Professional Documents

Culture Documents

IMG - 0136 PSME Code 2008 128

Uploaded by

Arwyn BermasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMG - 0136 PSME Code 2008 128

Uploaded by

Arwyn BermasCopyright:

Available Formats

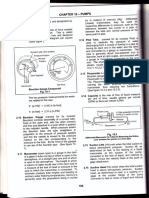

CHAPTER 6 - ELEVATORS, DUMBWAITERS, ESCALATORS AND MOVING WALKS

9.1.13 Handrails. Handrails shall conform to the gravity under any load condition up to and

following: including the rated load condition up to and

including the rated load with the power

a. Number Required. Two moving handrails supply interrupted do not require brakes.

shall be provided on each moving walk.

c. Application of B.rakes. Electrically

Exception: A single moving handrail may be released brakes specified in Sc. 6.9.1.14 (b)

used for moving walks having a slope of 3 shall stop the treadway automatically upon

degrees or less, a speed of (0.36 m/s), or failure of power or when any of the safety

less and a width of 610 mm or less. devices specified in Section 6.9.2 operate-

Brakes on the main drive shaft, if not of the

b. Location. The moving handrail at both the electrically released type, shall be applied

entrance and exit landings shall extend at should the drive chain part.,

normal height not less than 305 mm beyond

the end of the exposed treadway. The point d. Speed Reducers. Speed reducers shall

at which the moving handrail enters or meet the requirements for design and

leaves an enclosure shall be not more than application as established for various types

254 mm above the floor line. in the appropriate Gear Manufacture/s

Practice Standards.

c. Handrail Guards. Hand or finger guards

shall be provided at the points where the The loading shall be considered to be

handrails enter the enclosures. uniform and the service to be 24 hours per

day.

d. Enclosure. The moving handrail return run

and its driving and supporting machinery e. Ghain Drives. Chain drives shall be of the

shall be fully enclosed. types covered by ANSI 829.1 and

ANSI/SAE SP-68.

e. Speed. Each moving handrail shall move in

the same direction and at substantially the When operating at the load rating of tl'e

same speed as the treadway. treadway, the load imposed on such chains

shall not exceed the horsepower rating as

9.1.14 Drive, Motor and Erake established by these standards.

a. Connection Between Drive and Main The loading shall be considered to be

Drive Shaft. The driving machine shall be uniform and the service to be 24 hours per

connected to the riiain drive shaft by toothed day.

gearing, a coupling or a chain.

f. V-Belt Drives. The load imposed on V-belt

b. Brakes Required. Each moving walk shail drives, when operating at the load rating of

be provided with an electrically-released, the treadway, shall not exceed the

mechanically-applied brake capable of horsepower rating as established by

stopping and holding the treadway with any ANSI/RMA IP-20.

load up to the load rating. The brake shall

be located on the driving machine, the main The loading shall be considered to be

drive shaft, or specially attached braking uniform and the service to be 24 hours per

surface attached directly to the treadway. day.

Where a chain is used to connect the driving g. Other Components. Pallet propelling

machine to the main drive shaft, a brake chains and drive and breaking components

shall be provided on the main drive shaft. lt other than those specified shall have a

is not required that this brake be of the factor of safety of not less than 10.

electrically-released type if an electrically-

released brake is provided on the driving

machine. 9.1.15 Supporting Structure. The supporting

structure for the treadway, balustrades, and

Exception [Sec. 6.9.1.14(b)]: Moving walks machinery shall conform to the requirements

which will not run in the down direction bv of the AISC Specification for Design,

128

You might also like

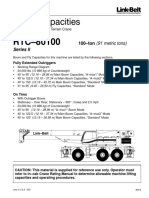

- Link Belt HTC 8670 Charts PDFDocument8 pagesLink Belt HTC 8670 Charts PDFJose MorenoNo ratings yet

- Asme-B30.22 - 02Document41 pagesAsme-B30.22 - 02Brayan Montalban GarciaNo ratings yet

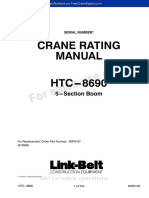

- Manual HTC-8690 PDFDocument243 pagesManual HTC-8690 PDFJennifer Ramos100% (1)

- Operation, Service AND Parts Manual: Single and Double Girder Top Running Bridges With Individual Motor Driven TrucksDocument20 pagesOperation, Service AND Parts Manual: Single and Double Girder Top Running Bridges With Individual Motor Driven TrucksBrad BorgesNo ratings yet

