Professional Documents

Culture Documents

Hse Goals and Targets

Uploaded by

VICTOROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hse Goals and Targets

Uploaded by

VICTORCopyright:

Available Formats

DREDGING LIMITED

HSE MS STANDARD PROCEDURE

This procedure shall remain the sole property of

UTM DREDGING LIMITED

And shall be returned upon request

TITLE

DOCUMENT NO: 1135

HSE GOALS AND TARGETS

HSEQMS-P-14

APPROVED NAME JULIUS RONE

BY POSITION MD/CEO

SIGNATURE

DATE January 2019

This procedure and the following revisions have been accepted for use by

UTM DREDGING LIMITED

DATE SECTION REVISION NATURE OF REVISION COMPLETED REVIEWED BY

( S) N O. BY

10-01-19 - 0 New Procedure VICTOR TASIE VICTOR TASIE

HSE GOALS AND TARGETS YEAR 2020

As from the result of 2019, HSE performance review, these and the entire management following

revision have set the following objectives and targets for 2020.

It becomes our collective responsibility to achieve these tasking plans. We request the General

manager and respective head of departments, managers and the entire work force of UTM Dredging

Limited to get fully committed towards achieving these objectives and targets

HSE Objectives

Protect personnel from any health hazards that may be associated with the work

Provide accident free environment to UTM and Contractors' employees

Maintain compliance with all the applicable HSE Legal/Regulatory requirements

Improve HSE culture among UTM and Contractors employees

Reduce environmental impacts and improve performance regularly

HSE TARGETS

NO FATALITY

NO LOST TIME

S/N Contractor’s Leading KPI REMARKS/ HOW TO ACHIEVE KPI

Indicators

1 Number of SSHE 12 Management must be committed to the process,

walkthrough inspection Documentation must be made and record keeping to be in

carried out. good order and ready for review and inspection.

2 Number of hazards 360 Always Identify hazards associated with emergency, no

identified routine situations and health hazards

3 % of Identified Hazards 100 Set up targets for all workers and monitor progress daily.

closed out

4 Number of Safety 25 Will Be Proactive & Learn From other incidents by discussing

Alert/Lessons learned with staffs during safety meetings

shared

6 Number of Tool box & Safety 420 Will Continue To Do More

meeting held

7 Number of emergency drills 120 Will Work Harder To Achieve KPI

conducted

8 Number of PTW/JSA Audits 250 Will Continue To Monitor The System For Effectiveness

conducted

9 Number of Alcohol & Drug 8 Carryout unexpected random drug and alcohol test

test conducted

10 Number of Near Miss 4 Continue to discusses previous incident during toolbox or

Reported safety meetings

11 % Number of Near Miss 4 No Near Miss Recorded

Reports Investigated

12 % of MCCP Compliance 100% In Total Compliance

13 Annual compliance of training 80% Through management commitment and planning

plan

14 Annual compliance of HSE 100% Through management commitment and planning

management review meeting

15 Annual compliance of 90% Continuous communication with all staffs and form of

emergency mock drills encouragement

16 Annual compliance of HSE 90% Through management commitment and planning

inspection and audits

ACTIVE MONITORING

SAFETY

Muster & First Aid Drills Quarterly Tool Box Meetings - 1 Per Week

Audits & Inspections Monthly Drugs & Alcohol Screening Random

Meetings with top Head /Managers Monthly Pre Employment defence Driving Assessment-

100%

HSE Review Meetings With Head / Managers Quarterly Pre Employment defensive Driving Training –

100 %

HSE meetings with Contractors Bi Annually HEALTH

General HSE Meetings Weekly Health & Hygiene Examination = Bi annually

New Employee HSE Inductions On Appointment Pre Employment Medical Fitness Examination

Man Over Board Drills ( As Contain on drill matrix ) Post Employment Medical Fitness Examination

ENVIRONMENT TRAINING

Serious Environment Pollution =0 Pre job hazard identification & Risk assessment

(HIRA) Entire team = 100%

Monitoring of proper fumigation / waste management › 95% On Job Training ( OJT) for key New Personnel =

(Only Qualified & Licensed Managers for Offices / Base 90%

Julius Rone –

MD /CEO

You might also like

- WDC 2013-14 Health & Safety ReportDocument18 pagesWDC 2013-14 Health & Safety ReportSarah WalkerNo ratings yet

