Professional Documents

Culture Documents

C&P Constant Effort Supports

Uploaded by

Achraf Boudaya0 ratings0% found this document useful (0 votes)

23 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views1 pageC&P Constant Effort Supports

Uploaded by

Achraf BoudayaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

04/10

Constant Effort Supports

General Description Upper and lower travel stops are incorporated in all units to prevent excessive

overtravel.

The Constant Effort Support designed and manufactured by Carpenter and

Paterson incorporates the latest design concepts, resulting in a constant All supports are fitted with clearly visible travel scale.

supporting effort through the total travel of the unit. The simplified construction, Carpenter and Paterson Constant Supports are also available using a range of

together with the established principle of a compression spring working in special materials which have been selected for use in the offshore industry.

conjunction with a bell crank lever, achieves a mathematically perfect counter-

balancing of spring and load moments about the main pivot point. Special Range

With a fixed spring housing of substantial construction the unit can be installed in Special Constant Supports are designed to suit customer’s specific requirements, i.e.

many arrangements. The spring housing prevents the ingress of foreign bodies higher loads, travels and configurations other than those indicated in the standard

such as construction debris, thus reducing the danger of damage or restriction of range.

the unit’s function.

Load Adjustment

The Constant Support is based on a simple mechanical principle: Although the supports are preset to the customer’s specified load and travel, it is

In order to produce a Constant Supporting Effect the load moment about the Main sometimes necessary to adjust this preset load to accommodate minor variations in

Pivot must be counter-balanced by an equal spring moment throughout the travel actual site conditions. A simple operation of turning the load adjuster screw in the

range. appropriate direction to increase or decrease the load is all that is necessary.The

amount of adjustment is shown on the adjacent scale calibrated in 2 per cent divisions.

The maximum adjustment being p20 per cent of the operating load.

Presetting

All Constant Supports are fitted with preset pins which are painted red. These pins are

factory positioned within the unit to suit the customer’s specified installation condition.

On completion of installation and prior to removal of the pins, the pipework system can

Referring to the diagram, take three positions of be hydraulically tested or acid cleaned without further deflection of the spring

the load travel - Top, Mid, Bottom - and equate assembly. The preset pins must be removed before commissioning the system (refer

the moments of these points about the Main Pivot to installation instructions).

F1 a1 = Wb1

Our standard presetting pins will enable loads of up to twice the capacity of the support

F2 a2 = Wb2 to be taken during the hydraulic testing period.

F3 a3 = Wb3

Should it be necessary to carry loads in excess of this, we must be notified at time of

F1 a1 = F2 a2 = F3 a3 = W ordering to ensure the supports are designed with adequate safety margins.

b1 b2 b3

Standard Range Infinitely Variable Travel Locking Mechanism

The Constant Support may be fitted with an infinitely variable locking device (within

Carpenter and Paterson Constant Effort Supports are constructed to

the travel limits of the unit) that will lock the support thus preventing upward and

accommodate loads between 10 Kg and 45700 Kg with a standard range of

downward movement for temporary conditions of underload or overload.

travels from 40 mm to 610 mm in 10 mm increments.

Constant Supports are manufactured having a deviation of p5 per cent of the The locking mechanism is only incorporated when specified.

specified load. The locking mechanism should always be positioned at the extreme of the adjustment

(Approved by UK and Foreign Authorities) before the pipework system is commissioned.

3

You might also like

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Constant Effort SupportsDocument31 pagesConstant Effort SupportsKen SidhartaNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Constant Spring Units: Carpenter & Paterson LTDDocument9 pagesConstant Spring Units: Carpenter & Paterson LTDhcsharma1967No ratings yet

- CPA CES CatalogueDocument28 pagesCPA CES CatalogueVishal RatnamNo ratings yet

- Installation ManualDocument12 pagesInstallation ManualGhayath Omer0% (1)

- SPMT Stability of Hydraulic EngDocument4 pagesSPMT Stability of Hydraulic Engparamarthasom1974No ratings yet

