIT TYPE - CLCF 3.5 - Comfort

Insulation Polyurethane Foam (40 kg/m3) Panel thickness mm: 50

Roof Absent Panel internal side Galvanised Steel

Type of roof Absent Panel external side Painted Galvanised Steel

Absent/No Roof Coil conn cabinet Absent

Support With baseframe Door type With hinges

Damper class Standard: Class 2 EN1751 Screw and bolts Galvanised Steel (standard)

Drain pan material Galvanised Steel Packing type: Hygienic packing

Internal frame Galvanised Steel Eyes bolts Absent

Inspection side (supply air flow Right Connection side (supply air flow Right

on back) on back)

Width mm 1617 Height + basement mm 1008 + 100

Length mm 2910 Total weight kg 855

SUPPLY SIDE

Section 1 LENGTH: (mm) 2910 Weight :(kg) 855

Section accessories

CLCFWin Rel. 3.3.1.30 12-02-2018- 9/37

AHU1050/1000/289.627

Intake Section ALUMINUM PROFILE DAMPER

Damper - 1 off insp.side shaft dimensions 310x1507 mm .

Airflow 10000 m³/h

Motorisable (linkage not incl.)

Actuator absent

With blade gasket (Leakage Class 2 according to EN1751)

Total pressure drop section 9 Pa

MATERIAL DIMENSIONS N. EFFICIENCY

Soft Bag Filter Synthetic fiber mm

592 x 592 x 48 2 class G4 EN779 DP CL(Pa) 55+149

287 x 592 x 48 mm 3 class F9 EN779 (E) DP MP(Pa) 82+224

Synthetic fiber 592 x 592 x 535 mm 2 Des. Temp. 4.0 °C DP DT(Pa) 109+298

287 x 592 x 535 mm 3 Vtunnel 2.02 m/s

Filter frame Galvanised Steel

Side removal

TUBES Cu/0.4 TYPE 60x30 CAPAC. (kW) 150.0 FLUID Water

Cooling coil FINS Al/0.11 DIM (mm) 840x1305 EAT/RH (°C-%) 34.0-59 FLOW. (Kg/h) 25727

FRAME Zn/1.5 ROWS (n) 8 LAT/RH (°C-%) 14.4-100 EWT/LWT 7 12

(°C)

CONN.Ø. 2 1/2" F.SPACE (mm) 2 Vcoilface 2.53 DP (kPa) 41

VOL. (lt) 40.5 CIRCUITS (n) 19 DP tot/dry (Pa) 263/119

FTA (mm) 1510

Sens./Tot. 0.45

Cu-Al-FeZn P60AR 8R-14T-1305A-2.0pa 19C 2 1/2"

Total pressure drop section 263 Pa

TUBES Cu/0.4 TYPE 60x30 CAPAC. (kW) 80.3 FLUID Water

Heating coil FINS Al/0.11 DIM (mm) 840x1305 EAT (°C) 4.0 FLOW. (Kg/h) 6912

FRAME Zn/1.5 ROWS (n) 2 LAT (°C) 27.7 EWT/LWT (°C) 80 70

CONN.Ø. 1 1/2" F.SPACE (mm) 2.5 Vcoilface 2.53 DP (kPa) 13.7

VOL. (lt) 11.3 CIRCUITS (n) 7 DP tot/dry (Pa) 25/25

FTA (mm) 1485

Cu-Al-FeZn P60AC 2R-14T-1305A-2.5pa 7C 1 1/2"

Total pressure drop section 25 Pa

FAN TYPE Forward curved AIRFLOW 10000 m³/h

Supply Fan SIZE TLZ400R EXTERNAL STATIC PRESSURE 200 Pa

MATERIAL Galvanised Steel TOTAL STATIC PRESSURE 802 Pa

PROTECTION Galvanised Steel RPM 1138 rpm

PULLEY - F30 ABSORBED POWER 3.6 kW

BELT DRIVE A EFFICIENCY STATIC/TOTAL 62/67 %

FAN DICHARGE VELOCITY: 10.81 m/s

FAN DICHARGE DIMENSION: L 507 mm - H 507 mm

In duct sound power: (dBA) 86.1

Octave in duct power level

F [Hz] 63 125 250 500 1000 2000 4000 8000

Supply [dB] 83 81 82 81 82 77 76 71

SL430*290-DM1090*600

GR2-1*5-1*6-1*5-1*5

Adjustable pitch pulley

Rubber insulators

With flexible connection on fan dicharge

CLCFWin Rel. 3.3.1.30 12-02-2018- 10/37

AHU1050/1000/289.627

PROTECTION IP 55 RPM 1440

Motor IE2 INSULATION CLASS F POWER SUPPLY 400V/3ph/50Hz

POLES N. 4 STARTING TYPE Star-Delta

INSTALLED POWER 5.5 kW RATED AMPS (A) 11.5

PULLEY VAR - F38 MAX AMPS (A) 73.6

MOTOR 50 Hz POWER INPUT: (kW) 4.49

SFPv (SFPe): (W/l/s) 1.6

CLCFWin Rel. 3.3.1.30 12-02-2018- 11/37

AHU1050/1000/289.627

AHU sound levels Octave band (dB/Hz)

Tot. dB(A) 63 125 250 500 1000 2000 4000 8000

Sound power level supply inlet 78 70 78 63 77 76 60 48 41

Sound power level supply outlet 85 79 83 86 81 82 76 73 69

Sound power level return inlet

Sound power level return outlet

Airborne sound power 62 62 57 62 56 52 35 31

- before installing the unit, read the IOM

- unit is designed at 0 m on sea level, and with air density 1,2 kg/m3

- make the electrical wiring following the drawing inside of the motor power box or on motor label

- to avoid electrical motors overload, do not start the unit without filters or other component or without ducts or with door open

- the unit has been designed with the required external static pressure and considering a status of filters: with plant pressure drop less

then the required, with different status of filters and without proper control, the airflow and the sound power will be more than the

indicated

- the cross flow recuperator has been designed in order to resist to the indicated differential pressure between the plates. Do not exceed

this value enslaving properly dampers or other interception devices. RHW and PHE are not airtight devices and leakage between flows

always occurs. Exact value can depends on static pressure and unit configuration; to avoid contamination, the pressures on the fresh air

side shall be higher than on the return air side

- performance data of the heat recuperator are considered for counterflow of air; in case both flows are in same direction, performance

data could be substantially different from those

-If footprint of PHE section or of other sections exceed 2300 mm x 2400 mm, a special transport could be necessary. Please contact the

factory

- unit is designed for a maximum air temperature of 55°C

- depending on supply air temperature and outdoor condition, condensate on profiles can occur

- if water temperature entering the coil is below 1°C, freezing of coil fins can occur

- link the fan working to intercepting devices, as dampers or similar, avoiding fan working with those devices closed

- filter frame “side removable” could cause filter bypass due to not perfect airtight between filter cells

- if unit is provide of roof in kit, it will be provide separately, to mount on site by customer

- standard painted panel skin colour RAL9002

- if the door lenght is < 360 mm, also if selected, the inspection window will not be provided - in some cases

the inspection window could be partially occluded by components or components frame

- calculate sound pressure levels are indicative only. It corresponds to: free filed hemispheric sound radiation from the unit casing, the

inlet and outlet opening. Other sources, acoustic character of the room, air flow noise, duct connection and vibration can influence the

sound pressure in dependence. In practise, therefore measured values on site may be different from the calculation ones

- unit has been designed in wet condition

- unit weight does not include water/refrigerant and control (if provided)

- tolerance on sound levels are: - airborne level : +/-3 Db; duct level : +/-5 Db @ 63-125 Hz

and +/-3 Db @ 250-8000 Hz

- due to the gasket between sections, the total length of the unit will be around mm.5+ longer for each break point

- dimensions of CLCF unit could be increase by mm.4 due to the plastic profile

- in case unit is provided of flat roof, it will be mm.20 out all around the unit

- in case unit is provided of sloped roof, it will be mm.100 out all around the unit

- due to bigger heater and bends, the steam coil finned area will be light reduced respect what indicated, with consequent increase of

the air velocity thought it

-based on dimensions mentioned in datasheet, a special transport could be required

- for FC units, it's possible to install the inspection doors only at the bottom

This technical sheet and the attached drawing is the only document reporting the air handling unit construction features, also if not in

conformity with offer or other requests/documents sent to us, including mechanical specifications, technical description or similar.

For general construction features not indicated in it, refer to available documentation.