- VPO PPE MatrixDocument1 pageVPO PPE MatrixMohamedSaidNo ratings yet

- Annexure - IV - Contractor HSE Capability Assessment Sheet - Rev 00 - VibrantDocument4 pagesAnnexure - IV - Contractor HSE Capability Assessment Sheet - Rev 00 - VibrantGovindKrishnanNo ratings yet

- 2015 HSE Campaign PDFDocument4 pages2015 HSE Campaign PDFAnkit Dudeja100% (1)

- 2013 HSE Annual Report Web FINALDocument74 pages2013 HSE Annual Report Web FINALThiếu Nhiều Thứ100% (1)

- Training Matrix بيردتلا ةفوفصم: PDWB-HSE-FRM-030Document1 pageTraining Matrix بيردتلا ةفوفصم: PDWB-HSE-FRM-030mahmoud nada100% (1)

- HEO Monthly HSE Perfomance Report 24 FeDocument11 pagesHEO Monthly HSE Perfomance Report 24 Feabdulla kasim100% (1)

- Health & Safety Professioanl CVDocument5 pagesHealth & Safety Professioanl CVnaveedNo ratings yet

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- Attachment Q6 - HSE Plan 2019Document1 pageAttachment Q6 - HSE Plan 2019aymenmoatazNo ratings yet

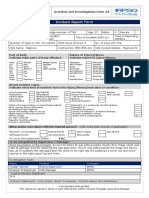

- Incident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5ADocument2 pagesIncident Report Form: RPSG-IMS-F-24 Accident and Investigation Form 5ARocky Bis100% (1)

- Safe Work Practice in Confined Space: 2019 Vulnerability Refresh & Reminder ProgramDocument2 pagesSafe Work Practice in Confined Space: 2019 Vulnerability Refresh & Reminder ProgramMuhammad TohirNo ratings yet

- Report Flowchart GuideDocument1 pageReport Flowchart GuideTXsafetymasters12100% (1)

- Training Matrix ProcedureDocument5 pagesTraining Matrix ProcedureSérgio CoutoNo ratings yet

- HSE Observation Card LogDocument1 pageHSE Observation Card Logramod100% (1)

- Safety Induction EssentialsDocument42 pagesSafety Induction EssentialsAdeel Ahmed100% (2)

- Scaffold Safety AssessmentDocument2 pagesScaffold Safety Assessmentarnel sungkip100% (1)

- HSE Inspection Matrix - c416Document1 pageHSE Inspection Matrix - c416Venkadesh PeriathambiNo ratings yet

- EHS Calendar September 2019 Training Fire Safety PPE AuditsDocument1 pageEHS Calendar September 2019 Training Fire Safety PPE AuditsSiddharth RanaNo ratings yet

- 4.4.3.3 Data and Trend AnalysisDocument6 pages4.4.3.3 Data and Trend AnalysisIndermohan MehtaNo ratings yet

- Hse Audit Checklist PDFDocument6 pagesHse Audit Checklist PDFnorlieNo ratings yet

- Safety Assessment Questionnaire AppendixDocument26 pagesSafety Assessment Questionnaire AppendixSignam Specialised CoatingsNo ratings yet

- Noise Monitoring Record FormDocument2 pagesNoise Monitoring Record FormMalefane Cortez TlatlaneNo ratings yet

- Stop Work AuthortyDocument8 pagesStop Work AuthortyRonald Sarillana100% (1)

- Monthly HSE Performance Report Form DTLP FEB-21Document2 pagesMonthly HSE Performance Report Form DTLP FEB-21Muhammad Khan100% (1)

- HSE StatisticsDocument5 pagesHSE Statisticsgiri943100% (1)

- Hse Objective & Program: I. Lagging IndicatorDocument11 pagesHse Objective & Program: I. Lagging Indicatorhitly malianorNo ratings yet

- HSE Training ReportDocument1 pageHSE Training ReportpjosesmNo ratings yet

- Safety Monitoring Plan (OGF-HSE-035)Document1 pageSafety Monitoring Plan (OGF-HSE-035)sarge18No ratings yet

- LifeSavingRules - Supplementary Rules PostersDocument11 pagesLifeSavingRules - Supplementary Rules PostersInternational Association of Oil and Gas ProducersNo ratings yet

