Professional Documents

Culture Documents

Observation For Missed Practical Sessions-CH2303

Uploaded by

Suleka RanasingheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Observation For Missed Practical Sessions-CH2303

Uploaded by

Suleka RanasingheCopyright:

Available Formats

Observation for Missed Practical Sessions- CH2303

(Cancelled Due to Student’s Union Actions)

Observations for Group 05 (21.09.2020)

Experiment: Determination of softening point of resin tar or similar material using the Ring and

Ball Apparatus

Temperature when ball touches the bottom plate

Sample 01 (T1) : 43 ᵒC

Sample 02 (T2) : 43 ᵒC

Experiment: Determination of kinematic viscosity by Saybolt and Engler viscometers

Saybolt Viscometer

Sample Sample Required time (seconds) for

Temperature (oC)

No. filling 60 ml volume

1 727

2 Room Temperature (30 oC) 736

3

SAE 40

4 382

5 40 oC 598

6

Engler Viscometer

Sample Sample Efflux Time (seconds) for

Temperature (oC)

No. filling 100 ml volume

1 905

2 Room Temperature (32 oC) 942

3

SAE 40

4 387

5 40 oC 341

6

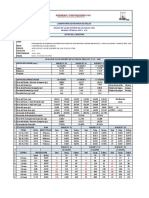

Observations for Group 01 (21.09.2020)

Experiment: Determination of the Aniline point of a petroleum fraction

Aniline Point of Kerosene (Heating) : 62 oC

Aniline Point of Kerosene (Cooling) : 58 oC

Aniline Point of Diesel (Heating) : 76 oC

Aniline Point of Diesel (Cooling) : 75 oC

Experiment: Determination of the flash point and the fire point of Solvents

Pensky Martens closed cup tester

Kerosene Diesel

Sample 01 Sample 02 Sample 01 Sample 02

Flash point (0C) 41.5 67

Cleveland open cup tester

Kerosene Diesel

Sample 01 Sample 02 Sample 01 Sample 02

Flash point (0C) 33 35 42 42

Fire point (0C) 35 36 55 53

Observations for Group 02 (21.09.2020)

Experiment: Determination of the viscosity of very viscous liquid

I. . Universal Torsion Viscometer:-

Measurement No Angle

1 347

2 321

II. Universal Penetrometer:-

Measurement No Depth (mm)

1 14.24

2 14.06

3 14.82

III. Rotary Viscometer:-

Measurement No Viscosity (mPaS)

1 218

2 -

Experiment: Determination of the water and sediment content of crude oil

Sample No Volume of Water and Sediment (ml)

1 2.2

2 3.1

Observations for Group 05 (23.09.2020)

Experiment: ASTM Distillation

SI No Volume of distillate collected(ml) Temperature (oC) Temperature (ºF)

01 0 121

02 10 160

03 20 169.5

04 30 176

05 40 183

06 50 189

07 60 196

08 70 206

09 80 215

10 90 227

11 95 235

12 97 242

EXPERIMENT: Proximate analysis of coal

Determination of inherent moisture

Weight of watch glass (W1) = 35.64 g

Weight of watch glass + 5g of coal (W 2) = 40.64 g

Weight of watch glass + coal (after drying at 110 °C for 1 hr) (W 3) = 40.56 g

Determination of volatile matter

Weight of silica crucible +lid (W4) = 15.38 g

Weight of silica crucible +lid + 1g of coal (W5) = 16.38 g

Weight of silica crucible +lid + coal (after drying at 680 °C for 7 min) (W 6) = 16.11 g

Determination of ash

Weight of silica crucible +lid (W7) = 16.17 g

Weight of silica crucible +lid + 1g of coal (W8) = 17.17 g

Weight of silica crucible +lid + coal (after drying at 680 °C for 1 hr) (W 9) = 16.77 g

Observations for Group 06 (23.09.2020)

Experiment: Viscosity Index

Time taken to flow at 100 ᵒF :- 26 min 10 sec

Time taken to flow at 210 ᵒF :- 2 min 25 sec

Viscometer constant :- 0.10276

Experiment: Determination of Melting Point

Temperature at solid begins to melt (T1) - 80.5 °C

Temperature at melting is complete (T2) – 82 °C

You might also like

- Hermetic Compressor PDFDocument17 pagesHermetic Compressor PDFchildey100% (1)

- Cummins L10 Series Workshop ManualDocument558 pagesCummins L10 Series Workshop ManualMarielis Contreras0% (1)

- Viscotube r2Document15 pagesViscotube r2wisnu prabowo muktiNo ratings yet

- Heating and Cooling Load Calculations: International Series of Monographs In: Heating, Ventilation and RefrigerationFrom EverandHeating and Cooling Load Calculations: International Series of Monographs In: Heating, Ventilation and RefrigerationRating: 3.5 out of 5 stars3.5/5 (6)

