Professional Documents

Culture Documents

Coralatex C106: Bonding Agent For Cement Mortar System

Uploaded by

Helen ChoiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coralatex C106: Bonding Agent For Cement Mortar System

Uploaded by

Helen ChoiCopyright:

Available Formats

CORALATEX C106

Bonding Agent for Cement Mortar System

水泥添加劑 (防水,黏度,強度及增塑)

1.0 Description

CORALATEX C106 is a kind of SBR copolymer modified admixture aiming at improving both physical and

chemical properties of cement mortars. With CORALATEX C106, your cement products will increase plasticity,

water-tightness, cohesion, workability, impact/abrasive resistance and surface bonding strength. Consequently,

the concrete will have lower shrinkage rate comparing with normal cement mixture. Because of it‘s non-

hydrolyzable nature, it can be applied for those areas where are in continuous contact with water or sea water.

CORALATEX C106 is not harmful substrate and does not require special environmental treatment.

2.0 Physical Data

Appearance Milky White Liquid

Density 1.02 at 20c

PH 8.5 – 10

Non-volatile content 50%

Freezing Point -2c

Solubility 100% in a Water

3.0 Mixing Formulation and Scope of Application: Priming, Concrete Repair, Finishing, Flooring

Components

Scope of Work Formulation Proportion Testing Method HKHA/MIS(2002/2004) CORAL Water Output Estimated

No. Specification Part D Clause 2.1.20 ATEX (Approx.) Coverage

Cement Dry Sand Granite Granite MP C106 (Approx.)

chip 2- chip 5- Cellulos

5mm 10mm e fibers

Quality floor screed or C106-01 By Weight 50KG 125KG ----- ----- 7.5Ltr 15.5Ltr 0.1M3 10M2/10mm

screed repair 5 mm-25 mm thickness

thickness By Volume (Approx.) 1 2 ----- ----- 1 2 ----- -----

10M2/10mm

General floor screed C106-02 By Weight 50KG 150KG ----- ----- 4Ltr 19Ltr 0.1M3 thickness

>25mm

By Volume (Approx.) 1 2.5 ----- ----- 1 5 ----- -----

General floor topping, 10M2/10mm

C106-03 By Weight 50KG 75KG 75KG ----- 7.5Ltr 15.5Ltr 0.1M3 thickness

Topping Repair

15-25 mm By Volume (Approx.) 1 1.25 1.25 ----- 1 2 ----- -----

High strength/heavy duty 10M2/10mm

C106-04 By Weight 50KG 75KG ----- 75KG 4Ltr 19Ltr 0.1M3 thickness

floor screed, render, slab

> 25mm By Volume (Approx.) 1 1.25 ----- 1.25 1 5 ----- -----

Spalling, tiling, floor slab C106-05 By Weight 50KG 125KG ----- ----- 9Ltr 14Ltr 0.1M3 10M2/10mm

installation and thickness

waterproofing rendering By Volume (Approx.) 1 2 ----- ----- 1 1.5 ----- -----

10M2/10mm

C106-06 By Weight 50KG 150KG ----- ----- 4.5Ltr 18.5Ltr 0.1M3 thickness

General floor slab

> 38 mm

By Volume (Approx.) 1 2.5 ----- ----- 1 4 ----- -----

General cement work: 3 15M2/10mm

C106-07 By Weight 50KG 100KG ----- 100KG 4Ltr 19Ltr 0.15M thickness

repair, screeding, render,

slab > 25mm By Volume (Approx.) 1 1.5 ----- 1.5 1 5 ----- -----

2

Fibre Concrete: Quality C106-08 By Weight 50 KG 150 KG ----- ----- 150g 4Ltr 19Ltr 0.13 M3 13M /10mm

Topping, Slab, Roofing, (Quartz Sand) thickness

Spraying application

>50mm By Volume (Approx.) 1 2.5 ----- ----- ----- 1 5 ----- -----

C106-A By Weight 50KG 50KG ----- ----- 25Ltr 10Ltr ----- 1 – 3mm

High strength primer thickness

adhesives layer for mortar

and for tiles installation By Volume (Approx.) 1 0.75 ----- ----- 2.5 1 ----- 105-120m2

* Dry Sand means that those sand without moisture content

* For C106-A adhesion coat, all onward screeding must be applied before it starts to set (such as high compressive strength, impact resistance etc.)

