Professional Documents

Culture Documents

HP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03

Uploaded by

ANDI JAYAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03

Uploaded by

ANDI JAYACopyright:

Available Formats

Jotspec

Technical specification

New construction

EPC: Meindo Elang Indah Name: External Pipeline Coating and Structure

Client: ENI Indonesia Unit ID: Sub contr:

Cons/Eng: Version: 1 Date: 12/3/2015

Project: HP//ENI///Package/ORF ENI Jangkrik - Pipeline Coating

Prepared by: Willy Djainudin - Jotun Paints

2015-12-03 16:47:20 (UTC) Page 1 of 6

Summary

Project HP//ENI///Package/ORF ENI Jangkrik - Pipeline Coating Prepared by Willy Djainudin - Jotun Paints

Customer Approved by Willy Djainudin Version 1

Location Date 12/3/2015

The paint specification(s) include(s) the following positions and areas

Position Area m²

Steel structure and external pipeline 1

Repair Damage exposed to steel structure 1

Repair Damage NOT exposed to steel structure 1

Total 3

Summary of products and volumes

Product Consumption (l)

BARRIER,GREY 0

HARDTOP XP,STD 138 BLUE 0

PENGUARD MIDCOAT,BUFF 1

JOTUN THINNER NO. 10,CLEAR 0

JOTUN THINNER NO. 17,CLEAR 0

Total 2

2015-12-03 16:47:20 (UTC) Page 2 of 6

Technical specification

Project HP//ENI///Package/ORF ENI Jangkrik - Pipeline Coating Prepared by Willy Djainudin - Jotun Paints

Customer Approved by Willy Djainudin Version 1

Location Date 12/3/2015

Position Steel structure and external pipeline ISO 12944-2 category N/A

Substrate Carbon Steel Area 1 m² No. 1

Surface Prep. Surfaces to be coated shall be degreased to ISO 12944-4, Part 6.1.4 Alkaline Cleaning, and abrasive blast cleaned to Sa 2½ (ISO 8501-1) with a

minimum surface profile 45 µm, grade Fine to Medium G, Ry5 (ISO 8503-2).

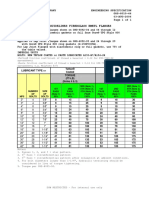

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 10°C 23°C 40°C

coat

Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

BARRIER,GREY FC 100 53 60 113 40 2 h 2 mth 1.5 h 1 mth40 min 7 d 17 15 0 0

PENGUARD MIDCOAT,BUFF FC 100 82 200 244 40 * * 6h 7d 3h 5d 17 15 0 0

HARDTOP XP,STD 138 BLUE FC 100 63 70 111 40 14 h * 7h * 4h * 10 15 0 0

Total 330

Remarks:

2015-12-03 16:47:20 (UTC) Page 3 of 6

Technical specification

Project HP//ENI///Package/ORF ENI Jangkrik - Pipeline Coating Prepared by Willy Djainudin - Jotun Paints

Customer Approved by Willy Djainudin Version 1

Location Date 12/3/2015

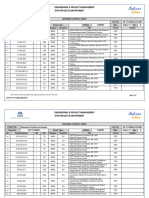

Position Repair Damage exposed to steel structure ISO 12944-2 category N/A

Substrate Carbon Steel Area 1 m² No. 2

Surface Prep. Surfaces to be coated shall be degreased to ISO 12944-4, Part 6.1.4 Alkaline Cleaning, and abrasive blast cleaned to Sa 2½ (ISO 8501-1) with a

minimum surface profile 45 µm, grade Fine to Medium G, Ry5 (ISO 8503-2).