- Central Luzon State University's Agricultural Machinery Design Lab ActivityDocument21 pagesCentral Luzon State University's Agricultural Machinery Design Lab ActivityLarry Olipas100% (2)

- Kubera-Petroleum Product PassportDocument2 pagesKubera-Petroleum Product Passportptintimaritimsekawan100% (1)

- Auto wiring diagram componentsDocument4 pagesAuto wiring diagram componentsDanny Alexander Bodegas pinedaNo ratings yet

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDocument2 pagesSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1No ratings yet

- Proximate Analysis of CoalDocument30 pagesProximate Analysis of Coalvince coNo ratings yet

- Aspen Hysys Simulation of Methanol Production ProcessDocument2 pagesAspen Hysys Simulation of Methanol Production ProcessAditiya Muhammad FattahNo ratings yet

- China Shandong Ruyi Sahiwal of Pakistan 2×660MW Coal-Fired Power Station Project 1 Boiler, Set To Start The Debugger StepsDocument32 pagesChina Shandong Ruyi Sahiwal of Pakistan 2×660MW Coal-Fired Power Station Project 1 Boiler, Set To Start The Debugger StepsJawad HussainNo ratings yet

- Sandvik Lh203 Underground Loader: Technical SpecificationDocument7 pagesSandvik Lh203 Underground Loader: Technical Specificationgonzalo hernandez aguilarNo ratings yet

- Daihatsu DK 20 ManualDocument626 pagesDaihatsu DK 20 Manualshujauddin84100% (2)

- Đánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDocument1 pageĐánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDuy Nguyễn VănNo ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Chemistry Investigatory Project On Bio-Diesel Made by Kamal/KishanDocument15 pagesChemistry Investigatory Project On Bio-Diesel Made by Kamal/KishanKishan Saluja76% (82)

- Market Analysis of Uk FuelDocument16 pagesMarket Analysis of Uk FuelYeshua ResearchNo ratings yet

- Scorpio Tankers Inc. Company Presentation November 2016Document25 pagesScorpio Tankers Inc. Company Presentation November 2016Juan Sebastian Gonzalez RamirezNo ratings yet

- Distillation and Vapor Pressure Test of Gasoline Fuel 1Document19 pagesDistillation and Vapor Pressure Test of Gasoline Fuel 1Krishna Belela100% (1)

- FLASH POINT OF BITUMEN OBSERVATION SHEETDocument1 pageFLASH POINT OF BITUMEN OBSERVATION SHEETmohd waseemNo ratings yet

- Final Quiz-ME-170Document4 pagesFinal Quiz-ME-170omeo habibNo ratings yet

- Name Ean Peose: Experiment MeasurementsDocument4 pagesName Ean Peose: Experiment MeasurementsandrewNo ratings yet

- Quality certificate analysisDocument6 pagesQuality certificate analysisClaudia TiradoNo ratings yet

- Test Items Specification Obtained Required: ConclutionDocument17 pagesTest Items Specification Obtained Required: Conclutionعمير اعجاز وڑائچNo ratings yet

- Exp 1Document23 pagesExp 1Sadia HasanNo ratings yet

- California Bearing Ratio Test: MDD 2.055 GM/CC Omc 8.2 %Document2 pagesCalifornia Bearing Ratio Test: MDD 2.055 GM/CC Omc 8.2 %RotiNo ratings yet

- Physical Chemistry Experiment 4Document5 pagesPhysical Chemistry Experiment 4Suzanne Clariz M. BaltazarNo ratings yet

- Clock 859Document1 pageClock 859statisticssalesNo ratings yet

- Slalom Acoustics Tunnel Fire Test USADocument5 pagesSlalom Acoustics Tunnel Fire Test USAAroaNo ratings yet

- MT GraphsDocument3 pagesMT GraphsMuhammad UsamaNo ratings yet

- Supporting Information Life Cycle Greenhouse Gas Emissions of Different CO Supply Options For An Algal BiorefineryDocument15 pagesSupporting Information Life Cycle Greenhouse Gas Emissions of Different CO Supply Options For An Algal BiorefineryPratham AroraNo ratings yet

- Age HardeningDocument7 pagesAge HardeningKierraNo ratings yet

- Review Analisis: Tabel 2. Variabel Dan Respon PenelitianDocument8 pagesReview Analisis: Tabel 2. Variabel Dan Respon PenelitianheraNo ratings yet

- Michelin Tire and Underwriter ReportDocument75 pagesMichelin Tire and Underwriter ReportKirth RegisNo ratings yet

- EQ2615 Epoxy Adhesive PDFDocument12 pagesEQ2615 Epoxy Adhesive PDFPedro RosaNo ratings yet