CLCFWin Rel. 3.3.1.30 12-02-2018- 12/37

AHU1050/1000/289.627

Ecodesign

Manufacturer TRANE

Unit model CLCF 3.5

Typology NRVU;UVU

SFPint / SFPint limit 2016 [W/(m³/s)]

SFPint / SFPint limit 2018 [W/(m³/s)] 170 / 230

Type of HRS -

Thermal efficiency of heat recovery [%] -

Class of casing leakage at -400 Pa / +400 Pa L1(M) / L1(M)

Maximum internal leakage rate [%] L1(M)

Supply

Nominal flow rate [m³/s] 2.78

Type of drive for var. speed scheduled inst. of var. speed drive

Effective electric power input [Kw] 4.7

Face velocity [m/s] 2.02

Nominal external pressure [Pa] 200

Internal pressure drop of ventilation components [Pa] 80

Static efficiency of fan [%] 47.1

Energy consumption of the filters (kWh/annum) D

Internet address for disassembly instructions

AHU doesn't fall under Ecodesign

CLCFWin Rel. 3.3.1.30 12-02-2018- 13/37

AHU1050/1000/289.627

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/289.627

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-2 City

Project

Serial number

Supply Fan

FAN TYPE Forward curved SIZE TLZ400R

P. Tot. [Pa]

64 60

55

66

7.5 50

65

1733 49 60

44 1700

5.5

1580

30

1367 [dB]

4

1460

22

3

1340

1000 18.5

2.2 15

1220

1.5 11

1100

633

1.1 980

7.5

0.8 8605.5

0.6 4

0.4 3740

267

6202.2

0.2 0.3 0.4 0.6 0.8

[kW] 1.1

500

0.8 7.3 13.9 20.4 26.9 33.5 40

Qx1000 [m3/h]

Airflow 10000 m³/h Fan efficiency 62/67 %

EXTERNAL STATIC PRESSURE 200 Pa RPM 1138 rpm

Internal pressure drops of AHU 602 Pa ABSORBED POWER 3.6 kW

Dynamic pressure 70 Pa Sound power level 86.1 db(A)

CLCFWin Rel. 3.3.1.30 12-02-2018- 14/37

AHU1050/1000/289.627

Modelbox CLCF PU50 (EN 1886)

- Casing Strength: D1

- Air Leakage: L1

- Filter Bypass: F9

- Thermal Transmittance: T2

- Thermal Bridging: TB2

TRANE participates in the ECC programme for

Air Handling Units (AHU); check ongoing validity

of certificate online

www.eurovent-certification.com or using

www.certiflash.com.

SFP 1.6 W/l/s = 1.6 kW/m3/s calculated using

EN BS 13779 standards.

Designed at mid-point filter status, wet coil

condition.

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/212.075

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-3 City

Project

Serial number

SUPPLY AIRFLOW m³/h 6000 RETURN AIRFLOW // m³/h

UNIT TYPE - CLCF 2.5 - Comfort

Insulation Polyurethane Foam (40 kg/m3) Panel thickness mm: 50

Roof Absent Panel internal side Galvanised Steel

Type of roof Absent Panel external side Painted Galvanised Steel

Absent/No Roof Coil conn cabinet Absent

Support With baseframe Door type With hinges

Damper class Standard: Class 2 EN1751 Screw and bolts Galvanised Steel (standard)

Drain pan material Galvanised Steel Packing type: Hygienic packing

Internal frame Galvanised Steel Eyes bolts Absent

Inspection side (supply air flow Right Connection side (supply air flow Right

on back) on back)

Width mm 1617 Height + basement mm 708 + 100

Length mm 2775 Total weight kg 627

SUPPLY SIDE

Section 1 LENGTH: (mm) 2775 Weight :(kg) 627

Section accessories

CLCFWin Rel. 3.3.1.30 12-02-2018- 15/37

AHU1050/1000/212.075

Mixing Box ALUMINIUM PROFILE DAMPERS

Fresh air damper - 1 off insp.side shaft dimensions 310x1507 mm.

Airflow 6000 m³/h

Motorisable (linkage not incl.)

Actuator absent

With blade gasket (Leakage Class 2 according to EN1751)

Return damper - 1 off insp.side shaft dimensions 310x1507 mm.

Airflow 6000 m³/h

Motorisable (linkage kit not included)

Actuator absent

With blade gasket (Leakage Class 2 according to EN1751)

Ricirculation factor % : 85

Total pressure drop section 22 Pa

MATERIAL DIMENSIONS N. EFFICIENCY

Soft Bag Filter Synthetic fiber mm

592 x 592 x 48 2 class G4 EN779 DP CL(Pa) 60+161

287 x 592 x 48 mm 1 class F9 EN779 (E) DP MP(Pa) 90+242

Synthetic fiber 592 x 592 x 535 mm 2 Des. Temp. 18.4 °C DP DT(Pa) 120+322

287 x 592 x 535 mm 1 Vtunnel 1.81 m/s

Filter frame Galvanised Steel

Side removal

TUBES Cu/0.4 TYPE 40x34.6 CAPAC. (kW) 42.3 FLUID Water

Cooling coil FINS Al/0.11 DIM (mm) 560x1305 EAT/RH (°C-%) 26.0-54 FLOW. (Kg/h) 7255

FRAME Zn/1.5 ROWS (n) 5 LAT/RH (°C-%) 12.1-100 EWT/LWT 7 12

(°C)

CONN.Ø. 1 1/2" F.SPACE (mm) 2 Vcoilface 2.37 DP (kPa) 38.4

VOL. (lt) 22.5 CIRCUITS (n) 7 DP tot/dry (Pa) 141/97

FTA (mm) 1485

Sens./Tot. 0.67

Cu-Al-FeZn P40AR 5R-14T-1305A-2.0pa 7C 1 1/2"

Total pressure drop section 141 Pa

TUBES Cu/0.4 TYPE 40x34.6 CAPAC. (kW) 27.5 FLUID Water

Heating coil FINS Al/0.11 DIM (mm) 560x1305 EAT (°C) 18.4 FLOW. (Kg/h) 2368

FRAME Zn/1.5 ROWS (n) 1 LAT (°C) 31.8 EWT/LWT (°C) 80 70

CONN.Ø. 3/4" F.SPACE (mm) 3 Vcoilface 2.37 DP (kPa) 23.2

VOL. (lt) 4.8 CIRCUITS (n) 3 DP tot/dry (Pa) 19/19

FTA (mm) 1465

Cu-Al-FeZn P40AC 1R-14T-1305A-3.0pa 3C 3/4"

Total pressure drop section 19 Pa

CLCFWin Rel. 3.3.1.30 12-02-2018- 16/37

AHU1050/1000/212.075

FAN TYPE Forward curved AIRFLOW 6000 m³/h

Supply Fan SIZE TLZ280R EXTERNAL STATIC PRESSURE 200 Pa

MATERIAL Galvanised Steel TOTAL STATIC PRESSURE 714 Pa

PROTECTION Galvanised Steel RPM 1556 rpm

PULLEY - F25 ABSORBED POWER 2.1 kW

BELT DRIVE A EFFICIENCY STATIC/TOTAL 57/65 %

FAN DICHARGE VELOCITY: 12.79 m/s

FAN DICHARGE DIMENSION: L 361 mm - H 361 mm

In duct sound power: (dBA) 86.5

Octave in duct power level

F [Hz] 63 125 250 500 1000 2000 4000 8000

Supply [dB] 81 79 81 80 81 79 77 71

SL340*290-DM820*430

GR1-1*2-1*2-1*2-1*3

Adjustable pitch pulley

Rubber insulators

With flexible connection on fan dicharge

PROTECTION IP 55 RPM 1420

Motor IE2 INSULATION CLASS F POWER SUPPLY 400V/3ph/50Hz

POLES N. 4 STARTING TYPE Direct

INSTALLED POWER 3 kW RATED AMPS (A) 6.5

PULLEY VAR - F28 MAX AMPS (A) 45.5

MOTOR 50 Hz POWER INPUT: (kW) 2.67

SFPv (SFPe): (W/l/s) 1.6

CLCFWin Rel. 3.3.1.30 12-02-2018- 17/37

AHU1050/1000/212.075

AHU sound levels Octave band (dB/Hz)

Tot. dB(A) 63 125 250 500 1000 2000 4000 8000

Sound power level supply inlet 76 67 75 61 74 74 58 46 39

Sound power level supply outlet 85 77 81 85 80 81 78 74 69

Sound power level return inlet

Sound power level return outlet

Airborne sound power 61 60 56 61 55 54 36 31

- before installing the unit, read the IOM

- unit is designed at 0 m on sea level, and with air density 1,2 kg/m3

- make the electrical wiring following the drawing inside of the motor power box or on motor label

- to avoid electrical motors overload, do not start the unit without filters or other component or without ducts or with door open