* If there are special requirement of Mortar, you can consult Technical Department for specified formulation.

www.labondhk.com Member Of Master Proofer Corporation LTD www.labondhk.com

LABOND Range of products are designed, manufactured and supplied by MASTER PROOFER COMPANY LTD

Head Office: 139A Hung UK Tsuen, Ping Shan, Yuen Long, N.T., Hong Kong

Tel :(852)2609 2300 Fax:(852) 2609 2309 E-mail:master@masterproofer.com

Every endeavor has been made to ensure that the information given herein is true and reliable, but it is given only for the guidance of our customers. The Company cannot accept any responsibility for loss or damage or

infringement of patent right that may result from the use of the information, due to the possibility of variations of processing or working conditions and of workmanship outside our control.. Users are advised to

Confirm the suitability of the products with their own tests. Any dimensions shown are approximate. Form-S1.1 960401

Form-MKT/LABF/341.01

Control Reference: TCH/C106/290.05 Version:05 page 1 / 4

CORALATEX C106

Bonding Agent For Cement Mortar

4.0 TESTING RESULT OF TECHNICAL PROPERTIES

4.1 Compressive and Flexural Strength at 28th Day

Standard Compressive Strength Flexural Strength Hong Kong MateriaLab

HKHA/MTS BS6319:part 3:1983 N/mm2 Test Report

Formulation (2002/2004) N/mm2

C106-01 70 11.2 040123RM40097(3), (4)

C106-02 38 7.4 040123RM40098(3), (4)

C106-03 55 6.0 040123RM40099(3), (4)

C106-04 76 8.0 040123RM40100(3), (4)

C106-05 71 15.6 040123RM40101(3), (4)

C106-06 31 6.2 040123RM40102(4), (5)

C106-07 70 7.6 040123RM40103(3), (4)

C106-08 57 8.6 IN HOUSE TEST

C106-A 35 13.2 040123RM40104(3), (4)

* The results shown in above table reflect maximum laboratory strengths achieved by formulation, casting and curing cubes in ideal conditions; site strengths may

be vary subject to actual site conditions.

4.2 Curing Shrinkage Rate: Testing Method ASTM C596-89

Formulation: C106-01: MateriaLab Test Report No. 040123RM40097(5)

Age (Days) Average shrinkage of specimen as percent

of effect gauge length (%)

7 0.0046

14 0.0061

21 0.0082

28 0.0087

Formulation: C106-05: MateriaLab Test Report No. 040123RM40101(5)

Age (Days) Average shrinkage of specimen as percent

of effect gauge length (%)

7 0.0068

14 0.0069

21 0.0075

28 0.0084

www.labondhk.com Member Of Master Proofer Corporation LTD www.labondhk.com

Control Reference: TCH/C106/290.05 Version:05 page 2 / 4

CORALATEX C106

Bonding Agent For Cement Mortar

4.3 Adhesion Strength - Testing Method HKHA/MTS (02/04) Specification, Part D Clause 2.1.15 (Method 1)

Formulation: C106-A: MateriaLab Test Report No. 040123RM40104(6)

Formulation N/mm2 Mode of Failure

70% of failure plane was mortar failure.

C106-A 2.1

30% of failure plane was concrete substrate failure.

5% of failure plane was concrete substrate failure.

C106-05 1.7

95% of failure plane was concrete substrate failure.

The results shown in above table reflects maximum laboratory strengths achieved by casting and curing cubes in ideal conditions; site strengths may be vary

subject to actual site conditions.

