Professional Documents

Culture Documents

Disassembly:: W 0704 M0 Gas-Mixer

Uploaded by

Helder PintoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Disassembly:: W 0704 M0 Gas-Mixer

Uploaded by

Helder PintoCopyright:

Available Formats

Maintenance works: W 0704 M0

Gas-mixer

Turn off motor according to technical instruction no. 1100-0105 and secure against unauthorized

restart.

Interval every

Maintenance works 10000 Oh 20000 Oh 30000 Oh

10 Replace the circuit board and the rubber

sleeve

20 Replace the servomotor

20/30 Overhaul *)

*) only for B15, B16, B17, B21, B27, special gasses, hot cooling 95 – 110 °C

Disassembly:

Hexagon head cap screw 1, Remove cover 2 and conical

nipple 3.

Switch off supply voltage to control motor and circuit board (i. e.

disconnect clamp of DM455 and withdraw fuse from module

interface).

Disassemble the circuit board and servomotor and replace

these.

Issued: Doku./Bilek Checked: Entwicklungsgruppe B Date: 2002-04

EN 0704M0_EN.doc Index: d Page - No.: 1 / 4

Maintenance works: W 0704 M0

Gas-mixer

Remove hexagon nut 4, discs 5 and threaded rod 6.

Remove steel plate.

Turn the circuit-board shaft of the gas mixer in the

direction "AUF" (open) (20 mA).

Switch on supply voltage to control motor and circuit

board (connect clamp of DM455 and insert fuse into

module interface).

Caution: danger of short-circuit

The control motor will unscrew itself out of the gas-mixer

shaft (if the motor does not run, check whether the

Auto/Man button in dia.ne (screen 41) is set to 'Auto',

turn the potentiometer in the direction of

"ZU"(shut)(4 mA), and subsequently in the direction of

"AUF" (open) (20 mA)).

Switch off supply voltage to control motor and circuit W0704 35

board again.

Remove wiring from control motor and circuit board.

Issued: Doku./Bilek Checked: Entwicklungsgruppe B Date: 2002-04

EN 0704M0_EN.doc Index: d Page - No.: 2 / 4

Maintenance works: W 0704 M0

Gas-mixer

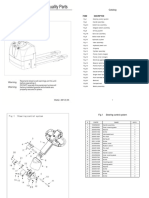

Layout of cables:

W0704-36

Name Stepping motor R/I converter plate Simulation device

Motor phase 1 (+) Ph1+ (green) 1 (green) 11 (green)

Motor phase 1 (-) Ph1- (red) 2 (red) 12 (red)

Motor phase 2 (+) Ph2+ (black) 3 (black) 21 (black)

Motor phase 2 (-) Ph2- (grey) 4 (blue) 22 (blue)

+ 24 V IN 1 (yellow) 30 V (yellow)

+ mA OUT 2 (black) Iein

Schirm 3 (Schirm) no connection

Attention: The colours of the cores might change according to the manufacturer!

Inspection:

Check if the gas mixer shaft can be easily moved in the gas mixer case.

(Check: slide the motor forward and back while it screws itself out of the gas-mixer shaft.)

Check shaft and setting thread for wear. Replace, if necessary.

Relubricate the adjusting screw thread and apply a small amount of grease to the shaft.

Assembly:

Assemble the spring to the new

servomotor.

Connect the cabling of the servomotor and

the circuit board. Turn the circuit-board

shaft of the gas mixer in the direction "ZU"

(shut) (4 mA).

Switch on the power supply of the

servomotor and circuit board again. Fit the

servomotor into the screw thread by hand.

The motor will screw itself into the gas-

mixer shaft and open until it reaches the W0704 37

mechanical stop. Switch off the power

supply of the motor and circuit board

again. To continue the assembly, follow

the disassembly procedure in reverse

order.

Do not assemble the circuit board yet.

Issued: Doku./Bilek Checked: Entwicklungsgruppe B Date: 2002-04

EN 0704M0_EN.doc Index: d Page - No.: 3 / 4

Maintenance works: W 0704 M0

Gas-mixer

Adjusting the 0% position:

Turn the circuit-board shaft in the direction "AUF" (open) (20 mA) until it reaches the mechanical stop.