- ARCA Fly Antriebe GBDocument6 pagesARCA Fly Antriebe GBcvfNo ratings yet

- Budgit Motor Driven Trolley PDFDocument20 pagesBudgit Motor Driven Trolley PDFGopu MayyalaNo ratings yet

- Pub004 003 00 - 0111Document12 pagesPub004 003 00 - 0111Arman MominNo ratings yet

- User Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesDocument12 pagesUser Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesTGM KalimantanNo ratings yet

- User Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesDocument12 pagesUser Instructions: Installation Operation Maintenance Automax CENTURA™ CE SeriesIsaac Isaias AlvarezNo ratings yet

- v.001 - Vryhof - Product Brochure - STEVTENSIONER - For WebDocument6 pagesv.001 - Vryhof - Product Brochure - STEVTENSIONER - For WebjeedanNo ratings yet

- Fuji Frenic Mega GuideDocument673 pagesFuji Frenic Mega GuideSantiago RoseroNo ratings yet

- Alignment With Target Values Reduces Vibrations PDFDocument4 pagesAlignment With Target Values Reduces Vibrations PDFSantyagoNo ratings yet

- Operation, Service AND Parts Manual: Single and Double Girder Top Running Bridges With Individual Motor Driven TrucksDocument20 pagesOperation, Service AND Parts Manual: Single and Double Girder Top Running Bridges With Individual Motor Driven TrucksBrad BorgesNo ratings yet

- ASME VIII DIV 1 - M-11 - Posição Vertical Instalação PsvsDocument1 pageASME VIII DIV 1 - M-11 - Posição Vertical Instalação PsvsPaulo Paulucci NetoNo ratings yet

- Warning: ESD5100 Series Speed Control UnitDocument6 pagesWarning: ESD5100 Series Speed Control Unitinstrumentacion.hsrNo ratings yet

- Electric Actuators With Fail Safe Unit: For Automatic Opening or Closing of A Valve in The Event of An EmergencyDocument8 pagesElectric Actuators With Fail Safe Unit: For Automatic Opening or Closing of A Valve in The Event of An EmergencyThanThansccNo ratings yet

- In FQM enDocument8 pagesIn FQM enVao Van Ngam VaoNo ratings yet

- Specification Bulletin 695 33Document28 pagesSpecification Bulletin 695 33mojsic6313No ratings yet

- TV I Air BalancerDocument4 pagesTV I Air Balancerandri putrantoNo ratings yet

- HWC - O&M ManualDocument16 pagesHWC - O&M ManualAONLANo ratings yet

- Corner pressures and foundation loads for tower craneDocument22 pagesCorner pressures and foundation loads for tower craneAndrei KraikoNo ratings yet

- Speed Control For Cummins PT™ Fuel System: ApplicationsDocument4 pagesSpeed Control For Cummins PT™ Fuel System: ApplicationsSebastian FloresNo ratings yet

- Speed Control For Cummins PT™ Fuel System: ApplicationsDocument4 pagesSpeed Control For Cummins PT™ Fuel System: ApplicationsDavid GomezNo ratings yet

- VM 3156 Eriez Feeder Model HS46 HS66 IOMDocument12 pagesVM 3156 Eriez Feeder Model HS46 HS66 IOMMaintenanceNo ratings yet

- IMG - 0136 PSME Code 2008 128Document1 pageIMG - 0136 PSME Code 2008 128Arwyn BermasNo ratings yet

- FT-01 ServiceManualDocument7 pagesFT-01 ServiceManualsalam87No ratings yet

- Applications: Electrically Powered Governor SystemsDocument4 pagesApplications: Electrically Powered Governor SystemsAndreaNo ratings yet

- 15572771980345kk4ub Nari CD ProtDocument3 pages15572771980345kk4ub Nari CD ProtKelly chatNo ratings yet

- HPB Install Manual ABB - Distribution BUS BarsDocument11 pagesHPB Install Manual ABB - Distribution BUS BarsArunallNo ratings yet

- Stamford PMG Pi14f AscotDocument10 pagesStamford PMG Pi14f AscotJan AhmedNo ratings yet

