Professional Documents

Culture Documents

For Safe Operation: Installation Manual

Uploaded by

Amjad HossenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Safe Operation: Installation Manual

Uploaded by

Amjad HossenCopyright:

Available Formats

SV-72 CONTROL BOX AND DD MOTOR INSTRUCTION MANUAL Ver 01 2.1.

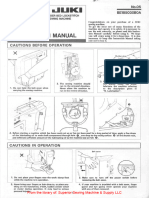

3 Machine side coupling installation: AFG00446

Catalogue: ①Insert the coupling to the center of the inner shaft and tighten with the setting screw temporarily.

1.For safe operation ②Insert the pressing fan and the spring washer using a M6 hexagon screw to tighten to the machine sha

2.Installation manual ③Insert an allen key or a screw driver to the machine coupling auxiliary hole to assist installation and

3.Operating way for control box panel and parameter setting Tighten the machine’s pressing fan screw.

4.Common parameter list ④Insert the coupling rubber cushion onto the machine.

⑤Direct drive motor installation is completed. Assembling

1. For safe operation auxiliary hole

1.1 Prior the use of this product, please read the instruction Manual. Keep this Instruction Manual and the Align the machine coupling

screw hole upper position to

user may read it at anytime when necessary the machine shaft trench

1.2 Before turn on the power, be sure to check the power voltage and phase agreeing with the nameplate area and tighten it with a

setting screw.

that indicated in the control box.

Trench

* The operated voltage should follow the nameplate with ±10% range. Upper

screw hole

1.3 Grounding the machine is always necessary for safe and normal operation.

1.4 Check lubricating oil prior to operation.

1.5 When the first time power transmission, please operate with low speed and check the rotational Coupling rubber cushion

direction of the motor.

1.6 So as to prevent personal injuries during operation, be careful not allow to touch the moving parts. Also Accessories to tighten the coupling

never try to stop it with external forces.

1.7 For the following conditions, turn off the power or disconnect the power plug from receptacle:

* For threading needle or replacing bobbin. Motor coupling pit

* To plug or unplug any connectors from control box. point should align with

* For maintenance and repairing. rubber cushion raise

* When lift the sewing machine and remove the belt.

2.2.Installation manual for motor:

point

* When machine is not at use, inspected or adjusted.. ①Prior installing the motor, align the coupling angle.

* When lighting and thunder occurs.. ②After proper alignment, install it onto the machine,

1.8 Operating environment hexagon socket screw(M6xL12) x3 , hold it first

* Operating environment temperature 5℃~45℃. tightening the screws in the front cover

* Operating environment temperature 30%~95%.

* Not close to high frequency or heat sources (such as electric heater).

of the motor, then tighten the screws.

* Dew, corrosive gases, and dust places should be avoided. Raise point Pit point

* Indoor use only, avoid the direct sunlight. 2.3.Needle up/down positioning adjustment:

1.9 Warranty and maintenance If after installation positioning is not accurate, then remove the setting screw from the pulley and

* The warranty period of the product is 18 months from the date of manufacture. adjust it to the proper angle.

* Warranty void if improper use / man-made damage / voltage abnormal / bad grounding /

self-dismantling / self-repair.

* Warranty void if foreign matter into / natural disasters / lightning / salt corrosion / damp / fall /

self-transport damage. Hexagon socket screw ×3

* Repair parts should be provided by our company / maintenance person should be approved by our

company. (M6×L12)×3

2. Installation manual

2.1.1.Check whether the motor exterior is 2.1.2.Prior installing the motor, remove some

ok and also confirm that coupling is parts from the machine as shown below and

properly installed. proceed for installation Coupling angle of pi point and

raise point should be align

Screw×2

Machine side coupling

3. Control box How to connecter the Cordially& Parameter setting

3.1 Connector Diagram General Parameter List

NO. Item Range Unit LS OL PB CS O2 SC MC

Sewing machine

P1 2 ~ 80 *100spm 40 60 20 40 60 60 60

Motor Power CN4 maximum speed

Synchronizer CN1 Sewing machine

P2 10 ~ 25 *10spm 20 20 20 20 20 20 20

positioning speed

Motor’s pulley

P3 50 ~ 100 (note1) *1mm 75 85 65 75 85 85 85

Speed unit CN3 dimension

Motor encoder CN2 Machine’s pulley

P4 50 ~ 120 (note1) *1mm 75 55 65 65 55 55 55

dimension

ON: Refer motor pulley ratio measurement

Pulley ratio setting

P5 OF: Refer P.3 and P.4 -- AT AT AT AT AT AT AT

Display CN5 mode

AT: Auto measurement

AC power input CN8 Virtual needle down ON: Valid

P6 -- OF OF OF OF OF OF OF

positioning function OF: Invalid

The angles between

virtual needle down

P7 70 ~ 250 *1∘ 180 180 180 180 180 180 180

positioning point and

needle up signal

3.2 Panel key functions 3.3 Error message indicator

P8 Soft start stitches 0 ~ 19 *1 stitch 0 0 0 0 0 0 0

Error Code Description of error detected

P9 Soft start speed 25 ~ 200 *10spm 40 40 25 40 40 40 40

E.1 or E.A Synchronizer failure

F1 Synchronizer mode

ON: Valid

-- OF OF OF OF OF OF OF

OF: Invalid

E.2 Motor is not rotating F2

Motor rotating ON: Clock wise

-- ON OF ON OF OF OF OF

direction OF: Counter Clock wise

E.5 Speed unit output failure Accelerating speed

F4 1 ~ 8 (fast~slow) -- 3 3 3 3 3 3 3

slope

Decelerating speed

E.8 Setting speed over the motor maximum speed F5

slope

1 ~ 14 (fast~slow) -- 4 3 6 6 3 3 3

Motor’s braking force

E.9 IPM is failed F9 1~8 -- note2 note2 note2 note2 Note2 Note2 Note2

when positioning

Auto needle up

ON: Valid

E.0 or E.C Braking timing error L1 positioning when

OF: Invalid

-- ON ON ON ON ON ON ON

power on

3.4 Parameter setting Reversed revolution

L3 angles after pedal heel 0~250 *1∘ 0 0 0 0 0 0 0

Select the machine type and motor specification STEPS down

Increase motor current

Machine Type Motor Type L4 0~20 -- 0 0 0 0 0 0 0

1. Press and simultaneously, and limitation

LS Lock Stitch 45 SM71S-4550 motor 0: needle up

turn ON the power until panel display “rS” Function when pedal

OL Overlock. 55 SM71S -5535 motor 1: foot lifting

then release the key. L5 is heeled. -- 0 0 0 0 1 1 60

PB Postbed 65 SM71S -6535 motor 2: none

(note3)

TN Twin Needle U6 SM80-6535 motor 3: needle up & foot lifting

2. Press key, thus machine type will be 0: Output when motor rotates

CS ChainStitch d8 SM7-3570 motor Thread Suction

cycled increased. L6 control mode

1: Motor control middle suction

-- 0 0 0 0 0 2 1

CM Skiving Machine dA SM7-6560 motor 2:Sensor control middle suction

O2 OverLock d9 SM7-3570V2 motor (note3)

3. Press key to save and enter motor 1&2 Depend on Parameter L7,L8

specification selection. suction &foot lifter dA SM7-6560 motor L7

Thread SD output ON

0~99 *1 stitch 0 0 0 0 10 5 10

SC OverLock & sensor db SM7-5070 motor stitches(Middle)

Save Suction Auto Foot d2 SM6-5535 motor Thread SD output *10

4. Press key, thus motor specification L8 0~99 0 0 0 0 1 3 99

OFF stitches(Middle) stitch

MC OverLock & without dE SM7-5560 motor

will be cycled increased. Thread SD_OUT acts

sensor L9 time when motor 0~10 *100ms 0 0 0 0 1 0 10

Save Suction stops

5. Press key to save.

Sensor control Front

Parameter setting STEPS Parameter Setting Key Description C4 0~250 *1 stitch 0 0 0 0 0 10 10

Suction stitches

Sensor control back

1.Press key and turn on the power until the panel display “PA. C5 0~249 *1 stitch 0 0 0 0 0 40 40

Suction stitches

0:Padel control

Auto Foot lifter after

Release key, the panel display parameters number. (or) 1. Press one time to 1. Press one time to enter C6 1:Sensor control -- 0 0 0 0 0 2 0

back sensor suction

increase Number. Parameter or parameter 2: Auto Foot lifter after back sensor suction

Motor auto stop after

2.In normal mode, then press key until the panel display “PA”. 2. Hold Press to value. C7 0:unable 1:able -- 0 0 0 0 0 1 0

sensor suction

decrease number 2. Press 2 Seconds to

Release key, the panel display parameters number. Save Parameter value note1. 1digital display is hundreds, 2digital display are tens and units respectively

note2. This value depends on motor specification.

note3. The function is valid in SV-72 control box

You might also like

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Doosan b40x-5, b45x-5, b50x-5 Lift Truck Service Repair ManualDocument463 pagesDoosan b40x-5, b45x-5, b50x-5 Lift Truck Service Repair ManualPeace AlexNo ratings yet

- Kubota GR2100 Work Shop ManualDocument299 pagesKubota GR2100 Work Shop ManualREG30750% (2)

- M105S WSM e PDFDocument554 pagesM105S WSM e PDFJuan Carlos100% (1)

- CA-idms Ads Alive User Guide 15.0Document142 pagesCA-idms Ads Alive User Guide 15.0svdonthaNo ratings yet

- kubotaRTV1100 Service Manual) PDFDocument521 pageskubotaRTV1100 Service Manual) PDFChad Spears100% (1)

- F2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36: Workshop ManualDocument315 pagesF2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36: Workshop Manualrgcsadlerhotmail.comNo ratings yet

- Handbook - European Choral AssociationDocument24 pagesHandbook - European Choral AssociationMonica SaenzNo ratings yet

- 379,398,399 D and A REV1Document167 pages379,398,399 D and A REV1Roland LamoureuxNo ratings yet

- 28 ESL Discussion Topics Adult StudentsDocument14 pages28 ESL Discussion Topics Adult StudentsniallNo ratings yet

- BR13S-7 SB4357E Opt PDFDocument593 pagesBR13S-7 SB4357E Opt PDFMelwyn Fernandes100% (1)

- F2880, F3680, RCK72P-F36, RCK72R-F36, RCK60P-F36, RCK60R-F36: Workshop ManualDocument315 pagesF2880, F3680, RCK72P-F36, RCK72R-F36, RCK60P-F36, RCK60R-F36: Workshop ManualJuan CarlosNo ratings yet

- DOOSAN B15S-2, B18S-2 LIFT TRUCK Service Repair ManualDocument36 pagesDOOSAN B15S-2, B18S-2 LIFT TRUCK Service Repair ManualManuals CE & AgNo ratings yet

- PW160 7E0 - S - CSS Net - 2007 05 04Document1,140 pagesPW160 7E0 - S - CSS Net - 2007 05 04tinphuloiNo ratings yet

- Loan Agreement: Acceleration ClauseDocument2 pagesLoan Agreement: Acceleration ClauseSomething SuspiciousNo ratings yet

- Practice Quiz Reflection Project Initiation and Key ComponentsDocument3 pagesPractice Quiz Reflection Project Initiation and Key ComponentsFalastin Tanani67% (3)

- Rc250 ManualDocument153 pagesRc250 ManualRandolfCabeza71% (7)

- For Safe Operation: Description of Error DetectedDocument1 pageFor Safe Operation: Description of Error DetectedAmjad HossenNo ratings yet

- Planetary Gearboxes Mounting Instruction V1.5 EngDocument2 pagesPlanetary Gearboxes Mounting Instruction V1.5 EngRee-anne SabanalNo ratings yet

- Servo Motor VI Fortuna Serie 6 PDFDocument77 pagesServo Motor VI Fortuna Serie 6 PDFheribertosfaNo ratings yet

- User Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesDocument12 pagesUser Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesIsaac Isaias AlvarezNo ratings yet

- User Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesDocument12 pagesUser Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesTGM KalimantanNo ratings yet

- JH 600Document22 pagesJH 600Joel MoralesNo ratings yet

- Currenza C2 Coin Changer Quick Start Up PDFDocument2 pagesCurrenza C2 Coin Changer Quick Start Up PDFZakaria AllaliNo ratings yet

- (OM) Operation ManualDocument5 pages(OM) Operation ManualDennys GuizarNo ratings yet

- MVB 140 16530-CDocument62 pagesMVB 140 16530-CKevin Milla100% (2)

- For Safe Operation: Parameter Setting Key DescriptionDocument1 pageFor Safe Operation: Parameter Setting Key DescriptionDollar NeedNo ratings yet

- 44mm Concrete Vibrator ManualDocument4 pages44mm Concrete Vibrator ManualDj MacNo ratings yet

- Service Manual Contents Notice: For Use in Service Manual Form SB4062E SB2191E01 O C T - 2 0 0 1Document15 pagesService Manual Contents Notice: For Use in Service Manual Form SB4062E SB2191E01 O C T - 2 0 0 1Manuals CE & AgNo ratings yet

- PACCAR Alternator InstructionsDocument7 pagesPACCAR Alternator Instructionsquepex76No ratings yet

- Kubota Tractor m9540 Low Profile Workshop ManualDocument7 pagesKubota Tractor m9540 Low Profile Workshop Manualdewey100% (45)

