Professional Documents

Culture Documents

Ele-Ms-03 Lightning-Earthing System

Uploaded by

Võ Khắc Ghi0 ratings0% found this document useful (0 votes)

13 views3 pagesOriginal Title

ELE-MS-03 LIGHTNING-EARTHING SYSTEM

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views3 pagesEle-Ms-03 Lightning-Earthing System

Uploaded by

Võ Khắc GhiCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

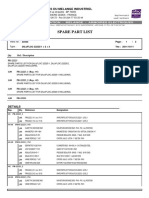

Project SMART & EXCELLENCE GALLERY

Date

REF

(ROSACO ONLY)

METHOD STATEMENT

LIGHTNING – EARTHING SYSTEM

1/3 ELE MS-03

I) PREPARATION TASK

1) Checking for finishing of construction works related to the installation works of lightning system and

earthing system: The equipotential system and earthing grids should carry out at simultaneous time of

structure’s foundation constructions or when it was finished while the base floors weren’t started yet.

The lightning protection system and grounding system (operating earthing system/ equipment

grounding system) will be carried out after finishing of structures and roofs.

2) Safety measure readiness:

Scaffold, support, cramp, operating floor, guard-rail, lifeline.

Safety belt, hardness

Extinguishers, ventilation fan, welding cinder accumulating tray or weld spatter shield (if

required)

Protective goggles for drilling works and welding mask.

Safety checking for operating electric equipment, portable lamp (if required), source supply

and cord.

Helm and boots, gloves and leather gloves

Caution boards and warning signs, barricade (if required).

The construction works will be carried out only in a good weather (dry weather) and in

absence of rainclouds and rainstorms (mist conditions).

3) Latest version and approved of the detailed drawings for the installation works

Layout of the ground grids and locations shown intervals between earthing wires/ earthing

rods, types of using wires and rods, inspection pit’s positions, connection points from grids to

lightning protection system/ grounding system. Detailed matarials for grounding ditchs/ earthing

holes, the depth/ structure of ditchs/ holes.

Layout and section dwg.s of grounding wire’s installing details, installation positions and

structure of the grounding station. Details of using materials, such as ground wire’s clamps, pipe’s

clamps and pipes, supports...

Lay out of the lightning protection system shown intervals between lightning rods, protection

radius, lightning conductor’s routes and wire’s riser points. Installation dwg.s in details of cable’s

clamps, connection boxes, using materials and installation’s methods...

Technical specifications/ Catalogues for the using materials of the earthing system such as

welding materials, moulds, grounding enhanced materials (GEM)... (if required)

Technical specifications/ Catalogues for the using equipments of the lightning protection

system such as air termination and lightning conductors... (if required)

4) Material’s preparation Refer to related list of materials

Lightning rods and rod’s supports, lightning conductors, earthing wires and rods, conductor

clamps, accessories...

Pipes and pipe’s supports/ clamps, connection boxes, grounding stations, insulators,

grounding bars...

Grounding enhanced materials, moulds, welding materials, welding rods, inspection pit’

housings.

Paint, cloth, cutting wheels, disc drinder, steel brushes,...

Anchor bolts, U-bolt, bolts/ screws, pipe’s bushings, ...

5) Tools check ensuring a good and safe operation

Leveler, plumb, Ohm meter/VOM, Earthing tester (Earth resistance meter)

Electric welding machines (if required), cutting machines/ cable’s shears, grinders, portable

driller, blow torches...

Hand tools

2/3 ELE MS-03

II) INSTALLATION

1) Locate earthing rods/ earthing wells, inspection pits and earthing grids. Verify the real dimentions of

excavation holes and ditches at the site and take an adusting if these points and lines collide with

existing structures and update to construction’s dwgs.

