Professional Documents

Culture Documents

Checklist of Requirements For Permit To Operate (Po) Application

Checklist of Requirements For Permit To Operate (Po) Application

Uploaded by

Erika CadawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checklist of Requirements For Permit To Operate (Po) Application

Checklist of Requirements For Permit To Operate (Po) Application

Uploaded by

Erika CadawanCopyright:

Available Formats

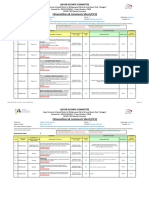

CPD FORM PO-3-2019 ver. 1.

Department of Environment and Natural Resources

ENVIRONMENTAL MANAGEMENT BUREAU

Region VII

CHECKLIST OF REQUIREMENTS FOR PERMIT TO OPERATE (PO) APPLICATION

Type of Application Requirements Notes

For Boilers >50HP; if Coal fired provide fuel

analysis for metallic components of your coal

Required Emission Testing Generator Set >300 kW (375kVA)

A. 1, 2, 4, 5, 6, 7, 9, 10a/b, & (exclude B. 6 if with Emission Test Result)

New (1) 11 and B. 1, 2, 3, 4, 5, 6 & 7, Other Sources Generating > 10MT/yr of

8 Pollutants

For Manufacturing but not required for emission

All items excluding A. 9

testing

For Non Manufacturing All items excluding B. 2 & 3

Lumberyard or Resaw Mill with Production

Capacity of ≤ 100 m3/yr and Below

A. 1, 2, 4, 5, 6, 7, 10a/b & 11 Stand-by Generator Sets with Rated Capacity of

New (II) If Manufacturing but only Generator Set ≤ 300kW

and B. 1, 4, & 5, 8 ≤ 300kW and For Boilers ≤50HP for Non-

or For Boilers ≤50HP is the APSE include B. 2, 3

Manufacturing Establishments

For Rice and Corn Mill (NOT covered by the All items excluding A. 4, 5, 10a, 11 but include

Philippine EIS System) B. 2

For Rice and Corn Mill (NOT covered by the

A. 1, 2, 4, 5, 7, 8, 9, 10a, 11, All items excluding A. 4, 5, 9, 10a, 11

Renewal Philippine EIS System)

B. 8

Exempted for emission testing All items excluding A. 9

A. 1, 2, 4, 5, 7, 8, 9, 10a, 11, Same Type of Equipment Covered by Existing or For Manufacturing Additional APSE: provide

&B. 4,8 Previous Permit to Operate Justification, show existing annual production and

Additional / Replacement projected annual production

A. 1, 2, 4, 5, 7, 8, 9, 10a, 11, For Different Type of Equipment Not Covered by

&B. 4, 5, 6, 7,8 Existing or Previous Permit to Operate Exlude A. 9 For Boilers ≤ 50HP, Generator Set ≤

300 kW (375kVA), Other Sources Generating ≤

A. 1, 2, 3, 4, 5, 8, 9, 10a, 11 10MT/yr of Pollutants

Change of Name/Ownership

B. 8 Exclude B. 6, 7 Regardless of Capacity Generator

Set, Boiler

A. MANDATORY REQUIREMENTS/ATTACHMENTS

1. Transmittal Letter

2. Duly Accomplished and Notarized Application Form (signed by PCO and Managing Head)

3. Proof of Ownership (e.g. SEC or DTI Registration & Other Documents)

4. DENR ID Number as Hazardous Waste Generator/Receipt of Application

5. Copy of the Environmental Compliance Certificate (ECC) or Certificate of Non-Coverage (CNC) from DENR-EMB, if applicable

6. Project/Company Vicinity Map

7. Geo-tag Photos of all Actual Air Pollution Source Installation (APSI) and Air Pollution Control Facility (APCF)

8. Copy of Active/Previous Permit

9. Copy of Latest Emission Test Results (Summary Only) from a DENR-EMB Accredited Emission Testing Firm, if applicable

10. a. Copy of Pollution Control Officer Accreditation/COA no./ b. Letter of Appointment/designation

11. Copy of Discharge Permit or Proof of Application

B. ENGINEER'S REPORT (signed by PCO/PME/ChE and concurred by Managing Head)

1. Project Information or Company Profile

2. Brief Description of Manufacturing Process (with Process Flow Illustrations/Diagram), if applicable

3. Tabulated List of Raw Materials, Finished Products and Wastes with Corresponding Quantities (Volume, Weight or Number of Pieces), if applicable