- Fassi/f800 900XP 22Document54 pagesFassi/f800 900XP 22Henrry Huarcaya BallonNo ratings yet

- Lifting Capacities: Series IIDocument28 pagesLifting Capacities: Series IIsrikanthc85No ratings yet

- CRW90 Computer VersionDocument97 pagesCRW90 Computer VersionRogelio Castillo AvalosNo ratings yet

- Link Belt HTC 8660Document8 pagesLink Belt HTC 8660Diana Gabriela VillaNo ratings yet

- IMG - 0132 PSME Code 2008 124Document1 pageIMG - 0132 PSME Code 2008 124Arwyn BermasNo ratings yet

- On Site RTC 80130 R3K4-3399Document308 pagesOn Site RTC 80130 R3K4-3399srikanthc85No ratings yet

- IMG - 0101 PSME Code 2008 92Document1 pageIMG - 0101 PSME Code 2008 92Master JaguarNo ratings yet

- IMG - 0124 PSME Code 2008 115Document1 pageIMG - 0124 PSME Code 2008 115Bugoy2023No ratings yet

- SCC2600ADocument31 pagesSCC2600AWinson LamNo ratings yet

- RTC8040-SII Linkbelt CapsDocument12 pagesRTC8040-SII Linkbelt CapsMongia MoghiNo ratings yet

- Link Belt Rough Terrain Cranes Spec 9d470bDocument96 pagesLink Belt Rough Terrain Cranes Spec 9d470bMauro BatalhaNo ratings yet

- Ankaegybunpedvbjfassi F380a.24 Knuckleboom Crane NetworkDocument66 pagesAnkaegybunpedvbjfassi F380a.24 Knuckleboom Crane NetworkEdgar GonzalezNo ratings yet

- IMG - 0107 PSME Code 2008 98Document1 pageIMG - 0107 PSME Code 2008 98Master JaguarNo ratings yet

- IMG - 0095 PSME Code 2008 86Document1 pageIMG - 0095 PSME Code 2008 86Arwyn BermasNo ratings yet

- Camera Dollies and Crane SafetyDocument2 pagesCamera Dollies and Crane SafetyflorelmagNo ratings yet

- IMG - 0061 PSME Code 2008 50Document1 pageIMG - 0061 PSME Code 2008 50Master JaguarNo ratings yet

- Crawler-Crane-Scc1800 SanyDocument27 pagesCrawler-Crane-Scc1800 SanyIman aprilah100% (1)

- Link-Belt HTC-8690 Truck Crane Operator's Manual PDFDocument55 pagesLink-Belt HTC-8690 Truck Crane Operator's Manual PDFalexis giovanniNo ratings yet

- Grua SANY SC2600 - 260 TonDocument33 pagesGrua SANY SC2600 - 260 TonJosue GonzalezNo ratings yet

- Crane Operations and Safety: Section 12Document8 pagesCrane Operations and Safety: Section 12Khalid ZaeemNo ratings yet

- Fassi Crane: Use and MaintenanceDocument49 pagesFassi Crane: Use and Maintenanceניקולאי איןNo ratings yet

- Gottwald HMK 300 EDocument8 pagesGottwald HMK 300 Ecos jrNo ratings yet

- Crawler CraneDocument51 pagesCrawler CraneDodi IrwandiNo ratings yet

- Fassi Crane: Use and MaintenanceDocument60 pagesFassi Crane: Use and Maintenanceניקולאי איןNo ratings yet

- SANY - Crane SCC - 150 - TonDocument21 pagesSANY - Crane SCC - 150 - TonAlen ShakespeareNo ratings yet

- F380A420AXP.24 S.N. 0037Document72 pagesF380A420AXP.24 S.N. 0037ניקולאי איןNo ratings yet

- Crawler Crane scc1500d PDFDocument21 pagesCrawler Crane scc1500d PDFMONOJ100% (1)

- F160 23 PDFDocument52 pagesF160 23 PDFДенис Черный100% (2)

- Link Belt RTC8060Document12 pagesLink Belt RTC8060Jerome YangNo ratings yet

- Cable Drum Hoist Spec 96B PDFDocument16 pagesCable Drum Hoist Spec 96B PDFAmanNo ratings yet

- 2Document1 page2AbitNo ratings yet

- Operation, Service AND Parts Manual: Single and Double Girder Top Running Bridges With Individual Motor Driven TrucksDocument20 pagesOperation, Service AND Parts Manual: Single and Double Girder Top Running Bridges With Individual Motor Driven TrucksVinothRajagopalNo ratings yet

- ENSAMBLAJE de MONORRIEL - Single Girder Assem Underrun Bridges-113533-92Document28 pagesENSAMBLAJE de MONORRIEL - Single Girder Assem Underrun Bridges-113533-92VaniloNo ratings yet

- Fassi Crane: Use and MaintenanceDocument46 pagesFassi Crane: Use and Maintenanceניקולאי איןNo ratings yet

- Abb CRP AzipodDocument16 pagesAbb CRP AzipodScott_B4U50% (2)

- Greater Working Efficiency and Versatility For Railway Construction and MaintenanceDocument2 pagesGreater Working Efficiency and Versatility For Railway Construction and MaintenanceBubbaNo ratings yet

- Electrical Motor SpecificationDocument3 pagesElectrical Motor Specificationbadmike71No ratings yet

- Vertical Hollow Shaft Motors: Frames RG284 To RG405Document12 pagesVertical Hollow Shaft Motors: Frames RG284 To RG405ayavuzbvsNo ratings yet

- Sinamics V20: The Cost-Effective, Reliable and Easy-To-Use AC Drive For Basic ApplicationsDocument16 pagesSinamics V20: The Cost-Effective, Reliable and Easy-To-Use AC Drive For Basic ApplicationsIonut PorumbNo ratings yet

- Grove Rt640 LCDocument17 pagesGrove Rt640 LCCésar Augusto Quiroga MontenegroNo ratings yet

- Fassi Crane: Use and MaintenanceDocument52 pagesFassi Crane: Use and Maintenanceניקולאי איןNo ratings yet

- Safe Use of CranesDocument33 pagesSafe Use of Craneswasim Akram100% (1)

- Global GVR GVS (Downloaded 170401)Document13 pagesGlobal GVR GVS (Downloaded 170401)Zohaib ZiadNo ratings yet

- E & M of E.O.T.Document10 pagesE & M of E.O.T.bisweswar100% (1)

- Electric Overhead Traveling Crane Erection and Maintenance PDFDocument10 pagesElectric Overhead Traveling Crane Erection and Maintenance PDFSalman KhanNo ratings yet

- Safe Use of Tower Cranes 2Document20 pagesSafe Use of Tower Cranes 2xisijocoNo ratings yet

- Src550h Rough-Terrain CraneDocument11 pagesSrc550h Rough-Terrain CraneRene Ramos MenesesNo ratings yet

- Viking: Product ManualDocument26 pagesViking: Product ManualCristian RobiconNo ratings yet

- IMG - 0128 PSME Code 2008 119Document1 pageIMG - 0128 PSME Code 2008 119Bugoy2023No ratings yet

- HMK300E Brochure English 4 PDFDocument8 pagesHMK300E Brochure English 4 PDFJo2020MeNo ratings yet

- Private Residence Lift For Disabled PersonsDocument6 pagesPrivate Residence Lift For Disabled PersonsDuarte OliveiraNo ratings yet

- Passenger ElevatorDocument17 pagesPassenger ElevatorAnant NimjeNo ratings yet

- Vertical Reciprocating Conveyor: Modular Straddle Style (PM Series) Completion InstructionsDocument6 pagesVertical Reciprocating Conveyor: Modular Straddle Style (PM Series) Completion InstructionsjanetNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- IMG - 0320 MCQ Industrial Plant Engg 223Document1 pageIMG - 0320 MCQ Industrial Plant Engg 223Arwyn BermasNo ratings yet

- IMG - 0313 MCQ Industrial Plant Engg 209Document1 pageIMG - 0313 MCQ Industrial Plant Engg 209Arwyn BermasNo ratings yet

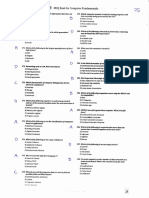

- IMG - 0091 MCQ Bank For Computer Fundamentals MRC 16Document1 pageIMG - 0091 MCQ Bank For Computer Fundamentals MRC 16Arwyn BermasNo ratings yet

- IMG - 0092 MCQ Bank For Computer Fundamentals MRC 17Document1 pageIMG - 0092 MCQ Bank For Computer Fundamentals MRC 17Arwyn BermasNo ratings yet

- IMG - 0291 MCQ Industrial Plant Engg 167Document1 pageIMG - 0291 MCQ Industrial Plant Engg 167Arwyn BermasNo ratings yet

- IMG - 0093 MCQ Bank For Computer Fundamentals MRC 18Document1 pageIMG - 0093 MCQ Bank For Computer Fundamentals MRC 18Arwyn BermasNo ratings yet

- IMG - 0097 MCQ Bank For Computer Fundamentals MRC 22Document1 pageIMG - 0097 MCQ Bank For Computer Fundamentals MRC 22Arwyn BermasNo ratings yet

- IMG - 0100 MCQ Bank For Computer Fundamentals MRC 25Document1 pageIMG - 0100 MCQ Bank For Computer Fundamentals MRC 25Arwyn BermasNo ratings yet

- IMG - 0099 MCQ Bank For Computer Fundamentals MRC 24Document1 pageIMG - 0099 MCQ Bank For Computer Fundamentals MRC 24Arwyn BermasNo ratings yet

- IMG - 0094 MCQ Bank For Computer Fundamentals MRC 19Document1 pageIMG - 0094 MCQ Bank For Computer Fundamentals MRC 19Arwyn BermasNo ratings yet

- IMG - 0095 MCQ Bank For Computer Fundamentals MRC 20Document1 pageIMG - 0095 MCQ Bank For Computer Fundamentals MRC 20Arwyn BermasNo ratings yet

- IMG - 0292 MCQ Industrial Plant Engg 169Document1 pageIMG - 0292 MCQ Industrial Plant Engg 169Arwyn BermasNo ratings yet

- IMG - 0096 MCQ Bank For Computer Fundamentals MRC 21Document1 pageIMG - 0096 MCQ Bank For Computer Fundamentals MRC 21Arwyn BermasNo ratings yet

- IMG - 0210 PSME Code 2008 199Document1 pageIMG - 0210 PSME Code 2008 199Arwyn BermasNo ratings yet

- IMG - 0205 PSME Code 2008 194Document1 pageIMG - 0205 PSME Code 2008 194Arwyn BermasNo ratings yet

- IMG - 0295 MCQ Industrial Plant Engg 175Document1 pageIMG - 0295 MCQ Industrial Plant Engg 175Arwyn BermasNo ratings yet

- IMG - 0208 PSME Code 2008 197Document1 pageIMG - 0208 PSME Code 2008 197Arwyn BermasNo ratings yet

- IMG - 0073 MCQ EE Board Problem 2012 30Document1 pageIMG - 0073 MCQ EE Board Problem 2012 30Arwyn BermasNo ratings yet

- IMG - 0203 PSME Code 2008 192Document1 pageIMG - 0203 PSME Code 2008 192Arwyn BermasNo ratings yet

- IMG - 0209 PSME Code 2008 198Document1 pageIMG - 0209 PSME Code 2008 198Arwyn BermasNo ratings yet

- IMG - 0207 PSME Code 2008 196Document1 pageIMG - 0207 PSME Code 2008 196Arwyn BermasNo ratings yet

- IMG - 0201 PSME Code 2008 190Document1 pageIMG - 0201 PSME Code 2008 190Arwyn BermasNo ratings yet

- IMG - 0077 MCQ EE Board Problem 2012 34Document1 pageIMG - 0077 MCQ EE Board Problem 2012 34Arwyn BermasNo ratings yet

- IMG - 0075 MCQ EE Board Problem 2012 32Document1 pageIMG - 0075 MCQ EE Board Problem 2012 32Arwyn BermasNo ratings yet

- IMG - 0076 MCQ EE Board Problem 2012 33Document1 pageIMG - 0076 MCQ EE Board Problem 2012 33Arwyn BermasNo ratings yet

- IMG - 0078 MCQ EE Board Problem 2012 35Document1 pageIMG - 0078 MCQ EE Board Problem 2012 35Arwyn BermasNo ratings yet

- IMG - 0074 MCQ EE Board Problem 2012 31Document1 pageIMG - 0074 MCQ EE Board Problem 2012 31Arwyn BermasNo ratings yet

- IMG - 0072 MCQ EE Board Problem 2012 29Document1 pageIMG - 0072 MCQ EE Board Problem 2012 29Arwyn BermasNo ratings yet

- IMG - 0079 MCQ EE Board Problem 2012 36Document1 pageIMG - 0079 MCQ EE Board Problem 2012 36Arwyn BermasNo ratings yet

- IMG - 0071 MCQ EE Board Problem 2012 28Document1 pageIMG - 0071 MCQ EE Board Problem 2012 28Arwyn BermasNo ratings yet

