Professional Documents

Culture Documents

Energy Conservation Opportunities 251: Figure 15-3. Water Level Controls and Pressure Relief Valve

Uploaded by

Rohit Shrestha0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

1 (152)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesEnergy Conservation Opportunities 251: Figure 15-3. Water Level Controls and Pressure Relief Valve

Uploaded by

Rohit ShresthaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Energy Conservation Opportunities 251

Figure 15-3. Water Level Controls and Pressure Relief Valve

High Fuel-to-air Ratios and High Air-to-fuel Ratios

A high fuel-to-air ratio causes sooting and lowers boiler ef-

ficiency. In certain conditions, it may also be dangerous if there’s

not enough air for complete combustion and dilution of the fuel.

A high fuel-to-air condition can be caused by an improperly ad-

justed burner, a blocked exhaust stack, the blower or dampers set

incorrectly or any condition which results in a negative pressure

in the boiler room. A negative pressure in the boiler room can be

the result of one or a combination of conditions such as an ex-

haust fan pulling a negative pressure in the boiler room, a re-

stricted combustion air louver into the room, or even adverse

wind conditions. High air-to-fuel ratios also reduce boiler effi-

ciency. If too much air is brought in, the hot gases are diluted too

much and rapidly swept out of the tubes before proper heat trans-

fer can occur. High air volumes are caused by improper blower or

damper settings.

252 HVAC Fundamentals

ECOs:

• Ensure the proper amount of air for combustion is available.

Check that primary and secondary air can enter the boiler’s

combustion chamber only in regulated quantities and at the

correct place.

• Inspect boiler gaskets, refractory, brickwork and castings for

hot spots and air leaks.

• Defective gaskets, cracked brickwork and broken casings

allow uncontrolled and varying amounts of air to enter the

boiler and prevent accurate fuel-air ratio adjustment.

• Perform a flue-gas analysis. Take stack temperatures and

oxygen readings routinely, and inspect the boiler for leaks.

• Repair all defects before resetting the fuel-air ratio. Consider

installing an oxygen analyzer with automatic trim for larger

boilers. This device continuously analyzes the fuel-air ratio

and automatically adjusts it to meet the changing stack draft

and load conditions.

• Check that controls are turning off boilers and pumps as

outlined in the sequence of operations. Observe the fire

when the boiler shuts down. If it does not cut off immedi-

ately, check for a faulty solenoid valve, and repair or replace

it as needed.

• Adjust controls on multiple systems so a second boiler will

not fire until the first boiler can no longer satisfy the de-

mand. Make sure that reset controls work properly to sched-

ule heating water temperature according to the outside air

temperature.

• Install automatic blowdown controls. Pipe the blowdown

water through a heat exchanger to recover and reuse waste

heat.

You might also like

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Boiler Operation On DcsDocument4 pagesBoiler Operation On Dcsarif100% (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- General Description of Afbc BoilerDocument8 pagesGeneral Description of Afbc BoilerSaurabh Barange100% (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- General Procedures For Raising SteamDocument3 pagesGeneral Procedures For Raising SteamAlma Dela PeñaNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- The Basic 10 For Boiler Tuning: Tip SheetDocument2 pagesThe Basic 10 For Boiler Tuning: Tip SheetEliecer Romero MunozNo ratings yet

- Boiler ControlDocument38 pagesBoiler ControlTharun JagadeeshNo ratings yet

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Boiler ControlDocument38 pagesBoiler ControlTharun JagadeeshNo ratings yet

- Why Draft Control Rev12Document2 pagesWhy Draft Control Rev12yash1239No ratings yet

- Boiler Commissioning and Operation Check ListDocument14 pagesBoiler Commissioning and Operation Check Listtsrinivasan5083100% (3)

- Boiler Inspection Guidance PDFDocument5 pagesBoiler Inspection Guidance PDFAnonymous yCpjZF1rFNo ratings yet

- Boiler Inspection MaintenanceDocument5 pagesBoiler Inspection Maintenanceskthen72No ratings yet

- Boiler Instrumentation and ControlDocument54 pagesBoiler Instrumentation and ControlSunny Gupta100% (2)

- Boiler Control Process OverviewDocument27 pagesBoiler Control Process OverviewSandeep Kumar Krishnaraj100% (1)

- Aph FireDocument25 pagesAph Firesekhar_ntpcNo ratings yet

- Furnaces 2012Document54 pagesFurnaces 2012mujeebmehar100% (1)

- Industry and TechnologyDocument2 pagesIndustry and TechnologyDinushika SandamaliNo ratings yet

