Professional Documents

Culture Documents

Latest Advances in RBI - RBI Task If Required PDF

Uploaded by

Ahmed Abd ElmegeedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Latest Advances in RBI - RBI Task If Required PDF

Uploaded by

Ahmed Abd ElmegeedCopyright:

Available Formats

Current trends and challenges in

implementing an effective RBI program

Session 6

RBI Task if required

Peter Nutty

Asset Integrity Management

Subject Matter Expert

Technut Limited

01/10/2020 (c) Technut Ltd 1

Group Discussion – RBI of pressure vessel

01/10/2020 (c) Technut Ltd 2

Group Discussion – RBI of pressure vessel

The atmospheric crude distillation unit (CDU) is the first processing unit in a refinery downstream of the

desalter. The unit is a complex column that fractionates crude oil into the basic product streams. These basic

product streams from the crude distillation unit can vary widely depending on the refinery operating

objectives.

Typical boiling point cuts from the atmospheric crude unit include: naphtha, kerosene, diesel, gas oil, heavy gas

oil, and residue, which is fed to the vacuum crude unit for further distillation and separation under vacuum.

Normally, these product streams are sent to downstream units for further processing before being sent to

product tanks

The crude oil is sent through a process heater and is partially vaporized before entering the fractionator near

the bottom of the column.

01/10/2020 (c) Technut Ltd 3

RBI of pressure vessel

• Stripping steam also is injected at the

bottom of the column. One or more

process pump-around heat exchanger loops

and a top reflux stream are used to cool the

rising vapours, which separates the crude

mixture into product streams

• Product streams are extracted through side

draws to the steam stripping columns.

• The column pressure and product draw

temperatures are used to control the

product streams to quality specifications,

usually to the final or 95% of the boiling

point for the product stream

01/10/2020 (c) Technut Ltd 4

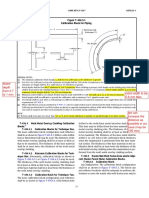

RBI of pressure vessel

01/10/2020 (c) Technut Ltd 5

Each section of the vessel is assessed – why?

01/10/2020 (c) Technut Ltd 6

Likewise, each section has different consequences – why?

01/10/2020 (c) Technut Ltd 7

Brainstorming session

• Where do we start? Think about the end-to-end process,

the fluids, pressure, temperatures, material(s) and what is

going on inside and outside the vessel

• What resources do we need?

• What documents do we need for the assessment?

• What are the boundaries of the assessment?

• What type(s) of risk assessment could we undertake?

• What is our acceptable risk and where does it come from?

• What type(s) of mitigation could we expect to be

implemented?

• Could we use NII or robotics?

01/10/2020 (c) Technut Ltd 8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Exploring The Latest Breakthroughs in Inspection and Remote Monitoring Techniques For Safe Efficient and Cost-EffectivDocument40 pagesExploring The Latest Breakthroughs in Inspection and Remote Monitoring Techniques For Safe Efficient and Cost-EffectivAhmed Abd ElmegeedNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Increasing Reliability and Availability of Assets With Asset Performance Management APMDocument22 pagesIncreasing Reliability and Availability of Assets With Asset Performance Management APMAhmed Abd ElmegeedNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Building An Effective Computerised Asset Management System C Insights Best Practices Lessons LearntDocument31 pagesBuilding An Effective Computerised Asset Management System C Insights Best Practices Lessons LearntAhmed Abd ElmegeedNo ratings yet

- Latest Advances in RBI - RBI Task If Required PDFDocument8 pagesLatest Advances in RBI - RBI Task If Required PDFAhmed Abd ElmegeedNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Latest Advances in RBI - Session 3Document20 pagesLatest Advances in RBI - Session 3Ahmed Abd ElmegeedNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Latest Advances in RBI - Session 1Document30 pagesLatest Advances in RBI - Session 1Ahmed Abd ElmegeedNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Latest Advances in RBI - Session 1Document30 pagesLatest Advances in RBI - Session 1Ahmed Abd ElmegeedNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Building Implementing A Holistic...Document41 pagesBuilding Implementing A Holistic...Ahmed Abd ElmegeedNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Ultratrend DMS 4.1 Manual PDFDocument22 pagesUltratrend DMS 4.1 Manual PDFAhmed Abd ElmegeedNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Latest Advances in RBI - Session 2 - 1Document38 pagesLatest Advances in RBI - Session 2 - 1Ahmed Abd ElmegeedNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Coverpage To Material/Test CertificateDocument3 pagesCoverpage To Material/Test CertificateAhmed Abd ElmegeedNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Document review status updateDocument6 pagesDocument review status updateAhmed Abd ElmegeedNo ratings yet

- Latest Advances in RBI - Session 3Document20 pagesLatest Advances in RBI - Session 3Ahmed Abd ElmegeedNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Latest Advances in RBI - Session 2 - 1Document38 pagesLatest Advances in RBI - Session 2 - 1Ahmed Abd ElmegeedNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Coverpage To Material/Test CertificateDocument8 pagesCoverpage To Material/Test CertificateAhmed Abd ElmegeedNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Coverpage To Material/Test CertificateDocument7 pagesCoverpage To Material/Test CertificateAhmed Abd ElmegeedNo ratings yet

- Coverpage To Material/Test CertificateDocument3 pagesCoverpage To Material/Test CertificateAhmed Abd ElmegeedNo ratings yet

- Coverpage To Material/Test CertificateDocument3 pagesCoverpage To Material/Test CertificateAhmed Abd ElmegeedNo ratings yet

- Coverpage To Material/Test CertificateDocument7 pagesCoverpage To Material/Test CertificateAhmed Abd ElmegeedNo ratings yet