- Manitex 1770CDocument6 pagesManitex 1770CJAIME MOTANo ratings yet

- Technical Data Gearbox SelectionDocument2 pagesTechnical Data Gearbox Selectionpenulis kata penulis kataNo ratings yet

- Korfund Spring Mounts PDFDocument50 pagesKorfund Spring Mounts PDFBaher SalehNo ratings yet

- Turbine Control Interface - PksDocument2 pagesTurbine Control Interface - PksJames IzquierdoNo ratings yet

- Current Sensing Bay o Net Fuse Link Catalog Ca132009enDocument4 pagesCurrent Sensing Bay o Net Fuse Link Catalog Ca132009enGerardo BáezNo ratings yet

- VSD Advantages, Disadvantages, Selection Criteria and Installation TipsDocument9 pagesVSD Advantages, Disadvantages, Selection Criteria and Installation Tipsrbabar2000142No ratings yet

- Cooling Water Quality Rittal 3363_gbDocument1 pageCooling Water Quality Rittal 3363_gbjunkyjunk4495No ratings yet

- Greatork IOM ... MANUALDocument36 pagesGreatork IOM ... MANUALRAMESH RAMASAMY100% (1)

- Selection of Diesel GeneratorDocument3 pagesSelection of Diesel GeneratordankorankoNo ratings yet

- Din 15019-2Document7 pagesDin 15019-2Reda El-AwadyNo ratings yet

- Metering Pump BL CatalogueDocument8 pagesMetering Pump BL Cataloguesathyanand tkNo ratings yet

- Mts Alignment Solution BrochureDocument4 pagesMts Alignment Solution BrochureSWAPNIL PATILNo ratings yet

- Actuador Electrico RotorkDocument16 pagesActuador Electrico RotorkAriel AgueroNo ratings yet

- TK 880 SVC Man Rev e PDFDocument75 pagesTK 880 SVC Man Rev e PDFstefanVasNo ratings yet

- Cummins GTA19 G2spec SheetDocument8 pagesCummins GTA19 G2spec SheetEdwin PinzonNo ratings yet

- Xforce PDocument6 pagesXforce PRAB HFRNo ratings yet

- JETIR1608015Document3 pagesJETIR1608015Raka JoniNo ratings yet

- Technical Note - Foundation Design For High Voltage Induction Motors PDFDocument2 pagesTechnical Note - Foundation Design For High Voltage Induction Motors PDFMashudi FikriNo ratings yet

- Variable Spring SupportsDocument12 pagesVariable Spring SupportsMadhan RajNo ratings yet

- Vibrating Wire Load CellDocument4 pagesVibrating Wire Load Cells pradhanNo ratings yet

- Couplings Type TSK - TSP - Tsa - TSC - TLKDocument4 pagesCouplings Type TSK - TSP - Tsa - TSC - TLKhamadaNo ratings yet

- Optimizing motor operation with inverter drivesDocument26 pagesOptimizing motor operation with inverter drivesCARLOS GONÇALVESNo ratings yet

- Greatork AVA AVAM AVAT AVATM AVAMD Operating ManualDocument52 pagesGreatork AVA AVAM AVAT AVATM AVAMD Operating ManualWhat's UpNo ratings yet

- Zenith mx60Document18 pagesZenith mx60jorge100% (2)

- Manual Varec Series 180 181 Double Port Regulator Varec en en 5197388Document4 pagesManual Varec Series 180 181 Double Port Regulator Varec en en 5197388reneNo ratings yet

- Horizontal Balancing Machines: Series HM4/HM40, HM5/HM50Document4 pagesHorizontal Balancing Machines: Series HM4/HM40, HM5/HM50Samuel TanNo ratings yet

- 80 1143 03 Rev. 07.1 11 430 Man. Opt. 9 PDFDocument68 pages80 1143 03 Rev. 07.1 11 430 Man. Opt. 9 PDFCristi MarianNo ratings yet

- Model G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersDocument4 pagesModel G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersAchraf BoudayaNo ratings yet