Switch on the power supply of the motor and circuit board. The gas mixer closes until it reaches the

mechanical stop. Switch off the power supply of the motor and circuit board again. Turn the circuit-board

shaft in the direction "ZU" (shut) (4 mA) until it reaches the mechanical stop (now the mixer is "ZU" (shut)

(0%) and the potentiometer is "ZU" (shut) (4mA)).

Assemble the circuit board with the potentiometer shaft on the servomotor (there are two types: circuit

boards with a ribbed potentiometer shaft and circuit boards with a smooth potentiometer shaft).

Assembling circuit boards with a ribbed potentiometer shaft:

The ribbed potentiometer shaft prevents the shaft from sliding in the rubber sleeve. Insert the new rubber

sleeve into the transmission unit leaving only approx. 1 mm of the rubber sleeve sticking out from the

blind hole. Insert the circuit board with potentiometer shaft into the rubber sleeve. Assemble the circuit

board using 4 M4 nuts. Lock the M4 nuts using locking paint.

Assembling circuit boards with a smooth potentiometer shaft:

Glue the new rubber sleeve onto the potentiometer shaft using Loctite 454 glue to prevent the

potentiometer shaft from sliding in the rubber sleeve. Before gluing the rubber sleeve to the potentiometer

shaft, make sure to carefully remove all the white powdery deposit in the rubber sleeve which was left

behind during its manufacture. Slide the rubber sleeve onto the potentiometer shaft. Lift the rubber sleeve

at the front from the shaft using a flat screwdriver. Insert a drop of super glue into the opening created

and move the screwdriver one full turn around the potentiometer shaft (to make sure that the glue is

evenly spread along the front part of the rubber sleeve and to prevent glue from entering the

potentiometer). The curing time of the glue is 2 minutes. Slightly press on the potentiometer to insert the

circuit board with potentiometer shaft into the blind hole. Assemble the circuit board using 4 M4 nuts.

Lock the M4 nuts using locking paint.

Switch on the potentiometer supply voltage.

The rest of the assembly is carried out in reversed order of the disassembly.

4, 5, 6

2, 3

Issued: Doku./Bilek Checked: Entwicklungsgruppe B Date: 2002-04

EN 0704M0_EN.doc Index: d Page - No.: 4 / 4

You might also like

- GeneralDocument50 pagesGeneralwaleedyehia100% (2)

- Man D2842Document122 pagesMan D2842Helder Pinto100% (3)

- Manual Tecnico Bomba StanadyneDocument3 pagesManual Tecnico Bomba StanadyneIvo Silva100% (4)

- Maintenance Program JenbacherDocument11 pagesMaintenance Program JenbacherHelder Pinto100% (1)

- L28-32H GenSet TierII PDFDocument824 pagesL28-32H GenSet TierII PDFHelder Pinto100% (1)

- Componentes Hidráulicos (SK210 Y SK330)Document38 pagesComponentes Hidráulicos (SK210 Y SK330)alexis reyes100% (35)

- Running Problems - Restricted Functions - Audi 0B5 GearboxDocument4 pagesRunning Problems - Restricted Functions - Audi 0B5 GearboxKeldo Gliana100% (3)

- Shogun 2001 Fuel ProblemDocument6 pagesShogun 2001 Fuel ProblemJose GilmerNo ratings yet

- Crude Pump Installation Manual - SULZER PDFDocument992 pagesCrude Pump Installation Manual - SULZER PDFnobelr100% (4)

- LA206001 Park Brake Lamp Illuminated PDFDocument4 pagesLA206001 Park Brake Lamp Illuminated PDFGino Pier100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- M453Document221 pagesM453Helder Pinto100% (2)

- Defect EliminationDocument4 pagesDefect EliminationHossein100% (1)

- Nauticus 3D BeamDocument114 pagesNauticus 3D BeamMinca AndreiNo ratings yet

- Jenbacher: DisassemblyDocument4 pagesJenbacher: DisassemblyArîfNo ratings yet

- W 0700m6 - Gas Mixer PDFDocument5 pagesW 0700m6 - Gas Mixer PDFPopa MihaiNo ratings yet

- Service InformationDocument4 pagesService InformationMarcelo GiussaniNo ratings yet

- TP13 020 PDFDocument7 pagesTP13 020 PDFALFREDONo ratings yet

- AA04111 PC200-7 Modif. Tapas Mando FinalDocument4 pagesAA04111 PC200-7 Modif. Tapas Mando Finaljoaquin suarezNo ratings yet

- Service Bulletin: AB Volvo PentaDocument4 pagesService Bulletin: AB Volvo PentaDan LiamNo ratings yet

- ABB AC - Motor 500KW - Final Service ReportDocument4 pagesABB AC - Motor 500KW - Final Service ReportZi MingNo ratings yet

- Electronic Unit Injector - Install: Disassembly and AssemblyDocument4 pagesElectronic Unit Injector - Install: Disassembly and AssemblysxturboNo ratings yet

- Manual For 1215 Kva Rig AlternatorDocument18 pagesManual For 1215 Kva Rig Alternatorprem080910No ratings yet

- Caterpillar Cat 235 EXCAVATOR (Prefix 64R) Service Repair Manual (64R01258 and Up)Document25 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 64R) Service Repair Manual (64R01258 and Up)rpoy9396615No ratings yet

- Solenoid Valve (Proportional Reducing) - Calibrate - Negative Flow Control - 084527Document18 pagesSolenoid Valve (Proportional Reducing) - Calibrate - Negative Flow Control - 084527Juan Lopez100% (1)

- El7 5GTM 3Document109 pagesEl7 5GTM 3tomasNo ratings yet

- MPC 4502 - 5502 New Fuser Detect FuseDocument4 pagesMPC 4502 - 5502 New Fuser Detect FuseMatloob Khan0% (1)

- Microfilter FinalDocument6 pagesMicrofilter FinalRobs BankNo ratings yet

- NN044207 - D - GB MH2200lDocument12 pagesNN044207 - D - GB MH2200lAlex_andru_1969No ratings yet

- Food Processor ©Document17 pagesFood Processor ©pukymottoNo ratings yet

- Food Processor ŽDocument15 pagesFood Processor ŽAndrei Și Mihaela GeantăNo ratings yet

- Parts & Service News: Component Code Ref No. DateDocument6 pagesParts & Service News: Component Code Ref No. DateJose Miguel Oyola Coronado0% (1)

- Technical Information: ! Safety Notice Page 1 of 5Document5 pagesTechnical Information: ! Safety Notice Page 1 of 5Epure Gabriel100% (2)

- Additional Use and Maintenance Instructions (Motors With BrakDocument12 pagesAdditional Use and Maintenance Instructions (Motors With BrakAli HashemiNo ratings yet

- Piston & Rod RemovalDocument5 pagesPiston & Rod RemovalsxturboNo ratings yet

- 3 Instructions D1 - 1Document125 pages3 Instructions D1 - 1thanhNo ratings yet

- Unit Injector Synchronization - AdjustDocument5 pagesUnit Injector Synchronization - AdjustAhmed Rezk100% (1)

- ElsaWin Docs hs2 A en-GB SRC 48 496200 Master PDFDocument3 pagesElsaWin Docs hs2 A en-GB SRC 48 496200 Master PDFJulius BaltrūnasNo ratings yet

- RP 1007 01Document23 pagesRP 1007 01Anil PanjaniNo ratings yet

- Desarmado BrazoDocument6 pagesDesarmado Brazojuliocop02No ratings yet

- HTFF525AS HTFF525AW Service ManualDocument22 pagesHTFF525AS HTFF525AW Service ManualUEE100% (1)

- Boletin de Servicio MotoresDocument5 pagesBoletin de Servicio MotoresJuan Carlos Moncada PáezNo ratings yet