- BoilerDocument10 pagesBoilerkanbouchNo ratings yet

- Boiler Instrumentation and Control Present Ti OnDocument17 pagesBoiler Instrumentation and Control Present Ti Onrajtheheartthrob_singh100% (1)

- Fluidos Termicos y Circuitos de CalentamientoDocument38 pagesFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNo ratings yet

- Operation and Maintenance of Boilers: Prepared byDocument22 pagesOperation and Maintenance of Boilers: Prepared byZAHID HUSSAIN100% (1)

- Unit III Boiler Control IDocument26 pagesUnit III Boiler Control ILotus FlowerNo ratings yet

- Siemens Boiler Control OverviewDocument12 pagesSiemens Boiler Control OverviewAnonymous zMWvcTNo ratings yet

- New Microsoft Word DocumentDocument25 pagesNew Microsoft Word DocumentRathin KukrejaNo ratings yet

- Section 1.4 - Processing Control EquipmentDocument35 pagesSection 1.4 - Processing Control EquipmentLakshman Kumar JulapalliNo ratings yet

- Meg 5-LF-35-36 Aux Steam SystemDocument23 pagesMeg 5-LF-35-36 Aux Steam SystemAkash KandwalNo ratings yet

- How To Maximize Burner EfficiencyDocument3 pagesHow To Maximize Burner Efficiencyfawmer61No ratings yet

- Industrial BoilerDocument30 pagesIndustrial Boilerஇராம் பாபுNo ratings yet

- UNIT 4 Power Plant InstrumentationDocument63 pagesUNIT 4 Power Plant InstrumentationKalai SelvanNo ratings yet

- Boiler Safe OperationDocument9 pagesBoiler Safe OperationMARISSA DINLASANNo ratings yet

- Energy Conservation Opportunities 243Document2 pagesEnergy Conservation Opportunities 243Rohit ShresthaNo ratings yet

- Install An Automatic Blowdown Control System: BackgroundDocument5 pagesInstall An Automatic Blowdown Control System: BackgroundNaNo ratings yet

- Parts of Boiler: Furnace BurnerDocument40 pagesParts of Boiler: Furnace BurnerGanesh MuruganNo ratings yet

- Boiler EfficiencyDocument28 pagesBoiler EfficiencyRintu BiswasNo ratings yet

- O 040894100Document7 pagesO 040894100IJERDNo ratings yet

- Energy Conservation Opportunities 249: Figure 15-1. Inspecting Firing ChamberDocument2 pagesEnergy Conservation Opportunities 249: Figure 15-1. Inspecting Firing ChamberRohit ShresthaNo ratings yet

- University of Cebu Main-Campus College of Engineering Mechanical EngineeringDocument6 pagesUniversity of Cebu Main-Campus College of Engineering Mechanical EngineeringRhadel GantuangcoNo ratings yet

- PPS Boiler Safe OperationDocument9 pagesPPS Boiler Safe OperationAraNo ratings yet

- Lecture 4 - Case StudiesDocument8 pagesLecture 4 - Case StudiesBrian MasauliNo ratings yet

- Boiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerDocument9 pagesBoiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerChriscarl De LimaNo ratings yet

- Week 13Document29 pagesWeek 13Mariel PernitoNo ratings yet

- BoilersDocument67 pagesBoilerssahilchemNo ratings yet

- Xxii. Measurements and Controls in Boiler PlantDocument16 pagesXxii. Measurements and Controls in Boiler PlantRajneesh VachaspatiNo ratings yet

- Steam System Basics: Watertube BoilersDocument4 pagesSteam System Basics: Watertube BoilersNaNo ratings yet

- Boiler OperationsDocument10 pagesBoiler OperationsSatyandra MishraNo ratings yet

- Thermo 4Document9 pagesThermo 4Emran MuhammadNo ratings yet

- Boiler Plant Operations and MaitainanceDocument32 pagesBoiler Plant Operations and Maitainanceanilkumarv123No ratings yet

- S. P. Thermal Systems Inc.: 4504 Green Meadow Blvd. Beamsville, Ontario L0R 1B5, CanadaDocument8 pagesS. P. Thermal Systems Inc.: 4504 Green Meadow Blvd. Beamsville, Ontario L0R 1B5, CanadaShankar JhaNo ratings yet

- Prepared By: Zerihun Kassa: UM at EABSC, Dec 2018Document32 pagesPrepared By: Zerihun Kassa: UM at EABSC, Dec 2018zerihun kassaNo ratings yet