4.4 Water Permeability Test – CRD-C 48-92 Standard

Formulation: C106-05 : MateriaLab In-House Test : 075231CN80407(2)

Testing Pressure Water Head Testing Direction Coefficient of

Result

(Bar) (Meter) (Bar) Permeability (m/s)

No water

0.5 5 meters Front Pressure #

penetration

4.5 Toxicity Test for Contact with Drink Water per National Standard of China GB/T17219-1998.

Test Report No. W312-0167-2003

Result: Passed, Suitable for direct contact with drink water for Human.

Standard of Tested Value

Unit Result

Content requirement C106 Mortar

Arsenic mg/L ≤0.005 <0.005 Passed

Mercury [Hg] mg/L ≤0.001 <0.001 Passed

Chromium [Cr] mg/L ≤0.005 <0.005 Passed

Cadmium [Cd] mg/L ≤0.001 <0.001 Passed

Lead [Pb] mg/L ≤0.005 <0.005 Passed

Silver [Ag] mg/L ≤0.005 <0.005 Passed

Nitrate (Nitrogen[N]) mg/L ≤2 <2 Passed

Chloroform μg/L ≤6 <6 Passed

Carbon Tetrachloride μg/L ≤0.3 0.1 Passed

Benzo[a]pyrene μg/L ≤0.001 zero Passed

Fluoride [F] mg/L ≤0.1 <0.1 Passed

Zinc [Zn] mg/L ≤0.1 <0.1 Passed

Iron [Fe] mg/L ≤0.02 <0.02 Passed

Copper [Cu] mg/L ≤0.1 <0.1 Passed

Manganese [Mn] mg/L ≤0.01 <0.01 Passed

5.0 PACKAGING

5 liter/Can, 25 liter/ Drum, 150 liter/Bulk Drum.

6.0 TECHNICAL ADVISORY NOTE

7.1 Adhesive Coat: C106-A

This is a compulsory layer to ensure high bond strength between old and new cement substrate. The bond coat is

applied on the dampened surface. Onward mortar has to be applied onto the bond coat before it starts to set.

Otherwise, it must be removed or thoroughly cross hatch scratched and reapplied. Application of adhesive coat

under strong sunlight should be avoided. Bond Coat thickness will be 1-3mm depending on substrate condition.

7.0 SPECIFICATION GUIDE

Clean the substrate to achieve sound, firm and free from dust, oil. Apply “LABOND CORALATEX C106-A” bond

coat (where necessary)onto dampened substrate and then apply LABOND CORALATEX C106 – “Mixing

Formulation No. of paragraph 4.0” according to Manufacturer specification.

www.labondhk.com Member Of Master Proofer Corporation LTD www.labondhk.com

Control Reference: TCH/C106/290.05 Version:05 page 3 / 4

CORALATEX C106

Bonding Agent For Cement Mortar

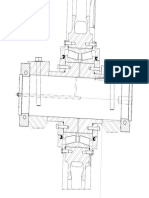

8.0 TYPICAL DRAWINGS

A) Waterproofing Rendering B) Floor screed/paving

C) Concrete Repair D) Broken Edge Repair

C106 – 07

1 coat”C106-A” bond coat

9.0 GENERAL APPLICATION

C106-05 : Waterproofing Screed on Roof

C106-01: Floor screed

C106 -04: Road/Concrete paving

C106-A/01: Grouting and Adhesive for Tiles

C016-05: Spalling Concrete Repair C106-05: Waterproofing Rendering

www.labondhk.com Member Of Master Proofer Corporation LTD www.labondhk.com

Control Reference: TCH/C106/290.05 Version:05 page 4 / 4

You might also like

- Chapt 3 - Collapse of The Fargo Grain ElevatorDocument3 pagesChapt 3 - Collapse of The Fargo Grain ElevatorHelen Choi100% (1)

- Mix Design DLC-DelDocument9 pagesMix Design DLC-DelSanjay Constructions100% (1)

- Geomembrane HDPE Smooth Black PDFDocument1 pageGeomembrane HDPE Smooth Black PDFandriarisetiawan0% (1)

- Design Criteria Manual Metro Light RailDocument423 pagesDesign Criteria Manual Metro Light Railjuan diego100% (1)