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 10°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

BARRIER,GREY FC 100 53 60 113 40 2 h 2 mth 1.5 h 1 mth40 min 7 d 17 15 0 0

PENGUARD MIDCOAT,BUFF FC 100 82 200 244 40 * * 6h 7d 3h 5d 17 15 0 0

HARDTOP XP,STD 138 BLUE FC 100 63 50 79 40 14 h * 7h * 4h * 10 15 0 0

Total 310

Remarks:

2015-12-03 16:47:20 (UTC) Page 4 of 6

Technical specification

Project HP//ENI///Package/ORF ENI Jangkrik - Pipeline Coating Prepared by Willy Djainudin - Jotun Paints

Customer Approved by Willy Djainudin Version 1

Location Date 12/3/2015

Position Repair Damage NOT exposed to steel structure ISO 12944-2 category N/A

Substrate Carbon Steel Area 1 m² No. 3

Surface Prep. Surfaces shall be prepared by mechanical preparation methods to ISO 8501-1 St 3 to ensure the surface is correctly prepared by removing loose

residual corrosion, failed coatings and other contamination so that what remains is intact and well adhered to the surface.

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 10°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

PENGUARD MIDCOAT,BUFF FC 100 82 200 244 40 * * 6h 7d 3h 5d 17 15 0 0

HARDTOP XP,STD 138 BLUE FC 100 63 50 79 40 14 h * 7h * 4h * 10 15 0 0

Total 250

Remarks:

2015-12-03 16:47:20 (UTC) Page 5 of 6

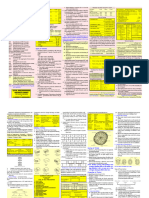

* please refer to the relevant technical datasheets and AG application guide for recoating and curing conditions

NR: Not recommended for this exposure or generic type:

Unless otherwise agreed in writing, all product supplied and technical advice given by us are subject to our standard terms and conditions of sale. In the event that supplies are made and

technical advice is given by one of our associated companies or dealers, then such supplies and technical advice shall be subject to the standard terms of sale of that company, a copy of which

is available upon request. The given data must be considered as guidelines only, the figures in some columns may be rounded. Drying times and paint consumptions may vary depending on

actual conditions.

For updated information about our products please refer to our web site at www.jotun.com

2015-12-03 16:47:20 (UTC) Page 6 of 6

You might also like

- P68 M13 Painting Documents PDFDocument708 pagesP68 M13 Painting Documents PDFJohn TerryNo ratings yet

- !JotTest Resist 86 TestReport Pull-OffDocument3 pages!JotTest Resist 86 TestReport Pull-OffMaricelSoledadTorrijosZuñigaNo ratings yet

- HSB - Hydro-Slurry BlastingDocument7 pagesHSB - Hydro-Slurry BlastingbalangceNo ratings yet

- Dimensions and Dimensional Tolerances of Straight Tees, NPS 1 - 2 To NPS 48, ASME B16Document4 pagesDimensions and Dimensional Tolerances of Straight Tees, NPS 1 - 2 To NPS 48, ASME B16groshan20No ratings yet

- BS Flange Tables EDocument3 pagesBS Flange Tables ERashedul HasanNo ratings yet

- CX500 Hoists PDFDocument2 pagesCX500 Hoists PDFmiltonc100% (1)

- CEILCOTE 505 Coroline.Document2 pagesCEILCOTE 505 Coroline.stuart3962No ratings yet

- Alpha HoistsDocument2 pagesAlpha HoistsminakirolosNo ratings yet

- Extra Work ModelDocument2 pagesExtra Work ModelkathalyogiNo ratings yet

- JSA For Confined Space 20 12 2019 - TS3Document5 pagesJSA For Confined Space 20 12 2019 - TS3narasimhamurthy414No ratings yet

- Comment Response Sheet of Surface Preparation and Painting ProcedureDocument22 pagesComment Response Sheet of Surface Preparation and Painting ProcedureAgung PrasetyooNo ratings yet

- Midcoat Msds Comp ADocument17 pagesMidcoat Msds Comp AajuhaseenNo ratings yet

- Dfy - Coating Quality Key PointsDocument1 pageDfy - Coating Quality Key PointsMohammed SadiqNo ratings yet

- PM10 Emissions from Abrasive Blasting of SteelDocument6 pagesPM10 Emissions from Abrasive Blasting of Steellara_rajkumar667No ratings yet

