Professional Documents

Culture Documents

Design Calculations To Evaluate Performance Parameters of Compressor Valve-Ijaerdv04i0749408 PDF

Uploaded by

Diego Murillo ContrerasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Calculations To Evaluate Performance Parameters of Compressor Valve-Ijaerdv04i0749408 PDF

Uploaded by

Diego Murillo ContrerasCopyright:

Available Formats

e-ISSN (O): 2348-4470

Scientific Journal of Impact Factor (SJIF): 4.72

p-ISSN (P): 2348-6406

International Journal of Advance Engineering and Research

Development

Volume 4, Issue 7, July -2017

DESIGN CALCULATIONS TO EVALUATE PERFORMANCE

PARAMETERS OF COMPRESSOR VALVE

Chaitanya D. Patil1, Prof. M. R. Khodke2, Akash Baheti3

1

Mechanical Engineering Department, Vishwakarma Institute of Technology, Pune

2

Mechanical Engineering Department, Vishwakarma Institute of Technology, Pune

3

Design and Development Department, Burckhardt Compression India Pvt. Ltd., Kondhapuri

Abstract — Compressor sizing is important process which play vital role in multi-stage reciprocating compressor.

Proper selection of compressor and its sizing is significant concern which will give proper compressor efficiency. It

covers various performing factors including pressure, temperature, flow, cylinder sizing, power rating, etc. Due to multi-

staging there are various factors which have to take into account while sizing of compressor. For sizing some parameters

are initially decided and then effective parameters are calculated considering handled gas. Various standards are taken

into considerations while sizing.

Keywords- Compressor, Sizing, Pressure, Temperature, Volume flow.

I. INTRODUCTION

A reciprocating compressor or piston compressor is a compressor that uses pistons driven by a crankshaft to

deliver gases at high pressure. Reciprocating compressors are typically used where high compression ratios (ratio of

discharge to suction pressures) are required per stage without high flow rates, and the process fluid is relatively dry. The

reciprocating compressors are standardized in API 618: Reciprocating Compressors for Petroleum, Chemical, and Gas

Industry Services. Arrangements may be of single-or dual-acting design.

Reciprocating compressors are typically used where high compression ratios (ratio of discharge to suction

pressures) are required per stage without high flow rates, and the process fluid is relatively dry. Wet gas compressors

tend to be centrifugal types. High flow, low compression ratio applications are best served by axial flow compressors.

Rotary types are primarily specified in compressed air applications, though other types of compressors are also found in

air service.

H. Bukac presented 6 different mathematical dynamic model of self-acting compressor valve and derived

equation of motion. [1] Klaus Brun and Marybeth Nored investigated valve performance in terms of life and efficiency.

With the help of experimental procedure, life is calculated. [2] From API standards 618, various factors that are affecting

performance of compressor are taken into account while sizing of compressor. [3] Mircea Horia Tierean studied design

procedure for compressor valve considering gas flow through valve plates and then thermal behavior is studied. [4]

Royce N. Brown analyzed sizing of centrifugal compressor. It also involves selection of compressor with the help of

different parameters. [5] H. Ali Marefat investigated process multi-stage centrifugal compressor and design procedure is

derived. [6] Tonye K. Jack studied reciprocating process gas compressor with the help of mathematical relationship and

computational program is developed. [7] Chris Schmidt presented air compressor energy use to estimate energy savings

in compressed air system. [8]

II. COMPRESSOR SIZING

Compressor sizing is many types of compressors are available and can be selected due to peculiarities in their designs. A

typical chart of different compressor types are shown in Figure 1, although types other than reciprocating compressor are

not discussed in detail. Types of compressors are categorized mainly by positive displacement and dynamic [2].

@IJAERD-2017, All rights Reserved 602

International Journal of Advance Engineering and Research Development (IJAERD)

Volume 4, Issue 7, July-2017, e-ISSN: 2348 - 4470, print-ISSN: 2348-6406

Fig-1: Types of Compressor

2.1 Initial Considerations:

While developing reciprocating gas compressor certain factors need to be fixed before sizing depending on the

application and working of compressor. It involves:

Gas being handled: It may be air or any other gas that is being flown in compressor, but their properties need to

be considered while sizing of compressor. Properties like gas composition, molecular weight, density are going

to affect the performance of compressor.

Capacity at suction: It is solely depending on application and customer’s requirement. Capacity defines the

number of stages and volumetric efficiency.

Suction pressure and temperature: These are the factors that are decided depending on the working site of

compressor. Suction parameters are input to compressor.

Discharge pressure: Discharge pressure is the output to all process of compressor. It is predefined in order to

develop such compressor with specific number of stages. Number of stages vary mainly depending on discharge

pressure.

