Professional Documents

Culture Documents

C22-YS20-S-7962 - A - Package Layout - PS2 PDF

Uploaded by

sartajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C22-YS20-S-7962 - A - Package Layout - PS2 PDF

Uploaded by

sartajCopyright:

Available Formats

requirements of the List of Prohibited Substances

All materials supplied are in compliance with the

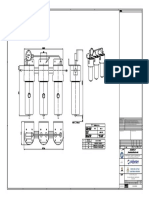

7186

3745

5

3370

4

5 POSSIBLE POSITIONS FOR 2995

3

ATTACHEMENT BEAM HOIST 2 2355

1 1745

ELEC. MOTOR

FLYWHEEL

CYL. LINE

CYL. LINE

CRANKCASE

TP1 COMPRESSOR A COMPRESSOR B

TP1

4094

COOLING

3825

TOWER

2683

COOLING

2502

TOWER

1963

1944

VIEW A VIEW F

19573

HP RECEIVER

HP RECEIVER

COOLING

TOWER

13700 1466 800

TP21 TP10

AIR OUTLET AIR OUTLET

5298 5298

TP22

TP9

1405

HP MAKE-UP WATER

RECEIVER TP10 1" GM

805

OVER FLOW 2" GM

TP9 AIR OUTLET

500

C

350

TP9 DRAIN 2" GM

TP10 AIR OUTLET

984

1286

TP6 TP7 TP6 TP7 HP

700 HP 700 HP B RECEIVER

FILTERS FILTERS F VIEW B

1000 800

530

752

TP16

752

AIR TP8 AIR TP8

CONTROL

CONTROL

PANEL

DRYER

PANEL

410 TP12 DRYER TP5 TP12 350 TP3

1120 R700 TP5 R700 410 TP2 TP4

TP2

VIEW C

TP17 TP17 TP11

TP11 D D E

368

368

TP18

TP19

TP18 E

TP20 TP19 TP20

COMPRESSOR A COMPRESSOR B A

TP3

5601

TP16 TP4 TP14

860 1120

1505

675

500

535

495

TP15 TP13

285

285

937

REFERENCE DRAWING:

DRAWING No. TITLE

TP15 377 377

DOOR WITH

DOOR WITH

C22-YS20-H-4950 SPECIFICATION OF HIGH PRESSURE COMPRESSOR IN SA3-PS2

WINDOW

WINDOW

TP13

TP14

D-D E-E

182 TP15

TP16

TP1 C22-YS20-S-7952 LAYOUT OF HIGH PRESSURE COMPRESSOR IN SA3-PS2

61TP3

TP4

COMP.

COMP.

250 250

60

60

AXIS

AXIS

C22-YS20-D-7954 P&ID - AUX OIL & WATER OF HIGH PRESSURE COMPRESSOR IN SA3-PS2

1710 1787

42

C22-YS20-D-7953 P&ID - AIR OF HIGH PRESSURE COMPRESSOR IN SA3-PS2

1322

TP1

3750 6000

ENGINEER'S STAMP: CONTRACTOR'S STAMP:

AIR INLET AIR INLET

ITEM TP COMMENT CONNECTION CLASS/NORME COMMENTS

TP1 FILTER INLET NO CONNECTION -

499 1605 9492 1605 499 TP2 HP AIR OUTLET 3/4" 900 lbs ASME B16.5

TP3 HP AIR OUTLET COMP. A 2" 600 lbs ASME B16.5 ENCLOSURE LIMIT

TP4 HP AIR OUTLET COMP. B 2" 600 lbs ASME B16.5 ENCLOSURE LIMIT

A FOR INFORMATION ACC OA SAA 26/04/2020

TP5 DRYER AIR INLET 1"1/2 600 lbs ASME B16.5

TP6 DRYER AIR OUTLET 1"1/2 600 lbs ASME B16.5

TP7 HP FILTER INLET 1" G FEMALE - REV. ISSUED FOR BY CHECKED APPROVED DATE

TP8 HP FILTER OUTLET 1" G FEMALE -

Project No.