- Boiler Operation and MaintenanceDocument25 pagesBoiler Operation and MaintenanceJom BonhayagNo ratings yet

- 22-32973 JC - York SXA Website Content Development - Maintenance Tips Brochure - MP1r1Document1 page22-32973 JC - York SXA Website Content Development - Maintenance Tips Brochure - MP1r1Sean RameyNo ratings yet

- Boiler-Steam Generator Protection PDFDocument12 pagesBoiler-Steam Generator Protection PDFأمير حارث100% (1)

- Boiler Operation and Safety PrecautionDocument66 pagesBoiler Operation and Safety PrecautionSahil Mishra100% (1)

- Objective:-Identify The Routine Maintenance Parts of The Coal Fired Thermal Power Plant LayoutDocument5 pagesObjective:-Identify The Routine Maintenance Parts of The Coal Fired Thermal Power Plant LayoutSuraj KumarNo ratings yet

- Boiler Maintenance and OperationsDocument30 pagesBoiler Maintenance and OperationsSuresh SenanayakeNo ratings yet

- Glycol Dehydration Instrumentation and ControlsDocument3 pagesGlycol Dehydration Instrumentation and ControlsdndudcNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Air Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)Document2 pagesAir Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)rohitNo ratings yet

- Air Conditioning Systems 69: Heat Pump (Air-Air)Document2 pagesAir Conditioning Systems 69: Heat Pump (Air-Air)Rohit ShresthaNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Compressors: Chapter FiveDocument2 pagesCompressors: Chapter FiveRohit ShresthaNo ratings yet

- Figure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Document2 pagesFigure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Rohit ShresthaNo ratings yet

- Figure 4-.2 Air Conditioning System ExampleDocument2 pagesFigure 4-.2 Air Conditioning System ExamplerohitNo ratings yet

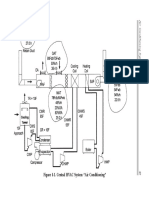

- Figure 4-1. Central HVAC System "Air Conditioning"Document2 pagesFigure 4-1. Central HVAC System "Air Conditioning"rohitNo ratings yet

- Air Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemDocument2 pagesAir Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemrohitNo ratings yet

- Air Conditioning Systems 51Document2 pagesAir Conditioning Systems 51rohitNo ratings yet

- Air Conditioning Systems 55Document2 pagesAir Conditioning Systems 55rohitNo ratings yet

- Air Conditioning Systems 57Document2 pagesAir Conditioning Systems 57rohitNo ratings yet

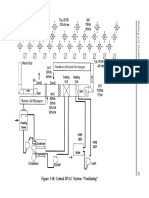

- Figure 3-10. Central HVAC System "Ventilating"Document2 pagesFigure 3-10. Central HVAC System "Ventilating"rohitNo ratings yet

- Heating and Ventilating Systems 25Document2 pagesHeating and Ventilating Systems 25rohitNo ratings yet

- Heating and Ventilating Systems 43: MAT (%OA ×Document2 pagesHeating and Ventilating Systems 43: MAT (%OA ×rohitNo ratings yet

- Heating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerDocument2 pagesHeating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerrohitNo ratings yet

- Heating and Ventilating Systems 41: Figure 3-8. Oil BurnerDocument2 pagesHeating and Ventilating Systems 41: Figure 3-8. Oil BurnerrohitNo ratings yet

- Heating and Ventilating Systems 35Document2 pagesHeating and Ventilating Systems 35rohitNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- 1 PDFDocument2 pages1 PDFrohitNo ratings yet

- Heating and Ventilating Systems 29: Figure 3-2. Steam BoilerDocument2 pagesHeating and Ventilating Systems 29: Figure 3-2. Steam BoilerrohitNo ratings yet

- Figure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamDocument2 pagesFigure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamrohitNo ratings yet

- Heating and Ventilating Systems 33Document2 pagesHeating and Ventilating Systems 33rohitNo ratings yet

- Heat Flow 15Document2 pagesHeat Flow 15rohitNo ratings yet

- Latent HeatDocument2 pagesLatent HeatrohitNo ratings yet

- Heat Flow 17: ConductionDocument2 pagesHeat Flow 17: ConductionrohitNo ratings yet

- Heating and Ventilating Systems 27Document2 pagesHeating and Ventilating Systems 27rohitNo ratings yet

- Air Volume: HVAC Systems 11Document2 pagesAir Volume: HVAC Systems 11rohitNo ratings yet

