Professional Documents

Culture Documents

Water Chillers 93: Compressors and Motors

Uploaded by

Rohit Shrestha0 ratings0% found this document useful (0 votes)

7 views2 pagesrohit

Original Title

1 (73)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentrohit

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesWater Chillers 93: Compressors and Motors

Uploaded by

Rohit Shrestharohit

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Water Chillers 93

Likewise, water chillers have a critical range of flow rates in

which they will safely operate. If the designer chooses to vary the

flow through the chiller to save on pumping energy at any con-

dition less than full load, the control system must be properly

designed to operate safely. Because of these design limitations

and safety concerns, chillers are usually designed for constant

water flow. However, there is an energy-saving opportunity if the

chiller pump is variable flow.

Cooling equipment is normally designed for a 10°F tempera-

ture difference or delta T (∆T). For example, chillers and cooling

coils might be designed to operate with a supply water tempera-

ture of 45°F and a return temperature of 55°F, while the cooling

tower (tower range) and water-cooled condenser (condenser rise)

operate between 85°F and 95°F.

PLANT MAINTENANCE AND OPERATION

Good maintenance and the proper operation of plant equip-

ment cannot be overemphasized. Proper maintenance helps en-

sure efficient operation of equipment and systems (thereby

reducing energy usage) and helps prolong equipment life. The

following maintenance procedures can help in the optimization of

chiller plant equipment and determine the cause of any abnor-

malities and correct them as needed.

Compressors and Motors

Follow manufacturer’s guidelines for compressor and motor

maintenance and observe compressor operation. Frequent stop-

ping and starting or continuous running may indicate inefficient

operation. It is also important to listen to the compressor. A high

noise level may be a sign of a loose drive coupling or excessive

vibration. Next, inspect the compressor for oil leaks and use a

leak detector to check for refrigerant leaks. Establish normal op-

erating pressures and temperatures for the system. Routinely

record operating temperatures and oil pressures in a log. Be sure

94 HVAC Fundamentals

to compare readings with manufacturer’s specifications to ensure

normal operation.

Pumps and Motors

Follow manufacturer ’s guidelines for pump and motor

maintenance. Observe and listen to the pump operation. Keep the

pump and motor properly lubricated; lubricate motor bearings

and all moving parts according to manufacturer’s recommenda-

tions. Keep pump and motor properly aligned. Water balance

pumps for proper flow quantity; change impellers as needed.

Fans and Motors

Follow manufacturer’s guidelines for fan and motor mainte-

nance. Lubricate motor and fan bearings and all moving parts

according to manufacturer’s recommendations. Keep fan and

motor drives properly aligned. Inspect condition of belt(s) and

check belt tension. Observe and listen for any unusual noise or

vibration.

Condensers and Cooling Towers

Clean tubes on water-cooled condensers and keep condenser

coil faces clean on air-cooled condensers. Perform chemical treat-

ment to determine if desolved solids concentrations are being

maintained at acceptable levels on evaporative condensers and

cooling towers. Monitor effectiveness of water treatment pro-

gram. Keep the tower clean to minimize drops in air and water

pressure. Check overflow pipe clearance for proper operating

water level. Clean intake strainer. Determine if there is air re-cir-

culation from tower outlet back to tower inlet. Inspect towers for

proper nozzle performance.

Plant Retrofit

The biggest energy users in chilled-water plants are the

motors driving the chiller compressors, pumps, and fans. There-

fore, significant energy savings can be achieved by:

You might also like

- Motor Vehicle Air Conditioning System Operation and Refrigerant Cycle of Motor Vehicles PDFDocument49 pagesMotor Vehicle Air Conditioning System Operation and Refrigerant Cycle of Motor Vehicles PDFmariA ANNANo ratings yet

- 1 Building Maintenance Checklist HVACDocument17 pages1 Building Maintenance Checklist HVACamochieno100% (3)

- Water Cooled Chiller - SOPDocument13 pagesWater Cooled Chiller - SOParunceedee100% (4)

- Refrigeration PipingDocument43 pagesRefrigeration PipingenigmazeeNo ratings yet

- Preventive Maintenance - Keeping Refrigeration Equipment in ShapeDocument5 pagesPreventive Maintenance - Keeping Refrigeration Equipment in ShapeSanjay RanaNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Chapter 2 - Air Conditioning System - Part 2Document23 pagesChapter 2 - Air Conditioning System - Part 2khairul izzudinNo ratings yet

- Types of Air Conditioning SystemDocument5 pagesTypes of Air Conditioning SystemLArry Vasquez100% (2)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- CTV Eb 84Document8 pagesCTV Eb 84btgottlieb100% (3)

- Air-Cooled Chiller Maintenance ChecklistDocument2 pagesAir-Cooled Chiller Maintenance ChecklistMd Rizwan Khan100% (3)

- Chiller Maintenance ChecklistDocument2 pagesChiller Maintenance ChecklistAssem Elhajj100% (17)

- Reciprocating Compressors:: Operation and MaintenanceFrom EverandReciprocating Compressors:: Operation and MaintenanceRating: 4 out of 5 stars4/5 (7)

- Service Bulletin: WarningDocument11 pagesService Bulletin: Warningninzau100% (1)

- 04 2429GDocument11 pages04 2429Gzanella159051No ratings yet

- Method of Statement For Precommissioning & Commissioning of ChillersDocument4 pagesMethod of Statement For Precommissioning & Commissioning of Chillersvin ssNo ratings yet

- File 1428726206Document8 pagesFile 1428726206Rizwanahmad Khan Rizwanahmad KhanNo ratings yet

- Chilled Water System FundamentalsDocument14 pagesChilled Water System Fundamentalsjohnnybe51No ratings yet

- ChecklistDocument2 pagesChecklistdassayevNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Energy Optimization: An Approach To Total Energy ManagementDocument33 pagesEnergy Optimization: An Approach To Total Energy ManagementGajanan Shirke AuthorNo ratings yet

- Starting of Main EngineDocument5 pagesStarting of Main EngineAayush Agrawal100% (1)

- Kencana Square Water-Cooled Chiller GuideDocument11 pagesKencana Square Water-Cooled Chiller Guidejames_chan2178No ratings yet

- Hvac Water BalancingDocument5 pagesHvac Water BalancingAwais Jalali100% (2)

- Operation & Maintinance of Diesel Generator - 101527Document15 pagesOperation & Maintinance of Diesel Generator - 101527Wasim IqbalNo ratings yet

- ChecklistDocument3 pagesChecklistAndy Noven KrisdiantoNo ratings yet

- Sp9907-A - Chiller Statup ProceduresDocument4 pagesSp9907-A - Chiller Statup ProceduresEmerson Penaforte100% (1)

- Module 3 - Chiller SystemDocument45 pagesModule 3 - Chiller Systemmadan karkiNo ratings yet

- Final Directory Map Board List Hall 1Document14 pagesFinal Directory Map Board List Hall 1Phool JaiswalNo ratings yet

- (BS en 14511-1 - 2013) - Air Conditioners, Liquid Chilling Packages and Heat Pumps With Electrically Driven Compressors For Space Heating and Cooling. Terms, Definitions and CDocument18 pages(BS en 14511-1 - 2013) - Air Conditioners, Liquid Chilling Packages and Heat Pumps With Electrically Driven Compressors For Space Heating and Cooling. Terms, Definitions and Ctunca100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Boiler Inspection MaintenanceDocument5 pagesBoiler Inspection Maintenanceskthen72No ratings yet

- 2009-08 EMOs For Cooling SystemsDocument4 pages2009-08 EMOs For Cooling Systemsnikola ilicNo ratings yet

- Energy Conservation Opportunities 243Document2 pagesEnergy Conservation Opportunities 243Rohit ShresthaNo ratings yet

- Chiller Service 1Document14 pagesChiller Service 1VENKATNo ratings yet

- MD Radzuan A Rahman - PM - TUGASANDocument4 pagesMD Radzuan A Rahman - PM - TUGASANSyafiz NawawiNo ratings yet

- Air HandleDocument32 pagesAir HandleRobert Emile Santiago JimenezNo ratings yet

- Proper Cooling Critical for Transformer HealthDocument4 pagesProper Cooling Critical for Transformer Healthلندا أسحق حنوNo ratings yet

- WC Centrifugal Chiller 400V-SSDocument8 pagesWC Centrifugal Chiller 400V-SSAhmadNo ratings yet

- c20 Ca 603 e - 10011999Document44 pagesc20 Ca 603 e - 10011999nazir305No ratings yet

- Buiolding MantenanceDocument13 pagesBuiolding MantenanceSean ChanNo ratings yet

- Maintenance of Compressed Air Systems For Peak PerformanceDocument3 pagesMaintenance of Compressed Air Systems For Peak PerformanceAnonymous XcROzJm73WNo ratings yet

- Module 4 - Cooling TowerDocument15 pagesModule 4 - Cooling Towermadan karkiNo ratings yet

- Air-Cooled Chillers Maintenance & Inspection ChecklistDocument3 pagesAir-Cooled Chillers Maintenance & Inspection ChecklistdjukalNo ratings yet

- 3054E and 3056E Industrial Engines-Maintenance IntervalsDocument36 pages3054E and 3056E Industrial Engines-Maintenance IntervalsprabumnNo ratings yet

- Ewctv - Trane Chiller Spec SheetDocument20 pagesEwctv - Trane Chiller Spec SheetHanan SFNo ratings yet

- Compressor Water Wash SystemDocument10 pagesCompressor Water Wash SystemCarlos GonzálezNo ratings yet