- the unit has been designed with the required external static pressure and considering a status of filters: with plant pressure drop less

then the required, with different status of filters and without proper control, the airflow and the sound power will be more than the

indicated

- the cross flow recuperator has been designed in order to resist to the indicated differential pressure between the plates. Do not exceed

this value enslaving properly dampers or other interception devices. RHW and PHE are not airtight devices and leakage between flows

always occurs. Exact value can depends on static pressure and unit configuration; to avoid contamination, the pressures on the fresh air

side shall be higher than on the return air side

- performance data of the heat recuperator are considered for counterflow of air; in case both flows are in same direction, performance

data could be substantially different from those

-If footprint of PHE section or of other sections exceed 2300 mm x 2400 mm, a special transport could be necessary. Please contact the

factory

- unit is designed for a maximum air temperature of 55°C

- depending on supply air temperature and outdoor condition, condensate on profiles can occur

- if water temperature entering the coil is below 1°C, freezing of coil fins can occur

- link the fan working to intercepting devices, as dampers or similar, avoiding fan working with those devices closed

- filter frame “side removable” could cause filter bypass due to not perfect airtight between filter cells

- if unit is provide of roof in kit, it will be provide separately, to mount on site by customer

- standard painted panel skin colour RAL9002

- if the door lenght is < 360 mm, also if selected, the inspection window will not be provided - in some cases

the inspection window could be partially occluded by components or components frame

- calculate sound pressure levels are indicative only. It corresponds to: free filed hemispheric sound radiation from the unit casing, the

inlet and outlet opening. Other sources, acoustic character of the room, air flow noise, duct connection and vibration can influence the

sound pressure in dependence. In practise, therefore measured values on site may be different from the calculation ones

- unit has been designed in wet condition

- unit weight does not include water/refrigerant and control (if provided)

- tolerance on sound levels are: - airborne level : +/-3 Db; duct level : +/-5 Db @ 63-125 Hz

and +/-3 Db @ 250-8000 Hz

- due to the gasket between sections, the total length of the unit will be around mm.5+ longer for each break point

- dimensions of CLCF unit could be increase by mm.4 due to the plastic profile

- in case unit is provided of flat roof, it will be mm.20 out all around the unit

- in case unit is provided of sloped roof, it will be mm.100 out all around the unit

- due to bigger heater and bends, the steam coil finned area will be light reduced respect what indicated, with consequent increase of

the air velocity thought it

-based on dimensions mentioned in datasheet, a special transport could be required

- for FC units, it's possible to install the inspection doors only at the bottom

This technical sheet and the attached drawing is the only document reporting the air handling unit construction features, also if not in

conformity with offer or other requests/documents sent to us, including mechanical specifications, technical description or similar.

For general construction features not indicated in it, refer to available documentation.

CLCFWin Rel. 3.3.1.30 12-02-2018- 18/37

AHU1050/1000/212.075

Ecodesign

Manufacturer TRANE

Unit model CLCF 2.5

Typology NRVU;UVU

SFPint / SFPint limit 2016 [W/(m³/s)]

SFPint / SFPint limit 2018 [W/(m³/s)] 200 / 230

Type of HRS -

Thermal efficiency of heat recovery [%] -

Class of casing leakage at -400 Pa / +400 Pa L1(M) / L1(M)

Maximum internal leakage rate [%] L1(M)

Supply

Nominal flow rate [m³/s] 1.67

Type of drive for var. speed scheduled inst. of var. speed drive

Effective electric power input [Kw] 2.8

Face velocity [m/s] 1.81

Nominal external pressure [Pa] 200

Internal pressure drop of ventilation components [Pa] 85

Static efficiency of fan [%] 42.4

Energy consumption of the filters (kWh/annum) D

Internet address for disassembly instructions

AHU doesn't fall under Ecodesign

CLCFWin Rel. 3.3.1.30 12-02-2018- 19/37

AHU1050/1000/212.075

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/212.075

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-3 City

Project

Serial number

Supply Fan

FAN TYPE Forward curved SIZE TLZ280R

P. Tot. [Pa]

60 56

63

63 50

5.5 60

4

2067 49 56 44 2730

254022

3 [dB]

1633

18.5

2350

2.2

15

2160

1200

1.5 11

1970

1.1 1780

7.5

767

0.8 5.5

1590

0.6

14004

0.4 3

1210

2.2

333 0.3

0.2 1020

[kW] 1.1

830

0.8

0.3 640

0.4

0 3.6 7.2 10.8 14.3 17.9 21.5

Qx1000 [m3/h]

Airflow 6000 m³/h Fan efficiency 57/65 %

EXTERNAL STATIC PRESSURE 200 Pa RPM 1556 rpm

Internal pressure drops of AHU 514 Pa ABSORBED POWER 2.1 kW

Dynamic pressure 98 Pa Sound power level 86.5 db(A)

CLCFWin Rel. 3.3.1.30 12-02-2018- 20/37

AHU1050/1000/212.075

Modelbox CLCF PU50 (EN 1886)

- Casing Strength: D1

- Air Leakage: L1

- Filter Bypass: F9

- Thermal Transmittance: T2

- Thermal Bridging: TB2

TRANE participates in the ECC programme for

Air Handling Units (AHU); check ongoing validity

of certificate online

www.eurovent-certification.com or using

www.certiflash.com.

SFP 1.5 W/l/s = 1.5 kW/m3/s calculated using

EN BS 13779 standards.

Designed at mid-point filter status, wet coil

condition.

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/156.240

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-4 City

Project

Serial number

SUPPLY AIRFLOW m³/h 3000 RETURN AIRFLOW // m³/h

UNIT TYPE - CLCF 1.5 - Comfort

Insulation Polyurethane Foam (40 kg/m3) Panel thickness mm: 50

Roof Absent Panel internal side Galvanised Steel

Type of roof Absent Panel external side Painted Galvanised Steel

Absent/No Roof Coil conn cabinet Absent

Support With baseframe Door type With hinges

Damper class Standard: Class 2 EN1751 Screw and bolts Galvanised Steel (standard)

Drain pan material Galvanised Steel Packing type: Hygienic packing

Internal frame Galvanised Steel Eyes bolts Absent

Inspection side (supply air flow Right Connection side (supply air flow Right

on back) on back)

Width mm 1008 Height + basement mm 708 + 100

Length mm 2320 Total weight kg 443

SUPPLY SIDE

Section 1 LENGTH: (mm) 2320 Weight :(kg) 443

Section accessories

CLCFWin Rel. 3.3.1.30 12-02-2018- 21/37

AHU1050/1000/156.240

Intake Section ALUMINUM PROFILE DAMPER

Damper - 1 off insp.side shaft dimensions 210x898 mm .

Airflow 3000 m³/h

Motorisable (linkage not incl.)

Actuator absent

With blade gasket (Leakage Class 2 according to EN1751)

Total pressure drop section 9 Pa

MATERIAL DIMENSIONS N. EFFICIENCY

Soft Bag Filter Synthetic fiber mm

592 x 592 x 48 1 class G4 EN779 DP CL(Pa) 48+134

287 x 592 x 48 mm 1 class F9 EN779 (E) DP MP(Pa) 72+201

Synthetic fiber 592 x 592 x 535 mm 1 Des. Temp. 4.0 °C DP DT(Pa) 96+268

287 x 592 x 535 mm 1 Vtunnel 1.51 m/s

Filter frame Galvanised Steel

Side removal

TUBES Cu/0.4 TYPE 40x34.6 CAPAC. (kW) 47.0 FLUID Water

Cooling coil FINS Al/0.11 DIM (mm) 560x710 EAT/RH (°C-%) 34.0-59 FLOW. (Kg/h) 8061

FRAME Zn/1.5 ROWS (n) 5 LAT/RH (°C-%) 13.6-100 EWT/LWT 7 12

(°C)

CONN.Ø. 1 1/2" F.SPACE (mm) 2 Vcoilface 2.17 DP (kPa) 43.9

VOL. (lt) 14.5 CIRCUITS (n) 6 DP tot/dry (Pa) 135/86

FTA (mm) 890

Sens./Tot. 0.44

Cu-Al-FeZn P40AR 5R-14T-710A-2.0pa 6C 1 1/2"

Total pressure drop section 135 Pa

TUBES Cu/0.4 TYPE 40x34.6 CAPAC. (kW) 24.0 FLUID Water

Heating coil FINS Al/0.11 DIM (mm) 560x710 EAT (°C) 4.0 FLOW. (Kg/h) 2066

FRAME Zn/1.5 ROWS (n) 1 LAT (°C) 27.6 EWT/LWT (°C) 80 70

CONN.Ø. 3/4" F.SPACE (mm) 2 Vcoilface 2.17 DP (kPa) 29.2

VOL. (lt) 3.2 CIRCUITS (n) 2 DP tot/dry (Pa) 18/18

FTA (mm) 870

Cu-Al-FeZn P40AC 1R-14T-710A-2.0pa 2C 3/4"