- Design of Slabs To EC2Document12 pagesDesign of Slabs To EC2smartman35100% (2)

- Low Cost Sealing of Low Volume Roads EditedDocument22 pagesLow Cost Sealing of Low Volume Roads Editedhaumbamil100% (3)

- 7 JUN 20t&: Department of Public Works and HighwaysDocument14 pages7 JUN 20t&: Department of Public Works and HighwaysFaustino AbadNo ratings yet

- FPMTAGChapter10 ThinOverlaysDocument41 pagesFPMTAGChapter10 ThinOverlayswilliam alachanNo ratings yet

- Coatings 09 00812 s001Document9 pagesCoatings 09 00812 s001cavoixanh89No ratings yet

- Experimental Investigation of Effect ofDocument6 pagesExperimental Investigation of Effect ofNewton GalileoNo ratings yet

- 6.6 Bondit SBRDocument4 pages6.6 Bondit SBRCristal Haze VictoriaNo ratings yet

- Collepadri - Properties of SCC and Flowing ConcreteDocument7 pagesCollepadri - Properties of SCC and Flowing Concrete4493464No ratings yet

- 00 Flowcrete Uk Technical DataDocument2 pages00 Flowcrete Uk Technical DataCAITLIN AndrewNo ratings yet

- Fly Ash Based Geopolymer ConcreteDocument8 pagesFly Ash Based Geopolymer ConcreteSharad KumarNo ratings yet

- Tds Plexus Ma420 EngDocument2 pagesTds Plexus Ma420 EngCarlos SantosNo ratings yet

- Mix Design 2Document15 pagesMix Design 2partha_svnitNo ratings yet

- Ст Дiтрiх Продуктивнiсть пiдсилювача для вапнякового цементу 2016 АНГDocument4 pagesСт Дiтрiх Продуктивнiсть пiдсилювача для вапнякового цементу 2016 АНГCementarNo ratings yet

- TC Statement 13Document1 pageTC Statement 13Amit Raj GuptaNo ratings yet

- TDS-EN-Condur EA1SB (HST) - Rev 014-Oct 21Document2 pagesTDS-EN-Condur EA1SB (HST) - Rev 014-Oct 21LONG LASTNo ratings yet

- Proportioning of A Concrete MixDocument11 pagesProportioning of A Concrete MixSude FilizNo ratings yet

- 3 - Alumina MonlithicsDocument53 pages3 - Alumina Monlithicsengr kazamNo ratings yet

- The Semi-Rigid Pavement With Higher Performances For Roads and Parking ApronsDocument7 pagesThe Semi-Rigid Pavement With Higher Performances For Roads and Parking ApronsDai QimeiNo ratings yet

- 1 - Mix Design - Chuan Lim - g40 s4 (160-210)Document1 page1 - Mix Design - Chuan Lim - g40 s4 (160-210)ronel bayotNo ratings yet

- SCC Class A G40 Concrete MixDocument1 pageSCC Class A G40 Concrete MixWunNaNo ratings yet

- Self Compacting Concrete SCCDocument17 pagesSelf Compacting Concrete SCC8790922772100% (1)

- Repoint MasonryDocument2 pagesRepoint MasonryMarco Antonio Alfaro HernandezNo ratings yet

- Day 2 S2 BNBC 2020Document38 pagesDay 2 S2 BNBC 2020November RainNo ratings yet

- M-15 PCCDocument38 pagesM-15 PCCRaj PandeyNo ratings yet

- Snow CreteDocument2 pagesSnow CreteAndrew PiNo ratings yet

- Finishing Material-Product Testing-SVN - Rev1Document15 pagesFinishing Material-Product Testing-SVN - Rev1HNmaichoiNo ratings yet

- Base Build-Up Urban Pathways 2018Document1 pageBase Build-Up Urban Pathways 2018Ovidiu ChirvaseNo ratings yet

- Rate Analysis For Gypsum Board Ceiling WorksDocument19 pagesRate Analysis For Gypsum Board Ceiling WorksSourav100% (1)

