Professional Documents

Culture Documents

De Nitrification

Uploaded by

kiran raghukiranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

De Nitrification

Uploaded by

kiran raghukiranCopyright:

Available Formats

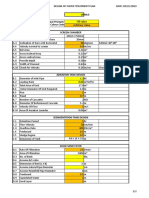

DESIGN OF SEWERAGE TREATMENT PLANT FOR EXTENDED AERATION

NAME OF WORK :- CONSTRUCTION OF PROPOSED SEWERAGE TREATMENT PLANT

THIMMAIGUDA AT HYDERABAD

PRE - ANOXIEC EXTENDED AERATION SYSTEM

Capacity: Average Flow 0.50 MLD

S No Description of Parameter Value Unit Reference

Quantity of Sewage Generated 500000.00 Lpd

0.50 MLD

500.00 Cum/day

Raw Sewage Characteristics

1 Average Sewage flow entering the treatment plant 500000.00 lpd

Assumed Peak Factor 3.00

2 Peak Sewage flow entering the treatment plant 1500000.00 lpd

3 COD 450.00 mg/Lt

4 BOD 250.00 mg/Lt

5 TDS 100.00 mg/Lt

6 TSS 375.00 mg/Lt

7 pH 5.5 - 9.0 As Per Guide Lines

1 ANOXIC TANK

As Per Metclaff & Eddy

Waste water Characteristices

COD 450.00 mg/Lt

BOD 250.00 mg/Lt

TDS 100.00 mg/Lt

TSS 375.00 mg/Lt

pH 5.5 - 9.0 As Per Guide Lines

Rb COD 80.00

NOX 28.30

TP 6.00

Alkalinity 140 as CACO3

Dixolved Oxyzen 0.20 mg/l

Design Conditions

Influent Flow rate 500.00 cum/day

Temperature 15.00

MLSS 4500.00 g/cum

MLVSS 6000.00 g/cum

Aerobic SRT 12.50

Aeration basin volume

Mixing Energy 10.00 kw/cum

RAS ratio 0.60

Ra 255.00 kg/h

Active Bio mass equation as per Metclaff & Eddy

Xb 2635.18 g/cum

Aerobic tank No3 , N

IR ratio 1.0- R concentration

3.12

The Amount of NO3-N fed for Anoxic Tank 3720.00 Cum/day

NO3 feed 22320.00 g/day

Anoxic Volume of tank

Detention time 2.50 h

t 0.104 d

52.08 Cum

g/day Hence ok as per SDNR

F/Mb 0.91 using the curve ratio 0-2

Fraction of rb COD 0.13

13.33 Percent

Temperature Correction 0.22(1.026)^15-20

0.19 g/g d

Amount of NO2 , N that can be removed 254957.03

Oxygen requiered

Oxyzen Credit 63.78 kg/d

2.66 kg/h

Net Oxyzen Requiered 252.34 kg/h

Anoxic Zone Mixing Energy 10.00 kw/cum

Volume 52.08

Power 0.52 KW

Size Of Anoxic Tank required 52.08 Cum

Depth 3.50 m

Area 14.88 Sqm

Width 4.00 m

Length 3.72 m

Free board 0.50 m

Width Provided 4.00 m

Length Provided 4.00 m

Volume Provided 56.00 CUM

Mixing power for Anoxic Zone 3 watt/m2 -8 watt/m2 ( Metclaf& Eddy, Fifth Edition , Vol , pg=

(proposed mixing intensity at Anoxic zone for complete mixing)

Minimum power selection 5.00 Watt/m³

The selection of mixer shall also refering to the thrust which refering to the geometry of the tank.

Hence, Minimum mixing power for Anoxic Zone

= 280 W

= 0.28 kW

Mixing power from selected submersible mixer

= 0.28 kW (min)

You might also like

- Workbook Contents: Find More Excel Spreadsheets For Engineering atDocument34 pagesWorkbook Contents: Find More Excel Spreadsheets For Engineering atGabrielito Pachacama100% (1)

- Softener CalculationDocument5 pagesSoftener CalculationAri WijayaNo ratings yet

- De NitrificationDocument3 pagesDe Nitrificationkiran raghukiranNo ratings yet

- 40 KLD MBR QuoteDocument15 pages40 KLD MBR QuoteV Narasimha RajuNo ratings yet

- UASB-Process Design For Various Types of WastewatersDocument21 pagesUASB-Process Design For Various Types of WastewatersapitbhuNo ratings yet

- Effluent Treatment Plant Tech Report for LAIL Sugar MillDocument28 pagesEffluent Treatment Plant Tech Report for LAIL Sugar MillGarad MadhukarNo ratings yet

- CIP Procedure of RO MembraneDocument2 pagesCIP Procedure of RO MembraneTanzila SiddiquiNo ratings yet

- Summary Report: RO System Flow DiagramDocument3 pagesSummary Report: RO System Flow Diagramjugal ranaNo ratings yet

- 1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedDocument11 pages1295 - Offer 50 KLD Package Type STP 27.08.2022 - RemovedsanjeevNo ratings yet

- MBR Membrane Offer for 30 MLD STPDocument8 pagesMBR Membrane Offer for 30 MLD STPakshay salviNo ratings yet

- Design of Carbon Filters: InputsDocument5 pagesDesign of Carbon Filters: InputsarcelitasNo ratings yet

- Flocculator Eng PDFDocument2 pagesFlocculator Eng PDFAbdul LatifNo ratings yet

- Design Flow Rates and Water Quality Parameters for Wastewater Treatment SystemDocument17 pagesDesign Flow Rates and Water Quality Parameters for Wastewater Treatment SystemMohamed ArafatNo ratings yet

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDocument8 pages04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyNo ratings yet

- Design FMR HighDensityDocument2 pagesDesign FMR HighDensityPandiaraj MkNo ratings yet

- Hydro-Flo Technologies, Inc.: Chemical Name Acid - Typical Project Name XX-XXXXDocument4 pagesHydro-Flo Technologies, Inc.: Chemical Name Acid - Typical Project Name XX-XXXXPutra TatorNo ratings yet

- FWD CALCULATION NOTESDocument10 pagesFWD CALCULATION NOTESMuhammad Ashraful ArifinNo ratings yet

- List of SymbolsDocument11 pagesList of SymbolsKaarthic EmayNo ratings yet

- Flotador Por Ar Dissolvido - (Access Engineering)Document10 pagesFlotador Por Ar Dissolvido - (Access Engineering)fabio.v.mullerNo ratings yet

- Activated Sludge Calculations With Excel QuizDocument2 pagesActivated Sludge Calculations With Excel Quiztrantrunghoa290784No ratings yet

- Clarifier DesignDocument5 pagesClarifier DesignSwaminathan ThayumanavanNo ratings yet

- Water treatment design parametersDocument2 pagesWater treatment design parametersRyeanKRumano100% (1)

- Filters Pressurized Filters Pressure Filter 200Document2 pagesFilters Pressurized Filters Pressure Filter 200eljammalNo ratings yet

- Al Ain Sludge Status - BwiDocument1 pageAl Ain Sludge Status - BwiHRK65No ratings yet

- Annexure 16 - Tool For Design of Tube SettlerDocument1 pageAnnexure 16 - Tool For Design of Tube SettlerWikaz FiansyahNo ratings yet

- 20 KLD STP Upgreation PROPOSAL-GMCPLDocument7 pages20 KLD STP Upgreation PROPOSAL-GMCPLTech Monger100% (1)

- Calculator GWR Contact Time Calculator v9Document16 pagesCalculator GWR Contact Time Calculator v9HeruNo ratings yet

- WTP CalculationsDocument10 pagesWTP CalculationsAngshuman Roy ChoudhuryNo ratings yet

- Hyd - Cal. WTP BaggiDocument27 pagesHyd - Cal. WTP BaggiChief Engineer PMUNo ratings yet

- Uasb/egsb Applications For Industrial Wastewater TreatmentDocument10 pagesUasb/egsb Applications For Industrial Wastewater Treatmentalberto_03No ratings yet

- WTP Report - 1.5MLD PDFDocument97 pagesWTP Report - 1.5MLD PDFDesign TeamNo ratings yet

- 105.a.0 - RO-DM Plant Chain Sizing CalcDocument7 pages105.a.0 - RO-DM Plant Chain Sizing Calcmkchy12No ratings yet

- Sewage Treatment WorksheetDocument18 pagesSewage Treatment WorksheetRemedanNo ratings yet

- Nitrogen RemovalDocument96 pagesNitrogen RemovalnusageniNo ratings yet

- 6000 M3/D STP Process Design & Unit SizingDocument8 pages6000 M3/D STP Process Design & Unit SizingMinakshi SinghNo ratings yet

- (EDITED-FINAL) Sludge - Storage CalculationDocument17 pages(EDITED-FINAL) Sludge - Storage CalculationIftikhar KamranNo ratings yet

- Rapid Sand Filters ExplainedDocument43 pagesRapid Sand Filters ExplainedLakshmi Keshav KNo ratings yet

- Hydrochloric acid Regeneration of Cation Exchange Resin 225 HDocument8 pagesHydrochloric acid Regeneration of Cation Exchange Resin 225 HPravin BoteNo ratings yet

- 250 KLD MBR Membrane System DesignDocument2 pages250 KLD MBR Membrane System DesignNithin BharathiNo ratings yet

- DM PlantDocument9 pagesDM Plantsohag97No ratings yet

- Dual Media FilterDocument4 pagesDual Media FilterPandiaraj Mk100% (1)

- Degasifier 18-02-2017 Sheet 1Document1 pageDegasifier 18-02-2017 Sheet 1Abu SuraisyNo ratings yet

- Tech City-STP 100 KLD Price Comparison (03092016)Document10 pagesTech City-STP 100 KLD Price Comparison (03092016)Preston VargheseNo ratings yet

- 45 KLD STP PROPOSAL VRANDAVAN GREENS PDFDocument9 pages45 KLD STP PROPOSAL VRANDAVAN GREENS PDFTech MongerNo ratings yet

- MM Aqua Technologies LTD.: TubedekDocument47 pagesMM Aqua Technologies LTD.: TubedekSourabh Manuja100% (1)

- Chemical Pump Dosing CalcsDocument4 pagesChemical Pump Dosing CalcsAnonymous BJ9omONo ratings yet

- DESIGN of Biological Systems For 4MLD Waste Water TreatmentDocument34 pagesDESIGN of Biological Systems For 4MLD Waste Water TreatmentInigo JohnsonNo ratings yet

- 02 - Biological WWTP III - Membrane BioreactorDocument26 pages02 - Biological WWTP III - Membrane BioreactorAhmed100% (1)

- Mfrs. & suppliers of evaporator, MEE, ATFD, ETP equipmentDocument10 pagesMfrs. & suppliers of evaporator, MEE, ATFD, ETP equipmentrajesh kothariNo ratings yet

- MBR C0 IntroductionDocument4 pagesMBR C0 IntroductionAlfonso José García LagunaNo ratings yet

- Today'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"Document57 pagesToday'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"saravan1891No ratings yet

- Techno-Commercial Offer For 150 KLD STP, Based Upon MBBR.Document9 pagesTechno-Commercial Offer For 150 KLD STP, Based Upon MBBR.Anshika RaiNo ratings yet

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDocument6 pagesDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266No ratings yet

- Sps and Wetwell NTLDocument3 pagesSps and Wetwell NTLProject ManagerStructuresNo ratings yet

- Conversion Table For Wastewater TreatmentDocument5 pagesConversion Table For Wastewater TreatmentAG-Metal /Tretman Otpadnih Voda/Wastewater TreatmentNo ratings yet

- 12 - NPS Pipe Thickness CalculatorDocument5 pages12 - NPS Pipe Thickness CalculatorSalman KhanNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- Water Tank DesignDocument3 pagesWater Tank Designkiran raghukiranNo ratings yet

- Water Tank CLPMDocument3 pagesWater Tank CLPMkiran raghukiranNo ratings yet

- Steel & Con 22-09-14Document24 pagesSteel & Con 22-09-14kiran raghukiranNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- TrussDocument1 pageTrusskiran raghukiranNo ratings yet

- Water Tank DesignDocument3 pagesWater Tank Designkiran raghukiranNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- SlabsDocument11 pagesSlabskiran raghukiranNo ratings yet

- Water Tank CLPMDocument3 pagesWater Tank CLPMkiran raghukiranNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- SlabsDocument11 pagesSlabskiran raghukiranNo ratings yet

- TrussDocument1 pageTrusskiran raghukiranNo ratings yet

- Steel & Con 22-09-14Document24 pagesSteel & Con 22-09-14kiran raghukiranNo ratings yet

- Water Tank CLPMDocument3 pagesWater Tank CLPMkiran raghukiranNo ratings yet

- SlabsDocument11 pagesSlabskiran raghukiranNo ratings yet

- Design of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250Document5 pagesDesign of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250kiran raghukiranNo ratings yet

- TrussDocument1 pageTrusskiran raghukiranNo ratings yet

- Steel & Con 22-09-14Document24 pagesSteel & Con 22-09-14kiran raghukiranNo ratings yet

- PileprDocument13 pagesPileprkiran raghukiranNo ratings yet

- 100 Bedded Hospital at Jadcherla: Load CalculationsDocument3 pages100 Bedded Hospital at Jadcherla: Load Calculationskiran raghukiranNo ratings yet

- RCC ELSR structural design calculationsDocument41 pagesRCC ELSR structural design calculationskiran raghukiranNo ratings yet

- PileprDocument13 pagesPileprkiran raghukiranNo ratings yet

- Combined Footing Pcf1 Node L/C Fy MX MZ Node Fy MX MZDocument3 pagesCombined Footing Pcf1 Node L/C Fy MX MZ Node Fy MX MZkiran raghukiranNo ratings yet

- SBC foundation design parameters and calculationsDocument21 pagesSBC foundation design parameters and calculationskiran raghukiranNo ratings yet

- PURLINDocument1 pagePURLINkiran raghukiranNo ratings yet

- Design of Drain Wall Stability CheckDocument3 pagesDesign of Drain Wall Stability Checkkiran raghukiranNo ratings yet

- STP Design SheetsDocument86 pagesSTP Design Sheetskiran raghukiran100% (1)

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection Checkkiran raghukiranNo ratings yet

- 02 WholeDocument155 pages02 WholeTayeb CheliremNo ratings yet

- Dual FMGC Failure-1Document19 pagesDual FMGC Failure-1abhishesh pandeyNo ratings yet

- PT SURYA CITRA INTI SEMESTA PROJECT REFERENCE LISTDocument1 pagePT SURYA CITRA INTI SEMESTA PROJECT REFERENCE LISTAgus RiyanaNo ratings yet

- Math 7, Q1, Wk4, Day 2Document3 pagesMath 7, Q1, Wk4, Day 2dennis sombilonNo ratings yet

- Unit 1 Cultural Issues and ValuesDocument3 pagesUnit 1 Cultural Issues and ValuesACHRAF DOUKARNENo ratings yet

- Gauss's LawDocument10 pagesGauss's LawAliceAlormenuNo ratings yet

- Metrology and Measurement SystemsDocument18 pagesMetrology and Measurement SystemssalemNo ratings yet

- Geographic AtmosphereDocument2 pagesGeographic AtmosphereLexter FalloNo ratings yet

- Pengembangan Perangkat Pembelajaran Mata Kuliah Kalkulus Lanjut 1 Dengan Scaffolding Berbasis Kemampuan Pemecahan MasalahDocument23 pagesPengembangan Perangkat Pembelajaran Mata Kuliah Kalkulus Lanjut 1 Dengan Scaffolding Berbasis Kemampuan Pemecahan MasalahNisaaNo ratings yet

- IGKO Olympiad Sample Question Paper 1 PDF With Answers For Class 3Document15 pagesIGKO Olympiad Sample Question Paper 1 PDF With Answers For Class 3ARITRA MondalNo ratings yet

- Office Address: National Government Center EDSA, Diliman, Quezon City, Philippines Telephone Nos.: (02) 929-6071 To 78 Website: WWW - Nia.gov - PH Telefax No. (632) 928-9343 TIN No. 000-916-415Document2 pagesOffice Address: National Government Center EDSA, Diliman, Quezon City, Philippines Telephone Nos.: (02) 929-6071 To 78 Website: WWW - Nia.gov - PH Telefax No. (632) 928-9343 TIN No. 000-916-415IMEG MindanaoNo ratings yet

- Malaysian Online Journal of Educational Sciences: JANUARY 2021, 9Document19 pagesMalaysian Online Journal of Educational Sciences: JANUARY 2021, 9guanyitorNo ratings yet

- Chapter No # 03 Product Innovation CharterDocument11 pagesChapter No # 03 Product Innovation CharterabzuarNo ratings yet

- ĐỀ ÔN TỐT NGHIỆP THPT SỐ 2Document4 pagesĐỀ ÔN TỐT NGHIỆP THPT SỐ 2Lê Minh NguyệtNo ratings yet

- Spiral Spring ApparatusDocument3 pagesSpiral Spring ApparatusaqibNo ratings yet

- Local Media3854443116550985649Document17 pagesLocal Media3854443116550985649Mediado Karen TomenioNo ratings yet

- Silt Flushing Tunnel Design Manual PDFDocument7 pagesSilt Flushing Tunnel Design Manual PDFShivsagar yadavNo ratings yet

- (Haus & Melcher) Electromagnetic Fields and EnergyDocument863 pages(Haus & Melcher) Electromagnetic Fields and EnergyFlavio AbreuNo ratings yet

- HIN4801 MODULE OVERVIEWDocument6 pagesHIN4801 MODULE OVERVIEWZukiswa PetseNo ratings yet

- Seismic Force CANADA Code - CNBC2005-V421Document7 pagesSeismic Force CANADA Code - CNBC2005-V421Niko NištićNo ratings yet

- Explains The Indicators For FitnessDocument7 pagesExplains The Indicators For FitnessCHITO PENJIE ODUYANo ratings yet

- GMOdetective Thesis V1.2 - CleanDocument237 pagesGMOdetective Thesis V1.2 - CleanGuy AidelbergNo ratings yet

- 10.design 3D Steel Frame ViewDocument21 pages10.design 3D Steel Frame ViewPanha PorNo ratings yet

- UID 104 Unity CollaborationDocument4 pagesUID 104 Unity CollaborationMary Joyce AvendańoNo ratings yet

- GSS Open RecruitmentDocument3 pagesGSS Open RecruitmentFazrie AkbarNo ratings yet

- Challenge - Redefining Business Sustainability in Philippine Business Culture (J&T Express)Document4 pagesChallenge - Redefining Business Sustainability in Philippine Business Culture (J&T Express)ANGELICA GABRIELLE UYNo ratings yet

- Magnetic Particle Test Record Truck Crane Articulating Boom (Gb-La03)Document2 pagesMagnetic Particle Test Record Truck Crane Articulating Boom (Gb-La03)Hario PramuditoNo ratings yet

- Fish Bowl Strategy: Fishbowl Is A Strategy For Organizing Medium-To Large-Group Discussions. Students AreDocument2 pagesFish Bowl Strategy: Fishbowl Is A Strategy For Organizing Medium-To Large-Group Discussions. Students AreAllysa Marie BorladoNo ratings yet

- Beneficial Utilisation of Sasol Coal Gasification Ash: Martin Ginster and Ratale H. MatjieDocument5 pagesBeneficial Utilisation of Sasol Coal Gasification Ash: Martin Ginster and Ratale H. MatjieAnonymous fS6Znc9No ratings yet

- Closing Speech for Mental Health WeekDocument2 pagesClosing Speech for Mental Health WeekPARDS MOTOVLOGS100% (2)