Total pressure drop section 18 Pa

FAN TYPE Forward curved AIRFLOW 3000 m³/h

Supply Fan SIZE TLZ250R EXTERNAL STATIC PRESSURE 200 Pa

MATERIAL Galvanised Steel TOTAL STATIC PRESSURE 634 Pa

PROTECTION Galvanised Steel RPM 1671 rpm

PULLEY - F20 ABSORBED POWER 1 kW

BELT DRIVE A EFFICIENCY STATIC/TOTAL 56/59 %

FAN DICHARGE VELOCITY: 8.04 m/s

FAN DICHARGE DIMENSION: L 322 mm - H 322 mm

In duct sound power: (dBA) 83.2

Octave in duct power level

F [Hz] 63 125 250 500 1000 2000 4000 8000

Supply [dB] 73 74 77 76 80 75 74 68

SL270*195-DM700*380

GR1-1*1-1*2-1*1-1*2

Adjustable pitch pulley

Rubber insulators

With flexible connection on fan dicharge

CLCFWin Rel. 3.3.1.30 12-02-2018- 22/37

AHU1050/1000/156.240

PROTECTION IP 55 RPM 1400

Motor IE2 INSULATION CLASS F POWER SUPPLY 400V/3ph/50Hz

POLES N. 4 STARTING TYPE Direct

INSTALLED POWER 1.5 kW RATED AMPS (A) 3.6

PULLEY VAR - F24 MAX AMPS (A) 24.3

MOTOR 50 Hz POWER INPUT: (kW) 1.25

SFPv (SFPe): (W/l/s) 1.5

CLCFWin Rel. 3.3.1.30 12-02-2018- 23/37

AHU1050/1000/156.240

AHU sound levels Octave band (dB/Hz)

Tot. dB(A) 63 125 250 500 1000 2000 4000 8000

Sound power level supply inlet 72 63 71 57 70 69 53 41 34

Sound power level supply outlet 83 69 76 81 76 80 74 71 66

Sound power level return inlet

Sound power level return outlet

Airborne sound power 58 55 52 57 54 50 33 28

- before installing the unit, read the IOM

- unit is designed at 0 m on sea level, and with air density 1,2 kg/m3

- make the electrical wiring following the drawing inside of the motor power box or on motor label

- to avoid electrical motors overload, do not start the unit without filters or other component or without ducts or with door open

- the unit has been designed with the required external static pressure and considering a status of filters: with plant pressure drop less

then the required, with different status of filters and without proper control, the airflow and the sound power will be more than the

indicated

- the cross flow recuperator has been designed in order to resist to the indicated differential pressure between the plates. Do not exceed

this value enslaving properly dampers or other interception devices. RHW and PHE are not airtight devices and leakage between flows

always occurs. Exact value can depends on static pressure and unit configuration; to avoid contamination, the pressures on the fresh air

side shall be higher than on the return air side

- performance data of the heat recuperator are considered for counterflow of air; in case both flows are in same direction, performance

data could be substantially different from those

-If footprint of PHE section or of other sections exceed 2300 mm x 2400 mm, a special transport could be necessary. Please contact the

factory

- unit is designed for a maximum air temperature of 55°C

- depending on supply air temperature and outdoor condition, condensate on profiles can occur

- if water temperature entering the coil is below 1°C, freezing of coil fins can occur

- link the fan working to intercepting devices, as dampers or similar, avoiding fan working with those devices closed

- filter frame “side removable” could cause filter bypass due to not perfect airtight between filter cells

- if unit is provide of roof in kit, it will be provide separately, to mount on site by customer

- standard painted panel skin colour RAL9002

- if the door lenght is < 360 mm, also if selected, the inspection window will not be provided - in some cases

the inspection window could be partially occluded by components or components frame

- calculate sound pressure levels are indicative only. It corresponds to: free filed hemispheric sound radiation from the unit casing, the

inlet and outlet opening. Other sources, acoustic character of the room, air flow noise, duct connection and vibration can influence the

sound pressure in dependence. In practise, therefore measured values on site may be different from the calculation ones

- unit has been designed in wet condition

- unit weight does not include water/refrigerant and control (if provided)

- tolerance on sound levels are: - airborne level : +/-3 Db; duct level : +/-5 Db @ 63-125 Hz

and +/-3 Db @ 250-8000 Hz

- due to the gasket between sections, the total length of the unit will be around mm.5+ longer for each break point

- dimensions of CLCF unit could be increase by mm.4 due to the plastic profile

- in case unit is provided of flat roof, it will be mm.20 out all around the unit

- in case unit is provided of sloped roof, it will be mm.100 out all around the unit

- due to bigger heater and bends, the steam coil finned area will be light reduced respect what indicated, with consequent increase of

the air velocity thought it

-based on dimensions mentioned in datasheet, a special transport could be required

- for FC units, it's possible to install the inspection doors only at the bottom

This technical sheet and the attached drawing is the only document reporting the air handling unit construction features, also if not in

conformity with offer or other requests/documents sent to us, including mechanical specifications, technical description or similar.

For general construction features not indicated in it, refer to available documentation.

CLCFWin Rel. 3.3.1.30 12-02-2018- 24/37

AHU1050/1000/156.240

Ecodesign

Manufacturer TRANE

Unit model CLCF 1.5

Typology NRVU;UVU

SFPint / SFPint limit 2016 [W/(m³/s)]

SFPint / SFPint limit 2018 [W/(m³/s)] 189 / 230

Type of HRS -

Thermal efficiency of heat recovery [%] -

Class of casing leakage at -400 Pa / +400 Pa L1(M) / L1(M)

Maximum internal leakage rate [%] L1(M)

Supply

Nominal flow rate [m³/s] 0.83

Type of drive for var. speed scheduled inst. of var. speed drive

Effective electric power input [Kw] 1.3

Face velocity [m/s] 1.51

Nominal external pressure [Pa] 200

Internal pressure drop of ventilation components [Pa] 76

Static efficiency of fan [%] 40.2

Energy consumption of the filters (kWh/annum) D

Internet address for disassembly instructions

AHU doesn't fall under Ecodesign

CLCFWin Rel. 3.3.1.30 12-02-2018- 25/37

AHU1050/1000/156.240

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/156.240

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-4 City

Project

Serial number

Supply Fan

FAN TYPE Forward curved SIZE TLZ250R

P. Tot. [Pa]

59 56

51

60

46

4 59

1983 3 47 55 40 3000

18.5

2790 [dB]

2.2

1567

15

2580

1.5 237011

1150

1.1 2160

7.5

1950

0.8 5.5

733

0.6 1740

4

0.4 3

1530

2.2

0.3 1320

317 0.2 1.5

[kW] 1110

1.1

900

0.6

0.3

690

0 2.8 5.6 8.4 11.3 14.1 16.9

Qx1000 [m3/h]

Airflow 3000 m³/h Fan efficiency 56/59 %

EXTERNAL STATIC PRESSURE 200 Pa RPM 1671 rpm

Internal pressure drops of AHU 435 Pa ABSORBED POWER 1 kW

Dynamic pressure 39 Pa Sound power level 83.2 db(A)

CLCFWin Rel. 3.3.1.30 12-02-2018- 26/37

AHU1050/1000/156.240

Modelbox CLCF PU50 (EN 1886)

- Casing Strength: D1

- Air Leakage: L1

- Filter Bypass: F9

- Thermal Transmittance: T2

- Thermal Bridging: TB2

TRANE participates in the ECC programme for

Air Handling Units (AHU); check ongoing validity

of certificate online

www.eurovent-certification.com or using

www.certiflash.com.

SFP 1.7 W/l/s = 1.7 kW/m3/s calculated using

EN BS 13779 standards.

Designed at mid-point filter status, wet coil

condition.

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/328.201

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-5 City

Project

Serial number

SUPPLY AIRFLOW m³/h 15000 RETURN AIRFLOW // m³/h

UNIT TYPE - CLCF 5 - Comfort

Insulation Polyurethane Foam (40 kg/m3) Panel thickness mm: 50

Roof Absent Panel internal side Galvanised Steel

Type of roof Absent Panel external side Painted Galvanised Steel

Absent/No Roof Coil conn cabinet Absent

Support With baseframe Door type With hinges

Damper class Standard: Class 2 EN1751 Screw and bolts Galvanised Steel (standard)

Drain pan material Galvanised Steel Packing type: Hygienic packing

Internal frame Galvanised Steel Eyes bolts Absent

Inspection side (supply air flow Right Connection side (supply air flow Right

on back) on back)

Width mm 1617 Height + basement mm 1314 + 100

Length mm 2980 Total weight kg 970

SUPPLY SIDE

Section 1 LENGTH: (mm) 2980 Weight :(kg) 970

Section accessories

CLCFWin Rel. 3.3.1.30 12-02-2018- 27/37

AHU1050/1000/328.201

Intake Section ALUMINUM PROFILE DAMPER

Damper - 1 off insp.side shaft dimensions 510x1507 mm .