- S 2400 Hot Mix Asphalt ConcreteDocument8 pagesS 2400 Hot Mix Asphalt ConcreteChaudary Azhar SaleemNo ratings yet

- Standard External Base CoatingDocument6 pagesStandard External Base CoatingErich ThomasNo ratings yet

- Rate Analysis For Ceiling WorksDocument15 pagesRate Analysis For Ceiling WorksTax ProffessionalNo ratings yet

- L 310TDS 1Document4 pagesL 310TDS 1Chetan MahajanNo ratings yet

- Wearing Course Type SMA With High Performance With Neat Bitumen, Addition of Fiber-Polymer CompoundDocument7 pagesWearing Course Type SMA With High Performance With Neat Bitumen, Addition of Fiber-Polymer CompoundRajkoNo ratings yet

- Material Consumption PDFDocument10 pagesMaterial Consumption PDFShyamontika Choudhury ChakrabartiNo ratings yet

- Construction Materials (CE 1206) : Bituminous MaterialDocument22 pagesConstruction Materials (CE 1206) : Bituminous Materialvarunsingh214761100% (1)

- 2.2.1 Mixed Metal Oxide Tubular Anodes Rev 1Document2 pages2.2.1 Mixed Metal Oxide Tubular Anodes Rev 1Soltani AliNo ratings yet

- Çimsa Eco White TDS (EN)Document1 pageÇimsa Eco White TDS (EN)Babu NysemereNo ratings yet

- Steel Plates For Extended Painted LifeDocument8 pagesSteel Plates For Extended Painted LifeKYAW SOENo ratings yet

- Polishing Process For Heatcure Fiber Optic Connectors: 1. GeneralDocument4 pagesPolishing Process For Heatcure Fiber Optic Connectors: 1. GeneralAbNo ratings yet

- Zahraaalturaihee, Production Editor, 1Document8 pagesZahraaalturaihee, Production Editor, 1Данило ГадайчукNo ratings yet

- Maincote™ EC-11: Waterborne Elastomeric Acrylic Resin For Industrial Maintenance CoatingsDocument10 pagesMaincote™ EC-11: Waterborne Elastomeric Acrylic Resin For Industrial Maintenance CoatingsLong An ĐỗNo ratings yet

- High Performance Binder in Asphalt Concrete With Neat Bitumen, With PolymersDocument8 pagesHigh Performance Binder in Asphalt Concrete With Neat Bitumen, With PolymersRajkoNo ratings yet

- Technical Data Sheet: Primerless MMA AdhesivesDocument3 pagesTechnical Data Sheet: Primerless MMA AdhesivespronavNo ratings yet

- Rez 3400Document17 pagesRez 3400Elsa FaisalNo ratings yet

- Maccaferri: Paraweb 2SDocument1 pageMaccaferri: Paraweb 2SMohamed HammamiNo ratings yet

- Influence of Sand Ratio On The Fluidity Properties of SCC in CRTS III Type Track SystemDocument6 pagesInfluence of Sand Ratio On The Fluidity Properties of SCC in CRTS III Type Track SystemDastardly HeelNo ratings yet

- ENCE353 Superposition Handout2011Document6 pagesENCE353 Superposition Handout2011Robin ParmarNo ratings yet

- Bitumen Test-Part BDocument31 pagesBitumen Test-Part Bபிரபாகரன் முனிசாமிNo ratings yet

- Procedure Test of Kraft PaperDocument4 pagesProcedure Test of Kraft PaperAhmad Ikhsan KurniantoNo ratings yet

- Espol 38.00 Revised 07032016Document2 pagesEspol 38.00 Revised 07032016Vinay YadavNo ratings yet

- Perlite Con PDFDocument2 pagesPerlite Con PDFAfshin MahpourNo ratings yet

- Sikalastic®-632: Product Data SheetDocument5 pagesSikalastic®-632: Product Data SheetShanaei MiskinNo ratings yet

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Document12 pagesIjciet: International Journal of Civil Engineering and Technology (Ijciet)Eng mohammadNo ratings yet