- Profile Laminate IPEDocument1 pageProfile Laminate IPEKarlaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 617 - Reactors & Secondary Reformers PDFDocument3 pages617 - Reactors & Secondary Reformers PDFAhmed Abd ElmegeedNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- HP Valves Material Certificates for NEM Energy BV ProjectDocument3 pagesHP Valves Material Certificates for NEM Energy BV ProjectAhmed Abd ElmegeedNo ratings yet

- Coverpage To Material/Test CertificateDocument3 pagesCoverpage To Material/Test CertificateAhmed Abd ElmegeedNo ratings yet

- WPS and PQR For Low Alloy With Martensitic ST - STDocument8 pagesWPS and PQR For Low Alloy With Martensitic ST - STAhmed Abd Elmegeed100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- MSS SP 25 Standard Marking System For Valves Fittings Flanges and Unions PDFDocument27 pagesMSS SP 25 Standard Marking System For Valves Fittings Flanges and Unions PDFTinuoye Folusho OmotayoNo ratings yet

- Bronze Iron Gate Globe Check ValveDocument87 pagesBronze Iron Gate Globe Check Valvemax_powerNo ratings yet

- Stress Analysis ReviewDocument18 pagesStress Analysis ReviewAhmed Abd ElmegeedNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Piping TCG Caliberation BlockDocument1 pagePiping TCG Caliberation BlockAhmed Abd ElmegeedNo ratings yet

- Math 8 Unit 1Document12 pagesMath 8 Unit 1api-114939020No ratings yet

- Fcu Pressure Drop PDFDocument18 pagesFcu Pressure Drop PDFvishalNo ratings yet

- Quantity Item by Warehouse List: PT Solusi Teknik IndustriDocument6 pagesQuantity Item by Warehouse List: PT Solusi Teknik IndustriShinyeNo ratings yet

- Lean Blow Out Limits of A Gas Turbine CombustorDocument10 pagesLean Blow Out Limits of A Gas Turbine CombustorFayçal MahieddineNo ratings yet

- COMPLETE Structural Design Notes Standard Drawings AmpDocument91 pagesCOMPLETE Structural Design Notes Standard Drawings AmpReden H. ArgawanonNo ratings yet

- Services by Airbus PortfolioDocument77 pagesServices by Airbus PortfolioPablo RestrepoNo ratings yet

- Mechanical Vibrations (ME 65) Chapter-8 Multi Degree of Freedom SystemsDocument36 pagesMechanical Vibrations (ME 65) Chapter-8 Multi Degree of Freedom SystemsGURUPRASAD KADAGADNo ratings yet

- GA GA GA GA - 2222 Running Tool Running Tool Running Tool Running ToolDocument12 pagesGA GA GA GA - 2222 Running Tool Running Tool Running Tool Running ToolhaudvNo ratings yet

- PHD Entrance MCQDocument11 pagesPHD Entrance MCQvandyNo ratings yet

- Simple Phenomena of Magnetism 1 MSDocument4 pagesSimple Phenomena of Magnetism 1 MSnssNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Data Structure & Program Design: B.E. (Computer Science Engineering) Fourth Semester (C.B.S.)Document4 pagesData Structure & Program Design: B.E. (Computer Science Engineering) Fourth Semester (C.B.S.)sahil kambleNo ratings yet

- Assignment 7Document4 pagesAssignment 7Lance quinn InfanteNo ratings yet

- My First Ttcn-3 Project With TtworkbenchDocument19 pagesMy First Ttcn-3 Project With TtworkbenchPramod KumarNo ratings yet

- Industry 4.0: Reshaping the Manufacturing LandscapeDocument20 pagesIndustry 4.0: Reshaping the Manufacturing Landscapeambika1969inNo ratings yet

- Service KitDocument2 pagesService Kiteshopmanual limaNo ratings yet

- SAE To Metric Conversion ChartDocument5 pagesSAE To Metric Conversion ChartLAliNo ratings yet

- Microsoft Power BI Web - Creating DashboardsDocument69 pagesMicrosoft Power BI Web - Creating Dashboardsnaua2010No ratings yet

- SeleneiumDocument112 pagesSeleneiumdungeonmasterNo ratings yet

- Tender Document 4666Document128 pagesTender Document 4666KishoreNo ratings yet

- PSV Circular 29 of 2023Document422 pagesPSV Circular 29 of 2023Bee MashigoNo ratings yet

- DIGI Usecases MAIN DOC V20 enDocument18 pagesDIGI Usecases MAIN DOC V20 enZine eddine Hadj mokhnachrNo ratings yet

- Farm Machinery and Equipment II PDFDocument198 pagesFarm Machinery and Equipment II PDFKamalesh RawatNo ratings yet

- Spare Parts Manual: ModelsDocument78 pagesSpare Parts Manual: ModelsÁrpád AndrisNo ratings yet

- Shreyasi Ghosh: Get in ContactDocument2 pagesShreyasi Ghosh: Get in ContactKunjan SomaiyaNo ratings yet

- Rheyven B. JuanDocument20 pagesRheyven B. JuanRheyven JuanNo ratings yet

- Chander Raj ProjectDocument46 pagesChander Raj ProjectSHAIK SAMEERNo ratings yet

- Crouch 2009Document9 pagesCrouch 2009ClaudiaFariaNo ratings yet

- Pig Handling System Brochure PDFDocument6 pagesPig Handling System Brochure PDFKRUNAL SHAHNo ratings yet

- Understanding Shortcut Gestures On Mobile Touch Devices: September 2014Document11 pagesUnderstanding Shortcut Gestures On Mobile Touch Devices: September 2014Abdul Haleem HaqmalNo ratings yet

- Document Management PDFDocument82 pagesDocument Management PDFTester25896No ratings yet