- HSE 2014 Annual Report WLinksDocument78 pagesHSE 2014 Annual Report WLinksarunradNo ratings yet

- HSE Evaluation Form PDFDocument4 pagesHSE Evaluation Form PDFFaizal ENRANo ratings yet

- Halliburton: Job Safety AnalysisDocument2 pagesHalliburton: Job Safety Analysisaneshse100% (1)

- Consequence Management Sytem EsepplDocument1 pageConsequence Management Sytem Eseppluttam mishra100% (2)

- Visitors HSES InductionDocument30 pagesVisitors HSES InductionPradeep KunduNo ratings yet

- HSE SOP-02 Orientation and TrainingDocument4 pagesHSE SOP-02 Orientation and Traininggede aris prayoga mahardikaNo ratings yet

- Hse Training MatrixDocument2 pagesHse Training MatrixYose Rizal100% (1)

- Project Monthly SHEQ Planning FormDocument3 pagesProject Monthly SHEQ Planning FormParashuram PatilNo ratings yet

- Sshe Performance Monthly Report: Project: PeriodDocument1 pageSshe Performance Monthly Report: Project: PeriodYudi Arkananta100% (1)

- Eohsms Objectives and TargetsDocument5 pagesEohsms Objectives and TargetsHassan AbdullahNo ratings yet

- ErtyyuioluiolDocument16 pagesErtyyuioluiolVinoth Sudalai100% (1)

- Eye Protection Safety CampaignDocument11 pagesEye Protection Safety CampaignLamtua Purba100% (2)

- Ladder Inspection Checklist: General Condition OK Needs Repair Not ApplicableDocument1 pageLadder Inspection Checklist: General Condition OK Needs Repair Not ApplicableWaqas KhanNo ratings yet

- Att 1 HSE Objectives & TargetsDocument1 pageAtt 1 HSE Objectives & TargetsAbdul Hakam Mohamed Yusof100% (1)

- HSE Action PlanDocument5 pagesHSE Action PlansantosoNo ratings yet

- HSE Programme and Training PDFDocument5 pagesHSE Programme and Training PDFatirahNo ratings yet

- HSE-P-07 Work Permit Procedure Issue 2.1Document30 pagesHSE-P-07 Work Permit Procedure Issue 2.1eng20072007100% (1)

- 23 HSE Training MatrixDocument5 pages23 HSE Training Matrixsafety.officer100% (1)

- Lifting PermitDocument1 pageLifting PermitManesh MNo ratings yet

- HSE Monthly Report Mei 2020Document19 pagesHSE Monthly Report Mei 2020Rendi SeptiansyahNo ratings yet

- Health and Safety Improvement ProgramDocument11 pagesHealth and Safety Improvement ProgramEng Muhammad MarzoukNo ratings yet

- Notification and Reporting Procedure: How We Report HSE and Operational AccidentsDocument46 pagesNotification and Reporting Procedure: How We Report HSE and Operational AccidentsmohamedNo ratings yet

- HSE Performance MonitoringDocument5 pagesHSE Performance MonitoringUnachukwu Sopulu SopsyNo ratings yet

- HSE Assurance PlanDocument15 pagesHSE Assurance Planvlad88% (8)

- All Forms HSE Docs by Hseprof Com 1697423389Document76 pagesAll Forms HSE Docs by Hseprof Com 1697423389ahmedalderbi801No ratings yet

- EHS QuestionaireDocument26 pagesEHS QuestionaireR.GanesanNo ratings yet

- Cutting Machine Inspection ChecklistDocument1 pageCutting Machine Inspection ChecklistThein Myint OoNo ratings yet

- Site Safety Audit ReportDocument3 pagesSite Safety Audit Reportasem sawalmehNo ratings yet

- Security Policy: Dredging Limited Dredging LimitedDocument1 pageSecurity Policy: Dredging Limited Dredging LimitedVICTORNo ratings yet

- AHT Operations GuideDocument10 pagesAHT Operations Guidefundatia_gaudeamus100% (3)

- Mutual Rescission and Release Agreement PolicyDocument2 pagesMutual Rescission and Release Agreement PolicyVICTORNo ratings yet

- Mutual Rescission and Release Agreement PolicyDocument2 pagesMutual Rescission and Release Agreement PolicyVICTORNo ratings yet