- Parts Catalog Engine Generator SDG25S 3A3Document37 pagesParts Catalog Engine Generator SDG25S 3A3Вячелав ЕгоровNo ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- Integral SsDocument6 pagesIntegral Sskirk sutherlandNo ratings yet

- Cross Bar Replacement ITF - SM - 5825274-1EN - 3Document6 pagesCross Bar Replacement ITF - SM - 5825274-1EN - 3service iyadMedicalNo ratings yet

- SB 74-0002Document10 pagesSB 74-0002Santiago QuinapantaNo ratings yet

- Grundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetDocument13 pagesGrundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetLeduța DomnescuNo ratings yet

- SB 10106001 9340Document8 pagesSB 10106001 9340Larry MandamandaNo ratings yet

- Crankshaft Front Seal - Install: Shutdown SIS Previous ScreenDocument2 pagesCrankshaft Front Seal - Install: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- 2831transmission Cooler ReplacementDocument5 pages2831transmission Cooler ReplacementSsp VillalbaNo ratings yet

- CBD15 Spare Parts ListDocument45 pagesCBD15 Spare Parts ListKINTOLOBONo ratings yet

- S150-41-K001 SK330-SK350-6E Main Pump & Software ChangeDocument2 pagesS150-41-K001 SK330-SK350-6E Main Pump & Software ChangePHÁT NGUYỄN THẾ100% (2)

- Grundfos - CM1 5 A R I E AQQEDocument13 pagesGrundfos - CM1 5 A R I E AQQEVimal KalariaNo ratings yet

- Odification Ulletin: PAGE: 1/1Document3 pagesOdification Ulletin: PAGE: 1/1Jesus Mack GonzalezNo ratings yet

- Technical Bulletin: DATE: April 2012 NUMBER: 12/060 Issue: 1Document9 pagesTechnical Bulletin: DATE: April 2012 NUMBER: 12/060 Issue: 1Александр НовиковNo ratings yet

- Vibration Damper and Pulley - Remove and InstallDocument3 pagesVibration Damper and Pulley - Remove and Installbejoythomas100% (1)

- Calibracion InyectoresDocument4 pagesCalibracion InyectoresWladimir AmaguañaNo ratings yet

- Bomba Manual Hidráulica TronairDocument19 pagesBomba Manual Hidráulica TronairEdy Lopez DonisNo ratings yet

- Grundfos - TP 25 50 2 A O A GQQEDocument11 pagesGrundfos - TP 25 50 2 A O A GQQEJovisa MaricNo ratings yet

- 322 SensoresDocument4 pages322 SensoresjuankielecNo ratings yet

- Unit Injector - Install: Disassembly and AssemblyDocument5 pagesUnit Injector - Install: Disassembly and AssemblyJoze 23No ratings yet

- Armado de Valvula de Salida Del ConvertidorDocument2 pagesArmado de Valvula de Salida Del ConvertidorKerbin Enrique NuñezNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Federal Mogul BERU 18GZ46 - FBM80WPN - Z377Document2 pagesFederal Mogul BERU 18GZ46 - FBM80WPN - Z377Helder Pinto0% (1)

- Manual Spare Parts PDFDocument257 pagesManual Spare Parts PDFHelder PintoNo ratings yet

- Federal Mogul BERU 18GZ47 - FBM80WPNSDocument1 pageFederal Mogul BERU 18GZ47 - FBM80WPNSHelder PintoNo ratings yet

- P626 Spare Parts ManualDocument79 pagesP626 Spare Parts ManualHelder PintoNo ratings yet

- Infinity 2011Document240 pagesInfinity 2011Helder PintoNo ratings yet

- Mars 1er 2018 Resultats Historiques Du Groupe PSA en 2017Document4 pagesMars 1er 2018 Resultats Historiques Du Groupe PSA en 2017Helder PintoNo ratings yet

- L50MC Drawing For Cylinder CoverDocument1 pageL50MC Drawing For Cylinder CoverHelder PintoNo ratings yet

- Newton Laws of Motion JeopardyDocument19 pagesNewton Laws of Motion JeopardyJessiel GueribaNo ratings yet