4. Tabulated List of Air Pollution Source Equipment (APSE), Process Equipment (PE) and Air Pollution Control Facility (APCF)

4.1 For Fuel Burning Equipment, Specify the Corresponding Number of Units, Control Device, Fuel Type, Fuel consumption, and Rated Capacity in Hp or kW

4.2 For Non-Fuel Burning Equipment or Process Equipment, Specify the Corresponding Number of Units, Control Device, Fuel Type and Rated Material Output in

MTons/hr

4.3 For Air Pollution Control Facility, Specify the Corresponding Number of Units and Capacity in m 3/min

5. Detailed Description of Operation of each APSE, PE and APCF

6. Design Computation or Estimates with Emphasis on the ff.:

a) Computation or Estimates of Quantity of Pollutants Generated expressed in mg/NCM or Actual 3 rd Party Emission Test Results Summary or Ambient Air

Quality Test Results Summary, whichever is applicable

b) Computation/Estimates in the Design of APCF, if applicable

c) Predicted Collection Efficiency expressed as Ratio of Pollutants Generated with and w/o APCF, if applicable

d) Justification for Non-installation of APCF, if applicable

7. Technical Drawing illustrating the ff.:

a) Plant & Machinery Layout in Block Form clearly showing connections of APSI to APCF

b) Detailed Plan and Elevation Drawings with Labeled Parts and Dimensions of APSI and APCF clearly illustrating the Components of the APSI and APCF

8. Electronic Copy with the required signatures of All submitted documents

NOTE:

1. PLEASE PROVIDE E-COPY WITH SIGNATURES OF ALL SUBMITTED DOCUMENTS.

2. A Chemical Engineer (ChE) or Professional Mechanical Engineer (PME) or DENR-EMB Accredited Pollution Control

Officer of the company shall sign such engineer’s report concurred by the Managing Head or Head of Office.

3. All drawings should be submitted in a standard 50 x 90 cm blueprint or in A3 size paper duly signed and sealed by a Chemical Engineer (ChE) or

Professional Mechanical Engineer (PME) or combination of both pursuant to DAO 2004 -26, RA 9279 of 2004 (Chemical Engineering Law) and RA 8495 of

1998 (Philippine Mechanical Engineering Act).

Banilad, Mandaue City, Cebu, Philippines, 6014

Tel. Nos. (+6332) 3469426,3453905 Telefax No. 3461647

Email: emb_regionseven@yahoo.com.ph

You might also like

- Check in Activity 2Document4 pagesCheck in Activity 2Erika CadawanNo ratings yet

- 2018-Engineering-Report-Sample DENRDocument1 page2018-Engineering-Report-Sample DENRHenzel Hero Tumaneng jr100% (1)

- Packaged, Integrally Geared Centrifugal Air Compressors: ScopeDocument11 pagesPackaged, Integrally Geared Centrifugal Air Compressors: ScopeHonesto BautistaNo ratings yet

- B&W IR-CFB: Operating Experience and New Development: Technical PaperDocument8 pagesB&W IR-CFB: Operating Experience and New Development: Technical PaperS. P.No ratings yet

- Engineering Report For Generator Set: General InformationDocument2 pagesEngineering Report For Generator Set: General InformationRJ Padilla100% (3)

- Modified STR - TMTDocument8 pagesModified STR - TMTnazi1945No ratings yet

- Reply To Consultant Comments - Revised - With Letter HeadDocument3 pagesReply To Consultant Comments - Revised - With Letter HeadghadeerNo ratings yet

- PATENT DUCTUS ARTERIOSUS Concept MapDocument2 pagesPATENT DUCTUS ARTERIOSUS Concept MapErika CadawanNo ratings yet

- General Purpose Gear Units: ScopeDocument10 pagesGeneral Purpose Gear Units: ScopeAnonymous fvO1W3No ratings yet

- Special Purpose Centrifugal Fans: ScopeDocument11 pagesSpecial Purpose Centrifugal Fans: ScopeHonesto BautistaNo ratings yet

- MQ SP M 4015 PDFDocument25 pagesMQ SP M 4015 PDFjaseelNo ratings yet

- EXXON IP-10-01-01 Centrifugal PumpsDocument9 pagesEXXON IP-10-01-01 Centrifugal PumpsyerkoNo ratings yet

- Exxon IP 10-10-2 General Purpose Gear UnitsDocument3 pagesExxon IP 10-10-2 General Purpose Gear UnitsGilvan SilvaNo ratings yet