- Vessel Inspection Report TemplateDocument12 pagesVessel Inspection Report TemplateVICTORNo ratings yet

- Behavior Based Safety ProgramDocument2 pagesBehavior Based Safety ProgramVICTORNo ratings yet

- Chief Engineers Internal HandoverDocument4 pagesChief Engineers Internal HandoverVICTORNo ratings yet

- Boldbee Enterprises Letter HeadDocument1 pageBoldbee Enterprises Letter HeadVICTORNo ratings yet

- Logo 2Document1 pageLogo 2VICTORNo ratings yet

- Nor-Bkr-54-20-60t 0001Document2 pagesNor-Bkr-54-20-60t 0001VICTORNo ratings yet

- Check List Pre Transfer BunkerDocument2 pagesCheck List Pre Transfer BunkerVICTORNo ratings yet

- NON CONFORMITY Module 1Document13 pagesNON CONFORMITY Module 1VICTORNo ratings yet

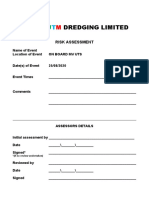

- Risk assessment for onboard dredging vessel eventDocument5 pagesRisk assessment for onboard dredging vessel eventVICTORNo ratings yet

- Familiarisation Crew MembersDocument2 pagesFamiliarisation Crew MembersVICTORNo ratings yet

- Risk assessment for onboard dredging vessel eventDocument5 pagesRisk assessment for onboard dredging vessel eventVICTORNo ratings yet

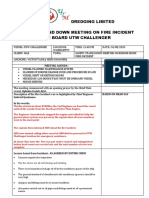

- Dredging Limited Safety Stand Down Meeting On Fire Incident On Board Utw ChallengerDocument2 pagesDredging Limited Safety Stand Down Meeting On Fire Incident On Board Utw ChallengerVICTORNo ratings yet

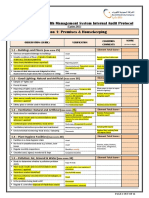

- Utm Dredging Limited: Health & Safety Management SystemDocument2 pagesUtm Dredging Limited: Health & Safety Management SystemVICTORNo ratings yet

- Nigeria Content Execution Strategy 01Document28 pagesNigeria Content Execution Strategy 01VICTORNo ratings yet

- Safe Storage of Hazardous Chemicals PolicyDocument3 pagesSafe Storage of Hazardous Chemicals PolicyVICTORNo ratings yet

- Accident Investigation ChecklistDocument2 pagesAccident Investigation ChecklistVICTORNo ratings yet

- Risk assessment for onboard dredging vessel eventDocument5 pagesRisk assessment for onboard dredging vessel eventVICTORNo ratings yet

- 10 Reliable Workplace Safety RecommendationsDocument6 pages10 Reliable Workplace Safety RecommendationsVICTORNo ratings yet

- Finance N Account SpreadsheetDocument11 pagesFinance N Account SpreadsheetVICTORNo ratings yet

- Crew Boat Table Provides Vessel DetailsDocument4 pagesCrew Boat Table Provides Vessel DetailsVICTORNo ratings yet

- Closed Out Actions SummaryDocument4 pagesClosed Out Actions SummaryVICTORNo ratings yet

- Behavior Based Safety ProcedureDocument11 pagesBehavior Based Safety ProcedureVICTOR100% (2)

- Policy and Procedure Manual TemplateDocument37 pagesPolicy and Procedure Manual TemplateBalaji Pharmacy - GMNo ratings yet

- Un Marine Contracted Vessel Hazard Tracking Form 03 11 !9Document4 pagesUn Marine Contracted Vessel Hazard Tracking Form 03 11 !9VICTORNo ratings yet

- Reefer Container Inspection Report for Abo OffshoreDocument2 pagesReefer Container Inspection Report for Abo OffshoreVICTORNo ratings yet

- Requisition FormDocument1 pageRequisition FormVICTORNo ratings yet

- Recognised Security Organisation Instruction 1 2018 PDFDocument21 pagesRecognised Security Organisation Instruction 1 2018 PDFHamzah HinduanNo ratings yet

- HO 2 - Qualified Audit ReportDocument3 pagesHO 2 - Qualified Audit ReportRheneir Mora100% (1)