- Measuring Viscosity with Ostwald ViscometerDocument12 pagesMeasuring Viscosity with Ostwald ViscometerhendraNo ratings yet

- Be - Mechanical Engineering - Semester 4 - 2023 - February - Applied Thermodynamics at Pattern 2019Document2 pagesBe - Mechanical Engineering - Semester 4 - 2023 - February - Applied Thermodynamics at Pattern 2019loharjay772No ratings yet

- Kuliah 5 DSC Tga, Dta 2023Document74 pagesKuliah 5 DSC Tga, Dta 2023Ofik Mahesa ChannelNo ratings yet

- MEASURING VISCOSITYDocument6 pagesMEASURING VISCOSITYJeremy Kyle Edson AustriaNo ratings yet

- Hydrometer Test: King Fahd University of Petroleum & Minerals CE 353 Soil Mechanics LaboratoryDocument8 pagesHydrometer Test: King Fahd University of Petroleum & Minerals CE 353 Soil Mechanics Laboratoryprashanth palaniNo ratings yet

- 2019 Report WeekDocument145 pages2019 Report WeekLabeed ShamilNo ratings yet

- Experiment 1:determination of Valve Timing of An Internal Combustion Engine Observation TableDocument18 pagesExperiment 1:determination of Valve Timing of An Internal Combustion Engine Observation Tableمحمد راشد بن زينNo ratings yet

- AnexoN Medicion GMACDocument129 pagesAnexoN Medicion GMACDavid PradaNo ratings yet

- Heat Transfer Lab ManualDocument7 pagesHeat Transfer Lab ManualAlen SajuNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- Radhey Testing & Consultants Pvt. Ltd. Agra: Observation Cum Calculation SheetDocument1 pageRadhey Testing & Consultants Pvt. Ltd. Agra: Observation Cum Calculation SheetChandan MondalNo ratings yet

- Understanding The Colour Coding: Kittiwake Viscotube ReadmeDocument15 pagesUnderstanding The Colour Coding: Kittiwake Viscotube ReadmemusaveerNo ratings yet

- Workbook: Case (Main) : Material StreamsDocument1 pageWorkbook: Case (Main) : Material StreamsSchaieraNo ratings yet

- ED 72.19 Biomass Heating ValuesDocument5 pagesED 72.19 Biomass Heating Valuesst109597No ratings yet

- 2 2 6-JoyDocument6 pages2 2 6-Joyjoyalhaddad3No ratings yet

- HDTL 025Document1 pageHDTL 025Angga 99No ratings yet

- Overall SummaryDocument1 pageOverall SummaryTIPAZONo ratings yet

- Tamson-Products PPSXDocument79 pagesTamson-Products PPSXIan JoeNo ratings yet

- Ensayo de Valor Soporte de Los Suelos CBRDocument2 pagesEnsayo de Valor Soporte de Los Suelos CBREDUARDO MAYHUA VARGASNo ratings yet

- Chapter 4Document26 pagesChapter 4Md Ashiqur RahmanNo ratings yet

- Hydrometer Test: King Fahd University of Petroleum & Minerals CE 353 Soil Mechanics LaboratoryDocument9 pagesHydrometer Test: King Fahd University of Petroleum & Minerals CE 353 Soil Mechanics Laboratoryraja qammarNo ratings yet

- Optimizing LNG ProductionDocument75 pagesOptimizing LNG ProductionApriliaPuspitaSNo ratings yet

- 4.0 Experimental ProcedureDocument9 pages4.0 Experimental ProcedureSyazwan MansorNo ratings yet

- Development of 30Kg Crucible Furnace: BY Ore-Aruwaji Oluwaseyi 13/ENG06/027 Supervised by Engr. Dr. A. O. AdeoduDocument15 pagesDevelopment of 30Kg Crucible Furnace: BY Ore-Aruwaji Oluwaseyi 13/ENG06/027 Supervised by Engr. Dr. A. O. AdeoduVictor ImehNo ratings yet

- 1299 - EC0583Document5 pages1299 - EC0583Deipak HoleNo ratings yet

- Total Seriola 32 - Product Data SheetDocument3 pagesTotal Seriola 32 - Product Data Sheetjihad jamarei100% (1)

- 2015EHCNDocument3 pages2015EHCNsvvsnrajuNo ratings yet

- FM200 Cal1Document2 pagesFM200 Cal1Flash GuaranteeNo ratings yet

- Experiment 2Document5 pagesExperiment 2Patience LastyNo ratings yet

- Granular Pile AnchorDocument24 pagesGranular Pile Anchorgnklol3No ratings yet

- Danfoss - GLY12NRb - R134a - 115 - 60Document5 pagesDanfoss - GLY12NRb - R134a - 115 - 60Cristian GarciaNo ratings yet

- REPORTE PRACTICA 1 U2Document1 pageREPORTE PRACTICA 1 U2SANTIAGO YOSET HERNANDEZ MORGANNo ratings yet