- GP-06!01!01 TEMA Type Shell-And-Tube HeatDocument23 pagesGP-06!01!01 TEMA Type Shell-And-Tube HeatFrancesco AvogadroNo ratings yet

- Checklist of Requirements Permit To Operate - Air Pollution Sources/Control Installations (Poapsci)Document2 pagesChecklist of Requirements Permit To Operate - Air Pollution Sources/Control Installations (Poapsci)Tan MicNo ratings yet

- TS Generator SetsDocument43 pagesTS Generator SetszulkazaNo ratings yet

- MQ SP M 4048 PDFDocument42 pagesMQ SP M 4048 PDFjaseelNo ratings yet

- Dev 5Document9 pagesDev 5herrdevanshNo ratings yet

- Online Permitting and Monitoring System OpmsDocument85 pagesOnline Permitting and Monitoring System Opmskulafu 12No ratings yet

- Fig 1: External Cyclones BP Kwinana RCCU R2 Regenerator Fig 2: R1 & R2 Common StackDocument7 pagesFig 1: External Cyclones BP Kwinana RCCU R2 Regenerator Fig 2: R1 & R2 Common StackLindsey BondNo ratings yet

- 40 TS 220V 250 350 Ah Plante Type Lead Acid Battery SetsDocument14 pages40 TS 220V 250 350 Ah Plante Type Lead Acid Battery Setsp41005679No ratings yet

- 34MW - PLTD 190801Document42 pages34MW - PLTD 190801rasyidini100% (1)

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- RT17 Samss 518Document25 pagesRT17 Samss 518ahm3d16n0% (1)

- Grey CIDocument5 pagesGrey CIsaurabhsinh ranjitsinh bhattiNo ratings yet

- $RY4XJ4TDocument7 pages$RY4XJ4TLindsey BondNo ratings yet

- Product Manual 398 5 - V2Document7 pagesProduct Manual 398 5 - V2Puneet ChaurasiaNo ratings yet

- IP 10-4-1 (Reciprocating Process Compressors)Document9 pagesIP 10-4-1 (Reciprocating Process Compressors)luisNo ratings yet

- Tier 4 Engine OverviewDocument22 pagesTier 4 Engine OverviewferraryNo ratings yet

- 2 RA 8749 Workshop - Alfred Gene CalumbaDocument91 pages2 RA 8749 Workshop - Alfred Gene Calumbaianeil18No ratings yet

- ECS 16-7-1 - 2 - 800981dbDocument8 pagesECS 16-7-1 - 2 - 800981dbFlorin Daniel AnghelNo ratings yet

- SVENDBORG MÆRSK Marine Accident ReportDocument8 pagesSVENDBORG MÆRSK Marine Accident ReportAlbert StratingNo ratings yet

- ECS 3-3-11 - 2 - 800871adDocument13 pagesECS 3-3-11 - 2 - 800871adFlorin Daniel AnghelNo ratings yet

- HSC Part 4 E-July16Document390 pagesHSC Part 4 E-July16JuniorJavier Olivo FarreraNo ratings yet

- ECS 10-1-1 - 3 - 80099e3cDocument21 pagesECS 10-1-1 - 3 - 80099e3cFlorin Daniel AnghelNo ratings yet

- Batch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019Document3 pagesBatch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019அன்புடன் அஸ்வின்No ratings yet

- SIL98-9E: Service Information LetterDocument4 pagesSIL98-9E: Service Information LetterOmri AmayaNo ratings yet

- Genset POADocument3 pagesGenset POALawrence PiNo ratings yet

- STX Man B&W l23-30h-720 RPM p.1Document44 pagesSTX Man B&W l23-30h-720 RPM p.1vlasovalexander2404No ratings yet

- STR 40Document13 pagesSTR 40Karthikeyan SambandamNo ratings yet

- Rdso MC PCN 043 2011 PDFDocument18 pagesRdso MC PCN 043 2011 PDFAnySikaNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Is 2086 StiDocument6 pagesIs 2086 StiAnuj PandeyNo ratings yet

- Part 4, Vessel Systems and MachineryDocument390 pagesPart 4, Vessel Systems and MachineryMagaly BarraganNo ratings yet

- TN 03 QapDocument5 pagesTN 03 QapSachin KumarNo ratings yet

- Batch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023Document3 pagesBatch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023venkiNo ratings yet

- Air Resources Board: New Off-RoadDocument2 pagesAir Resources Board: New Off-RoadDavid J SandersNo ratings yet