Stroke Length and Speed: Stoke length is given by considering flow of gas being handled and size of compressor. Speed

of compressor defined the power rating required for compressor.

2.2 Sizing of Compressor:

Sizing of compressor involves various performing factors to be considered. Proper sizing of compressor is done first in

order to have more efficient working. This contains various standards which are followed with API 618 standards fifth

edition [3]. The step of procedure for sizing of compressor is given below by considering input data.

Input data:

Capacity at suction(Q) by customer requirement 291 m3/hr

Suction Pressure (Pamb = Ps) 1.013 bar a

Gas handled Air -

o

Suction Temperature (Ts) 45 C

Discharge pressure (Pd) 401.5 bar a

o

Discharge Temperature (Td) <180 C

No. of cylinder at suction (ns) 2 nos.

Stoke length (L) 0.1 m

Speed (N) 1485 rpm

Table 1. Initial recommended conditions

SELECTING NUMBER OF STAGES FOR COMPRESSOR

It mainly depends of both pressure parameters which are going to be taken into account while designing

compressor.

Overall pressure ratio = (Pd/Ps) (1)

@IJAERD-2017, All rights Reserved 603

International Journal of Advance Engineering and Research Development (IJAERD)

Volume 4, Issue 7, July-2017, e-ISSN: 2348 - 4470, print-ISSN: 2348-6406

Where, Pd = Discharge pressure = 401.5 bar a and Ps = Suction pressure = 1.013 bar a

Overall pressure ratio = 396.35

Compression ratio (R) is the ratio of discharge pressure to suction pressure:

Compressor ratio, R= = 3.308 when s = 5 (2)

Where, s is number of stages.

So in order to maintain compressor ratio below 3.5 the number of stages are decided.

Therefore five-stage air compressor is selected.

CALCULATE CYLINDER DIAMETER FOR ALL STAGES

Actual Capacity at suction, Q= = (3)

3

Q = 291 m /hr

So D = 0.166 m ≈ 0.165m

Where, ns is number of cylinders at first stage

L is Stroke length

N is speed

Therefore, cylinder diameter for first stage is selected as 165 mm.

For rest of the stages in multi-stage cylinder,

Cylinder diameter other than 1st stage, Di = (4)

So cylinder diameter configuration is 165mm, 125mm, 70mm, 42mm, and 25mm.

Note: Cylinder diameters are considered as per availability of standard sizes.

CALCULATE THE PRESSURE RATIO

Pressure ratio (Ri) for each stage is given by,

Pressure ratio Ri = (Pdi/Psi) (5)

Where, Pdi and Psi are discharge and suction pressure at different stages respectively.

So a single-stage compressor has only single R i.e. Compression ratio.

But multi-stage compressor has one compression ratio R and multiple number of pressure ratios (R i)

values same as number of stages.

DETERMINE THE ACTUAL VOLUMETRIC EFFICIENCY

In order to evaluate the energetic quality of a compressor volumetric efficiency is calculated. In the

ideal case the complete piston displacement at the end of the suction stroke is filled with gas at inlet condition. It

would contain the complete displacement mass. The actual delivered mass after a compression cycle is always

smaller than the ideal piston displacement mass [5].

The ratio of the actual delivered to the ideal mass per compression cycle or the respective mass flows is

called the volumetric efficiency.

This parameter does not have a direct indication of the energetic efficiency of the compressor. If the piston

displacement and the volumetric efficiency of a compressor is known, the volume flow (flow at suction

condition) follows [7].

Actual volumetric efficiency is given by,

vol. = – [C * *( – 1)] = 75.18 % (6)

DETERMINE THE REQUIRED PISTON DISPLACEMENT

Piston displacement (PD) is a measure of the compressor's size and is dependent on the size, number

and type of cylinders, and compressor RPM. Required piston displacement (PDR) is a calculated number that

will determine how large a compressor will be required to handle the specified capacity.

PDR = (Im3/hr) / vol. = 387.07 m3/hr (7)

Where, PDR is required piston displacement (m3/hr)

@IJAERD-2017, All rights Reserved 604

International Journal of Advance Engineering and Research Development (IJAERD)

Volume 4, Issue 7, July-2017, e-ISSN: 2348 - 4470, print-ISSN: 2348-6406

vol. is Volumetric Efficiency

Im3/hr is Capacity (inlet meters cubed per hour)

DETERMINE THE MINIMUM RPM REQUIRED OF THE SELECTED COMPRESSOR

With the compressor model and Required Piston Displacement known, the minimum RPM required

can be calculated.