- WCFX-E Guide SpecificationDocument3 pagesWCFX-E Guide SpecificationaftabNo ratings yet

- CSRH-Y Water Cooled Chiller - R134aDocument20 pagesCSRH-Y Water Cooled Chiller - R134antt_121987No ratings yet

- Don't Be A Compressor Killer: Know Causes To Prevent Failures!Document4 pagesDon't Be A Compressor Killer: Know Causes To Prevent Failures!Mechanical PowerNo ratings yet

- Main Engine Starting ProcedureDocument5 pagesMain Engine Starting ProcedureAbishek AbiNo ratings yet

- Cooling Tower Performance Test Code ComplianceDocument12 pagesCooling Tower Performance Test Code ComplianceFouzan AbdullahNo ratings yet

- Catalog CondensadorDocument60 pagesCatalog CondensadorIvánRubioNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleSATNA GSTNo ratings yet

- A C Cycle WWW - Innovationdiscoveries.spaceDocument49 pagesA C Cycle WWW - Innovationdiscoveries.spaceNaveen kumarNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleMubarek TeshomeNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant Cycleravi prajapatNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleramsiNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleZakir R. AliNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleGerardo DelgadoNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CyclemohdNo ratings yet

- 19DV Guide Specifications, 350 To 800 Nominal Tons (1231 To 2814 Nominal KW) - Published Date 8.4.2020Document10 pages19DV Guide Specifications, 350 To 800 Nominal Tons (1231 To 2814 Nominal KW) - Published Date 8.4.2020anganNo ratings yet

- Compressors: Chapter FiveDocument2 pagesCompressors: Chapter FiveRohit ShresthaNo ratings yet

- Figure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Document2 pagesFigure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Rohit ShresthaNo ratings yet

- Air Conditioning Condenser GuideDocument2 pagesAir Conditioning Condenser GuideRohit ShresthaNo ratings yet

- Air Conditioning Systems 51Document2 pagesAir Conditioning Systems 51rohitNo ratings yet

- Air Conditioning Systems 69: Heat Pump (Air-Air)Document2 pagesAir Conditioning Systems 69: Heat Pump (Air-Air)Rohit ShresthaNo ratings yet

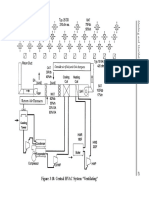

- Figure 4-1. Central HVAC System "Air Conditioning"Document2 pagesFigure 4-1. Central HVAC System "Air Conditioning"rohitNo ratings yet

- Figure 4-.2 Air Conditioning System ExampleDocument2 pagesFigure 4-.2 Air Conditioning System ExamplerohitNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Air Conditioning Systems 55Document2 pagesAir Conditioning Systems 55rohitNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Air Conditioning Systems 57Document2 pagesAir Conditioning Systems 57rohitNo ratings yet

- Heating and Ventilating Systems 29: Figure 3-2. Steam BoilerDocument2 pagesHeating and Ventilating Systems 29: Figure 3-2. Steam BoilerrohitNo ratings yet

- Air Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemDocument2 pagesAir Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemrohitNo ratings yet

- Air Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)Document2 pagesAir Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)rohitNo ratings yet

- Figure 3-10. Central HVAC System "Ventilating"Document2 pagesFigure 3-10. Central HVAC System "Ventilating"rohitNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Heating and Ventilating Systems 43: MAT (%OA ×Document2 pagesHeating and Ventilating Systems 43: MAT (%OA ×rohitNo ratings yet

- Heating and Ventilating Systems 25Document2 pagesHeating and Ventilating Systems 25rohitNo ratings yet

- 1 PDFDocument2 pages1 PDFrohitNo ratings yet

- Heating and Ventilating Systems 41: Figure 3-8. Oil BurnerDocument2 pagesHeating and Ventilating Systems 41: Figure 3-8. Oil BurnerrohitNo ratings yet

- Heat Flow 15Document2 pagesHeat Flow 15rohitNo ratings yet

- Heating and Ventilating Systems 35Document2 pagesHeating and Ventilating Systems 35rohitNo ratings yet

- Figure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamDocument2 pagesFigure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamrohitNo ratings yet

- Heating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerDocument2 pagesHeating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerrohitNo ratings yet

- Heating and Ventilating Systems 33Document2 pagesHeating and Ventilating Systems 33rohitNo ratings yet

- Heat Flow 17: ConductionDocument2 pagesHeat Flow 17: ConductionrohitNo ratings yet

- Latent HeatDocument2 pagesLatent HeatrohitNo ratings yet

- HVAC Systems 13: VentilatingDocument2 pagesHVAC Systems 13: VentilatingrohitNo ratings yet

- Heating and Ventilating Systems 27Document2 pagesHeating and Ventilating Systems 27rohitNo ratings yet