2) Drill earthing wells and connect earthing wires to rods to put in the well holes and press to designation

depths. Mix and pour GEM into the hole’s spaces (if required)

In case using of rod driving type: excavate a hole around the earthing rod positions with the pan hole

depth must lower than the finished top rod end about 10 to 15 cm, make scaffolds/ operating floor (if

required) for driving rods. Driving rods by boss hammers or pressing by machines/ jacking

mechanism to designation depth.

3) Excavate earthing ditches to designation depth and adjust this depth or ditch’s routes to prevent collides

of finished earthing wires and existed structures.

4) Lay down earthing wires in the ditches. The wires will be straightened and put and pressed close the

ditch’s bottoms.

5) Clean the top rods and end wires at the connection segments:

a) Welding joints: weld earthing wires to the rods, checking for the quality of connections by

vision and mechanic test and repairing if the joints failed. Weld connections will be accepted if the

weld encompassed through from honeycombs and a moderate hammer. Antirust treating for

connection’s surface (if required)

b) Bolting/ clamping joints: fit earthing wires to the rods by connection bolts/ clamps, checking for

the quality of connections by vision and bolt/ clamp tighten and repairing if the joints failed. The

joints will be accepted if the wires were not deformed and broken and they embedded around the

rod’s perimeter at the top end, tighten and aligned. Continuity check from wires to rods. Antirust

treating for connection’s surface (if required)

6) Mix and pour GEM into the ditch’s spaces (if required).

7) Backfilling for holes and ditches by soil layers with the thickness about 200-300mm, water and

compact soil follow designation requirements. All stinger of the earthing system to the lightning

protection system/ grounding system will be enclosed and marked.

8) Earth ground resistance testing and this value must be encompassed requirements with the

considerations about the reason factor. Repairing for the grid (if required).

9) Install inspection pits/ grounding connection boxes at the designation positions.

10) Install pipe’s supports and pipes (flutes) of the grounding wires from grounding stations to grounding

connection boxes/ pipes of the lightning conductors from lightning rod’s installation points to the

connection boxes and install the lightning counter. Install supports and cable’s clamps ... for

grounding wires and lightning conductors.

11) Pulling/ installing of grounding wires from inspection pit/ connection boxes to grounding station

positions/ lightning rod pad postion.

12) Install lightning rods to the supports/ columns and prepair slings and anchors.

13) Install set of lightning rods and string rod’s slings to anchors. Aligning for lightning rods and

supports.

14) Caulking/ sealing for holes of anchors and sleeves of lightning conductors... for the water proofing

purpose.

15) Termination for the lightning conductors and grounding wires to the connection boxes/ inspection

pits.

16) Checking and marking the finished wire’s routes on the construction dwgs. Send the requirement’s

letters for inspection and acceptance to consultant staffs by the pattern form.

17) Cleaning, removing waste and unsuitable materials out the site, keep the site neat and tide

3/3 ELE MS-03

You might also like

- Stringing Method StatementDocument18 pagesStringing Method StatementAbhish Raj75% (4)

- Work Method of Stringing ConductorsDocument5 pagesWork Method of Stringing ConductorsJatmiko Purwo Saputro50% (2)

- Power and Control Cable Method of StatementDocument7 pagesPower and Control Cable Method of StatementAhmad Dagamseh100% (1)

- Method Statement For Mock-Up InstallationDocument17 pagesMethod Statement For Mock-Up InstallationshareyhouNo ratings yet

- Geotechnical Engineering Calculations and Rules of ThumbFrom EverandGeotechnical Engineering Calculations and Rules of ThumbRating: 4 out of 5 stars4/5 (17)

- Honda 9.9 - BABJDocument137 pagesHonda 9.9 - BABJCraig Smith67% (3)

- Method Statement For Cable Containment For CablesDocument15 pagesMethod Statement For Cable Containment For CablesshareyhouNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Om615 616 617 PDFDocument221 pagesOm615 616 617 PDFAnonymous wpUyixsj100% (1)

- 12-SOP For Cable TerminationsDocument2 pages12-SOP For Cable TerminationsAbhay Godbole80% (5)

- Specification 33 KV LineDocument18 pagesSpecification 33 KV LineSatyaprasad NimmakayalaNo ratings yet

- Method Statement For Under Floor Trunkingt For Cables-1Document14 pagesMethod Statement For Under Floor Trunkingt For Cables-1shareyhou0% (1)

- Method Statement Lamps, Switches and Socket Outlets InstallationDocument2 pagesMethod Statement Lamps, Switches and Socket Outlets InstallationVõ Khắc GhiNo ratings yet

- Method Statement Pulling Ca BL EDocument2 pagesMethod Statement Pulling Ca BL EVõ Khắc GhiNo ratings yet

- Method Statement For Cable Pulling & Final Electrical Connections.Document6 pagesMethod Statement For Cable Pulling & Final Electrical Connections.Ubah ChigozieNo ratings yet

- Methodologies For EIAC Installation WorkDocument12 pagesMethodologies For EIAC Installation WorkArun KumarNo ratings yet

- Switchgear DesignDocument32 pagesSwitchgear DesignAnonymous utxGVB5VyNo ratings yet

- Switchboard & PanelboardDocument8 pagesSwitchboard & PanelboardWalidNo ratings yet

- EarthingDocument9 pagesEarthingSuresh PasumarthiNo ratings yet

- METHOD of STATEMENT For Grounding SystemDocument12 pagesMETHOD of STATEMENT For Grounding SystemHamada Khamis100% (1)

- Electrical Specification Division 16, Section 16116Document4 pagesElectrical Specification Division 16, Section 16116eng_asayedNo ratings yet

- QA&QC Earthing SystemDocument6 pagesQA&QC Earthing SystemMuhammadZahirKhanNo ratings yet

- C. Methode Statement-DikonversiDocument12 pagesC. Methode Statement-DikonversiHendra BudimanNo ratings yet

- Specifications For Lightning & Earthing Protection SystemDocument9 pagesSpecifications For Lightning & Earthing Protection SystemMuhammad Ibad Alam100% (1)

- Electrical BOQ Plot C LPSDocument5 pagesElectrical BOQ Plot C LPSAgrawal PrajaktaNo ratings yet

- Cluster 2 Study GuideDocument17 pagesCluster 2 Study GuideShavoy RichardsonNo ratings yet

- Cable Ladder Method of Statement.Document4 pagesCable Ladder Method of Statement.Ahmad DagamsehNo ratings yet

- Mauritius Institute of Training & Development Knowledge Based Training CentreDocument8 pagesMauritius Institute of Training & Development Knowledge Based Training CentreYashveerNo ratings yet

- Panel BoardDocument6 pagesPanel BoardSherif M. ElgebalyNo ratings yet

- Hydromechanical - Technical SpecificationsDocument16 pagesHydromechanical - Technical SpecificationsdishkuNo ratings yet

- Telecommodule 5Document40 pagesTelecommodule 5MADRIAGA, CYRILLE MAE RUMANo ratings yet

- EHV Line Maintenance - Reular and Condition Monitoring - RTC J - 20.09.2023Document36 pagesEHV Line Maintenance - Reular and Condition Monitoring - RTC J - 20.09.2023namdeonimbalkar6No ratings yet

- Saudi Aramco Piping QC Inspector Sample Interview Questions & Answers..Document5 pagesSaudi Aramco Piping QC Inspector Sample Interview Questions & Answers..Ch SIB100% (1)

- Installation Guide: Unitray Systems IncDocument34 pagesInstallation Guide: Unitray Systems IncboltgingerkoppyNo ratings yet

- Field Work Procedure: 8. 8.1 Pre Hand ChecksDocument7 pagesField Work Procedure: 8. 8.1 Pre Hand Checkselsayed abdemagied100% (1)

- ML C 650 c65mm158Document4 pagesML C 650 c65mm158Jair Mauricio Gonzalez FloresNo ratings yet

- Electrical Tool Box-01Document1 pageElectrical Tool Box-01Muhammad IrfanNo ratings yet

- Upgrading Skills For Pipe Fitters FabricatorsDocument4 pagesUpgrading Skills For Pipe Fitters FabricatorsKentDemeterio0% (1)

- Op-3-32. Checklist For Supervision of Sheet Pile Installation (Excavation Work)Document3 pagesOp-3-32. Checklist For Supervision of Sheet Pile Installation (Excavation Work)Garry Yan DiazNo ratings yet

- SECTION 16060 Grounding and BondingDocument18 pagesSECTION 16060 Grounding and BondingMARIANNo ratings yet

- Conduit and BoxDocument7 pagesConduit and BoxqaqcmepteamNo ratings yet

- Overhead Lines Andy PMDocument3 pagesOverhead Lines Andy PMengrandyNo ratings yet

- Unit A 2.3 Excavation and Cable Laying - 060601Document24 pagesUnit A 2.3 Excavation and Cable Laying - 060601Victor SichoneNo ratings yet

- Conductive FRP Piping Systems Field Installation and Testing Procedures Detailed Instructions - Conductivity Measurements Updated Nov-18-2013Document6 pagesConductive FRP Piping Systems Field Installation and Testing Procedures Detailed Instructions - Conductivity Measurements Updated Nov-18-2013monik_atabaresNo ratings yet

- Cable Tray Installation ProcedureDocument3 pagesCable Tray Installation ProcedureNorman Polilin100% (1)

- Solar InstallationDocument32 pagesSolar InstallationTomilayo Samuel AdeyemiNo ratings yet

- 804 - Ventilations PlantDocument5 pages804 - Ventilations PlantEmilian NickNo ratings yet

- Method of StatementDocument46 pagesMethod of StatementZack ThiemNo ratings yet

- Method Statement For Pre FabricationDocument5 pagesMethod Statement For Pre FabricationFs67% (3)

- Pipes Welding Works MS For Stream 56&57 - Flare8&12 InchDocument6 pagesPipes Welding Works MS For Stream 56&57 - Flare8&12 InchahmadNo ratings yet

- Installation Standard For SPPDocument4 pagesInstallation Standard For SPPSagar ChandaranaNo ratings yet

- Electric Poles SpecificationsDocument6 pagesElectric Poles SpecificationsInderjit GhaiNo ratings yet

- Piping QuestionnaireDocument10 pagesPiping QuestionnaireRahman100% (2)

- Electrical Spec.'S Wiring Devices & Methods of Installation 16130-1Document9 pagesElectrical Spec.'S Wiring Devices & Methods of Installation 16130-1Waleed Abd El-HamiedNo ratings yet

- 16 S 10 Standard Earthing Philosophy of GETCODocument4 pages16 S 10 Standard Earthing Philosophy of GETCOTheresa WestNo ratings yet

- Ammunition-Explosives-ESD Protection Requirements DoD Manual 4145.26-MDocument3 pagesAmmunition-Explosives-ESD Protection Requirements DoD Manual 4145.26-MAsif HameedNo ratings yet

- S-TR-CAB-INST-220-400-TROUGH (RevDocument18 pagesS-TR-CAB-INST-220-400-TROUGH (RevGerman Barota BorlagdanNo ratings yet

- (ERECTION PROCEDURE Insulation-Lagging) - BiddingDocument5 pages(ERECTION PROCEDURE Insulation-Lagging) - BiddingnuntaricherdchaiNo ratings yet

- Installation Instructions: Plastic Pipe Industry AssociationDocument27 pagesInstallation Instructions: Plastic Pipe Industry Associationahmedmohamed2014No ratings yet

- Fire Fighting Inside BuildingDocument3 pagesFire Fighting Inside BuildingHamada ELarabyNo ratings yet

- Electricity 22Document13 pagesElectricity 22christian foreroNo ratings yet

- LPS Maintenance & TestingDocument6 pagesLPS Maintenance & TestingAri HastantoNo ratings yet

- Fpa 5000 - Rps BasicDocument15 pagesFpa 5000 - Rps BasicGoran PatarakoskiNo ratings yet

- Road Safety-Basic Rules of The RoadDocument14 pagesRoad Safety-Basic Rules of The RoadGlobal EHSNo ratings yet

- CybVA 6 UserManual v1.1Document16 pagesCybVA 6 UserManual v1.1Hassan El-gendyNo ratings yet

- ABL1REM - RPM - Product CharacteristcsDocument4 pagesABL1REM - RPM - Product CharacteristcsRamon Fichelli StievanoNo ratings yet

- Ground ResistorDocument2 pagesGround Resistorashoksince2005No ratings yet

- Maxi Mouse User ManualDocument10 pagesMaxi Mouse User ManualjcatfordNo ratings yet

- General Price List - T & F Lifts 202110Document10 pagesGeneral Price List - T & F Lifts 202110Oscar Daniel PorrasNo ratings yet

- Harmonic PDFDocument38 pagesHarmonic PDFkaihaniNo ratings yet

- Parts Catalogue YSD4900Document33 pagesParts Catalogue YSD4900Willem van der BerghNo ratings yet

- Auto Switch 1Document2 pagesAuto Switch 1deepak_singla227No ratings yet

- DSA 2011 01967 - Spare Parts ListDocument2 pagesDSA 2011 01967 - Spare Parts ListMehedi HasanNo ratings yet

- Op 900CPR Op383-V01 27-08-13 PDFDocument3 pagesOp 900CPR Op383-V01 27-08-13 PDFMoriom PLC & ElectricalNo ratings yet

- Backhoe Operator AssessmentDocument27 pagesBackhoe Operator AssessmentGermain DgermainNo ratings yet

- PD800 At12b00438Document211 pagesPD800 At12b00438Rene Rosas100% (1)

- Perkins 830 II Parts Manual2Document428 pagesPerkins 830 II Parts Manual2XiangzhendongNo ratings yet

- Vingcard Allure: User ManualDocument54 pagesVingcard Allure: User ManualBilal El-Sayed AliNo ratings yet

- Empire Vent Free SR10, SR18, SR30 BF10, BF20, BF30Document25 pagesEmpire Vent Free SR10, SR18, SR30 BF10, BF20, BF30NorthernPropaneNo ratings yet

- 3 Phase Induction Motor ConstructionDocument25 pages3 Phase Induction Motor ConstructionsunilkumareceNo ratings yet

- Rolliflex Instrumentation Cables Presentation - PPSXDocument15 pagesRolliflex Instrumentation Cables Presentation - PPSXnikhilbhorNo ratings yet

- TEA1755T DatasheetDocument35 pagesTEA1755T DatasheetDext JafremNo ratings yet

- 5PX Datasheet Low PDFDocument2 pages5PX Datasheet Low PDFJoe DoeNo ratings yet

- Semiconductor Interview Questions and Answers 2022Document6 pagesSemiconductor Interview Questions and Answers 2022Naznin Nuria AfrinNo ratings yet

- 421 Power Transformers and ReactorsDocument21 pages421 Power Transformers and Reactorselectrical civilNo ratings yet

- Emergency Button For 7$, Arduino, WIFI and ESP8266: Technology Workshop Craft Home Food Play Outside CostumesDocument13 pagesEmergency Button For 7$, Arduino, WIFI and ESP8266: Technology Workshop Craft Home Food Play Outside CostumesJunior CostaNo ratings yet

- Digital TachometerDocument5 pagesDigital TachometerSARATH SASINo ratings yet

- Yamaha Outboard 40c 50cDocument114 pagesYamaha Outboard 40c 50cEinar GaltaNo ratings yet