Airflow 15000 m³/h

Motorisable (linkage not incl.)

Actuator absent

With blade gasket (Leakage Class 2 according to EN1751)

Total pressure drop section 9 Pa

MATERIAL DIMENSIONS N. EFFICIENCY

Soft Bag Filter Synthetic fiber mm

592 x 592 x 48 4 class G4 EN779 DP CL(Pa) 79+207

287 x 592 x 48 mm 2 class F9 EN779 (E) DP MP(Pa) 118+311

Synthetic fiber 592 x 592 x 535 mm 4 Des. Temp. 34.0 °C DP DT(Pa) 157+415

287 x 592 x 535 mm 2 Vtunnel 2.26 m/s

Filter frame Galvanised Steel

Side removal

TUBES Cu/0.4 TYPE 40x34.6 CAPAC. (kW) 225.0 FLUID Water

Cooling coil FINS Al/0.11 DIM (mm) 1160x1290 EAT/RH (°C-%) 34.0-59 FLOW. (Kg/h) 38589

FRAME Zn/1.5 ROWS (n) 6 LAT/RH (°C-%) 14.4-100 EWT/LWT 7 12

(°C)

CONN.Ø. 3" F.SPACE (mm) 2 Vcoilface 2.83 DP (kPa) 39.3

VOL. (lt) 64.7 CIRCUITS (n) 29 DP tot/dry (Pa) 260/164

FTA (mm) 1510

Sens./Tot. 0.45

Cu-Al-FeZn P40AR 6R-29T-1290A-2.0pa 29C 3"

Total pressure drop section 260 Pa

FAN TYPE Forward curved AIRFLOW 15000 m³/h

Supply Fan SIZE TLZ450R EXTERNAL STATIC PRESSURE 200 Pa

MATERIAL Galvanised Steel TOTAL STATIC PRESSURE 897 Pa

PROTECTION Galvanised Steel RPM 1061 rpm

PULLEY - F35 ABSORBED POWER 6.1 kW

BELT DRIVE A EFFICIENCY STATIC/TOTAL 62/68 %

FAN DICHARGE VELOCITY: 12.87 m/s

FAN DICHARGE DIMENSION: L 569 mm - H 569 mm

In duct sound power: (dBA) 88.9

Octave in duct power level

F [Hz] 63 125 250 500 1000 2000 4000 8000

Supply [dB] 87 85 85 84 85 80 79 74

SL430*290-DM1170*660

GR2-1*5-1*6-1*6-1*6

Adjustable pitch pulley

Rubber insulators

With flexible connection on fan dicharge

PROTECTION IP 55 RPM 1440

Motor IE2 INSULATION CLASS F POWER SUPPLY 400V/3ph/50Hz

POLES N. 4 STARTING TYPE Star-Delta

INSTALLED POWER 7.5 kW RATED AMPS (A) 15.3

PULLEY VAR - F38 MAX AMPS (A) 107.1

MOTOR 50 Hz POWER INPUT: (kW) 7.45

SFPv (SFPe): (W/l/s) 1.7

CLCFWin Rel. 3.3.1.30 12-02-2018- 28/37

AHU1050/1000/328.201

AHU sound levels Octave band (dB/Hz)

Tot. dB(A) 63 125 250 500 1000 2000 4000 8000

Sound power level supply inlet 83 74 84 66 81 81 65 53 46

Sound power level supply outlet 88 83 87 89 84 85 79 76 72

Sound power level return inlet

Sound power level return outlet

Airborne sound power 64 66 60 65 59 55 38 34

- before installing the unit, read the IOM

- unit is designed at 0 m on sea level, and with air density 1,2 kg/m3

- make the electrical wiring following the drawing inside of the motor power box or on motor label

- to avoid electrical motors overload, do not start the unit without filters or other component or without ducts or with door open

- the unit has been designed with the required external static pressure and considering a status of filters: with plant pressure drop less

then the required, with different status of filters and without proper control, the airflow and the sound power will be more than the

indicated

- the cross flow recuperator has been designed in order to resist to the indicated differential pressure between the plates. Do not exceed

this value enslaving properly dampers or other interception devices. RHW and PHE are not airtight devices and leakage between flows

always occurs. Exact value can depends on static pressure and unit configuration; to avoid contamination, the pressures on the fresh air

side shall be higher than on the return air side

- performance data of the heat recuperator are considered for counterflow of air; in case both flows are in same direction, performance

data could be substantially different from those

-If footprint of PHE section or of other sections exceed 2300 mm x 2400 mm, a special transport could be necessary. Please contact the

factory

- unit is designed for a maximum air temperature of 55°C

- depending on supply air temperature and outdoor condition, condensate on profiles can occur

- if water temperature entering the coil is below 1°C, freezing of coil fins can occur

- link the fan working to intercepting devices, as dampers or similar, avoiding fan working with those devices closed

- filter frame “side removable” could cause filter bypass due to not perfect airtight between filter cells

- if unit is provide of roof in kit, it will be provide separately, to mount on site by customer

- standard painted panel skin colour RAL9002

- if the door lenght is < 360 mm, also if selected, the inspection window will not be provided - in some cases

the inspection window could be partially occluded by components or components frame

- calculate sound pressure levels are indicative only. It corresponds to: free filed hemispheric sound radiation from the unit casing, the

inlet and outlet opening. Other sources, acoustic character of the room, air flow noise, duct connection and vibration can influence the

sound pressure in dependence. In practise, therefore measured values on site may be different from the calculation ones

- unit has been designed in wet condition

- unit weight does not include water/refrigerant and control (if provided)

- tolerance on sound levels are: - airborne level : +/-3 Db; duct level : +/-5 Db @ 63-125 Hz

and +/-3 Db @ 250-8000 Hz

- due to the gasket between sections, the total length of the unit will be around mm.5+ longer for each break point

- dimensions of CLCF unit could be increase by mm.4 due to the plastic profile

- in case unit is provided of flat roof, it will be mm.20 out all around the unit

- in case unit is provided of sloped roof, it will be mm.100 out all around the unit

- due to bigger heater and bends, the steam coil finned area will be light reduced respect what indicated, with consequent increase of

the air velocity thought it

-based on dimensions mentioned in datasheet, a special transport could be required

- for FC units, it's possible to install the inspection doors only at the bottom

This technical sheet and the attached drawing is the only document reporting the air handling unit construction features, also if not in

conformity with offer or other requests/documents sent to us, including mechanical specifications, technical description or similar.

For general construction features not indicated in it, refer to available documentation.

CLCFWin Rel. 3.3.1.30 12-02-2018- 29/37

AHU1050/1000/328.201

Ecodesign

Manufacturer TRANE

Unit model CLCF 5

Typology NRVU;UVU

SFPint / SFPint limit 2016 [W/(m³/s)]

SFPint / SFPint limit 2018 [W/(m³/s)] 224 / 230

Type of HRS -

Thermal efficiency of heat recovery [%] -

Class of casing leakage at -400 Pa / +400 Pa L1(M) / L1(M)

Maximum internal leakage rate [%] L1(M)

Supply

Nominal flow rate [m³/s] 4.17

Type of drive for var. speed scheduled inst. of var. speed drive

Effective electric power input [Kw] 7.8

Face velocity [m/s] 2.26

Nominal external pressure [Pa] 200

Internal pressure drop of ventilation components [Pa] 107

Static efficiency of fan [%] 47.7

Energy consumption of the filters (kWh/annum) D

Internet address for disassembly instructions

AHU doesn't fall under Ecodesign

CLCFWin Rel. 3.3.1.30 12-02-2018- 30/37

AHU1050/1000/328.201

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/328.201

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-5 City

Project

Serial number

Supply Fan

FAN TYPE Forward curved SIZE TLZ450R

P. Tot. [Pa]

66 63 58

11 67

7.5 52

66

1733 55 62

46 1500

5.5

1390

37

1367 [dB]

4 1280

30

3 1170

1000 22

18.5

2.2 1060

15

950

633 1.5 11

1.1 840

7.5

0.8 730

5.5

0.6 4

620

267 0.4 3

5102.2

0.2 0.6

[kW] 0.3 0.4 0.8 4001.1

1.1 9.2 17.4 25.5 33.6 41.8 49.9

Qx1000 [m3/h]

Airflow 15000 m³/h Fan efficiency 62/68 %

EXTERNAL STATIC PRESSURE 200 Pa RPM 1061 rpm

Internal pressure drops of AHU 698 Pa ABSORBED POWER 6.1 kW

Dynamic pressure 100 Pa Sound power level 88.9 db(A)

CLCFWin Rel. 3.3.1.30 12-02-2018- 31/37

AHU1050/1000/328.201

Modelbox CLCF PU50 (EN 1886)

- Casing Strength: D1

- Air Leakage: L1

- Filter Bypass: F9

- Thermal Transmittance: T2

- Thermal Bridging: TB2

TRANE participates in the ECC programme for

Air Handling Units (AHU); check ongoing validity

of certificate online

www.eurovent-certification.com or using

www.certiflash.com.