- AC Servo Motor Séries 5Document105 pagesAC Servo Motor Séries 5Gilberto Oliveira100% (1)

- Kde12ea PDFDocument20 pagesKde12ea PDFMohammed Abbas100% (1)

- Actual 0 1 2 3 4 5 6 7 8 9 Display Actual A B C D E F G H I J Display Actual K L M N O P Q R S T Display Actual U V W X Y Z DisplayDocument1 pageActual 0 1 2 3 4 5 6 7 8 9 Display Actual A B C D E F G H I J Display Actual K L M N O P Q R S T Display Actual U V W X Y Z DisplayJean Carruitero FajardoNo ratings yet

- MTR LincolnDocument4 pagesMTR LincolnJohn Renz Caling RetiroNo ratings yet

- Service Manual Contents Notice: For Use in Service Manual Form SB4099E SB4112E00 Sep. 2003Document21 pagesService Manual Contents Notice: For Use in Service Manual Form SB4099E SB4112E00 Sep. 2003Дима СелютинNo ratings yet

- Console Remote Control Installation InstructionsDocument18 pagesConsole Remote Control Installation InstructionsJoswyn LopesNo ratings yet

- IM Rime 4000 CompleteDocument37 pagesIM Rime 4000 CompleteVivi Puspita SariNo ratings yet

- 9typ8312 KTDocument25 pages9typ8312 KTaboubakry dialloNo ratings yet

- System Scale PrinterDocument113 pagesSystem Scale Printersava88No ratings yet

- B01-TB16O-003 - TB16OUT Basic Installation Instructions - ENG - 1.1Document2 pagesB01-TB16O-003 - TB16OUT Basic Installation Instructions - ENG - 1.1Kien Nguyen TrungNo ratings yet

- DODGE IEC Series Electric Clutches: Instruction ManualDocument4 pagesDODGE IEC Series Electric Clutches: Instruction ManualjoaocarimoNo ratings yet

- SG8957AE4,0311E3,9310E4,9320E4,8751E3 Control Box ManualDocument8 pagesSG8957AE4,0311E3,9310E4,9320E4,8751E3 Control Box ManualAlex MedinaNo ratings yet

- 13951.13951s.13952s.13952 Instructions enDocument7 pages13951.13951s.13952s.13952 Instructions enAlexutza StanNo ratings yet

- Sunstar Fortuna AC Servo Motor VDocument85 pagesSunstar Fortuna AC Servo Motor Vsongdongemdem28No ratings yet

- 03 - Repair and Overhaul Instructions En-FDocument26 pages03 - Repair and Overhaul Instructions En-FaaronNo ratings yet

- BOV FV Instruction ManualDocument5 pagesBOV FV Instruction ManualRayseanKangNo ratings yet

- Kubota WG972 Diagnose ManualDocument162 pagesKubota WG972 Diagnose ManualMax RibbinkNo ratings yet

- Gear Motors Install Instruction V1.7 EngDocument2 pagesGear Motors Install Instruction V1.7 EnghopgiamtocrasNo ratings yet

- Installation Instructions Performance TachometerDocument6 pagesInstallation Instructions Performance TachometerJuan Carlos SoHeNo ratings yet

- Oymc G7 Safety Precautions en 2Document30 pagesOymc G7 Safety Precautions en 2Thành Thế LộcNo ratings yet

- Motor Operating Device UEMC 40 A - , B - , D - : Installation and Operating GuideDocument33 pagesMotor Operating Device UEMC 40 A - , B - , D - : Installation and Operating Guideculjak_iNo ratings yet

- 56 143 5TC Coupler Brake Installation Service InstructionsDocument4 pages56 143 5TC Coupler Brake Installation Service InstructionsIvan PachecoNo ratings yet

- NEMA Motors - Manual PDFDocument20 pagesNEMA Motors - Manual PDFVilius BukysNo ratings yet

- ABB Power Distribution: Motor Operating Device UEMC 40 A - , B - , D - Installation and Operating GuideDocument33 pagesABB Power Distribution: Motor Operating Device UEMC 40 A - , B - , D - Installation and Operating GuideivanramljakNo ratings yet

- M9540LP WSM e 9y111-01660 PDFDocument73 pagesM9540LP WSM e 9y111-01660 PDFJuan CarlosNo ratings yet

- Actuador Electrico RotorkDocument16 pagesActuador Electrico RotorkAriel AgueroNo ratings yet