- Series LFII Residential SprinklersDocument6 pagesSeries LFII Residential SprinklersAchraf BoudayaNo ratings yet

- Series LFII Residential Flush Pendent Sprinklers 4.2 K-FactorDocument8 pagesSeries LFII Residential Flush Pendent Sprinklers 4.2 K-FactorAchraf BoudayaNo ratings yet

- Series LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorDocument4 pagesSeries LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorAchraf BoudayaNo ratings yet

- Series LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Document8 pagesSeries LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Achraf BoudayaNo ratings yet

- Sprinkler Spray PatternsDocument38 pagesSprinkler Spray PatternsAchraf BoudayaNo ratings yet

- Rociador Ty LDocument8 pagesRociador Ty LOscar Fernandez SanchezNo ratings yet

- Installer Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersDocument4 pagesInstaller Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersAchraf BoudayaNo ratings yet

- Series LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorDocument8 pagesSeries LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorAchraf BoudayaNo ratings yet

- Protect Sprinklers from DamageDocument4 pagesProtect Sprinklers from DamageAchraf BoudayaNo ratings yet

- Majestic Optima: Technical Data SheetDocument3 pagesMajestic Optima: Technical Data Sheetaditarian .pNo ratings yet

- Recessed Escutcheon Installation GuideDocument4 pagesRecessed Escutcheon Installation GuideAchraf BoudayaNo ratings yet

- Jotashield Extreme: Technical Data SheetDocument3 pagesJotashield Extreme: Technical Data SheetAchraf BoudayaNo ratings yet

- Flyer TycoDocument8 pagesFlyer TycoAchraf BoudayaNo ratings yet

- Jotaplast (ID) : Technical Data SheetDocument3 pagesJotaplast (ID) : Technical Data SheetBilher SihombingNo ratings yet

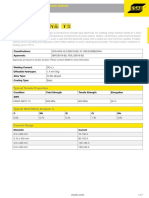

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Weld-On Brackets Type 35Document1 pageWeld-On Brackets Type 35Achraf BoudayaNo ratings yet

- Jotashield Flex: Technical Data SheetDocument3 pagesJotashield Flex: Technical Data SheetAchraf BoudayaNo ratings yet

- Esab Pipeweld 6010R: Classifications: ApprovalsDocument1 pageEsab Pipeweld 6010R: Classifications: ApprovalsAchraf BoudayaNo ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Jotun Essence Easy Clean Matt: Technical Data SheetDocument3 pagesJotun Essence Easy Clean Matt: Technical Data SheetAchraf BoudayaNo ratings yet

- Energy Absorber Type 32Document1 pageEnergy Absorber Type 32Achraf BoudayaNo ratings yet

- Typical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeDocument1 pageTypical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeAchraf BoudayaNo ratings yet

- Snubbers Type 30Document1 pageSnubbers Type 30Achraf BoudayaNo ratings yet

- Telescopic Spring Supports Type 29Document1 pageTelescopic Spring Supports Type 29Achraf BoudayaNo ratings yet

- Snubbers type 31 absorb heavy loads in nuclear installationsDocument1 pageSnubbers type 31 absorb heavy loads in nuclear installationsAchraf BoudayaNo ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Installation Extensions Type 33Document1 pageInstallation Extensions Type 33Achraf BoudayaNo ratings yet

- Rigid Struts Type 39Document1 pageRigid Struts Type 39Achraf BoudayaNo ratings yet

- Sway Braces Type 27Document1 pageSway Braces Type 27Achraf BoudayaNo ratings yet

- TFP720 02 2016Document8 pagesTFP720 02 2016Jun AntonioNo ratings yet

- List of Registered Contractors (Ministry of Public Works)Document234 pagesList of Registered Contractors (Ministry of Public Works)Alihusein AdamjiNo ratings yet

- John Day, Nav Lock Monolith Repair: 90% P&S Option 1: With Anchor ShaftDocument38 pagesJohn Day, Nav Lock Monolith Repair: 90% P&S Option 1: With Anchor Shaftodunze1No ratings yet