SFP 1.4 W/l/s = 1.4 kW/m3/s calculated using

EN BS 13779 standards.

Designed at mid-point filter status, wet coil

condition.

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/388.817

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-6 City

Project

Serial number

SUPPLY AIRFLOW m³/h 16000 RETURN AIRFLOW // m³/h

UNIT TYPE - CLCF 6 - Comfort

Insulation Polyurethane Foam (40 kg/m3) Panel thickness mm: 50

Roof Absent Panel internal side Galvanised Steel

Type of roof Absent Panel external side Painted Galvanised Steel

Absent/No Roof Coil conn cabinet Absent

Support With baseframe Door type With hinges

Damper class Standard: Class 2 EN1751 Screw and bolts Galvanised Steel (standard)

Drain pan material Galvanised Steel Packing type: Hygienic packing

Internal frame Galvanised Steel Eyes bolts Absent

Inspection side (supply air flow Right Connection side (supply air flow Right

on back) on back)

Width mm 1923 Height + basement mm 1314 + 100

Length mm 3395 Total weight kg 1155

SUPPLY SIDE

Section 1 LENGTH: (mm) 1935 Weight :(kg) 767

Section accessories

CLCFWin Rel. 3.3.1.30 12-02-2018- 32/37

AHU1050/1000/388.817

Mixing Box ALUMINIUM PROFILE DAMPERS

Fresh air damper - 1 off insp.side shaft dimensions 410x1813 mm.

Airflow 16000 m³/h

Motorisable (linkage not incl.)

Actuator absent

With blade gasket (Leakage Class 2 according to EN1751)

Return damper - 1 off insp.side shaft dimensions 410x1813 mm.

Airflow 16000 m³/h

Motorisable (linkage kit not included)

Actuator absent

With blade gasket (Leakage Class 2 according to EN1751)

Ricirculation factor % : 85

Total pressure drop section 22 Pa

MATERIAL DIMENSIONS N. EFFICIENCY

Soft Bag Filter Synthetic fiber 592 x 592 x 48 mm 6 class G4 EN779 DP CL(Pa) 68+180

class F9 EN779 (E) DP MP(Pa) 101+270

Synthetic fiber 592 x 592 x 535 mm 6 Des. Temp. 14.8 °C DP DT(Pa) 135+359

Vtunnel 2.01 m/s

Filter frame Galvanised Steel

Side removal

TUBES Cu/0.4 TYPE 40x34.6 CAPAC. (kW) 95.6 FLUID Water

Cooling coil FINS Al/0.11 DIM (mm) 1160x1570 EAT/RH (°C-%) 28.8-37 FLOW. (Kg/h) 16396

FRAME Zn/1.5 ROWS (n) 4 LAT/RH (°C-%) 12.2-100 EWT/LWT 7 12

(°C)

CONN.Ø. 2" F.SPACE (mm) 2 Vcoilface 2.48 DP (kPa) 31.3

VOL. (lt) 46.2 CIRCUITS (n) 19 DP tot/dry (Pa) 102/88

FTA (mm) 1760

Sens./Tot. 0.94

Cu-Al-FeZn P40AR 4R-29T-1570A-2.0pa 19C 2"

Total pressure drop section 102 Pa

TUBES Cu/0.4 TYPE 40x34.6 CAPAC. (kW) 81.0 FLUID Water

Heating coil FINS Al/0.11 DIM (mm) 1160x1570 EAT (°C) 14.8 FLOW. (Kg/h) 6974

FRAME Zn/1.5 ROWS (n) 1 LAT (°C) 29.6 EWT/LWT (°C) 80 70

CONN.Ø. 1 1/2" F.SPACE (mm) 3 Vcoilface 2.48 DP (kPa) 15.3

VOL. (lt) 14.0 CIRCUITS (n) 7 DP tot/dry (Pa) 21/21

FTA (mm) 1750

Cu-Al-FeZn P40AC 1R-29T-1570A-3.0pa 7C 1 1/2"

Total pressure drop section 21 Pa

Section 2 LENGTH: (mm) 1460 Weight :(kg) 388

Section accessories

CLCFWin Rel. 3.3.1.30 12-02-2018- 33/37

AHU1050/1000/388.817

FAN TYPE Forward curved AIRFLOW 16000 m³/h

Supply Fan SIZE TLZ500R EXTERNAL STATIC PRESSURE 200 Pa

MATERIAL Galvanised Steel TOTAL STATIC PRESSURE 715 Pa

PROTECTION Galvanised Steel RPM 869 rpm

PULLEY - F35 ABSORBED POWER 5.1 kW

BELT DRIVE A EFFICIENCY STATIC/TOTAL 62/68 %

FAN DICHARGE VELOCITY: 10.92 m/s

FAN DICHARGE DIMENSION: L 638 mm - H 638 mm

In duct sound power: (dBA) 87.9

Octave in duct power level

F [Hz] 63 125 250 500 1000 2000 4000 8000

Supply [dB] 85 85 83 85 82 80 77 72

SL430*290-DM1240*730

GR2-1*5-1*6-1*6-1*6

Adjustable pitch pulley

Rubber insulators

With flexible connection on fan dicharge

PROTECTION IP 55 RPM 1440

Motor IE2 INSULATION CLASS F POWER SUPPLY 400V/3ph/50Hz

POLES N. 4 STARTING TYPE Star-Delta

INSTALLED POWER 7.5 kW RATED AMPS (A) 15.3

PULLEY VAR - F38 MAX AMPS (A) 107.1

MOTOR 50 Hz POWER INPUT: (kW) 6.29

SFPv (SFPe): (W/l/s) 1.4

CLCFWin Rel. 3.3.1.30 12-02-2018- 34/37

AHU1050/1000/388.817

AHU sound levels Octave band (dB/Hz)

Tot. dB(A) 63 125 250 500 1000 2000 4000 8000

Sound power level supply inlet 80 72 79 65 79 78 62 50 43

Sound power level supply outlet 87 81 87 87 85 82 79 74 70

Sound power level return inlet

Sound power level return outlet

Airborne sound power 64 66 58 66 56 55 36 32

- before installing the unit, read the IOM

- unit is designed at 0 m on sea level, and with air density 1,2 kg/m3

- make the electrical wiring following the drawing inside of the motor power box or on motor label

- to avoid electrical motors overload, do not start the unit without filters or other component or without ducts or with door open

- the unit has been designed with the required external static pressure and considering a status of filters: with plant pressure drop less

then the required, with different status of filters and without proper control, the airflow and the sound power will be more than the

indicated

- the cross flow recuperator has been designed in order to resist to the indicated differential pressure between the plates. Do not exceed

this value enslaving properly dampers or other interception devices. RHW and PHE are not airtight devices and leakage between flows

always occurs. Exact value can depends on static pressure and unit configuration; to avoid contamination, the pressures on the fresh air

side shall be higher than on the return air side

- performance data of the heat recuperator are considered for counterflow of air; in case both flows are in same direction, performance

data could be substantially different from those

-If footprint of PHE section or of other sections exceed 2300 mm x 2400 mm, a special transport could be necessary. Please contact the

factory

- unit is designed for a maximum air temperature of 55°C

- depending on supply air temperature and outdoor condition, condensate on profiles can occur

- if water temperature entering the coil is below 1°C, freezing of coil fins can occur

- link the fan working to intercepting devices, as dampers or similar, avoiding fan working with those devices closed

- filter frame “side removable” could cause filter bypass due to not perfect airtight between filter cells

- if unit is provide of roof in kit, it will be provide separately, to mount on site by customer

- standard painted panel skin colour RAL9002

- if the door lenght is < 360 mm, also if selected, the inspection window will not be provided - in some cases

the inspection window could be partially occluded by components or components frame

- calculate sound pressure levels are indicative only. It corresponds to: free filed hemispheric sound radiation from the unit casing, the

inlet and outlet opening. Other sources, acoustic character of the room, air flow noise, duct connection and vibration can influence the

sound pressure in dependence. In practise, therefore measured values on site may be different from the calculation ones

- unit has been designed in wet condition

- unit weight does not include water/refrigerant and control (if provided)

- tolerance on sound levels are: - airborne level : +/-3 Db; duct level : +/-5 Db @ 63-125 Hz

and +/-3 Db @ 250-8000 Hz

- due to the gasket between sections, the total length of the unit will be around mm.5+ longer for each break point

- dimensions of CLCF unit could be increase by mm.4 due to the plastic profile

- in case unit is provided of flat roof, it will be mm.20 out all around the unit

- in case unit is provided of sloped roof, it will be mm.100 out all around the unit

- due to bigger heater and bends, the steam coil finned area will be light reduced respect what indicated, with consequent increase of

the air velocity thought it

-based on dimensions mentioned in datasheet, a special transport could be required

- for FC units, it's possible to install the inspection doors only at the bottom

This technical sheet and the attached drawing is the only document reporting the air handling unit construction features, also if not in

conformity with offer or other requests/documents sent to us, including mechanical specifications, technical description or similar.