- Air Volume: HVAC Systems 11Document2 pagesAir Volume: HVAC Systems 11rohitNo ratings yet

- Patna Plant Material Stock ReportDocument28 pagesPatna Plant Material Stock ReportBibhuti JhaNo ratings yet

- Jjmie: Experimental Study of Solar Powered Air Conditioning Unit Using Drop - in Hydro Carbon Mixture To Replace R-22Document8 pagesJjmie: Experimental Study of Solar Powered Air Conditioning Unit Using Drop - in Hydro Carbon Mixture To Replace R-22أبو أسامة حمديNo ratings yet

- Condenser DesignDocument12 pagesCondenser Designbirendrajee100% (1)

- Coolant TypeDocument1 pageCoolant Typesh4kesNo ratings yet

- Industrial Cooling Systems (ICS) TAE EVO 081 Refrigerated Water ChillerDocument2 pagesIndustrial Cooling Systems (ICS) TAE EVO 081 Refrigerated Water ChillerDanlap 11No ratings yet

- Copeland™ Scroll Indoor Refrigeration Units For RefrigerationDocument12 pagesCopeland™ Scroll Indoor Refrigeration Units For RefrigerationALBERT JHONATAN ROJAS ORTIZNo ratings yet

- Properties of Refrigerant R134aDocument6 pagesProperties of Refrigerant R134ajosephine-ngNo ratings yet

- Clint Over Prodotti ENG-GREEK 2018 WDocument2 pagesClint Over Prodotti ENG-GREEK 2018 WlibegradNo ratings yet

- Company ProfileDocument41 pagesCompany Profileyusuf mohd sallehNo ratings yet

- Water Cooled Centrifugal Chiller: Technical Data SheetDocument2 pagesWater Cooled Centrifugal Chiller: Technical Data SheetNguyễn Hồng TháiNo ratings yet

- MK TEKNOLOGI BIOPROSES REFRIGERASIDocument43 pagesMK TEKNOLOGI BIOPROSES REFRIGERASIFifin FadillahNo ratings yet

- 1 DM KSKD, Ixirk L%Uh: Wjyh BV M%Udkh Wvqùu Mèo SH Ixls K Fkdùu KV A J MyiqhDocument4 pages1 DM KSKD, Ixirk L%Uh: Wjyh BV M%Udkh Wvqùu Mèo SH Ixls K Fkdùu KV A J Myiqhඩාර්ක් රයිටර්No ratings yet

- HUAGUANG R134aDocument1 pageHUAGUANG R134aCésar100% (1)

- HVACDocument9 pagesHVACLawrence ConananNo ratings yet

- Refrigeration Systems Expansion ValvesDocument7 pagesRefrigeration Systems Expansion ValvesShahid AliNo ratings yet

- Service Chiler Trane RTHC 200TR ProjectDocument4 pagesService Chiler Trane RTHC 200TR Projectoki100% (1)

- MVE Doble Series (Qwick) - Cryogenic Vapor Shippers - Doble QWick 10/660 - Doble QWick 20/660 - Doble QWick 14/4500Document8 pagesMVE Doble Series (Qwick) - Cryogenic Vapor Shippers - Doble QWick 10/660 - Doble QWick 20/660 - Doble QWick 14/4500PrincestonNo ratings yet

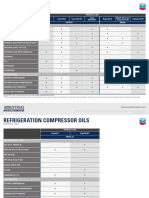

- Compressor Oil Comparison ChartDocument2 pagesCompressor Oil Comparison ChartKalezic NebojsaNo ratings yet

- Internship Report HvacDocument23 pagesInternship Report HvacIhsanul HaqNo ratings yet

- JNTU World - SEO Optimized Title for Refrigeration Cycle QuestionsDocument10 pagesJNTU World - SEO Optimized Title for Refrigeration Cycle QuestionsAyush SharmaNo ratings yet

- Fundamentals of RefrigerationDocument1 pageFundamentals of RefrigerationDheeraj KashyapNo ratings yet

- Complete HVAC Course OutlineDocument2 pagesComplete HVAC Course OutlineMohammed Abdul MoiedNo ratings yet

- Sanden: Multi-Flow CondenserDocument3 pagesSanden: Multi-Flow CondenserIgnasiNo ratings yet

- DSC04 - ACS-5E-H - 35-250 KW - 50HzDocument6 pagesDSC04 - ACS-5E-H - 35-250 KW - 50HzrepelindNo ratings yet

- Thermostatic Expansion Valves: Tle Thermo Expansion ValveDocument26 pagesThermostatic Expansion Valves: Tle Thermo Expansion ValveMeher YoussfiNo ratings yet

- HPDocument51 pagesHPKhan Basit KhanNo ratings yet

- Manual Shutdown LPGDocument11 pagesManual Shutdown LPGYoga NugrahaNo ratings yet