- A Four-Wheel-Drive Fully Electric Vehicle Layout With Two-Speed TransmissionsDocument5 pagesA Four-Wheel-Drive Fully Electric Vehicle Layout With Two-Speed TransmissionsG.L. ZortmanNo ratings yet

- Repair Instructions: Zf-Ecolite 6 S 500 TO Level 3 TrucksDocument136 pagesRepair Instructions: Zf-Ecolite 6 S 500 TO Level 3 TrucksCleiton avi0% (1)

- Bx22d Parts Book1Document314 pagesBx22d Parts Book1BlakeNo ratings yet

- Section 21 - Transmission Systems Chapter 1 - Semi-Powershift Transmission (Range Command)Document62 pagesSection 21 - Transmission Systems Chapter 1 - Semi-Powershift Transmission (Range Command)Cristian SterieNo ratings yet

- Section KDocument7 pagesSection KchristopherNo ratings yet

- SANTAFE (DMA) 2013 G 2.4 GDI 4 Wheel Drive (4WD) SystemDocument33 pagesSANTAFE (DMA) 2013 G 2.4 GDI 4 Wheel Drive (4WD) SystemSoporte Tecnico AutoMotrixNo ratings yet

- 6.B. Inggris Transmission 2Document23 pages6.B. Inggris Transmission 2Edwin Anugrah EffendyNo ratings yet

- S221 Transmission System Project ME3145Document20 pagesS221 Transmission System Project ME3145VIỆT LÊ BÁ QUỐCNo ratings yet

- Kalmar DCF360-450CSG Toplift Container Handlers 36 - 45 Tonnes PDFDocument16 pagesKalmar DCF360-450CSG Toplift Container Handlers 36 - 45 Tonnes PDFSARAMQRNo ratings yet

- Keyway and Effect of KeywayDocument3 pagesKeyway and Effect of KeywayHardik ParmarNo ratings yet

- Conveyor Belting Engineering ManualDocument474 pagesConveyor Belting Engineering ManualDavid Londoño OchoaNo ratings yet

- Transmicion R1600Document31 pagesTransmicion R1600Anonymous SxvgPDoEpNo ratings yet

- 13 - Toyota Tercel Sistema de SuspensionDocument57 pages13 - Toyota Tercel Sistema de SuspensionJuan Soto winterNo ratings yet

- Eckart 140 MotorDocument16 pagesEckart 140 MotorLALITHNo ratings yet

- Part Catalogue Suzuki RGXDocument60 pagesPart Catalogue Suzuki RGXAldi Kusumaw100% (1)

- Manual Suspensión Frontal de Nissan X-Trail 2.2.Document18 pagesManual Suspensión Frontal de Nissan X-Trail 2.2.Mario MaldonadoNo ratings yet

- Automobile IntroductionDocument67 pagesAutomobile IntroductionArvind KatyayanNo ratings yet

- Layout & Load DiagDocument9 pagesLayout & Load Diaghpss77No ratings yet

- Manual de Piezas de 845 Sola PDFDocument1,198 pagesManual de Piezas de 845 Sola PDFJHOVANY MENDIVELSO GOMEZ100% (3)

- Pump Series D-H-M-HD-PGH ParkerDocument13 pagesPump Series D-H-M-HD-PGH ParkerDaniel MarNo ratings yet

- Transmisión Marina Twin Disc.Document230 pagesTransmisión Marina Twin Disc.Edwin Enrique Osorio100% (6)

- Mechanical Engineering Department: Lab ReportDocument13 pagesMechanical Engineering Department: Lab ReportLukman HadiNo ratings yet

- IC2238074Document2 pagesIC2238074Fatjet MrrukuNo ratings yet

- 925261.vulic2016 Damping Excitation in TVCDocument14 pages925261.vulic2016 Damping Excitation in TVCAamir BalochNo ratings yet

- MILAN FINAL YEAR REPORT EditDocument56 pagesMILAN FINAL YEAR REPORT EditrekhaNo ratings yet

- Autowini 2020 09 14 BM2020091400510712Document2 pagesAutowini 2020 09 14 BM2020091400510712lebesguesNo ratings yet

- Handouts MD Day 6Document8 pagesHandouts MD Day 6James Ivan AnoreNo ratings yet

- PTCDocument6 pagesPTCAndrey GyrychNo ratings yet

- Hub Reduction, InstallingDocument16 pagesHub Reduction, InstallingwawanNo ratings yet