- Nitobond ArDocument2 pagesNitobond Aradilabad newsNo ratings yet

- Ad20210607 Parking GuyanaDocument7 pagesAd20210607 Parking GuyanaStephan CheongNo ratings yet

- EN9848Document1 pageEN9848Ali md YounusNo ratings yet

- Transocean - C5-I Typical Coating System INDUSTRIALDocument1 pageTransocean - C5-I Typical Coating System INDUSTRIALfpiccoli_4No ratings yet

- Isobond: SBR Bonding AdmixtureDocument3 pagesIsobond: SBR Bonding AdmixtureHussain MarzooqNo ratings yet

- HP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03Document6 pagesHP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03ANDI JAYANo ratings yet

- AIJ Guidelines For Practical Applications of CFD To Pedestrian Wind Environment Around BuildingsDocument13 pagesAIJ Guidelines For Practical Applications of CFD To Pedestrian Wind Environment Around BuildingsHelen ChoiNo ratings yet

- Development of Turbulence Models For Shear Flows BDocument28 pagesDevelopment of Turbulence Models For Shear Flows BHelen ChoiNo ratings yet

- TPU Global COE Program "New Frontier of Education and Research in Wind Engineering"Document38 pagesTPU Global COE Program "New Frontier of Education and Research in Wind Engineering"Helen ChoiNo ratings yet

- Cooperative Project For CFD Prediction of Pedestrian Wind Environment in The Architectural Institute of JapanDocument28 pagesCooperative Project For CFD Prediction of Pedestrian Wind Environment in The Architectural Institute of JapanHelen ChoiNo ratings yet

- Numerical Simulation of Turbulent Flow Over Surface Mounted Obstacles With Sharp Edges and CornersDocument19 pagesNumerical Simulation of Turbulent Flow Over Surface Mounted Obstacles With Sharp Edges and CornersHelen ChoiNo ratings yet

- Recommendations On The Use of CFD in Predicting Pedestrian Wind EnvironmentDocument4 pagesRecommendations On The Use of CFD in Predicting Pedestrian Wind EnvironmentHelen ChoiNo ratings yet

- Computational Fluid Dynamic (CFD) Simulation of Flow Around Tall BuildingsDocument12 pagesComputational Fluid Dynamic (CFD) Simulation of Flow Around Tall BuildingsHelen ChoiNo ratings yet

- Multiprime P940: Multi Purpose Epoxy Prime Sealer (Anti-Abrasion, Anti-Dust)Document1 pageMultiprime P940: Multi Purpose Epoxy Prime Sealer (Anti-Abrasion, Anti-Dust)Helen ChoiNo ratings yet

- Recommendations On The Use of CFD in Wind EngineerDocument12 pagesRecommendations On The Use of CFD in Wind EngineerHelen ChoiNo ratings yet

- Thanetop P772: (抗磨、抗塵、抗滑溜) 1.0 DescriptionDocument1 pageThanetop P772: (抗磨、抗塵、抗滑溜) 1.0 DescriptionHelen ChoiNo ratings yet

- KOBELCO CONSTRUCTION MACHINERY CO.,LTD. Large Size Crawler Cranes Ground Pressure - Outrigger Reaction ForceDocument1 pageKOBELCO CONSTRUCTION MACHINERY CO.,LTD. Large Size Crawler Cranes Ground Pressure - Outrigger Reaction ForceHelen ChoiNo ratings yet

- Aleo 掛墻式浴缸龍頭 - K-72282T 1493088968 - 安裝 PDFDocument2 pagesAleo 掛墻式浴缸龍頭 - K-72282T 1493088968 - 安裝 PDFHelen ChoiNo ratings yet

- Project: Lot8 at Macau: SUBJECT: Calculation For The WindowDocument50 pagesProject: Lot8 at Macau: SUBJECT: Calculation For The WindowHelen ChoiNo ratings yet

- Section Properties Macau CodeDocument26 pagesSection Properties Macau CodeHelen ChoiNo ratings yet