- ANNEX 16 - Special Conditions of Quality Management - Rev.1Document3 pagesANNEX 16 - Special Conditions of Quality Management - Rev.1gatot suhermanNo ratings yet

- Hollow Core PDFDocument19 pagesHollow Core PDFAlessandro BicegoNo ratings yet

- Pds Honel Brochure 2022Document5 pagesPds Honel Brochure 2022aj.chat.gpt.coderNo ratings yet

- MCHW Vol 1 Series 2600 Web PDFDocument8 pagesMCHW Vol 1 Series 2600 Web PDFalejandraoy9No ratings yet

- Engineering: Pervious ConcreteDocument6 pagesEngineering: Pervious ConcreteDusmanta Kumar BeheraNo ratings yet

- Img 0008Document1 pageImg 0008shafiq_05No ratings yet

- Smart Construction ReportDocument22 pagesSmart Construction Reportsamyak jainNo ratings yet

- Elasto-Shield Lining Standard Details GuideDocument9 pagesElasto-Shield Lining Standard Details GuideLee WinklerNo ratings yet

- DSR 2011-2012 (Final)Document401 pagesDSR 2011-2012 (Final)shivaji.sarvadeNo ratings yet

- Country Bar Chair Bar HeightDocument5 pagesCountry Bar Chair Bar HeightO'Neil JonesNo ratings yet

- BHA#2 Trip TPN - DZ 20.6 (TPN-223)Document1 pageBHA#2 Trip TPN - DZ 20.6 (TPN-223)Setya AminNo ratings yet

- Of Structures: Design and Drawing T/ Hrs. Part-A 1 Oj Psrt-&. 'E X" .-EDocument2 pagesOf Structures: Design and Drawing T/ Hrs. Part-A 1 Oj Psrt-&. 'E X" .-EkarthiksampNo ratings yet

- Residence PH72 111W57 2022Document3 pagesResidence PH72 111W57 2022mmmNo ratings yet

- DATA BOOK FOR CONSTRUCTION PROJECTSDocument66 pagesDATA BOOK FOR CONSTRUCTION PROJECTSvishnukesavieam10% (1)

- BIKE TIRE RECYCLING MACHINE FOR PAVER BLOCKSDocument7 pagesBIKE TIRE RECYCLING MACHINE FOR PAVER BLOCKSEijay ReyesNo ratings yet

- Nordberg 105 S N 34380Document33 pagesNordberg 105 S N 34380Gilberto Garnica MurilloNo ratings yet

- Conc. Folded SlabDocument17 pagesConc. Folded SlabBenedict CharlesNo ratings yet

- Price List 2022Document2 pagesPrice List 2022dewi juniarNo ratings yet

- CP30 - ManualMCI 70Document187 pagesCP30 - ManualMCI 70Rajan Mullappilly89% (90)

- Boundary Wall Manufacturer in RaipurDocument1 pageBoundary Wall Manufacturer in Raipursiddharth JadhavNo ratings yet

- KS100 KD K Dek Details STD Q2 2013Document20 pagesKS100 KD K Dek Details STD Q2 2013DTS tycNo ratings yet

- Tpbo Paper-2Document32 pagesTpbo Paper-2RaghuNo ratings yet

- Forges and Blowers 1885Document2 pagesForges and Blowers 1885Joe LaPennaNo ratings yet

- 2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsDocument4 pages2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsMORELLI silvioNo ratings yet

- ASHRAE 0-2013 - Guideline The Commissioning ProcessDocument8 pagesASHRAE 0-2013 - Guideline The Commissioning Processhehehe heheheheheheNo ratings yet

- Function Test Report M01B Tank South AcisDocument1 pageFunction Test Report M01B Tank South AciszackteeNo ratings yet

- Assignment 2Document51 pagesAssignment 2Anisha KirlewNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Learning Robotics, with Robotics, by Robotics: Educational RoboticsFrom EverandLearning Robotics, with Robotics, by Robotics: Educational RoboticsNo ratings yet

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- RoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingFrom EverandRoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingNo ratings yet