Speed = 120 * f / P = 1500 rpm (8)

Where, f is frequency (in Hz)

P is no. of poles

DETERMINE INTER STAGES PRESSURES

Inter stage pressures are calculated depending upon the cylinder size for each stage. It gives discharge

pressure at each stage. Here suction pressure is given as input.

So discharge pressure at each stage, Pdi = Psi * (9)

At final stage, discharge pressure is calculated with the help of discharge pressure ratio of that stage.

I.e. Discharge pressure ratio, Ri = (10)

Discharge pressure at final stage = Ri * Pd (i-1)

Discharge Pressure at every stage is 3.53 bar a, 11.14 bar a, 30.635 bar a, 85.60 bar a, 410.024 bar a.

For safety considerations the safety relief valve is installed with pressure setting of 115% of each inter

stage discharge pressure and 110% for final stage discharge pressure. Safety relief valve is given in order to

have prevent compressor components with unexpected increase in pressure.

So SRV discharge pressure for each stage (PdSRV) = 115% of inter stage discharge pressure.

And SRV discharge pressure for final stage (PdSRV) = 110% of final discharge pressure.

SRV discharge pressure at each stage is 4.06 bar a, 12.81 bar a, 35.23 bar a, 98.44 bar a, 451.03 bar a.

DETERMINE ADIABATIC TEMPERATURE AT DISCHARGE.

The compressor's discharge temperature directly affects the life of the piston rings and valves. Here is

the formula to calculate the discharge temperature for compressor.

Discharge temperature = [(273+Ts) * ] - 273 oC (11)

o o o o

Discharge temperature at each stage is 181.29 C, 161.66 C, 165.01 C, 137.70 C, 172.03.

For safety relief valve considerations,

SRV discharge temperature, TdSRV = [(273+Ts) * – 273] oC (12)

Where, Ts for Stage 1 = 45 oC at stage suction

Ts for rest Stages = 40 oC at stage suction

SRV discharge temperature at each stage is 199.81 oC, 186.59 oC, 190.14 oC, 159.88 oC, 184.32 oC.

DETERMINE FLOW AT EACH STAGE DISCHARGE.

Flow rate at each stage is important in consideration with compressor performance. Flow at each stage

is given by,

Qs = Qs-1 * * m3/hr (13)

Qd = Qs * * m3/hr (14)

Qs for each stage is 291 m3/hr, 83.51 m3/hr, 31.19 m3/hr, 8.81 m3/hr, 2.43 m3/hr.

Qd for each stage is 119.30 m3/hr, 36.75 m3/hr, 13.47 m3/hr, 4.50 m3/hr, 1.01 m3/hr.

@IJAERD-2017, All rights Reserved 605

International Journal of Advance Engineering and Research Development (IJAERD)

Volume 4, Issue 7, July-2017, e-ISSN: 2348 - 4470, print-ISSN: 2348-6406

DETERMINE ISOTHERMAL EFFICIENCY FOR EACH STAGE

The isothermal efficiency is defined as the ratio of the work input to the isothermal process, to the work

input to the actual process between the same inlet and exit pressures.

Isothermal efficiency, iso. = ln (15)

Where, Ri = (Pd/Ps) & n = 1.4

ADIABATIC SHAFT POWER OF COMPRESSOR

Pad = (16)

Shaft power at each stage is 14.72 kW, 13.20 kW, 13.58 kW, 10.57 kW, and 14.00 kW.

Total shaft power = 66.08 kW + Pvalve + Pmw + Pfric + Psafety = 70.13 kW.

Summation of Pad for all stages gives Total Pad.

Then Shaft power includes Total Pad, valve power, friction power, safety factor and others.

MOTOR RATING

Motor rating is decided from maximum shaft power with 5% tolerance and margin of 10% over shaft power.

Motor rating is given by considering all factors and components which require power as input and finally

considering factor of safety the nearest motor rating is selected from standard motor ratings. [8]

Max shaft power = 70.13 + 5% = 73.64 kW max. So nearest motor rating recommended is 79 kW.

Finally by considering these performing parameters compressor machine configuration for piston-cylinder arrangement.

It will help to make proper arrangement for positioning of piston-cylinder for all stages.

Figure 2: Compressor Machine Configuration for piston-cylinder arrangement

With the help of RecipCalc software P-V diagram for current configuration compressor is developed. It clearly

differs actual effective versus isentropic ideal curves.

@IJAERD-2017, All rights Reserved 606

International Journal of Advance Engineering and Research Development (IJAERD)

Volume 4, Issue 7, July-2017, e-ISSN: 2348 - 4470, print-ISSN: 2348-6406

Figure 3: P-V diagram for designed compressor specification

2.3 Experimentation:

For experimentation the compressor arrangement is done and actual testing is done on working compressor.