- SPE 134169 Designing and Testing Cement System For SAGD ApplicationDocument12 pagesSPE 134169 Designing and Testing Cement System For SAGD Applicationadvantage025No ratings yet

- Artificial Intelligence in Construction Engineering and ManagementDocument271 pagesArtificial Intelligence in Construction Engineering and ManagementMárcia BibianoNo ratings yet

- Shotcreting Method Statement - RMZ The VaultDocument3 pagesShotcreting Method Statement - RMZ The VaultRakesh ReddyNo ratings yet

- Piles CPWD Specs2009Document31 pagesPiles CPWD Specs2009nipunNo ratings yet

- Catalina Punta Pluma 7495 HRDocument1 pageCatalina Punta Pluma 7495 HRmilenko CortesNo ratings yet

- Dae 15 Y764Document4 pagesDae 15 Y764Gerber GarciaNo ratings yet

- Cantilever BeamDocument5 pagesCantilever Beamkiran_wakchaureNo ratings yet

- Total Quantity of Drinking Water Supplied Per Day: 01 MLD Rate of Supply As Per Norms: 135 LPCD Per Capita Water Supply: 75 LPCDDocument2 pagesTotal Quantity of Drinking Water Supplied Per Day: 01 MLD Rate of Supply As Per Norms: 135 LPCD Per Capita Water Supply: 75 LPCDAlok ThakurNo ratings yet

- Slab Design Calculation PDFDocument2 pagesSlab Design Calculation PDFRandy ViolaNo ratings yet

- RCCDocument22 pagesRCClakshitaNo ratings yet

- C - 15 Concrete Mix Design CementDocument6 pagesC - 15 Concrete Mix Design CementEngineeri TadiyosNo ratings yet

- Residential Driveways Encroachmentsencroachment S: Regulations For Driveway and Encroachment Control 8-1Document4 pagesResidential Driveways Encroachmentsencroachment S: Regulations For Driveway and Encroachment Control 8-1luke elbertNo ratings yet

- Malvern Property News 25/03/2011Document25 pagesMalvern Property News 25/03/2011NQDMSNo ratings yet

- Continental Parts CatalogueDocument29 pagesContinental Parts Cataloguedomdum372No ratings yet

- Washrooms EstimateDocument93 pagesWashrooms EstimateAbu Bakar Muzamil ButtNo ratings yet

- BoronGrades Brochure ENDocument4 pagesBoronGrades Brochure ENIsha KainNo ratings yet

- Cmat 11Document4 pagesCmat 11Emmanuel Cafirma RiveraNo ratings yet

- ADSSC Standard and Typical Drawings Version 3 0Document5 pagesADSSC Standard and Typical Drawings Version 3 0Brv ManNo ratings yet

- HILTI Firestop Systems Specifiers GuideDocument628 pagesHILTI Firestop Systems Specifiers GuidewizaarzNo ratings yet

- 0020 - Iec - CCCW SystemDocument24 pages0020 - Iec - CCCW Systemcrazyboy00720000% (1)

- Noise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverDocument20 pagesNoise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverAvinash JagtapNo ratings yet

- Fulton Mall Redevelopment Plan Downtown FresnoDocument118 pagesFulton Mall Redevelopment Plan Downtown FresnoPaul HermanNo ratings yet

- Loading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Document27 pagesLoading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Muntasir Billah100% (1)

- Ideal Isar He30 Boiler Installation Manual - InstDocument68 pagesIdeal Isar He30 Boiler Installation Manual - InstAdamBeyonceLoweNo ratings yet

- Power of Analytics KPMG - Part 2Document12 pagesPower of Analytics KPMG - Part 2Catalina Maria VladNo ratings yet

- VRF PD Series Outdoor Unit Type GMV-PD: Air Conditioning and HeatpumpsDocument3 pagesVRF PD Series Outdoor Unit Type GMV-PD: Air Conditioning and Heatpumpsdino_pNo ratings yet

- PS Bank Tower, MakatiDocument5 pagesPS Bank Tower, MakatiJhon Micco ErginaNo ratings yet