TP9 AIR RECEIVER INLET 2" 600 lbs ASME B16.5

20407 KINGDOM OF SAUDI ARABIA

TP10 AIR RECEIVER OUTLET 2" 600 lbs ASME B16.5

TP11 COMPRESSOR WATER INLET 3" NP16 EN 1092-1

TP12 COMPRESSOR WATER OUTLET 3" NP16 EN 1092-1 SALINE WATER CONVERSION CORPORATION ( SWCC )

TP13 COOLING WATER INLET COMP.A 4" 150 lbs ASME B16.5 ENCLOSURE LIMIT

TP14

TP15

COOLING WATER OUTLET COMP. A

COOLING WATER INLET COMP.B

4" 150 lbs

4" 150 lbs

ASME B16.5

ASME B16.5

ENCLOSURE LIMIT

ENCLOSURE LIMIT

ننننا اثنامةنمنمارننهوينورااهانمنورن ةرمنورشورشم

INSTALL THE COMPRESSOR ON A SIMPLE INDUSTRIAL SLAB OF MINIMUM 300 mm THICKNESS WITHOUT TP16 COOLING WATER OUTLET COMP. B 4" 150 lbs ASME B16.5 ENCLOSURE LIMIT SHUQAIQ WATER TRANSMISSION SYSTEMS PHASE-3

SPECIAL PREPARATION FIXATION WITH CHEMICALS BOLTS TP17 DRYER WATER INLET 3/4" 150 lbs ASME B16.5

COUNTERMARK THE COMPRESSOR AND MOTOR FRAME HOLES ON CONCRETE BLOCK TP18 DRYER WATER OUTLET 3/4" 150 lbs ASME B16.5

TP19 WATER PUMP INLET 2" 150 lbs ASME B16.5

TP20 WATER PUMP OUTLET 2" 150 lbs ASME B16.5 سدنهملا

EQUIPMENTS WOULD STICK TO THE DIMENSIONS. TP21 COOLING TOWER INLET 4" 150 lbs ASME B16.5 ENGINEER

WEIGHT AND ARRANGEMENT AS PER THE DRAWING

TP22 COOLING TOWER OUTLET 4" 150 lbs ASME B16.5

CONTRACTOR

PACKAGE LAYOUT

SCALE

FOR HIGH PRESSURE COMPRESSORS

IN SA3-PS2

DRAWING NO. SHEET REV.

C 2 2 - Y S 2 0 - S - 7 9 6 2 1 of 1 A

SUBCONTRACTOR ATLASنCOPCO

You might also like

- Wheels & Tyres FinalDocument0 pagesWheels & Tyres Finalthisisjinesh0% (1)

- Piston Displacement Vs Crankshaft AngleDocument2 pagesPiston Displacement Vs Crankshaft AngleMurali KrishnaNo ratings yet

- Advance Filters: Filtros de AceiteDocument6 pagesAdvance Filters: Filtros de AceiteKevin Ortega80% (5)

- Honda HRA214 User ManualDocument41 pagesHonda HRA214 User ManualhighlandsguyNo ratings yet

- Teaching Aids Torque Converter - ModuleDocument16 pagesTeaching Aids Torque Converter - ModuleMohd HaikalNo ratings yet

- C22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test ProceduresDocument8 pagesC22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test Proceduressartaj100% (1)

- Manual de Parte 793D Parte IDocument869 pagesManual de Parte 793D Parte IJuan Vargas CNo ratings yet

- nsf250r 2012 Owners Manual English PDFDocument300 pagesnsf250r 2012 Owners Manual English PDFDavidNo ratings yet

- A320 Displays & PanelsDocument1,752 pagesA320 Displays & PanelsOleg TysiachnyiNo ratings yet

- Installation Method for Key Process EquipmentDocument54 pagesInstallation Method for Key Process EquipmentNGUYEN VINHNo ratings yet

- Below Ground Earthing LayoutDocument1 pageBelow Ground Earthing Layoutsartaj100% (1)