- 103 Series - DS - EN - 04.2011 - V1.4Document4 pages103 Series - DS - EN - 04.2011 - V1.4rafael lalaNo ratings yet

- GR1600EC: Workshop ManualDocument249 pagesGR1600EC: Workshop ManualalgisaaaNo ratings yet

- Vibratory Plate Compactor: Operating InstructionsDocument4 pagesVibratory Plate Compactor: Operating InstructionsxyxyquazNo ratings yet

- Service Manual Contents Notice: For Use in Service Manual Form SB4292E SB4293E00 July 2007Document21 pagesService Manual Contents Notice: For Use in Service Manual Form SB4292E SB4293E00 July 2007Manuals CE & AgNo ratings yet

- BK4655 PDFDocument12 pagesBK4655 PDFRodolfo Garduño ColínNo ratings yet

- Juki LK-1850 Instruction ManualDocument12 pagesJuki LK-1850 Instruction ManualOscar TorresNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Project Proposal DraftDocument1 pageProject Proposal DraftCarl Axel M. FajardoNo ratings yet

- PROP CASES OUTLINE 7 - Right of Way - Light & ViewDocument108 pagesPROP CASES OUTLINE 7 - Right of Way - Light & ViewKringle Lim - DansalNo ratings yet

- What On Earth Is A MainframeDocument132 pagesWhat On Earth Is A MainframeCarlos DantasNo ratings yet

- Rise of Al JazeeraDocument1 pageRise of Al Jazeeraইlish ProductionsNo ratings yet

- Expansions Meet Health Care Needs: Economists Question Trump Plan FiguresDocument10 pagesExpansions Meet Health Care Needs: Economists Question Trump Plan FiguresThe Daily Tar HeelNo ratings yet

- Introduction To Object Oriented Database: Unit-IDocument67 pagesIntroduction To Object Oriented Database: Unit-Ipreetham rNo ratings yet

- Permutation, Combination & ProbabilityDocument9 pagesPermutation, Combination & ProbabilityVicky RatheeNo ratings yet

- Review Systems of Linear Equations All MethodsDocument4 pagesReview Systems of Linear Equations All Methodsapi-265647260No ratings yet

- DRUGPDocument371 pagesDRUGPPolarogramaNo ratings yet

- m07srt Lesson KmarlinkDocument3 pagesm07srt Lesson Kmarlinkapi-515106812No ratings yet

- Rich Gas and Lean GasDocument7 pagesRich Gas and Lean GasManish GautamNo ratings yet

- Module 1Document64 pagesModule 1Jackyson RajkumarNo ratings yet

- No Experience ResumeDocument2 pagesNo Experience ResumeNatalia PantojaNo ratings yet

- File 1) GRE 2009 From - Nov - 18 PDFDocument84 pagesFile 1) GRE 2009 From - Nov - 18 PDFhuyly34No ratings yet

- Lesson Plan Wid Awt Method 2Document7 pagesLesson Plan Wid Awt Method 2Yan LianNo ratings yet

- MELASMA (Ardy, Kintan, Fransisca)Document20 pagesMELASMA (Ardy, Kintan, Fransisca)Andi Firman MubarakNo ratings yet

- Thom22e ch03 FinalDocument44 pagesThom22e ch03 FinalDionisius AlvianNo ratings yet

- ROXAS FARM SCHOOL Trifold BrochureDocument2 pagesROXAS FARM SCHOOL Trifold BrochureJude IledanNo ratings yet

- Education Programme: The School of Concrete TechnologyDocument28 pagesEducation Programme: The School of Concrete TechnologyThabiso Jacob MokwenaNo ratings yet

- FCC O Cials Denounce Lawmakers' Attempts To Censor NewsroomsDocument52 pagesFCC O Cials Denounce Lawmakers' Attempts To Censor NewsroomsKeithStewartNo ratings yet

- 88 Year Old Man Missing in SC - Please ShareDocument1 page88 Year Old Man Missing in SC - Please ShareAmy WoodNo ratings yet

- Fbla Scavenger Hunt 1Document3 pagesFbla Scavenger Hunt 1api-472648158No ratings yet

- The King's Avatar - Chapter 696 - Guild Feature - Gravity TalesDocument5 pagesThe King's Avatar - Chapter 696 - Guild Feature - Gravity TalesMayhaaaNo ratings yet

- Geography Paper 1Document7 pagesGeography Paper 1Sudhir TewatiaNo ratings yet

- Research Paper Effect of Mobile Banking On Customer-823Document11 pagesResearch Paper Effect of Mobile Banking On Customer-823amittaneja28No ratings yet