Experimentation results are evaluated and compared with calculated once for validation.

Finally both calculated and experimentation results are validated.

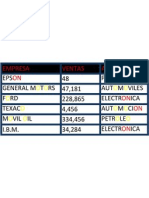

Sr Parameter UOM Calculated Expt. Read. 1 Expt. Read. 2 Expt. Read. 3

No

1. Compressor speed RPM 1485 1460 1480 1485

2. Suction pressure Bar a 1.013 1.013

3. Discharge Pressure stage 1 Bar a 3.53 3.1 3.2 3.1

4. Discharge Pressure stage 2 Bar a 11.14 10.8 11.2 11.1

5. Discharge Pressure stage 3 Bar a 30.635 31.1 30.7 30.5

6. Discharge Pressure stage 4 Bar a 85.60 85.1 86.0 85.9

7. Discharge Pressure stage 5 Bar g 410.024 405.1 412.2 409.5

Table 2. Validation of design calculation with experimentation

@IJAERD-2017, All rights Reserved 607

International Journal of Advance Engineering and Research Development (IJAERD)

Volume 4, Issue 7, July-2017, e-ISSN: 2348 - 4470, print-ISSN: 2348-6406

III. CONCLUSION

In this paper, a design procedure is provided for sizing of reciprocating compressor. The procedure for the sizing and

performance analysis calculations of reciprocating compressor is simplified in handling various parameters involved. It

will be helpful while designing any reciprocating compressor as per required data. With the use of these sizing procedure

one can clearly calculate effective parameters and design accordingly. Many factors influence the selection of a

reciprocating compressor. It is, therefore, out of scope herein to provide additional guidance beyond the rough estimation

stage, which will help to determine how well a reciprocating compressor may fit a process application.

ACKNOWLEDGEMENT

It is my great pleasure to acknowledge sense of gratitude to all, who have made it possible for me to complete this

dissertation work with success. It gives me great pleasure to express my deep gratitude to my dissertation guide Prof. M.

R. Khodke Sir for their support and help from time to time during project work. I express my co-guide Mr. Akash Baheti

for their valuable support. I also express my gratitude to Dr. S. R. Bahulikar sir to provide such a great platform for the

dissertation work and their great support and encouragement in the same. Finally yet importantly I would like to thank all

staff members and all our colleagues for their valuable suggestions and support.

REFERENCES

[1] H. Bukac Alabama, “Understanding Valve dynamics”, International Compressor Engineering Conference, School of

Mechanical Engineering, pp. 3-8, 2000.

[2] Klaus Brun, Marybeth Nored, “Valve performance and life of reciprocating compressors”, Turbomachinery

Laboratory, Texas A&M University, pp. 2-12, Septmeber 24-27, 2012.

[3] API standard 618, “Reciprocating compressors for petroleum, chemical and gas industry services”, American

Petroleum Institute, pp. 19-32, fifth edition, December 2007.

[4] Mircea Horia Tierean, Liana Sanda Baltes, “Design of Valves Used in Reciprocating Compressors”, Recent

advances in applied and theoritical mechanics, Material Engineering and Welding Department, Transilvania

University of Brasov, pp. 1-4.

[5] Royce N. Brown, Richard A. Lewis, “Centrifugal compressor application sizing, selection and modelling”,

Procedings of the twenty-third turbomachinery symposium, pp. 1-3.

[6] H. Ali Marefat, M. R. Shahhosseini, and M. A. Ashjari, “Adapted Design of Process Multi-Stage Centrifugal

Compressor and Comparison with Available Data”, International Journal of Materials, Mechanics and

Manufacturing, Vol. 1, No. 2, May 2013, pp.1-2.

[7] Tonye K. Jack, “ A Computer Program for Sizing and Performance Evaluation of Reciprocating Process Gas

Compressors”, IJCER | Mar-Apr 2012 | Vol. 2 | Issue No.2 |395-402, pp.1-6.

[8] Chris Schmidt, Energy & Resource Solutions, Inc. Kelly Kissock, University of Dayton, Department of Mechanical

Engineering, “Modeling and Simulation of Air Compressor Energy Use”, ACEEE Summer Study on Energy

Efficiency in Industry, 2005, pp. 2-3.