- Department of Environment and Natural Resources Environmental Management BureauDocument5 pagesDepartment of Environment and Natural Resources Environmental Management BureauFroilan MatutinoNo ratings yet

- TS-0002074 Rev AfDocument9 pagesTS-0002074 Rev AfRaul GarciaNo ratings yet

- C10512800 PDFDocument2 pagesC10512800 PDFArildo Chaves de AndradeNo ratings yet

- PNS BAFS PAES 256 - 2018 - Cacao Roaster - Methods of TestDocument12 pagesPNS BAFS PAES 256 - 2018 - Cacao Roaster - Methods of TestRonie LusaresNo ratings yet

- Positive Displacement Pumps - Controlled Volume: ScopeDocument8 pagesPositive Displacement Pumps - Controlled Volume: ScopeHonesto Bautista100% (1)

- Air Resources Board: 2/ Day of February 2007Document2 pagesAir Resources Board: 2/ Day of February 2007David J SandersNo ratings yet

- VNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecDocument29 pagesVNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecĐiệnBiênNhâm100% (1)

- Lead Acid Battery Manufacure PDFDocument437 pagesLead Acid Battery Manufacure PDFAhmed Fotoh100% (1)

- UREA Data 1Document8 pagesUREA Data 1simaproindia4958No ratings yet

- Method Statement For Coal Feeder ErectionDocument20 pagesMethod Statement For Coal Feeder ErectiontreyNo ratings yet

- Rmpu STR No. Rdsopestrac 0008-2003 - Rev 4 Final DraftDocument13 pagesRmpu STR No. Rdsopestrac 0008-2003 - Rev 4 Final DraftHVHBVNo ratings yet

- Sabp G 001Document12 pagesSabp G 001m4metz100% (1)

- RCER-2015-Volume II-B-Form PA-G1 General-Final (Repaired)Document29 pagesRCER-2015-Volume II-B-Form PA-G1 General-Final (Repaired)KARTHIKEYAN SIVANANTHAMNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Comprehensive Nursing Process Points PPMCDocument3 pagesComprehensive Nursing Process Points PPMCErika CadawanNo ratings yet

- Pa OlderDocument14 pagesPa OlderErika CadawanNo ratings yet

- NCM 103 - Fundamentals of Nursing Exam RationalizationDocument8 pagesNCM 103 - Fundamentals of Nursing Exam RationalizationErika CadawanNo ratings yet

- Acute GastroenteritisDocument2 pagesAcute GastroenteritisErika CadawanNo ratings yet

- M5 Post TaskDocument2 pagesM5 Post TaskErika CadawanNo ratings yet

- HYDROCEPHALUSDocument6 pagesHYDROCEPHALUSErika CadawanNo ratings yet

- Step 1: Compute For The Sums in The TableDocument6 pagesStep 1: Compute For The Sums in The TableErika CadawanNo ratings yet

- Chapter I: Assessment: Comprehensive Nursing Process RubricDocument4 pagesChapter I: Assessment: Comprehensive Nursing Process RubricErika Cadawan100% (1)

- Deficient Fluid Volume Related To Postoperative CoDocument1 pageDeficient Fluid Volume Related To Postoperative CoErika CadawanNo ratings yet

- Family Nursing Care Plan: Group A3 - ObDocument4 pagesFamily Nursing Care Plan: Group A3 - ObErika CadawanNo ratings yet

- M5 Post Task Cadawan ErikaDocument2 pagesM5 Post Task Cadawan ErikaErika CadawanNo ratings yet

- PEDIATRICS DISORDER PART 2 LECTURE MergedDocument33 pagesPEDIATRICS DISORDER PART 2 LECTURE MergedErika CadawanNo ratings yet

- Congenital Blood DisordersDocument32 pagesCongenital Blood DisordersErika CadawanNo ratings yet

- M2 Pre-TaskDocument1 pageM2 Pre-TaskErika CadawanNo ratings yet

- 5,6,7 CmcaDocument224 pages5,6,7 CmcaErika CadawanNo ratings yet

- Check in Activity2Document5 pagesCheck in Activity2Erika CadawanNo ratings yet

- 5,6,7 CMCA (Autosaved) (Autosaved)Document585 pages5,6,7 CMCA (Autosaved) (Autosaved)Erika CadawanNo ratings yet

- BiostatDocument20 pagesBiostatErika CadawanNo ratings yet

- M4: While Task Lesson 1 Frameworks and PrinciplesDocument14 pagesM4: While Task Lesson 1 Frameworks and PrinciplesErika CadawanNo ratings yet