- 2924-A110-13C67-DWG-0004 - R0.1 - Electrical Cable Routing and Tray Routing Layout AdsorberDocument7 pages2924-A110-13C67-DWG-0004 - R0.1 - Electrical Cable Routing and Tray Routing Layout AdsorberRonti ChanyangNo ratings yet

- Engineering Subcontractor's Static Design Report for PS2 Surge VesselsDocument42 pagesEngineering Subcontractor's Static Design Report for PS2 Surge VesselssartajNo ratings yet

- Voltage Regulator Denso Type PDFDocument22 pagesVoltage Regulator Denso Type PDFJulio Cesar PedrazaNo ratings yet

- Cobra 148gtl SCH RedrawDocument1 pageCobra 148gtl SCH RedrawdengaodengaoNo ratings yet

- NDS SD 208Document1 pageNDS SD 208mengineeringNo ratings yet

- Specification for Nozzle Loadings of EquipmentDocument16 pagesSpecification for Nozzle Loadings of EquipmentshervinyNo ratings yet

- PIG Handling TrollyDocument1 pagePIG Handling TrollyAnas Badar100% (1)

- Consolidated Valve and Strainer BOQDocument13 pagesConsolidated Valve and Strainer BOQSumantra ChattopadhyayNo ratings yet

- Al-Khobar Seawater Reverse Osmosis 2 Desalination PlantDocument4 pagesAl-Khobar Seawater Reverse Osmosis 2 Desalination PlantABAID ULLAHNo ratings yet

- Welcome To The SNG Barratt Jaguar E-Type Parts CatalogueDocument93 pagesWelcome To The SNG Barratt Jaguar E-Type Parts CatalogueJimmy SingerNo ratings yet

- Pipe SupportDocument8 pagesPipe SupportVignesh GandhirajNo ratings yet

- Data Sheet 26 - Fig FT702 150 T StrainerDocument1 pageData Sheet 26 - Fig FT702 150 T StrainerSteve NewmanNo ratings yet

- 26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002Document33 pages26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002ogyriskyNo ratings yet

- Hdpe Pipe Butt Welding ProceduresDocument7 pagesHdpe Pipe Butt Welding ProceduresRodrigo CarizNo ratings yet

- Steel Structure Design Report for Loading Station ShelterDocument35 pagesSteel Structure Design Report for Loading Station ShelterAkram FerchichiNo ratings yet

- New Holland - b90b Loader Backhoe Parts ManualDocument1,344 pagesNew Holland - b90b Loader Backhoe Parts Manualdimaqdc100% (6)

- Issue Summary Form SOP-0402-07, Revision 12: BNPP - PPS ProjectDocument710 pagesIssue Summary Form SOP-0402-07, Revision 12: BNPP - PPS ProjectMRITYUNJOY DUTTANo ratings yet

- Tansmisii CVT Pentru TractoareDocument35 pagesTansmisii CVT Pentru TractoareCochintu RaduNo ratings yet

- Check Valve List for Power PlantDocument4 pagesCheck Valve List for Power Plantbandithaguru6338No ratings yet

- LMB2-E-FC-PIP-OCS-MS1-0015 Stress & Flexibility Analysis Report For Steam Separator LMB-ADocument30 pagesLMB2-E-FC-PIP-OCS-MS1-0015 Stress & Flexibility Analysis Report For Steam Separator LMB-AAzhar BudimanNo ratings yet

- GSPL203-73-1513 R-0Document37 pagesGSPL203-73-1513 R-0api-3846497No ratings yet

- Ane Spinms PVV Mto 300031 PDFDocument17 pagesAne Spinms PVV Mto 300031 PDFAtty AttyNo ratings yet

- Benelli TNT 1130 - Service Manual - EN PDFDocument392 pagesBenelli TNT 1130 - Service Manual - EN PDFAlejandro Jose Malave Ramos100% (2)

- PTTEP Zawtika Project Phase 1B Jacket MTODocument105 pagesPTTEP Zawtika Project Phase 1B Jacket MTOvu tuanNo ratings yet