- 18-12-22 - Inc - Jr.iit - Star Co-Sc (Model-A) - Jee Adv - 2016 (P-I) - Wat-24 - Key & SolDocument15 pages18-12-22 - Inc - Jr.iit - Star Co-Sc (Model-A) - Jee Adv - 2016 (P-I) - Wat-24 - Key & SolasdfNo ratings yet

- Specification For Approval: Product InstructionDocument9 pagesSpecification For Approval: Product InstructionPavel BatehinNo ratings yet

- S3 Written Assignment 2Document2 pagesS3 Written Assignment 2Suleka RanasingheNo ratings yet

- Drying CurveDocument3 pagesDrying CurveSuleka RanasingheNo ratings yet

- DryigDocument9 pagesDryigSuleka RanasingheNo ratings yet

- T Time T (Min) Balance Reading (G) Moisture Evaporated at T T Mass of Moisture Available in The Sample (G) Moisture Content (DB) Mass of Water/mass of Dry Solid XDocument5 pagesT Time T (Min) Balance Reading (G) Moisture Evaporated at T T Mass of Moisture Available in The Sample (G) Moisture Content (DB) Mass of Water/mass of Dry Solid XSuleka RanasingheNo ratings yet

- AbstractDocument6 pagesAbstractSuleka RanasingheNo ratings yet

- Disc CentrifugeDocument9 pagesDisc CentrifugeSuleka RanasingheNo ratings yet

- S3 Written Assignment 2Document1 pageS3 Written Assignment 2Suleka RanasingheNo ratings yet

- 18CH036 Hydrotreating ProcessDocument17 pages18CH036 Hydrotreating ProcessSuleka RanasingheNo ratings yet

- 18CH036 Hydrotreating ProcessDocument17 pages18CH036 Hydrotreating ProcessSuleka RanasingheNo ratings yet

- Presentation FinalDocument5 pagesPresentation FinalSuleka RanasingheNo ratings yet

- Continuous Low Load OperactionRTA-79 - RT-Flex-08Document3 pagesContinuous Low Load OperactionRTA-79 - RT-Flex-08rafaelNo ratings yet

- Cummins Kta19-G3 (403kw) - CoopalDocument1 pageCummins Kta19-G3 (403kw) - Coopalfrezgi birhanuNo ratings yet

- Retentores DynamicsDocument43 pagesRetentores DynamicsAlex GuedesNo ratings yet

- HR Katalog PDFDocument78 pagesHR Katalog PDFImran MehboobNo ratings yet

- Generators Portable Supersilent DCA40SSI Rev 0 Final ManualDocument140 pagesGenerators Portable Supersilent DCA40SSI Rev 0 Final ManualЕвгений Иванов100% (1)

- Owner'S Manual: Gasoline Engine 4TDocument44 pagesOwner'S Manual: Gasoline Engine 4Tjonasasw0% (1)

- Midterm Exam - HydraulicDocument4 pagesMidterm Exam - HydraulicIVÁN ARAYA100% (2)

- Design and Fabrication of Exhaust Gas Heat Recovery Power Generation SystemDocument7 pagesDesign and Fabrication of Exhaust Gas Heat Recovery Power Generation SystemIJRASETPublicationsNo ratings yet

- Journal of Science and TechDocument18 pagesJournal of Science and TechDEEPAKKUMAR CNo ratings yet

- Finished NotesDocument2 pagesFinished NotesBellmore BalayongNo ratings yet

- PD400Document2 pagesPD400Gabriel CoresNo ratings yet

- Thesis Titles 2k14 2k16Document21 pagesThesis Titles 2k14 2k16yewise4645No ratings yet

- 21 Series Cartridges: Standard Design FeaturesDocument1 page21 Series Cartridges: Standard Design FeaturesBROCHIERNo ratings yet

- Scania Engine Underpower - LatestDocument10 pagesScania Engine Underpower - LatestKanesh MaheshNo ratings yet

- Accessory Gear Inspection ProcedureDocument15 pagesAccessory Gear Inspection ProcedurechdiNo ratings yet

- Amvi Rto Mains 2020 - Study Material: - Second EditionDocument27 pagesAmvi Rto Mains 2020 - Study Material: - Second EditionUjwala SonawaneNo ratings yet

- IntroductionDocument9 pagesIntroductionBekalu DanielNo ratings yet

- Grua RT 880eDocument20 pagesGrua RT 880eCarlos ZuñigaNo ratings yet

- Motor IvecoDocument4 pagesMotor IvecoGuille ClaverieNo ratings yet

- AMCO - RBI Engineer - Mr. Syed Hameed HussainDocument4 pagesAMCO - RBI Engineer - Mr. Syed Hameed HussainOwais MalikNo ratings yet