For general construction features not indicated in it, refer to available documentation.

CLCFWin Rel. 3.3.1.30 12-02-2018- 35/37

AHU1050/1000/388.817

Ecodesign

Manufacturer TRANE

Unit model CLCF 6

Typology NRVU;UVU

SFPint / SFPint limit 2016 [W/(m³/s)]

SFPint / SFPint limit 2018 [W/(m³/s)] 194 / 230

Type of HRS -

Thermal efficiency of heat recovery [%] -

Class of casing leakage at -400 Pa / +400 Pa L1(M) / L1(M)

Maximum internal leakage rate [%] L1(M)

Supply

Nominal flow rate [m³/s] 4.44

Type of drive for var. speed scheduled inst. of var. speed drive

Effective electric power input [Kw] 6.6

Face velocity [m/s] 2.01

Nominal external pressure [Pa] 200

Internal pressure drop of ventilation components [Pa] 93

Static efficiency of fan [%] 48.0

Energy consumption of the filters (kWh/annum) D

Internet address for disassembly instructions

AHU doesn't fall under Ecodesign

CLCFWin Rel. 3.3.1.30 12-02-2018- 36/37

AHU1050/1000/388.817

Offer N° 19-0022 Rel. 3.3.1.30 12-02-2018-

User HC1 AHU1050/1000/388.817

Client CHAM PALACE Date 10-09-2019

Unit reference AHU-6 City

Project

Serial number

Supply Fan

FAN TYPE Forward curved SIZE TLZ500R

P. Tot. [Pa]

65 61

56

67

50

11 66

1567

50 60 1300

7.5 43

45

1210

[dB]

1233 5.5

37

1120

30

4

1030

900

3 22

940

18.5

2.2 850

15

567

1.5 760

11

1.1 670

7.5

0.8 5.5

580

0.6 4

233 490

0.3 0.6 1.1 2.2

0.4 1.5

400

[kW]

1.9 11.7 21.6 31.4 41.2 51.1 60.9

Qx1000 [m3/h]

Airflow 16000 m³/h Fan efficiency 62/68 %

EXTERNAL STATIC PRESSURE 200 Pa RPM 869 rpm

Internal pressure drops of AHU 516 Pa ABSORBED POWER 5.1 kW

Dynamic pressure 72 Pa Sound power level 87.9 db(A)

CLCFWin Rel. 3.3.1.30 12-02-2018- 37/37

AHU1050/1000/388.817

You might also like

- Carrier Ingles 30rb 9pdDocument88 pagesCarrier Ingles 30rb 9pdCarlos CarloNo ratings yet

- VRFDocument37 pagesVRFJohn DaleNo ratings yet

- Daikin VRV IV CatalogueDocument46 pagesDaikin VRV IV CatalogueNathan Vo100% (5)

- Installation & Owner'S Manual: DX AHU Control BoxDocument17 pagesInstallation & Owner'S Manual: DX AHU Control BoxPatrick Simmons100% (1)

- Taking VRV Controls To The Next Level: Norman PennantDocument45 pagesTaking VRV Controls To The Next Level: Norman Pennantimecc ingenieriaNo ratings yet

- Carrier Info - 19xr-4pdDocument60 pagesCarrier Info - 19xr-4pdtermomontazaNo ratings yet

- Service & Troubleshooting Guide for Samsung HVAC SystemsDocument64 pagesService & Troubleshooting Guide for Samsung HVAC SystemsGingubaNo ratings yet

- ACUSDocument36 pagesACUSOsama.ShawkyNo ratings yet

- York 2018 Line CardDocument2 pagesYork 2018 Line CardNPUIUNo ratings yet

- Rooftop TraneDocument108 pagesRooftop TraneJuan Andres ArenasNo ratings yet

- Bas-Apg007-En 12012009 Air SystemsDocument274 pagesBas-Apg007-En 12012009 Air SystemsMark Izsm Amerson100% (4)

- 1.1test MethodologyDocument14 pages1.1test MethodologyjvfcvNo ratings yet

- Pacv - S - SKM PDFDocument44 pagesPacv - S - SKM PDFomar farukNo ratings yet

- SMARDT Catalogue TW ClassWaterCooled-En WebDocument7 pagesSMARDT Catalogue TW ClassWaterCooled-En WebBrunoWelterNo ratings yet

- 1Document114 pages1Mohamed FathiNo ratings yet

- Variable-Speed Water-Cooled Screw Chiller & Heat Pump: $ppmjohdbqbdjuz l8) Fbujohdbqbdjuz l8Document20 pagesVariable-Speed Water-Cooled Screw Chiller & Heat Pump: $ppmjohdbqbdjuz l8) Fbujohdbqbdjuz l8nglong24No ratings yet

- ClassiCool R410A 50HzDocument67 pagesClassiCool R410A 50HzGiftson ImmanuelNo ratings yet

- 8 65 105 EvapsDocument41 pages8 65 105 EvapsRestino KionyNo ratings yet

- DixellDocument39 pagesDixellSaša Ilić100% (1)

- Turbocor Compressor - Service - HireDocument4 pagesTurbocor Compressor - Service - Hireinfo3903No ratings yet

- DCM601A51 - Technical DataDocument405 pagesDCM601A51 - Technical Datathanhthuan100% (1)

- Toshiba Fault Code Map v1.00Document2 pagesToshiba Fault Code Map v1.00Anonymous mNQq7ojNo ratings yet

- Engineer Data VRV IV Cooling Part 1Document250 pagesEngineer Data VRV IV Cooling Part 1Tấn BìnhNo ratings yet

- 38HK 03 PD 60HZ 2011Document32 pages38HK 03 PD 60HZ 2011Ahmed Jabir100% (1)

- 30RBM-30RBP Chiller PSD PDFDocument38 pages30RBM-30RBP Chiller PSD PDFBilguun BurenjargalNo ratings yet

- Commercial Air Conditioners 2019 Rooftop Package R410A 50HzDocument15 pagesCommercial Air Conditioners 2019 Rooftop Package R410A 50Hzhany mohamedNo ratings yet

- 30xa 21PD PDFDocument136 pages30xa 21PD PDFAndrés HernándezNo ratings yet

- InteliLite AMF25 1 7 0 Global Guide PDFDocument741 pagesInteliLite AMF25 1 7 0 Global Guide PDFYuriyNo ratings yet

- Chillers CatalogueDocument42 pagesChillers CatalogueAlaa FaiqNo ratings yet

- Lennox Certified VRF Brochure Spanish V6Document10 pagesLennox Certified VRF Brochure Spanish V6Ariel Calero0% (1)

- CLCP PRC001 en PDFDocument43 pagesCLCP PRC001 en PDFAnonymous mNQq7ojNo ratings yet

- Day 1 E-Link Overview - Version 1Document271 pagesDay 1 E-Link Overview - Version 1Arshad MahmoodNo ratings yet

- SKM-Ducted Split UnitDocument20 pagesSKM-Ducted Split Unitmhmdjdgmailcom100% (1)

- Test Project ASC 2018Document16 pagesTest Project ASC 2018Macek Cah KendalNo ratings yet

- Liebert PDX 15 120 KW Brochure English PDFDocument12 pagesLiebert PDX 15 120 KW Brochure English PDFmido ahmedNo ratings yet

- Air-Cooled Screw Liquid ChillersDocument92 pagesAir-Cooled Screw Liquid ChillersBabak GhavidelNo ratings yet

- Chiller Daikin Ewadc12cfxs - 1118 Kw-Free CoolingDocument7 pagesChiller Daikin Ewadc12cfxs - 1118 Kw-Free CoolingBogdan-iulian BalintNo ratings yet

- Catalog VRV IV - 2016Document62 pagesCatalog VRV IV - 2016VietHienNo ratings yet

- ACS Screw Water Chiller Selection GuideDocument52 pagesACS Screw Water Chiller Selection Guideسہمہو الامہيرNo ratings yet

- Saiver AHUDocument12 pagesSaiver AHUNorsyafiqah RoziNo ratings yet

- Copeland Alco Controls General Product Catalogue 2023 en GB 5288442Document320 pagesCopeland Alco Controls General Product Catalogue 2023 en GB 5288442William ViturinoNo ratings yet

- Product Data: Features/BenefitsDocument60 pagesProduct Data: Features/BenefitsBJNE01No ratings yet

- MCS-Magnum Version 17 ManualDocument244 pagesMCS-Magnum Version 17 Manualvikash yadav100% (2)

- Catalog Ventilare Daikin PDFDocument192 pagesCatalog Ventilare Daikin PDFAlexandru PlesnicuteNo ratings yet

- Installation Manual for Middle Static Pressure Duct Type Air ConditionerDocument32 pagesInstallation Manual for Middle Static Pressure Duct Type Air ConditionerEuro-klima BitolaNo ratings yet

- trane-TCH-50-5047-4 (En) - 05012001Document2 pagestrane-TCH-50-5047-4 (En) - 05012001francisco_chamorr_12No ratings yet

- 40LX040 060 (Malaysia)Document8 pages40LX040 060 (Malaysia)Leed ENNo ratings yet

- Fuel Pump Design Calculation SheetDocument1 pageFuel Pump Design Calculation SheetIslam SolimanNo ratings yet

- TT 400, Applications Manual - ENDocument70 pagesTT 400, Applications Manual - ENanil kumarNo ratings yet

- Zamil ACDocument40 pagesZamil ACArt James100% (1)

- Trane ChillerDocument14 pagesTrane ChillerwesleyNo ratings yet

- Read This Manual Before Installation and Operation Make Sure That It Is Well Kept For Later ReferenceDocument32 pagesRead This Manual Before Installation and Operation Make Sure That It Is Well Kept For Later Referenceelshan_asgarov100% (1)

- Acuv SDocument32 pagesAcuv Sanoopkumar1231150No ratings yet

- SKM Fan Coil Series: Chilled WaterDocument33 pagesSKM Fan Coil Series: Chilled WaterHewa AkreyNo ratings yet

- Daikin Engineering Data VRV-WIII (2015)Document356 pagesDaikin Engineering Data VRV-WIII (2015)Adam Chan100% (1)

- 01 - Chemetics Anotrol 2000 InfoSheetDocument2 pages01 - Chemetics Anotrol 2000 InfoSheetWeb Logueando100% (1)

- ACUFDocument27 pagesACUFaries26marchNo ratings yet

- 2.0 CLCF Hospital AHU HygienicDocument17 pages2.0 CLCF Hospital AHU HygienicfebousNo ratings yet

- FT Ahu - RotativDocument12 pagesFT Ahu - RotativAndrei Eugen ZugravuNo ratings yet

- Ahu SelectionDocument28 pagesAhu SelectionkaamNo ratings yet

- TRANE - FCU SelectionsDocument16 pagesTRANE - FCU SelectionshanamanNo ratings yet

- Space Out-V E Out-HDocument4 pagesSpace Out-V E Out-HhanamanNo ratings yet

- Ysc033 063G3 PDFDocument88 pagesYsc033 063G3 PDFhanamanNo ratings yet

- Unitrane™ D-Line: Ducted Fan CoilsDocument56 pagesUnitrane™ D-Line: Ducted Fan CoilshanamanNo ratings yet

- AC Troubleshooting Guide Generic PDFDocument2 pagesAC Troubleshooting Guide Generic PDFxr28y ge3fl1No ratings yet

- MICRO-M-3: Microelectronic Operation and Unit TroubleshootingDocument32 pagesMICRO-M-3: Microelectronic Operation and Unit TroubleshootinghanamanNo ratings yet

- Fluke 62 Mini Infrared Thermometer, Infrared Thermometer Gun - Instruction SheetDocument2 pagesFluke 62 Mini Infrared Thermometer, Infrared Thermometer Gun - Instruction SheetIBJSC.comNo ratings yet

- Ucm-Cld Operating and Control Principles: L IM EDocument28 pagesUcm-Cld Operating and Control Principles: L IM EhanamanNo ratings yet

- UCM-CLD Set Up L80 - SB - 050 - EDocument9 pagesUCM-CLD Set Up L80 - SB - 050 - EEvgeniy MaslovNo ratings yet

- IES PresentationDocument21 pagesIES PresentationEric RussellNo ratings yet

- Halton MARVEL IOM 1Document30 pagesHalton MARVEL IOM 1olivertako11No ratings yet

- Air System Sizing Summary For NIVEL PB - Zona 1Document1 pageAir System Sizing Summary For NIVEL PB - Zona 1Roger PandoNo ratings yet

- Product Catalogue enDocument171 pagesProduct Catalogue enEljameely JamaleldeenNo ratings yet

- Duct Diffuser With Discs For Supply Air: Quick FactsDocument14 pagesDuct Diffuser With Discs For Supply Air: Quick FactsEdgar KaptiugNo ratings yet

- Applied Sciences: Technical Performance of An Inflatable Solar Dryer For Drying Amaranth Leaves in KenyaDocument11 pagesApplied Sciences: Technical Performance of An Inflatable Solar Dryer For Drying Amaranth Leaves in KenyaRianzarnainNo ratings yet

- Cs-A18bkp a24bkp Mac0111062c0Document82 pagesCs-A18bkp a24bkp Mac0111062c0bcvlad78No ratings yet

- Trickling Filter and Trickling Filter-Suspended Growth Process Design and Operation: A State-of-the-Art ReviewDocument19 pagesTrickling Filter and Trickling Filter-Suspended Growth Process Design and Operation: A State-of-the-Art ReviewMarisol BravoNo ratings yet

- Americ Confined Space Ventilator PDFDocument16 pagesAmeric Confined Space Ventilator PDFHarold Fernando Guavita ReyesNo ratings yet

- Amca 222-16Document34 pagesAmca 222-16Hany RifaatNo ratings yet

- Clestra M1-Uk-2017-Tech - E6151682Document2 pagesClestra M1-Uk-2017-Tech - E6151682EugeneNo ratings yet

- Halton Pollustop CatalogueDocument15 pagesHalton Pollustop CatalogueTùng Chu báNo ratings yet

- SIGA-SD - Ficha TecnicaDocument4 pagesSIGA-SD - Ficha TecnicaJeanNo ratings yet

- Frost Control Strategies For Airxchange Enthalpy WheelsDocument6 pagesFrost Control Strategies For Airxchange Enthalpy Wheelsenlightened1718No ratings yet

- Fabric Ducting & Diffusers: Technical DataDocument32 pagesFabric Ducting & Diffusers: Technical DataruwangaroshalNo ratings yet

- 4 AppendicesDocument12 pages4 AppendicesZainul Abedin SayedNo ratings yet

- Air Handling Units - Equipment GuideDocument84 pagesAir Handling Units - Equipment Guideesteban_f1100% (1)

- Product Design Guide: Whispertherm Vertical Stack With Whisperpack ChassisDocument62 pagesProduct Design Guide: Whispertherm Vertical Stack With Whisperpack ChassisSaman SafdarNo ratings yet

- Sensors - Bosch20 09 2023Document100 pagesSensors - Bosch20 09 2023matheus barbosa moreiraNo ratings yet

- Air Conditioning Systems OverviewDocument101 pagesAir Conditioning Systems OverviewA Wong100% (1)

- UL Class 1 HEPA Filters Technical SpecsDocument2 pagesUL Class 1 HEPA Filters Technical SpecsmaNo ratings yet

- Instructor'S Lesson Plan For: Maria's Restaurant Technician's GUIDE & WorkbookDocument61 pagesInstructor'S Lesson Plan For: Maria's Restaurant Technician's GUIDE & Workbookraul jaimesNo ratings yet

- Design Briefs Advanced VAV SystemsDocument27 pagesDesign Briefs Advanced VAV SystemsHESuarezNo ratings yet

- Standard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemDocument20 pagesStandard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemMaryanthony Namyalo100% (3)

- Draft Monitoring Protocol of Indoor Air QualityDocument19 pagesDraft Monitoring Protocol of Indoor Air QualityTervinder LambaNo ratings yet

- Hvac Performance Analysis For A Conference Room: Visvesvaraya Technological UniversityDocument27 pagesHvac Performance Analysis For A Conference Room: Visvesvaraya Technological UniversityRohanRayNo ratings yet

- Measuring Airflow VelocityDocument6 pagesMeasuring Airflow VelocityAngel Ramón GutiérrezNo ratings yet