- Ultra Low Headroom Electric Chain Hoist With Geared Travel Trolley. Range 1,000kg To 40,000kgDocument3 pagesUltra Low Headroom Electric Chain Hoist With Geared Travel Trolley. Range 1,000kg To 40,000kgsriguruprasathsNo ratings yet

- Iran Gas Pipeline Specification for Prefabricated Hot-BendDocument22 pagesIran Gas Pipeline Specification for Prefabricated Hot-Bendamini_mohiNo ratings yet

- Nioec SP 00 04 PDFDocument21 pagesNioec SP 00 04 PDFamini_mohiNo ratings yet

- GA-EN-TS00-PR-SPE-001-0 Specification For Surge Relief PackageDocument21 pagesGA-EN-TS00-PR-SPE-001-0 Specification For Surge Relief PackageChesterNo ratings yet

- Manual de Partes Motor Lister HR4/6/ S6Document208 pagesManual de Partes Motor Lister HR4/6/ S6Pablo Alfredo Loayza PeñalozaNo ratings yet

- Inspection Report of Monolithic Isolation Joint DeliveryDocument9 pagesInspection Report of Monolithic Isolation Joint DeliveryIqbal Nurrasa BaktiNo ratings yet

- DGS-2010-001 Design BasisDocument19 pagesDGS-2010-001 Design BasisJose ManjooranNo ratings yet

- Nitoseal 777 PDFDocument4 pagesNitoseal 777 PDFmilanbrasinaNo ratings yet

- S AA GEN CDF (Civ Design Fundamental) (Rev.0 2009)Document17 pagesS AA GEN CDF (Civ Design Fundamental) (Rev.0 2009)Mohammad Al JedyNo ratings yet

- 12 Inches Pig Receiver Supports Design PDFDocument13 pages12 Inches Pig Receiver Supports Design PDFolomuNo ratings yet

- #1 Pedestal Pipe Support PDFDocument3 pages#1 Pedestal Pipe Support PDFBayu Adi DharmaNo ratings yet

- Control Building Static Calculations: Design of Roof Beam 02 CalculationDocument21 pagesControl Building Static Calculations: Design of Roof Beam 02 Calculationisaacjoe77No ratings yet

- 16 B 2 Lec 18Document1 page16 B 2 Lec 18Jade Marielle DugeniaNo ratings yet

- Guide Document For Itemized Spring Hangers and Tie-Rod Data SheetsDocument19 pagesGuide Document For Itemized Spring Hangers and Tie-Rod Data SheetsAHMED AMIRANo ratings yet

- Wiik Catalogue 2007Document16 pagesWiik Catalogue 2007suosvannakNo ratings yet

- General Procedure for Road and River CrossingsDocument68 pagesGeneral Procedure for Road and River Crossingsrusli bahtiarNo ratings yet

- Bolt Table Directory (IPMCS)Document20 pagesBolt Table Directory (IPMCS)sourabhNo ratings yet

- LD-11 AmstrongDocument2 pagesLD-11 AmstrongGameR VanrenheitNo ratings yet

- Unicare Profile ComboDocument44 pagesUnicare Profile CombosaliqNo ratings yet

- Chirukhistsqali Weir RHS Manhole Chamber Calculation ReportDocument36 pagesChirukhistsqali Weir RHS Manhole Chamber Calculation Reporthasan_kygszNo ratings yet

- Boundary WallDocument1 pageBoundary WallnaseerNo ratings yet

- Reviewed Design Input for QIPP Slop Tank FabricationDocument2 pagesReviewed Design Input for QIPP Slop Tank FabricationMathivanan AnbazhaganNo ratings yet

- Knife Gate Valves PDFDocument2 pagesKnife Gate Valves PDFashish_pradhan75No ratings yet

- Econ Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800Document1 pageEcon Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800ChristianGuerreroNo ratings yet

- MINISTRY MUNICIPALITIES PUBLIC WORKS TWST COMPARTMENTS PUMPING STATIONDocument4 pagesMINISTRY MUNICIPALITIES PUBLIC WORKS TWST COMPARTMENTS PUMPING STATIONnazar750No ratings yet