@IJAERD-2017, All rights Reserved 608

You might also like

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Design Calculations To Evaluate Performance Parameters of Compressor Valve-Ijaerdv04i0749408Document7 pagesDesign Calculations To Evaluate Performance Parameters of Compressor Valve-Ijaerdv04i0749408mzqaqilaNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Basic Practices in Compressors SelectionDocument11 pagesBasic Practices in Compressors SelectionHector RodriguezNo ratings yet

- Axial Flow Compressor PDFDocument7 pagesAxial Flow Compressor PDFkamal arabNo ratings yet

- Aerodynamic Design of A Single Stage Axi PDFDocument9 pagesAerodynamic Design of A Single Stage Axi PDFAnkur BhatnagarNo ratings yet

- Aerodynamic Design of A Single Stage Axi PDFDocument9 pagesAerodynamic Design of A Single Stage Axi PDFMuntather SalahNo ratings yet

- Design Optimization of An Axial Flow Compressor For Industrial Gas TurbineDocument8 pagesDesign Optimization of An Axial Flow Compressor For Industrial Gas TurbinealiNo ratings yet

- Compressors Course-Chapter 3Document19 pagesCompressors Course-Chapter 3Abdallah SayedNo ratings yet

- Design and CFD Analysis of Centrifugal Compressor For A MicrogasturbineDocument7 pagesDesign and CFD Analysis of Centrifugal Compressor For A MicrogasturbineFurqanNo ratings yet

- PROJECT STANDARDS AND SPECIFICATIONS Compresser Systems Rev01 PDFDocument12 pagesPROJECT STANDARDS AND SPECIFICATIONS Compresser Systems Rev01 PDFsrisvasNo ratings yet

- Compresor CentrifugoDocument16 pagesCompresor CentrifugoIgnacio SotoNo ratings yet

- Compressor Modelling 2Document11 pagesCompressor Modelling 2RABIU M RABIUNo ratings yet

- Rotary Screw CompressorsDocument22 pagesRotary Screw Compressorsganeshdhage100% (2)

- Design, Modeling and Analysis of Reciprocating CompressorDocument8 pagesDesign, Modeling and Analysis of Reciprocating CompressorIJRASETPublicationsNo ratings yet

- Performance of A Coaxial Swirl Injector With Flow Path ReversalDocument8 pagesPerformance of A Coaxial Swirl Injector With Flow Path ReversalrakeshsakoteNo ratings yet

- Design and Analysis of A 111 Centrifugal Compressor For A Small Turbofan EngineDocument8 pagesDesign and Analysis of A 111 Centrifugal Compressor For A Small Turbofan EngineSuherman MuktiNo ratings yet

- Effect of Various Parameters On Working Condition of ChillerDocument8 pagesEffect of Various Parameters On Working Condition of ChillerAbdul Fatir KhanNo ratings yet

- Performance Analysis of Reciprocating Refrigerant CompressorDocument6 pagesPerformance Analysis of Reciprocating Refrigerant CompressorIjsrnet EditorialNo ratings yet

- Tip Clearance Influence in CFD Calculations and OpDocument12 pagesTip Clearance Influence in CFD Calculations and Opranjith manuNo ratings yet

- Selecting The Suitable Orifice Flow Mete PDFDocument11 pagesSelecting The Suitable Orifice Flow Mete PDFtareq.sefatNo ratings yet

- Design and Analysis of Heat ExchangerDocument34 pagesDesign and Analysis of Heat ExchangerAkshat Rathi100% (2)

- CFD Analysis of Flow in After BurnerDocument10 pagesCFD Analysis of Flow in After BurnermortezaastroNo ratings yet

- Classnotes - Compressor Performance - 1Document117 pagesClassnotes - Compressor Performance - 1Zatie ZulkifliNo ratings yet

- Iaetsd-Jaras-Cfd Simulation of Twin Screw Vacuum Pump WithDocument4 pagesIaetsd-Jaras-Cfd Simulation of Twin Screw Vacuum Pump WithiaetsdiaetsdNo ratings yet

- TEST - EditedDocument10 pagesTEST - EditedmoodydoodyNo ratings yet

- Compressor Practical Brief - 2019Document4 pagesCompressor Practical Brief - 2019DanielNo ratings yet

- Fuel Flow Analysis of Injector Nozzle: ISO 9001:2008 CertifiedDocument6 pagesFuel Flow Analysis of Injector Nozzle: ISO 9001:2008 CertifiedAbhishek HebballiNo ratings yet

- Compressor Map Prediction Tool: IOP Conference Series: Materials Science and EngineeringDocument11 pagesCompressor Map Prediction Tool: IOP Conference Series: Materials Science and Engineeringthlim19078656No ratings yet

- Design and Analysis of Piston For Two Stages Reciprocating Air CompressorDocument7 pagesDesign and Analysis of Piston For Two Stages Reciprocating Air CompressorMaria Jose Biasotti100% (1)

- The Design of Ultra-High-Speed Miniature Centrifugal CompressorsDocument14 pagesThe Design of Ultra-High-Speed Miniature Centrifugal CompressorsArmando SuberoNo ratings yet