- StatusDocument3 pagesStatusErika CadawanNo ratings yet

- Application For Overhead/Hoist Crane Installation: Department of Labor and EmploymentDocument1 pageApplication For Overhead/Hoist Crane Installation: Department of Labor and EmploymentErika Cadawan100% (1)

- Atmosphere and WeatherDocument29 pagesAtmosphere and WeatherAmbiga NaiduNo ratings yet

- Koretsky - SolucionárioDocument738 pagesKoretsky - Solucionárioetlrt100% (6)

- Boiler FundaDocument37 pagesBoiler FundaTanu SinghNo ratings yet

- Passage 1 Intensivo Semana 7Document2 pagesPassage 1 Intensivo Semana 7Enrique Baca D.No ratings yet

- ValenceDocument218 pagesValenceSubhabrata MabhaiNo ratings yet

- PYL 102 Problem Sheet 2Document1 pagePYL 102 Problem Sheet 2Armaan BhullarNo ratings yet

- 21 Types of Chemical Reactions-SDocument6 pages21 Types of Chemical Reactions-SMichael BensonNo ratings yet

- Exercise 6: Dew Point and Bubble Point Calculation: Assignment 1Document2 pagesExercise 6: Dew Point and Bubble Point Calculation: Assignment 1Junaid0% (1)

- Classifying Rocks InsideEarth5.1 3and5 6Document24 pagesClassifying Rocks InsideEarth5.1 3and5 6machinel1983No ratings yet

- Carnot CycleDocument6 pagesCarnot CycleAdrian ManzanoNo ratings yet

- Soil AnalysisDocument18 pagesSoil AnalysisMohsin Abbas Baltistani0% (1)

- Important Equation in Physics2Document5 pagesImportant Equation in Physics2Ghazi DallyNo ratings yet

- PII - Quantum Condensed Matter Physics - Ritchie (2019) 399pg PDFDocument399 pagesPII - Quantum Condensed Matter Physics - Ritchie (2019) 399pg PDFfdsdsfsdfmgNo ratings yet

- Directions For Material Recovery of Used Tires andDocument10 pagesDirections For Material Recovery of Used Tires andOlivier GouveiaNo ratings yet

- Script in Science GROUP 3 ExhibitDocument3 pagesScript in Science GROUP 3 ExhibitLawrence ConananNo ratings yet

- Dryness FractionDocument3 pagesDryness FractionJigme Lama100% (2)

- Class Note 5Document2 pagesClass Note 5alihasan12No ratings yet

- Solar Panel Repair BookDocument13 pagesSolar Panel Repair BookShiva PradhanNo ratings yet

- Articulo 2Document19 pagesArticulo 2Luis FelixNo ratings yet

- Chem ss1Document1 pageChem ss1Jesse MosesNo ratings yet

- 2000 Conceptions For Heat Transfer Correlation of NanofluidsDocument7 pages2000 Conceptions For Heat Transfer Correlation of NanofluidsAnonymous 7BQxlt8cNo ratings yet

- U.S. Energy Consumption by Source and Sector, 2019Document2 pagesU.S. Energy Consumption by Source and Sector, 2019rcmasterbNo ratings yet

- Weathering and Erosion PDFDocument37 pagesWeathering and Erosion PDFtadashiiNo ratings yet

- General Biology 2 Reviewer For Finals Examination. Goodluck!Document4 pagesGeneral Biology 2 Reviewer For Finals Examination. Goodluck!Kevin PepitoNo ratings yet

- Handout DRRM - Jose Abraham OngkikoDocument3 pagesHandout DRRM - Jose Abraham OngkikoYeye bonnellNo ratings yet

- ClassificationDocument38 pagesClassificationLaeeq AhmadNo ratings yet

- Diversity and Ecological Characteristics of Lianescent and Herbaceous Species of The Bingerville Botanical Garden (South of Cote Divoire)Document11 pagesDiversity and Ecological Characteristics of Lianescent and Herbaceous Species of The Bingerville Botanical Garden (South of Cote Divoire)IJAR JOURNALNo ratings yet

- A1 Iter DivertorDocument1 pageA1 Iter DivertorVirak BaglioneNo ratings yet

- Mastering Astronomy Homework 7 AnswersDocument7 pagesMastering Astronomy Homework 7 Answerscfhfp6dd100% (1)

- Chapter 5Document3 pagesChapter 5Shirah CoolNo ratings yet