- Test Report Long-Term Ring Bending Strain (SB)Document4 pagesTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroNo ratings yet

- Emirates National Oil Co. LTD: Belleli Energy SRLDocument7 pagesEmirates National Oil Co. LTD: Belleli Energy SRLKhairul JaggerNo ratings yet

- 4200 Alform SuperSlim Truss Bottom Chord Plan LayoutDocument5 pages4200 Alform SuperSlim Truss Bottom Chord Plan LayoutMahata PriyabrataNo ratings yet

- Pipeline AnchorBlockDocument37 pagesPipeline AnchorBlockAnonymous ciKyr0t100% (1)

- Paradip Refinery Water Supply ProjectDocument23 pagesParadip Refinery Water Supply ProjectTeja GajjarNo ratings yet

- UN 9252-02 Part 1 - UD-AU-000-EB-00019 PDFDocument17 pagesUN 9252-02 Part 1 - UD-AU-000-EB-00019 PDFManjeet Saini100% (1)

- 020-046 Watermain Thrust Block Details-ModelDocument1 page020-046 Watermain Thrust Block Details-ModelWynle OrgilNo ratings yet

- PSV CatalogDocument60 pagesPSV Catalogbuler empatsatuduaNo ratings yet

- Flange Dim EN1092 1 BS4504Document13 pagesFlange Dim EN1092 1 BS4504rcpretoriusNo ratings yet

- Seepage Flow Net FDMDocument68 pagesSeepage Flow Net FDMRenalyn AndradeNo ratings yet

- Loads on Air Cooler InletDocument1 pageLoads on Air Cooler Inletduf fu0% (1)

- Profis Anchor Design for KWIK HUS-EZ AnchorDocument6 pagesProfis Anchor Design for KWIK HUS-EZ AnchorJester AbucayNo ratings yet

- BPCL - RC - 171 179 1 9Document9 pagesBPCL - RC - 171 179 1 9isan.structural TjsvgalavanNo ratings yet

- BPCL - RC - 171 179 1 2Document2 pagesBPCL - RC - 171 179 1 2isan.structural TjsvgalavanNo ratings yet

- DSL100M2-60-02-V5 Page2Document1 pageDSL100M2-60-02-V5 Page2TxetxeluNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 16.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 16.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 17.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 17.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 18.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 18.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 09.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 09.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 15.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 15.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 10.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 10.DwgsartajNo ratings yet

- Shuqaiq Wts - Phase 3: ReferenceDocument1 pageShuqaiq Wts - Phase 3: ReferencesartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 06.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 06.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 07.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 07.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 02.DwgsartajNo ratings yet

- G:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 01.DwgDocument1 pageG:/Acad/1762 Shuqaiq Phase-3/01 - General Plot Plan/C24 - Sa3-Ps4/3D Plant/C24 - Abha Ps4/Isometric/Final - A2/Prodisos/Drawings/C24-Ya40-S-7001 - 01.DwgsartajNo ratings yet

- C22-Yb60-F-4767 - 1 Sa3-Ps2, Butterfly Valve, Painting ProcedureDocument94 pagesC22-Yb60-F-4767 - 1 Sa3-Ps2, Butterfly Valve, Painting ProceduresartajNo ratings yet

- Shuqaiq Wts - Phase 3: ReferenceDocument1 pageShuqaiq Wts - Phase 3: ReferencesartajNo ratings yet

- C22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFDocument3 pagesC22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFsartajNo ratings yet

- C22-YS20-S-7957 - A - HP Filter Layout - PS2 PDFDocument1 pageC22-YS20-S-7957 - A - HP Filter Layout - PS2 PDFsartajNo ratings yet

- Shuqaiq Wts - Phase 3: ReferenceDocument1 pageShuqaiq Wts - Phase 3: ReferencesartajNo ratings yet