- Torsion MEDocument24 pagesTorsion MEmohamed.hassan031No ratings yet

- M2.2.9 Critical Review and Selection of NDT MethodsDocument13 pagesM2.2.9 Critical Review and Selection of NDT MethodsAldy Bagus PratamaNo ratings yet

- (4.5.0 ZULU Beta) (DUMP ALL) BTFL - Cli - 20230916 - 172153Document27 pages(4.5.0 ZULU Beta) (DUMP ALL) BTFL - Cli - 20230916 - 172153Dan MultiNo ratings yet

- ACI 517-2R-87 Standard Specification For Tolerances For Accelerated Curing at Atmospheric PressureDocument17 pagesACI 517-2R-87 Standard Specification For Tolerances For Accelerated Curing at Atmospheric PressureKiramat ShahNo ratings yet

- Centum VPDocument101 pagesCentum VPgopalNo ratings yet

- ESPRIT Milling Tutorial 02Document11 pagesESPRIT Milling Tutorial 02Sandaruwan සුජීවNo ratings yet

- Analysis Procedure K2co3 PDFDocument3 pagesAnalysis Procedure K2co3 PDFPiyush PatelNo ratings yet

- Lec8 SecondOrder PDFDocument61 pagesLec8 SecondOrder PDFPhan Phuong NgocNo ratings yet

- f77 f55 User ManualDocument36 pagesf77 f55 User ManualGabi GabrielNo ratings yet

- Vol Damper (Smacna)Document9 pagesVol Damper (Smacna)MohamedOmar83No ratings yet

- Cryogenics Handbook PDFDocument227 pagesCryogenics Handbook PDFmangyanNo ratings yet

- Aero 3 - 8 Anna's SyllabusDocument110 pagesAero 3 - 8 Anna's SyllabusShiva UNo ratings yet

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document5 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNo ratings yet

- Patrol Box PlansDocument6 pagesPatrol Box PlansPePe ProjectsNo ratings yet

- Ghorbani - AlfalfaDocument7 pagesGhorbani - AlfalfaarizalNo ratings yet

- PC700-8 Uess15301 1208Document24 pagesPC700-8 Uess15301 1208LTATECNICONo ratings yet

- DHLDocument3 pagesDHLfmartinNo ratings yet

- Technical Brochure Metal Ceilings V100-V200-en EUDocument12 pagesTechnical Brochure Metal Ceilings V100-V200-en EUNicu PotîngNo ratings yet

- Types of Processors and RAM'sDocument26 pagesTypes of Processors and RAM'sSneha NairNo ratings yet

- Harbor GlenDocument31 pagesHarbor GlenElvis Felix fernandesNo ratings yet

- Unit-1 - Spur Gears - Lecture - 6 - Problems Spur Gear - Mahesh GaikwadDocument13 pagesUnit-1 - Spur Gears - Lecture - 6 - Problems Spur Gear - Mahesh GaikwadNikhil JadhavNo ratings yet

- Production Support ProcessDocument15 pagesProduction Support ProcesssantoshNo ratings yet

- 3 Esrtos IntroDocument8 pages3 Esrtos IntroVijayaraghavan VNo ratings yet

- Demineralization Mechanism and Influence of Parameters On High Ash Indian Coal by Chemical Leaching of Acid and Alkali SolutionDocument1 pageDemineralization Mechanism and Influence of Parameters On High Ash Indian Coal by Chemical Leaching of Acid and Alkali SolutionSushanta Kumar BeheraNo ratings yet

- SQL Server Connectivity Roadmap.: Preliminary TroubleshootingDocument7 pagesSQL Server Connectivity Roadmap.: Preliminary Troubleshootingapi-3748582No ratings yet

- Catalog: Ningbo Liftstar Material Handling Equipment Co., LTDDocument27 pagesCatalog: Ningbo Liftstar Material Handling Equipment Co., LTDKiều Văn TrungNo ratings yet

- A Interview QuestionsDocument363 pagesA Interview QuestionsJaishankar RenganathanNo ratings yet