- Design of A New Improved Intake Manifold For F-Sae Car: January 2016Document6 pagesDesign of A New Improved Intake Manifold For F-Sae Car: January 2016İlker EnesNo ratings yet

- Design and Experimental Investigations of Pressure Swirl Atomizer of Annular Type Combustion Chamber For 20 KW Gas Turbine EngineDocument11 pagesDesign and Experimental Investigations of Pressure Swirl Atomizer of Annular Type Combustion Chamber For 20 KW Gas Turbine EngineIAEME PublicationNo ratings yet

- Compressor Selection & SizingDocument14 pagesCompressor Selection & SizingKarthikeyan PalanichamyNo ratings yet

- Air Comperssor Test Rig ReciprocatingDocument4 pagesAir Comperssor Test Rig ReciprocatingShashank pNo ratings yet

- Developments in Diesel Spray Characterisation and Modelling: E.M.Sazhina@brighton - Ac.ukDocument15 pagesDevelopments in Diesel Spray Characterisation and Modelling: E.M.Sazhina@brighton - Ac.ukarunmurthyNo ratings yet

- 17.june16 Experimental Comparison of Single and Multistage Air Compressor Efficiencies Under The Same Receiver Tank PressureDocument11 pages17.june16 Experimental Comparison of Single and Multistage Air Compressor Efficiencies Under The Same Receiver Tank PressureJohn barry CorpuzNo ratings yet

- CFD Analysis of Swept and Leaned Transonic Compressor RotorDocument5 pagesCFD Analysis of Swept and Leaned Transonic Compressor RotorseventhsensegroupNo ratings yet

- Numerical Investigation of A Divergent Exhaust Diffuser of A Gas Turbine EngineDocument11 pagesNumerical Investigation of A Divergent Exhaust Diffuser of A Gas Turbine EngineIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Design, Development and Analysis of Centrifugal BlowerDocument8 pagesDesign, Development and Analysis of Centrifugal BlowerPankaj PatilNo ratings yet

- An Investigation On The Performance Characteristics of A Centrifugal CompressorDocument7 pagesAn Investigation On The Performance Characteristics of A Centrifugal CompressorIJERDNo ratings yet

- Design Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeDocument6 pagesDesign Optimization of Ice Plant Test-Rig: H. S. Salave, V. N. RaibholeNeeraj SamadhiyaNo ratings yet

- Pump Hydraulic CalculationsDocument14 pagesPump Hydraulic CalculationsJosue GonzalezNo ratings yet

- Numerical Prediction of Stability Limit in Centrifugal Compressors With Vaneless DiffuserDocument9 pagesNumerical Prediction of Stability Limit in Centrifugal Compressors With Vaneless DiffuserMiguelMazzucchelliNo ratings yet

- 18-MCE-73 M. Talha Ahsraf Lab Report Week 10Document6 pages18-MCE-73 M. Talha Ahsraf Lab Report Week 10Muhammad TalhaNo ratings yet

- Technical Note A FORTRAN Program For Calculating The Evaporation Rates in Diesel Engine Fuel SpraysDocument5 pagesTechnical Note A FORTRAN Program For Calculating The Evaporation Rates in Diesel Engine Fuel Spraysim19rahulNo ratings yet

- Catalogo Vortex FlowmeterDocument24 pagesCatalogo Vortex FlowmeterIzanNo ratings yet

- Orifice, Nozzle and Venturi Flow Rate Meters: Water & Air FlowmetersDocument4 pagesOrifice, Nozzle and Venturi Flow Rate Meters: Water & Air Flowmeterssiva_nagesh_2No ratings yet

- 2019 - IJFTE - Mehul CD NozzleDocument6 pages2019 - IJFTE - Mehul CD NozzleMehul BambhaniaNo ratings yet

- gt2014 26614Document9 pagesgt2014 26614medagamNo ratings yet

- How To Select Turbomachinery For Your Application PDFDocument10 pagesHow To Select Turbomachinery For Your Application PDFrafieeNo ratings yet

- Performance Analysis of A Hermetic Reciprocating CompressorDocument10 pagesPerformance Analysis of A Hermetic Reciprocating Compressorhermit44535No ratings yet

- Computation: Computational Analysis of The Performance Characteristics of A Supercritical CO Centrifugal CompressorDocument15 pagesComputation: Computational Analysis of The Performance Characteristics of A Supercritical CO Centrifugal CompressorBrahimABDNo ratings yet

- .0 .0 NOZZLE - Modelling and Parametric Fluid Flow Analysis (Document13 pages.0 .0 NOZZLE - Modelling and Parametric Fluid Flow Analysis (Rabei RomulusNo ratings yet

- Experiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineDocument2 pagesExperiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineMuket AgmasNo ratings yet

- Experiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineDocument2 pagesExperiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineM RoyNo ratings yet

- Parametric Study of Centrifugal Fan Performance ExDocument19 pagesParametric Study of Centrifugal Fan Performance ExlolNo ratings yet

- CFD Analysis of Flow in Pump Sump and Physical Validation For Better Performance of PumpDocument7 pagesCFD Analysis of Flow in Pump Sump and Physical Validation For Better Performance of PumpSujoyDeNo ratings yet

- Variety January 10 2022Document34 pagesVariety January 10 2022dipakNo ratings yet

- The State of U.S. Science & Engineering 2022Document46 pagesThe State of U.S. Science & Engineering 2022Fernando PereiraNo ratings yet

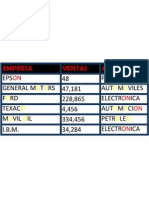

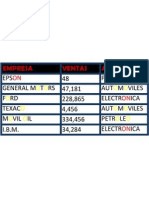

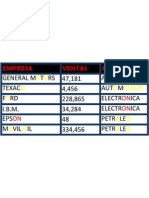

- Auto Industry MXDocument67 pagesAuto Industry MXDiego Murillo ContrerasNo ratings yet

- Final Mock ExamDocument4 pagesFinal Mock ExamDiego Murillo ContrerasNo ratings yet

- Production and Trade of Knowledge-And Technology - Intensive IndustriesDocument66 pagesProduction and Trade of Knowledge-And Technology - Intensive IndustriesDiego Murillo ContrerasNo ratings yet

- Deliverable 5.1 Whirlpool Business Case, Conceptualization and Evaluation StrategyDocument46 pagesDeliverable 5.1 Whirlpool Business Case, Conceptualization and Evaluation StrategyDiego Murillo ContrerasNo ratings yet

- Geometrical Anisotropy in Biphase Particle Reinforced CompositesDocument4 pagesGeometrical Anisotropy in Biphase Particle Reinforced CompositesDiego Murillo ContrerasNo ratings yet

- An Alternative Derivation of The Quaternion Equations of Motion For Rigid-Body Rotational DynamicsDocument4 pagesAn Alternative Derivation of The Quaternion Equations of Motion For Rigid-Body Rotational DynamicsDiego Murillo ContrerasNo ratings yet

- A Reduced Second-Order Approach For Linear Viscoelastic OscillatorsDocument8 pagesA Reduced Second-Order Approach For Linear Viscoelastic OscillatorsDiego Murillo ContrerasNo ratings yet

- Largest Companies in The WorldDocument92 pagesLargest Companies in The WorldDiego Murillo ContrerasNo ratings yet

- A Reduced Second-Order Approach For Linear Viscoelastic OscillatorsDocument8 pagesA Reduced Second-Order Approach For Linear Viscoelastic OscillatorsDiego Murillo ContrerasNo ratings yet

- Mechanics of Quantum-Dot Self-Organization by Epitaxial Growth On Small AreasDocument6 pagesMechanics of Quantum-Dot Self-Organization by Epitaxial Growth On Small AreasDiego Murillo ContrerasNo ratings yet

- Ilovepdf MergedDocument16 pagesIlovepdf MergedDiego Murillo ContrerasNo ratings yet

- Evidencia 11Document1 pageEvidencia 11brayhamtNo ratings yet

- S AIRODocument1 pageS AIRODiego Murillo ContrerasNo ratings yet

- S AIRODocument1 pageS AIRODiego Murillo ContrerasNo ratings yet

- S AIRODocument1 pageS AIRODiego Murillo ContrerasNo ratings yet

- Evidencia 11Document1 pageEvidencia 11brayhamtNo ratings yet

- S AIRODocument1 pageS AIRODiego Murillo ContrerasNo ratings yet

- S AIRODocument1 pageS AIRODiego Murillo ContrerasNo ratings yet

- Evidencia 11Document1 pageEvidencia 11Luis Miguel OrtegaNo ratings yet

- Fundamentals of Ship Maintenance and Repair For Future Marine Engineers PDFDocument11 pagesFundamentals of Ship Maintenance and Repair For Future Marine Engineers PDFShawn Wairisal100% (2)

- 04 Dispersion MeasuresDocument17 pages04 Dispersion MeasuresMuhammad AbdullahNo ratings yet

- System MDR 8400Document150 pagesSystem MDR 8400JESUSCALVILLONo ratings yet

- Previews 2502414 PreDocument9 pagesPreviews 2502414 PreAlex Andre RojasNo ratings yet