- Jotachar Approved Primer and Topcoat List: Important InformationDocument5 pagesJotachar Approved Primer and Topcoat List: Important InformationNurmalinda SihombingNo ratings yet

- Equipment Audit Sheet 23jan2015Document36 pagesEquipment Audit Sheet 23jan2015michaelnoiNo ratings yet

- 344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel StructureDocument327 pages344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel Structurej f100% (1)

- Tools & Consumables Consumption Report Rev 1Document6 pagesTools & Consumables Consumption Report Rev 1Mihai CozmaNo ratings yet

- F02 Project Status Purchased Parts QR83 2011 Version 1-0-01Document3 pagesF02 Project Status Purchased Parts QR83 2011 Version 1-0-01sujay13780No ratings yet

- Amal Hrsg-1 Project - Material Tracking Sheet: Procurement Manufacturing & Delivery StatusDocument4 pagesAmal Hrsg-1 Project - Material Tracking Sheet: Procurement Manufacturing & Delivery StatusNadim JilaniNo ratings yet

- Surface Prep Essential for Coating SuccessDocument6 pagesSurface Prep Essential for Coating SuccessAneesh JoseNo ratings yet

- 408.003 Monthly Paint Consumption ReportDocument3 pages408.003 Monthly Paint Consumption ReportCelal BozdoganNo ratings yet

- NORSOK Coating System No. 1 Carbon Steel 120CDocument5 pagesNORSOK Coating System No. 1 Carbon Steel 120CSam Jose100% (1)

- Worksheet Links Worksheet Links: Tool Links Internet LinksDocument386 pagesWorksheet Links Worksheet Links: Tool Links Internet Linkssg1967No ratings yet

- Material Unit CostsDocument4 pagesMaterial Unit CostsBonnie BalaguerNo ratings yet

- Painting Report FormatDocument1 pagePainting Report Formatrengaps0% (1)

- Seoul, Korea: Estimation SheetDocument6 pagesSeoul, Korea: Estimation SheetHRK65No ratings yet

- GS-09 (Painting) PDFDocument22 pagesGS-09 (Painting) PDFSarbendu PaulNo ratings yet

- CoatingCalculation DFT WFT LOSSDocument2 pagesCoatingCalculation DFT WFT LOSSnirmalmthp100% (1)

- FRP Webinar Highlights Strengthening with Composite MaterialsDocument26 pagesFRP Webinar Highlights Strengthening with Composite MaterialsAhmed AliNo ratings yet

- Paint consumption calculation summaryDocument10 pagesPaint consumption calculation summaryImam Situmeang100% (1)

- Site Weekly Cost Report-MounirDocument50 pagesSite Weekly Cost Report-MounirAna Caroline BritoNo ratings yet

- Paint Report PL1862Document1 pagePaint Report PL1862Mayur BandukeNo ratings yet

- Design No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263Document3 pagesDesign No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- Cafco Fendolite Mii Application Guidelines PDFDocument23 pagesCafco Fendolite Mii Application Guidelines PDFTanmay GorNo ratings yet

- MATERIAL TRACKING LISTDocument2 pagesMATERIAL TRACKING LISTgopaltryNo ratings yet

- SR - No Description QtyDocument12 pagesSR - No Description QtyBoyzannazNo ratings yet

- M3 U3 Bill of MaterialsDocument14 pagesM3 U3 Bill of MaterialsPotchinoParuntongNo ratings yet

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanDocument4 pagesDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanNo ratings yet

- Progress Summary: Piping Pre FabricationDocument9 pagesProgress Summary: Piping Pre FabricationWilson SombrioNo ratings yet

- Sky Climber SparesDocument7 pagesSky Climber SparesshambhoiNo ratings yet

- Painting SpecificationDocument19 pagesPainting SpecificationArunkumar Rackan0% (1)

- Torque Guidelines Fiberglass Emetl FlangesDocument1 pageTorque Guidelines Fiberglass Emetl FlangesvesselyNo ratings yet

- GAP Guidelines: Fireproofing For Hydrocarbon Fire ExposuresDocument7 pagesGAP Guidelines: Fireproofing For Hydrocarbon Fire ExposuresAlbert GuiNo ratings yet