- Quiz 3Document2 pagesQuiz 3JEANNE PAULINE OABELNo ratings yet

- TOR - DASTPEK 2023 Management - PSDDocument18 pagesTOR - DASTPEK 2023 Management - PSDRanya HusseinNo ratings yet

- 065D9CB4412Document8 pages065D9CB4412bkNo ratings yet

- GCC C20006 Mar Ac 026 - R0Document49 pagesGCC C20006 Mar Ac 026 - R0ahmed abdohNo ratings yet

- Industrial House Keeping Through 5S Technique (HINDI)Document79 pagesIndustrial House Keeping Through 5S Technique (HINDI)Aman Singh90% (69)

- Tangazo Tamisemi 2023-2024Document91 pagesTangazo Tamisemi 2023-2024SAIDI NYAHEGONo ratings yet

- Naushad AR - Curiculam VitaeDocument7 pagesNaushad AR - Curiculam VitaeSanjay KhanNo ratings yet

- COMSATS Business Case Competition ReportDocument21 pagesCOMSATS Business Case Competition ReportMuhammad Saeed AbbasiNo ratings yet

- Safety Campaign-Bypassing Safety Control-Feb 2022Document4 pagesSafety Campaign-Bypassing Safety Control-Feb 2022HSE99 BHDCNo ratings yet

- MODULE 6A Home Office and Branch AccountingDocument14 pagesMODULE 6A Home Office and Branch AccountingmcespressoblendNo ratings yet

- Unit 5 - TRANSFER PRICINGDocument28 pagesUnit 5 - TRANSFER PRICINGRachma DiniNo ratings yet

- AGROVETDocument37 pagesAGROVETcaroprinters01No ratings yet

- ISO 9001:2015 Transition ChecklistDocument11 pagesISO 9001:2015 Transition ChecklistCitizen KaneNo ratings yet

- Sample Lecture 1Document168 pagesSample Lecture 1Maryjoy DimaandalNo ratings yet

- Homework/Assignment: Full Name of Submitter: Vo Thi Thien My Student ID: IEIEIU18057Document7 pagesHomework/Assignment: Full Name of Submitter: Vo Thi Thien My Student ID: IEIEIU18057Trân LêNo ratings yet

- WWW - Fciweb.nic - In: Page 1 of 13Document14 pagesWWW - Fciweb.nic - In: Page 1 of 13Rahul RawatNo ratings yet

- Question f8 Audit RiskDocument4 pagesQuestion f8 Audit RiskTashfeenNo ratings yet

- Total Quality Management: Total Quality Management or TQM Is An Integrative Philosophy of Management ForDocument8 pagesTotal Quality Management: Total Quality Management or TQM Is An Integrative Philosophy of Management ForUpasana KanchanNo ratings yet

- A Study On Risk and Return Analysis and DataDocument10 pagesA Study On Risk and Return Analysis and DataShweta workNo ratings yet

- Term Project: Strategic MarketingDocument10 pagesTerm Project: Strategic Marketingmuhammad mustafa iqbalNo ratings yet

- Po809437 Retro SGN SignedDocument1 pagePo809437 Retro SGN SignedEddie Carvajal DiazNo ratings yet

- 6018-P1-Kunci-Bu EndahDocument39 pages6018-P1-Kunci-Bu EndahLilik SuryawanNo ratings yet

- BSCAT Pitblado Potts Fisher Greenfield PSP Dec 2015Document7 pagesBSCAT Pitblado Potts Fisher Greenfield PSP Dec 2015Hesham FandyNo ratings yet

- Safety Manual Blue PeterDocument102 pagesSafety Manual Blue Peterfaraz ahmedNo ratings yet

- Manpower Planning MethodsDocument15 pagesManpower Planning Methodsdonnellvineeth50% (2)

- MGT301 FINAL TERM SOLVED MCQsDocument16 pagesMGT301 FINAL TERM SOLVED MCQsmishi dollNo ratings yet

- CMO 63 ChecklistDocument2 pagesCMO 63 ChecklistmarrielleNo ratings yet

- Module 1: Overview of Production Operations Management: Unit 1: The Nature & Purpose of OrganizationsDocument4 pagesModule 1: Overview of Production Operations Management: Unit 1: The Nature & Purpose of OrganizationsUchayyaNo ratings yet