- C22-YS20-H-4965 - 0 - Cooling Tower DS - PS2 PDFDocument2 pagesC22-YS20-H-4965 - 0 - Cooling Tower DS - PS2 PDFsartajNo ratings yet

- C22-YS20-H-4965 - 0 - Cooling Tower DS - PS2 PDFDocument2 pagesC22-YS20-H-4965 - 0 - Cooling Tower DS - PS2 PDFsartajNo ratings yet

- C22-Yb60-F-4767 - 1 Sa3-Ps2, Butterfly Valve, Painting ProcedureDocument94 pagesC22-Yb60-F-4767 - 1 Sa3-Ps2, Butterfly Valve, Painting ProceduresartajNo ratings yet

- NDE Procedures for Butterfly Valve InspectionDocument23 pagesNDE Procedures for Butterfly Valve InspectionsartajNo ratings yet

- C22-YS20-S-7956 - A - Dryer Layout - PS2Document2 pagesC22-YS20-S-7956 - A - Dryer Layout - PS2sartajNo ratings yet

- Engineer's Sticker: Butterfly Valve SchematicsDocument4 pagesEngineer's Sticker: Butterfly Valve SchematicssartajNo ratings yet

- C22-Yb60-S-7769 - 0 - PS2, Butterfly Valve, General Arrangement DrawingsDocument13 pagesC22-Yb60-S-7769 - 0 - PS2, Butterfly Valve, General Arrangement DrawingssartajNo ratings yet

- fl3570hp SeriesDocument417 pagesfl3570hp SeriesfilipCARbovaNo ratings yet

- Department of Transportation Federal Aviation AdministrationDocument8 pagesDepartment of Transportation Federal Aviation AdministrationsandyNo ratings yet

- Assembly and Operation ManualDocument12 pagesAssembly and Operation ManualGodsniperNo ratings yet

- Torsen Differential White PaperDocument8 pagesTorsen Differential White PaperPadmAnabhNo ratings yet

- A51 A43 A34 A23 A22 A26 A24 A25 A32 A45: Position of Parts in Engine CompartmentDocument4 pagesA51 A43 A34 A23 A22 A26 A24 A25 A32 A45: Position of Parts in Engine CompartmentApril MckeeNo ratings yet

- Enerpac Hand Pumps With JacksDocument2 pagesEnerpac Hand Pumps With Jacksmarklamb1hotmailcoukNo ratings yet

- WB156-5 y WB 156PS-5 Retros KomatsuDocument10 pagesWB156-5 y WB 156PS-5 Retros KomatsuEdith perezNo ratings yet

- 4016TAG1ADocument2 pages4016TAG1AMadih ElghannamNo ratings yet

- Berkeley Hyundai Stock Report - 07.03.2024Document88 pagesBerkeley Hyundai Stock Report - 07.03.2024JammaNo ratings yet

- 08DDECVI28Document4 pages08DDECVI28Anonymous nhF45CNo ratings yet

- HYUNDAI A4AF1/2, A4BF1/2 & F4A32-1: 4 SPEED FWD With Lock Up (Electronic Control)Document3 pagesHYUNDAI A4AF1/2, A4BF1/2 & F4A32-1: 4 SPEED FWD With Lock Up (Electronic Control)krzysiek1975No ratings yet

- T SB 0385 09Document6 pagesT SB 0385 09goomba100% (1)

- 1/ General: 165 KW (1500 RPM)Document3 pages1/ General: 165 KW (1500 RPM)Nguyễn Tấn TrưởngNo ratings yet

- EngineDocument14 pagesEngineChandraranga De SilvaNo ratings yet

- Service Letter Essential Information Regarding Engine Behavior, Perfor-Mance and Manifold Pressure Data For ROTAX Engine Type 912 and 914 (Series)Document10 pagesService Letter Essential Information Regarding Engine Behavior, Perfor-Mance and Manifold Pressure Data For ROTAX Engine Type 912 and 914 (Series)mONo ratings yet

- Instructiuni Montare Stand Next Level Racing DDDocument14 pagesInstructiuni Montare Stand Next Level Racing DDGaby XiuNo ratings yet