- TechnimontDocument3 pagesTechnimonttonoxtonoxNo ratings yet

- Project Plan and Actuals TrackerDocument5 pagesProject Plan and Actuals TrackerRiaz MohammedNo ratings yet

- Finishing Materials & Cladding: Industrial InsulationDocument19 pagesFinishing Materials & Cladding: Industrial InsulationTariq Latif SaeedNo ratings yet

- Tank Installation Daily ReportDocument1 pageTank Installation Daily ReportSaddem HadfiNo ratings yet

- Al-Batin Method of StatmentDocument24 pagesAl-Batin Method of StatmentFo MuNo ratings yet

- Method Statement For Blasting and PaintingDocument11 pagesMethod Statement For Blasting and PaintingAbdullah Abdullah100% (2)

- Engineering & Project Management Site Projects DepartmentDocument7 pagesEngineering & Project Management Site Projects Departmentsmart_onyx17No ratings yet

- Paint Store Inventory 06 Dec 2019Document1 pagePaint Store Inventory 06 Dec 2019Somesh IngaleNo ratings yet

- Reliable: Pipeline Coating SolutionsDocument9 pagesReliable: Pipeline Coating Solutionsshoaib1985No ratings yet

- Corrosion Protection MeasuresDocument17 pagesCorrosion Protection MeasuresIliyanPetrov100% (1)

- Fire Hydrant and Detection System Installation Work OrderDocument15 pagesFire Hydrant and Detection System Installation Work OrderSizerCircuitNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- 6 Sigma PaintDocument38 pages6 Sigma PaintAnonymous fvO1W3No ratings yet

- Shapeshell - Steel Structure Painting Technical Specification 2020-02-10 PDFDocument4 pagesShapeshell - Steel Structure Painting Technical Specification 2020-02-10 PDFmorisNo ratings yet

- Shapeshell - Steel Structure Painting Technical Specification 2020-02-10Document4 pagesShapeshell - Steel Structure Painting Technical Specification 2020-02-10morisNo ratings yet

- Paint - Technical Specification 2022-01...Document1 pagePaint - Technical Specification 2022-01...Weng Hoe ChooNo ratings yet

- Technical Data Sheet Epoxy CoatingDocument4 pagesTechnical Data Sheet Epoxy CoatingANDI JAYANo ratings yet

- Technical Data Sheet Epoxy CoatingDocument4 pagesTechnical Data Sheet Epoxy CoatingANDI JAYANo ratings yet

- HP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03Document6 pagesHP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03ANDI JAYANo ratings yet

- HP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03Document6 pagesHP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03ANDI JAYANo ratings yet

- RiskWISE For Process Plant 2017Document2 pagesRiskWISE For Process Plant 2017ANDI JAYANo ratings yet

- Jotapipe DL 3002 Technical Data SheetDocument2 pagesJotapipe DL 3002 Technical Data SheetANDI JAYANo ratings yet

- Australian/New Zealand Standard™: Failure Modes and Effects Analysis (Fmea and Fmeca)Document13 pagesAustralian/New Zealand Standard™: Failure Modes and Effects Analysis (Fmea and Fmeca)ANDI JAYANo ratings yet

- IV. METAL ALLOYS: Common Types & UsesDocument8 pagesIV. METAL ALLOYS: Common Types & UsesDhina CasungcadNo ratings yet

- Design and Fabrication of Spur Gear Using Palm Fiber and Aluminum CompositeDocument21 pagesDesign and Fabrication of Spur Gear Using Palm Fiber and Aluminum Compositesabhari_ramNo ratings yet

- Civil Engineering Chart Subjectwise in A3 SizeDocument16 pagesCivil Engineering Chart Subjectwise in A3 SizeEr Aman RaahiNo ratings yet

- Versatility of Ribbond in Contemporary Dental PracDocument6 pagesVersatility of Ribbond in Contemporary Dental PracLUCERONo ratings yet