- Hytrel Extrusion Manual PDFDocument28 pagesHytrel Extrusion Manual PDFashkansoheylNo ratings yet

- DimensionsDocument103 pagesDimensionslaurariton100% (1)

- Standard Operating Procedure Carburetor Over Flow: Technical Support - ServiceDocument2 pagesStandard Operating Procedure Carburetor Over Flow: Technical Support - ServiceAnonymous nIcSGEw100% (1)

- Essay Test 2021 (Practice Test)Document3 pagesEssay Test 2021 (Practice Test)Philani HadebeNo ratings yet

- Bot115 Picaxe Create: RevolutionDocument33 pagesBot115 Picaxe Create: Revolutionabiel fernandezNo ratings yet

- Laporan Hasil Praktik Bahasa Inggris Dengan Tamu Asing Di Pantai KutaDocument12 pagesLaporan Hasil Praktik Bahasa Inggris Dengan Tamu Asing Di Pantai KutaEnal MegantaraNo ratings yet

- 1 IntroductionDocument25 pages1 IntroductionNida I. FarihahNo ratings yet

- RCC BoxDocument85 pagesRCC Boxabhijeet sahuNo ratings yet

- Milestone Math Review Part 1Document16 pagesMilestone Math Review Part 1api-249548920No ratings yet

- Asus Prime b250m Plus RGDocument13 pagesAsus Prime b250m Plus RGRenattech SilvaNo ratings yet

- Chapter8 SwitchingDocument60 pagesChapter8 SwitchingSalah AL-HakimiNo ratings yet

- Aircraft StructureDocument11 pagesAircraft StructureVagesh VagesNo ratings yet

- Title: "The Effect of Flooding in The Tourism Industry in Dagupan City" Rationale and Background of The StudyDocument4 pagesTitle: "The Effect of Flooding in The Tourism Industry in Dagupan City" Rationale and Background of The StudyTaehyung KimNo ratings yet

- Nutella: Italian PronunciationDocument1 pageNutella: Italian PronunciationhbnjknwvnffkjrpaadttirvorgNo ratings yet

- CU50 Service ManualDocument30 pagesCU50 Service ManualjhalmarckNo ratings yet

- COVID-19 Impact On Global Food IndustryDocument8 pagesCOVID-19 Impact On Global Food IndustryRavirajNo ratings yet

- Carte Tehnica Panou Fotovoltaic Cu Celule Policristaline Eging 250 WDocument1 pageCarte Tehnica Panou Fotovoltaic Cu Celule Policristaline Eging 250 WConstantin CilibiuNo ratings yet

- Project: Study On Building Construction Using Foam ConcreteDocument5 pagesProject: Study On Building Construction Using Foam ConcreteAzhagesanNo ratings yet

- Technical Specifications For LT/HT, XLPE Insulated Aluminium/Copper CablesDocument49 pagesTechnical Specifications For LT/HT, XLPE Insulated Aluminium/Copper CablesAjay KumarNo ratings yet

- AD GT3000 Catalogue en 12-07 CDocument52 pagesAD GT3000 Catalogue en 12-07 CMohamed AlkharashyNo ratings yet

- Flex-10 Virtual ConnectDocument2 pagesFlex-10 Virtual ConnectArif HusainNo ratings yet

- Primer Design 2013 PDFDocument58 pagesPrimer Design 2013 PDFMaila EscuderoNo ratings yet

- LeachingDocument14 pagesLeachingmichsantosNo ratings yet

- Srotomaya Shariram: Dr. Prasanna N. Rao Principal, SDM College of Ayurveda, Hassan-KaranatakaDocument21 pagesSrotomaya Shariram: Dr. Prasanna N. Rao Principal, SDM College of Ayurveda, Hassan-KaranatakaDrHemant ToshikhaneNo ratings yet

- ID 7851 Стомат Англ Задачі 1540 English Sem 2Document237 pagesID 7851 Стомат Англ Задачі 1540 English Sem 2acerNo ratings yet

- Serif Business LetterDocument18 pagesSerif Business LetterNeerajha RabindranathNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersFrom EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersRating: 4.5 out of 5 stars4.5/5 (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Global Landscape of Renewable Energy FinanceFrom EverandGlobal Landscape of Renewable Energy FinanceNo ratings yet

- DIY Free Home Energy Solutions: How to Design and Build Your own Domestic Free Energy SolutionFrom EverandDIY Free Home Energy Solutions: How to Design and Build Your own Domestic Free Energy SolutionRating: 5 out of 5 stars5/5 (1)

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Practical Methods for Analysis and Design of HV Installation Grounding SystemsFrom EverandPractical Methods for Analysis and Design of HV Installation Grounding SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet