Professional Documents

Culture Documents

Production: Without Marine Proteins in A Biofloc System

Uploaded by

AngeloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production: Without Marine Proteins in A Biofloc System

Uploaded by

AngeloCopyright:

Available Formats

Production of shrimp (Litopenaeus vannamei)

BIOFLOC PRODUCTION

WITHOUT MARINE PROTEINS IN A

BIOFLOC SYSTEM

By Eric De Muylder, Leon Claessens & Mekki Herizi, Crevetope

Production

of shrimp without water exchange with the

utilization of bioflocs has gained a lot of interest

recently. The presence of bioflocs in the shrimp

farming system not only maintains a good water quality, but also provides essential and high quality

nutrients to the shrimp. This additional feed makes it possible to obtain fast growth and low FCR. Avoid-

ing water exchange also increases biosecurity

since the water is often the source of patho-

gens.

Fish meal has become a valuable and expensive

ingredient and its utilization should be mini-

mized as much as possible. The future of aqua-

culture will depend on the possibility to pro-

duce seafood with a limited availability of this

raw material.

Bioflocs

At intensive aeration the feces of shrimp are

assimilated by bacteria. These bacteria form

colonies. Also rest products (fibers etc) and

micro-organisms are part of these bioflocs.

These bacteria take pollutants out of the water

(ammonia) and convert them into proteins.

Shrimp consume these bioflocs actively or

passively by filter feeding.

Goal of the experiment

The goals was to produce shrimp without the

utilization of marine proteins (no fish meal, no

squid meal, no shrimp meal) in the feeds and

use the bioflocs to recycle waste protein and

nitrogen in the shrimp tank to complement the

pelleted feeds with live organisms. Biofloc

AQUAFEED from Aquafeed.com

BIOFLOC PRODUCTION — AQUAFEED WINTER 2010

Material & Methods

Two diets were formulated and pressed on a 2 mm die: a reference diet with 20 % fish meal (FM) and a

diet without any marine protein (see table):

Table 1

Reference No FM

Danish fish meal 20

Corn Gluten 11 12

DDGS 9.5

Soybean meal 16 16

Hemoglobin powder 6

Wheat flour 31 24.3

Canola 12 12

Fish oil & Lecitihn 6 6.8

Wheat gluten 2 2

Other 2

Amino acid mix 7.4

Premix 2 2

Composition:

Crude Protein 37.74 38.43

Lipids 8.61 8.54

HUFA 0.89 0.76

Crude fibers 2.92 3.42

Ash content 6.44 5.66

Raw material cost (Euro/MT) 690 530

Shrimp were put in 12 nets of 150 L at the AFT—CreveTec Research center in Venray, Netherlands. The

nets were submerged in a bigger tank, which was connected to a biofloc reactor. Water quality was

maintained through bioflocs. Each net was stocked with 25 shrimp (Litopenaeus vannamei) of 13 g each.

The shrimp trial lasted for six weeks.

Table 2

Reference No FM

Initial individual weight (g) 13.05 12.85

Final individual weight (g) 22.44 22.63

Average growth (g/week) 1.565 1.629

FCR 1.81 1.44

Survival 77.00% 83.00%

AQUAFEED from Aquafeed.com

BIOFLOC PRODUCTION — AQUAFEED WINTER 2010

Crevetope shrimp produced in a biofloc system

Results

Both diets enabled excellent growth (>1,5g/week), and the

diet without marine proteins was at least as good as the

diet with 20 % fish meal.

Conclusion

It is unknown but certainly doubtful if the same results

would have been obtained in clear water without bioflocs.

Research in the past has proven that the presence of

bioflocs can increase growth by 15 % and decrease FCR by

40 %, which means that shrimp can benefit from the nutri-

The AFT— CreveTec Research center in

tional quality of bioflocs. Venray, Netherlands

A good balanced feed can be produced without the utiliza-

tion of marine proteins, as long as digestible protein sources are used and amino acids are balanced. The

diet without marine proteins is about €160 per tonne cheaper in raw material cost.

The combination of such a diet and utilization of a biofloc system enables sustainable production of

shrimp anywhere in the world:

– No water exchange during farming and recuperation of water for next cycle

– Recycling nutrient feces via bioflocs

– Limited utilization of natural resources

For more information or to obtain literature references, please contact Eric de Muylder or

visit www.crevetope.be

AQUAFEED from Aquafeed.com

You might also like

- Alternative Fish MealDocument13 pagesAlternative Fish Mealrommel duranNo ratings yet

- Tilapia Production in Biofloc Systems PDFDocument25 pagesTilapia Production in Biofloc Systems PDFAshokkumar KandasamyNo ratings yet

- Tilapia BioFloc PDFDocument25 pagesTilapia BioFloc PDFPRASHANTNo ratings yet

- Flocs SystemDocument39 pagesFlocs SystemYahya HamitisnaNo ratings yet

- Marine Proteins and Peptides: Biological Activities and ApplicationsFrom EverandMarine Proteins and Peptides: Biological Activities and ApplicationsNo ratings yet

- Plant Secondary Metabolites: Occurrence, Structure and Role in the Human DietFrom EverandPlant Secondary Metabolites: Occurrence, Structure and Role in the Human DietAlan CrozierNo ratings yet

- Unlocking The Hidden Potential of Plant Proteins Using Solid State Fermentation EnzymesDocument7 pagesUnlocking The Hidden Potential of Plant Proteins Using Solid State Fermentation EnzymesInternational Aquafeed magazineNo ratings yet

- The Digestibility of Hydrolyzed Soy ProteinDocument8 pagesThe Digestibility of Hydrolyzed Soy ProteinImran khanNo ratings yet

- AQUA2012Document15 pagesAQUA2012Agus Prihanto PurnomoNo ratings yet

- Biofloc Technology Aquaculture Doug Ernst PDFDocument26 pagesBiofloc Technology Aquaculture Doug Ernst PDFSantosh DasNo ratings yet

- Tilapia Production in Biofloc Systems Yoram Avnimelech Tecnion Israel InstDocument33 pagesTilapia Production in Biofloc Systems Yoram Avnimelech Tecnion Israel Instyudi100% (3)

- 12 Panel 3 Yoram AvnimelechDocument33 pages12 Panel 3 Yoram AvnimelechAnonymous dnQEPoumuzNo ratings yet

- Albert Tacon Recent Developments in Feeds and Feeding PDFDocument86 pagesAlbert Tacon Recent Developments in Feeds and Feeding PDFAnggaVaiNo ratings yet

- Productivity Study in 3 Different Ponds of Barwani District (M.P.) With Special Emphasis On Different Oil CakesDocument45 pagesProductivity Study in 3 Different Ponds of Barwani District (M.P.) With Special Emphasis On Different Oil CakesBhaskar ReddyNo ratings yet

- Litopenaeus Vannamei Rice Byproducts 2020Document10 pagesLitopenaeus Vannamei Rice Byproducts 2020Adrian AyalaNo ratings yet

- Novel Proteins for Food, Pharmaceuticals, and Agriculture: Sources, Applications, and AdvancesFrom EverandNovel Proteins for Food, Pharmaceuticals, and Agriculture: Sources, Applications, and AdvancesNo ratings yet

- Agrodok-Series No. 21 - On-Farm Fish CultureDocument67 pagesAgrodok-Series No. 21 - On-Farm Fish CultureEzekiel BulusNo ratings yet

- 1981 Robertson WHCDocument15 pages1981 Robertson WHCCarol FulaNo ratings yet

- Effect of Cassia Tora Leaves On Growth Performance of Labeo RohitaDocument3 pagesEffect of Cassia Tora Leaves On Growth Performance of Labeo RohitaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Lated Diet Has Growth and Feed Utilization Efficiency Advantages Over Trash FishDocument7 pagesLated Diet Has Growth and Feed Utilization Efficiency Advantages Over Trash Fishwaciy70505No ratings yet

- Epinephelus Coioides Feeding PDFDocument39 pagesEpinephelus Coioides Feeding PDFHafez MabroukNo ratings yet

- Marine Ornamental Shrimp: Biology, Aquaculture and ConservationFrom EverandMarine Ornamental Shrimp: Biology, Aquaculture and ConservationNo ratings yet

- Pengaruh Pemberian Pakan Dengan Kadar Protein Berbeda Terhadap Performa Pertumbuhan Ikan Kakap Putih (LatesDocument8 pagesPengaruh Pemberian Pakan Dengan Kadar Protein Berbeda Terhadap Performa Pertumbuhan Ikan Kakap Putih (LatesHilal AkuakulturNo ratings yet

- Pengaruh Pemberian Pakan Dengan Kadar Protein Berbeda Terhadap Performa Pertumbuhan Ikan Kakap Putih (LatesDocument8 pagesPengaruh Pemberian Pakan Dengan Kadar Protein Berbeda Terhadap Performa Pertumbuhan Ikan Kakap Putih (LatesHilal AkuakulturNo ratings yet

- A Study On Optimization of Fish Protein Hydrolysate Preparation by Enzymatic Hydrolysis From Tilapia Fish Waste MinceDocument10 pagesA Study On Optimization of Fish Protein Hydrolysate Preparation by Enzymatic Hydrolysis From Tilapia Fish Waste Mincesumaiya rahmanNo ratings yet

- 104755-Beef Rations Cereal StrawDocument8 pages104755-Beef Rations Cereal StrawJUAN MANUEL CABRALESNo ratings yet

- The System of Fish-Livestock/poultry IntegrationDocument58 pagesThe System of Fish-Livestock/poultry IntegrationEkaIriadentaNo ratings yet

- Biofloc Booklet v6Document16 pagesBiofloc Booklet v6Sri HarshaNo ratings yet

- Aquaculture: Spirulina Sp. LEB 18 Cultivation in Outdoor Pilot Scale Using AquacultureDocument10 pagesAquaculture: Spirulina Sp. LEB 18 Cultivation in Outdoor Pilot Scale Using AquacultureSeithikurippu R Pandi-PerumalNo ratings yet

- Goldfish: An Assessment of The Protein and Amino Acid Requirements in LarvaeDocument8 pagesGoldfish: An Assessment of The Protein and Amino Acid Requirements in LarvaeAldy BudiNo ratings yet

- Effect of Garlic Oil On Lamb Fattening Performance, RumenDocument10 pagesEffect of Garlic Oil On Lamb Fattening Performance, Rumenmekyno32No ratings yet

- 1 s2.0 S1876610214002434 MainDocument5 pages1 s2.0 S1876610214002434 Mainrora ade seftaNo ratings yet

- Optimasi Produksi Hidrolisat Protein Dari Tepung Ikan Menggunakan Enzim BromelinDocument15 pagesOptimasi Produksi Hidrolisat Protein Dari Tepung Ikan Menggunakan Enzim BromelinYohanes Eko Aditya100% (1)

- Feeding Chart For Semi-Intensive Pond Production of Nile Tilapia (Oreochromis Niloticus) Fed On A Plant-Based Diet and Economic PerformanceDocument11 pagesFeeding Chart For Semi-Intensive Pond Production of Nile Tilapia (Oreochromis Niloticus) Fed On A Plant-Based Diet and Economic PerformanceMuhammad DannyNo ratings yet

- Quality Characteristics of Chicken Burger Processed From Broiler Chicken Fed On Different Levels of Quinoa SeedsDocument9 pagesQuality Characteristics of Chicken Burger Processed From Broiler Chicken Fed On Different Levels of Quinoa SeedsMamta AgarwalNo ratings yet

- LF 4 Concentrated Algae FormulationsDocument23 pagesLF 4 Concentrated Algae FormulationsMaria AgwantaNo ratings yet

- Shrimp Silage Torrissen1981Document7 pagesShrimp Silage Torrissen1981javagri labNo ratings yet

- Tilapia AquacultureDocument23 pagesTilapia AquacultureyvettesarmientoNo ratings yet

- (Dec-2013, India) ICFIN 2013 Grasshoppers - Food Security and NutritionDocument11 pages(Dec-2013, India) ICFIN 2013 Grasshoppers - Food Security and NutritionJuan Carlos PeinadoNo ratings yet

- Kheriji S. Et Al. 2017Document10 pagesKheriji S. Et Al. 2017souhailaNo ratings yet

- Using Pineapple WasteDocument12 pagesUsing Pineapple Wastezihan.pohNo ratings yet

- Efficacy of Dietary Supplementation With Yeast Culture For Grazing Dairy Cows and For CalvesDocument8 pagesEfficacy of Dietary Supplementation With Yeast Culture For Grazing Dairy Cows and For CalvesJUAN MANUEL CABRALESNo ratings yet

- KéfirDocument9 pagesKéfiranaymgalvizNo ratings yet

- Uncovering The Promising Role of Grape Pomace As A Modulator ofDocument15 pagesUncovering The Promising Role of Grape Pomace As A Modulator ofSinisa VargaNo ratings yet

- Feed Additive of Binder Seaweed Grass in Fish Feed Formulation On Physical Characteristics and EfficiencyDocument8 pagesFeed Additive of Binder Seaweed Grass in Fish Feed Formulation On Physical Characteristics and EfficiencyInternational Journal of Multidisciplinary Research and AnalysisNo ratings yet

- Uso de La Pasta de Soya en La Acuacultura - DavisDocument26 pagesUso de La Pasta de Soya en La Acuacultura - DavisHanz Kevin Boy MendozaNo ratings yet

- Lecturer's Handbook On WheyDocument91 pagesLecturer's Handbook On WheyWhey Proteinpulver100% (1)

- Use of Apple By-Products in Poultry RationDocument4 pagesUse of Apple By-Products in Poultry RationOliver TalipNo ratings yet

- Hydrogen Rich WaterDocument26 pagesHydrogen Rich WaterManish MNo ratings yet

- Crude Glycerol in The Diets of The Juveniles Ofamazon Catfish (Female Pseudoplatystoma Punctifer X Male Leiarius Marmoratus)Document16 pagesCrude Glycerol in The Diets of The Juveniles Ofamazon Catfish (Female Pseudoplatystoma Punctifer X Male Leiarius Marmoratus)IJEAB JournalNo ratings yet

- FINAL - Vejle X Materiom Slide Deck - Intro Biomaterials - CompressedDocument53 pagesFINAL - Vejle X Materiom Slide Deck - Intro Biomaterials - CompressedJ NegiNo ratings yet

- Freshwater Fish FarmingDocument79 pagesFreshwater Fish FarmingMasthankhan PatanNo ratings yet

- 1 SMDocument8 pages1 SMRini AsariNo ratings yet

- Fish Sauce ArticleDocument10 pagesFish Sauce ArticleShafici CqadirNo ratings yet

- Physical and Chemical Analysis of Fish Feed Based On Fermentation of Kelakai Leaf (Stenochlaena Palustris (Burm.F.) Bedd)Document7 pagesPhysical and Chemical Analysis of Fish Feed Based On Fermentation of Kelakai Leaf (Stenochlaena Palustris (Burm.F.) Bedd)Mamta AgarwalNo ratings yet

- Aquaculture Probiotics Manufacturers in India - Finar ChemicalsDocument44 pagesAquaculture Probiotics Manufacturers in India - Finar Chemicalsfinar chemicalsNo ratings yet

- Fortification of Biscuits With Fish Protein Concentrate: February 2014Document9 pagesFortification of Biscuits With Fish Protein Concentrate: February 2014syafaiyah dj halidaNo ratings yet

- 0830AM-Josh SilvermanDocument15 pages0830AM-Josh SilvermanJ&A Partners JANNo ratings yet

- Production of Virgin Coconut Oil From Dry and WetDocument8 pagesProduction of Virgin Coconut Oil From Dry and Wetkiran shettyNo ratings yet

- Accepted Manuscript: 10.1016/j.aquaculture.2017.03.047Document36 pagesAccepted Manuscript: 10.1016/j.aquaculture.2017.03.047RogerioportelaNo ratings yet

- Anion Cation Balance in WaterDocument5 pagesAnion Cation Balance in WaterAngeloNo ratings yet

- Oliveira Pinto Culture of Marine Shrimp (Litopenaeus Vannamei) in Biofloc Technology System Using Artificially Salinized Freshwater ZootechnicalDocument6 pagesOliveira Pinto Culture of Marine Shrimp (Litopenaeus Vannamei) in Biofloc Technology System Using Artificially Salinized Freshwater ZootechnicalAngeloNo ratings yet

- Huang. Effects of Different Carbon Sources On Growth Performance of Litopenaeus Vannamei and Water Quality in The Biofloc System in Low SalinityDocument7 pagesHuang. Effects of Different Carbon Sources On Growth Performance of Litopenaeus Vannamei and Water Quality in The Biofloc System in Low SalinityAngeloNo ratings yet

- Zacarias S. Effect of Different Concentrations of Potassium and Magnesium OnDocument14 pagesZacarias S. Effect of Different Concentrations of Potassium and Magnesium OnAngeloNo ratings yet

- Valenzuela-Jiménez. Effect of Water Salinity On The Oxidative System of Juveniles of The North Atlantic White Shrimp Litopenaeus Setiferus RearedDocument13 pagesValenzuela-Jiménez. Effect of Water Salinity On The Oxidative System of Juveniles of The North Atlantic White Shrimp Litopenaeus Setiferus RearedAngeloNo ratings yet

- Antony Effects of Salinity and Na+K+ Ratio On Osmoregulation and Growth Performance of Black Tiger Prawn, Penaeus Monodon FabriciusDocument13 pagesAntony Effects of Salinity and Na+K+ Ratio On Osmoregulation and Growth Performance of Black Tiger Prawn, Penaeus Monodon FabriciusAngeloNo ratings yet

- Aquaculture: Martin Perez-Velazquez, D. Allen Davis, Luke A. Roy, Mayra L. González-FélixDocument5 pagesAquaculture: Martin Perez-Velazquez, D. Allen Davis, Luke A. Roy, Mayra L. González-FélixAngeloNo ratings yet

- Jahan The Effect of Fortification of Potassium and Magnesium in The Diet and Culture Water On Growth, Survival and OsmoregulationDocument9 pagesJahan The Effect of Fortification of Potassium and Magnesium in The Diet and Culture Water On Growth, Survival and OsmoregulationAngeloNo ratings yet

- Wudtisin. Possible Potassium and Magnesium Limitations For ShrimpDocument12 pagesWudtisin. Possible Potassium and Magnesium Limitations For ShrimpAngeloNo ratings yet

- Roy Requirements For The Culture of The Pacific White Shrimp, Reared in Low Salinity WatersDocument18 pagesRoy Requirements For The Culture of The Pacific White Shrimp, Reared in Low Salinity WatersAngeloNo ratings yet

- Davis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersDocument8 pagesDavis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersAngeloNo ratings yet

- Boyd C. Revisiting Ionic Imbalance in Low-Salinity Shrimp AquacultureDocument4 pagesBoyd C. Revisiting Ionic Imbalance in Low-Salinity Shrimp AquacultureAngeloNo ratings yet

- Esperanza-Leal Performance of Shrimp Postlarvae Reared in Indoor Nursery Tanks Under Biofloc Conditions at Different SalinitiesDocument13 pagesEsperanza-Leal Performance of Shrimp Postlarvae Reared in Indoor Nursery Tanks Under Biofloc Conditions at Different SalinitiesAngeloNo ratings yet

- Roy L. Effects of Varying Levels of Aqueous Potassium and Magnesium OnDocument9 pagesRoy L. Effects of Varying Levels of Aqueous Potassium and Magnesium OnAngeloNo ratings yet

- Wudtisin. Possible Potassium and Magnesium Limitations For ShrimpDocument12 pagesWudtisin. Possible Potassium and Magnesium Limitations For ShrimpAngeloNo ratings yet

- Raizada Survival and Growth of Tiger Shrimp (Penaeus Monodon) in Island Saline Water With Potassium SupDocument7 pagesRaizada Survival and Growth of Tiger Shrimp (Penaeus Monodon) in Island Saline Water With Potassium SupAngeloNo ratings yet

- ROY L. Supplementation of Potassium, Magnesium and Sodium Chloride in Practical Diets For The Pacific White ShrimpDocument10 pagesROY L. Supplementation of Potassium, Magnesium and Sodium Chloride in Practical Diets For The Pacific White ShrimpAngeloNo ratings yet

- Nicovita. INCREASED ION (Na+, K+, Ca++ and MG++) CONCENTRATIONS FOR THE CULTIVATION OF MARINE SHRIMP IN LOW SALINITY WATERSDocument7 pagesNicovita. INCREASED ION (Na+, K+, Ca++ and MG++) CONCENTRATIONS FOR THE CULTIVATION OF MARINE SHRIMP IN LOW SALINITY WATERSAngeloNo ratings yet

- Aquaculture: Martin Perez-Velazquez, D. Allen Davis, Luke A. Roy, Mayra L. González-FélixDocument5 pagesAquaculture: Martin Perez-Velazquez, D. Allen Davis, Luke A. Roy, Mayra L. González-FélixAngeloNo ratings yet

- Davis, Boyd & Rous Effects of Potassium, Magnesium and Age On Growth and Survival of Post-Larvae Reared in Low SalinityDocument4 pagesDavis, Boyd & Rous Effects of Potassium, Magnesium and Age On Growth and Survival of Post-Larvae Reared in Low SalinityAngeloNo ratings yet

- Zhu Effects of NaK Ratio in Seawater On Growth and Energy Budget of Juvenile Litopenaeus VannameiDocument12 pagesZhu Effects of NaK Ratio in Seawater On Growth and Energy Budget of Juvenile Litopenaeus VannameiAngeloNo ratings yet

- Zhu Effects of NaK Ratio in Seawater On Growth and Energy Budget of Juvenile Litopenaeus VannameiDocument12 pagesZhu Effects of NaK Ratio in Seawater On Growth and Energy Budget of Juvenile Litopenaeus VannameiAngeloNo ratings yet

- Roy Requirements For The Culture of The Pacific White Shrimp, Reared in Low Salinity WatersDocument18 pagesRoy Requirements For The Culture of The Pacific White Shrimp, Reared in Low Salinity WatersAngeloNo ratings yet

- Esparza-Leal The Effect of Low Salinity Water With Different Ionic Composition On The Growth and Survival of Litopenaeus Vannamei in Intensive CultureDocument15 pagesEsparza-Leal The Effect of Low Salinity Water With Different Ionic Composition On The Growth and Survival of Litopenaeus Vannamei in Intensive CultureAngeloNo ratings yet

- A Visit To Vientianne Giant River Prawn BroodstockDocument44 pagesA Visit To Vientianne Giant River Prawn BroodstockAngeloNo ratings yet

- 71 BiotecnologiaDocument15 pages71 BiotecnologiaJennifer CoxNo ratings yet

- Production: Without Marine Proteins in A Biofloc SystemDocument3 pagesProduction: Without Marine Proteins in A Biofloc SystemAngeloNo ratings yet

- A Visit To Vientianne Giant River Prawn BroodstockDocument44 pagesA Visit To Vientianne Giant River Prawn BroodstockAngeloNo ratings yet

- Bio-Filters The Need For An New Comprehensive Approach PDFDocument7 pagesBio-Filters The Need For An New Comprehensive Approach PDFjaime ortizNo ratings yet

- ING C1 CO JUN2016 CorrectorDocument6 pagesING C1 CO JUN2016 CorrectoraciameNo ratings yet

- PID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDocument7 pagesPID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDenisNo ratings yet

- 12 Logarithm Approximate FloatingDocument6 pages12 Logarithm Approximate FloatingPhilippe Englert VelhaNo ratings yet

- Iso Iec 25030 2007 eDocument44 pagesIso Iec 25030 2007 eAngélica100% (1)

- Full Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full ChapterDocument13 pagesFull Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full Chapterpoetrycloudyzjm12q100% (19)

- Hand Winches 122 Load Sheaves 126 Gear-And Worm Gear Winches 127 Electric Worm Gear Winches 131 Snatch Blocks 133Document14 pagesHand Winches 122 Load Sheaves 126 Gear-And Worm Gear Winches 127 Electric Worm Gear Winches 131 Snatch Blocks 133Rajaram JayaramanNo ratings yet

- Paper 1 Computer Science ASDocument194 pagesPaper 1 Computer Science ASLailaEl-BeheiryNo ratings yet

- Chapter 9Document28 pagesChapter 9Aniket BatraNo ratings yet

- Evan Lagueux - H Argument EssayDocument7 pagesEvan Lagueux - H Argument Essayapi-692561087No ratings yet

- MATH 304 Linear Algebra Lecture 9 - Subspaces of Vector Spaces (Continued) - Span. Spanning Set PDFDocument20 pagesMATH 304 Linear Algebra Lecture 9 - Subspaces of Vector Spaces (Continued) - Span. Spanning Set PDFmurugan2284No ratings yet

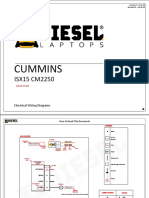

- Cummins: ISX15 CM2250Document17 pagesCummins: ISX15 CM2250haroun100% (4)

- 1.classification of Reciprocating PumpsDocument8 pages1.classification of Reciprocating Pumpsgonri lynnNo ratings yet

- GST RATE LIST - pdf-3Document6 pagesGST RATE LIST - pdf-3Niteesh KumarNo ratings yet

- Wiska Varitain - 0912Document18 pagesWiska Varitain - 0912Anonymous hHWOMl4FvNo ratings yet

- Nbme NotesDocument3 pagesNbme NotesShariq AkramNo ratings yet

- Midterm ReviewerDocument20 pagesMidterm ReviewerJonnafe IgnacioNo ratings yet

- 1en 02 PDFDocument96 pages1en 02 PDFAndrey100% (2)

- PretestDocument8 pagesPretestAlmonte Aira LynNo ratings yet

- Final Quiz 2 - Attempt ReviewDocument6 pagesFinal Quiz 2 - Attempt Reviewkoraijohnson7No ratings yet

- WD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerDocument3 pagesWD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerZowl SaidinNo ratings yet

- Hackerearth Online Judge: Prepared By: Mohamed AymanDocument21 pagesHackerearth Online Judge: Prepared By: Mohamed AymanPawan NaniNo ratings yet

- Aex-Kissan KeralaDocument25 pagesAex-Kissan Keralabsh08070No ratings yet

- Nursing Assessment in Family Nursing PracticeDocument22 pagesNursing Assessment in Family Nursing PracticeHydra Olivar - PantilganNo ratings yet

- NamalDocument5 pagesNamalAyusnab KarkiNo ratings yet

- 3E Hand Over NotesDocument3 pages3E Hand Over NotesAshutosh MaiidNo ratings yet

- Antenatal Care (ANC)Document77 pagesAntenatal Care (ANC)tareNo ratings yet

- Training Design SprintDocument11 pagesTraining Design Sprintardi wiantoNo ratings yet

- NCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Document8 pagesNCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Akash DasNo ratings yet

- Academic Performance of Senior High School Students 4Ps Beneficiaries in VNHSDocument19 pagesAcademic Performance of Senior High School Students 4Ps Beneficiaries in VNHSkathlen mae marollanoNo ratings yet

- Or HandoutDocument190 pagesOr Handoutyared haftu67% (6)