- Ragdoll Package 2018Document20 pagesRagdoll Package 2018Ora Wisteria100% (1)

- Types of Steel PDFDocument8 pagesTypes of Steel PDFIyappan MuruganNo ratings yet

- Asphalt Concrete Report Final VersionDocument11 pagesAsphalt Concrete Report Final VersionLorraine Custodio100% (1)

- Analytical Chemistry Reaction ObservationsDocument2 pagesAnalytical Chemistry Reaction ObservationsjoycepeterNo ratings yet

- Partial Replacement of Cement With Marble Powder: BY P.Rohith S.Niharika A.Ranjith B.Akshay P.JeevanDocument25 pagesPartial Replacement of Cement With Marble Powder: BY P.Rohith S.Niharika A.Ranjith B.Akshay P.Jeevankayyum khanNo ratings yet

- BILL OF MATERIALS SampleDocument2 pagesBILL OF MATERIALS SampleARIESNo ratings yet

- 4th Week3Document14 pages4th Week3Jerome Dela CruzNo ratings yet

- Sample Drawings 5Document9 pagesSample Drawings 5Sherwin DominguezNo ratings yet

- Item Brief Description of Item No No L B D Qty No: Plinth BeamsDocument4 pagesItem Brief Description of Item No No L B D Qty No: Plinth BeamsRakshit JainNo ratings yet

- Chapter One Lecture 1 On Introduction To Textile Fibers Bahir Dar University (Eitex)Document53 pagesChapter One Lecture 1 On Introduction To Textile Fibers Bahir Dar University (Eitex)aqsa imranNo ratings yet

- II.01.A. DRAEGER HPS - 3500 - Technical - Data - Sheet - ENDocument7 pagesII.01.A. DRAEGER HPS - 3500 - Technical - Data - Sheet - ENBayu NawungkridoNo ratings yet

- 01 - Transferencia de Masa Por Difusion PDFDocument13 pages01 - Transferencia de Masa Por Difusion PDFNinoska EspinozaNo ratings yet

- Connector LEMO M - SeriesDocument44 pagesConnector LEMO M - SeriesAmilcar LlantadaNo ratings yet

- Hydrocarbon For JEE Main and Advanced (ALP)Document10 pagesHydrocarbon For JEE Main and Advanced (ALP)Er. Vineet Loomba (IIT Roorkee)No ratings yet

- Pro Catalog FinalDocument12 pagesPro Catalog FinalPatrick NowickNo ratings yet

- Cbse Sample Paper For Class 11 ChemistryDocument11 pagesCbse Sample Paper For Class 11 ChemistryAshutosh RautNo ratings yet

- Quick Lime Powder ReportDocument6 pagesQuick Lime Powder Reportnasir ahmedNo ratings yet

- PT Pindo Deli Company Case Study PDFDocument6 pagesPT Pindo Deli Company Case Study PDFChiko Jrs NTu C'RickoNo ratings yet

- Maintenance Painting of Steelwork Manual Provides GuidanceDocument33 pagesMaintenance Painting of Steelwork Manual Provides GuidancerohanZorbaNo ratings yet

- Industrial Practice Report on Bashundhara Paper MillsDocument154 pagesIndustrial Practice Report on Bashundhara Paper MillsMubashwir Billah KhanNo ratings yet

- Intermolecular Forces and Phase Diagrams PracticeDocument10 pagesIntermolecular Forces and Phase Diagrams PracticeKyla BaysaNo ratings yet

- Pantile Church Instructions PDF PDFDocument1 pagePantile Church Instructions PDF PDFAlvaro ValderramaNo ratings yet

- Scci - Irr PT Bukit Asam - Maret 2021Document9 pagesScci - Irr PT Bukit Asam - Maret 2021wahyusetyawanNo ratings yet

- CAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic EtherDocument2 pagesCAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic Ethermohsin shaikh100% (1)

- Report On Bridge Decks Free of Steel Reinforcement: ACI ITG-3-04Document21 pagesReport On Bridge Decks Free of Steel Reinforcement: ACI ITG-3-04pechugonisNo ratings yet