- HVAC Systems 13: VentilatingDocument2 pagesHVAC Systems 13: VentilatingrohitNo ratings yet

- Systems - of - EquationsDocument39 pagesSystems - of - EquationsAnonymous 5aPb088W100% (1)

- Math 10 Q2 Week 5Document3 pagesMath 10 Q2 Week 5Ken FerrolinoNo ratings yet

- Pipe Clamp For Sway Bracing TOLCODocument1 pagePipe Clamp For Sway Bracing TOLCOEdwin G Garcia ChNo ratings yet

- Basic Electronics Lab ManualDocument47 pagesBasic Electronics Lab ManualAlpesh ThesiyaNo ratings yet

- Ticket Eater - User Manual 2006Document24 pagesTicket Eater - User Manual 2006tokio2424No ratings yet

- Siemens Micromaster 440 Manual PDFDocument312 pagesSiemens Micromaster 440 Manual PDFGustavo Barrera100% (1)

- Review Problems Chapter 4 Solutions PDFDocument4 pagesReview Problems Chapter 4 Solutions PDFAntoninoNo ratings yet

- Water Levels Forecast in Thailand: A Case Study of Chao Phraya RiverDocument6 pagesWater Levels Forecast in Thailand: A Case Study of Chao Phraya RiverErna UtamiNo ratings yet

- Trigonometric Ratios LPDocument3 pagesTrigonometric Ratios LPjoshgarciadlt100% (2)

- Index Terms LinksDocument31 pagesIndex Terms Linksdeeptiwagle5649No ratings yet

- KVS - Regional Office, JAIPUR - Session 2021-22Document24 pagesKVS - Regional Office, JAIPUR - Session 2021-22ABDUL RAHMAN 11BNo ratings yet

- Drop ForgingDocument18 pagesDrop ForgingpunkhunkNo ratings yet

- Cópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersDocument6 pagesCópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersFernanda AzevedoNo ratings yet

- Relay Maintenance and Testing: BenefitsDocument2 pagesRelay Maintenance and Testing: BenefitsojoladapoNo ratings yet

- Fib Lucas StaDocument5 pagesFib Lucas StafabriziomaccalliniNo ratings yet

- Practice Question ElectricityDocument3 pagesPractice Question ElectricityIvan SetyawanNo ratings yet

- Testing, Adjusting, and Balancing - TabDocument19 pagesTesting, Adjusting, and Balancing - TabAmal Ka100% (1)

- Chapter VI DP and NetworkDocument66 pagesChapter VI DP and NetworkSirgut TesfayeNo ratings yet

- Chapter 3Document23 pagesChapter 3pganoelNo ratings yet

- User's Manual HEIDENHAIN Conversational Format ITNC 530Document747 pagesUser's Manual HEIDENHAIN Conversational Format ITNC 530Mohamed Essam Mohamed100% (2)

- Analysis and Design of Telecommunication Tower Using Different Truss System by ETab SoftwareDocument12 pagesAnalysis and Design of Telecommunication Tower Using Different Truss System by ETab SoftwareEditor IJTSRDNo ratings yet

- 1.project FullDocument75 pages1.project FullKolliparaDeepakNo ratings yet

- JZ990D43501 eDocument6 pagesJZ990D43501 eМаксим ПасичникNo ratings yet

- Initial and Final Setting Time of CementDocument20 pagesInitial and Final Setting Time of CementTesfayeNo ratings yet

- A Comparative Study On The Academic Performance ofDocument18 pagesA Comparative Study On The Academic Performance ofDiether Allen L. YnionNo ratings yet

- Fitting Fundamentals: For SewersDocument21 pagesFitting Fundamentals: For SewersLM_S_S60% (5)

- Introduction To PercolationDocument25 pagesIntroduction To Percolationpasomaga100% (1)

- Coek - Info The Fabric of RealityDocument5 pagesCoek - Info The Fabric of RealityFredioGemparAnarqiNo ratings yet

- PythagorasDocument109 pagesPythagorasaditya00012No ratings yet

- Exercise 1 - Revision StringDocument2 pagesExercise 1 - Revision StringKu H6No ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- The Petroleum Engineering Handbook: Sustainable OperationsFrom EverandThe Petroleum Engineering Handbook: Sustainable OperationsRating: 3.5 out of 5 stars3.5/5 (5)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Guide to the Practical Use of Chemicals in Refineries and PipelinesFrom EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesRating: 5 out of 5 stars5/5 (1)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesFrom EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesRating: 5 out of 5 stars5/5 (7)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet