Professional Documents

Culture Documents

Technical Data Sheet: Forged Steel Gate, Globe, and Check Valves

Uploaded by

Cherbee FerrerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet: Forged Steel Gate, Globe, and Check Valves

Uploaded by

Cherbee FerrerCopyright:

Available Formats

brands you trust.

Technical Data Sheet

Forged Steel

Gate, Globe, and Check Valves

Crane ChemPharma & Energy www.cranecpe.com

Index

Gate Valves.......................................................................3-7

BOMs................................................................................ 3

Class 800....................................................................4-5

Class 1500..................................................................6-7

Globe Valves..................................................................8-14

BOMs................................................................................ 8

Class 800..................................................................9-10

Class 1500..............................................................11-12

Y-Globe Valves................................................... 13-14

Check Valves............................................................... 15-20

BOMs..............................................................................15

Piston Check....................................................... 16-18

Swing Check.......................................................19-20

Pressure Temperature..................................................21

How to Order................................................................... 22

Notes.................................................................................... 23

2 Crane ChemPharma & Energy www.cranecpe.com

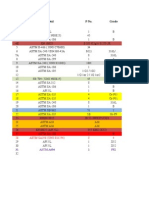

Forged Steel Gate Valves BOMs

Gate Valves

PART

ITEM A105N/Trim 8 A105N/Trim 5 F11/Trim 5 F22/Trim 5 F91/Trim 8 F304/304 F316/Trim 12 F316L/Trim 12

NAME

ASTM A 182 ASTM A 182 ASTM A 182

1 BODY ASTM A105N ASTM A105N ASTM A 182 F11 ASTM A 182 F22 ASTM A 182 F91

F-304 F-316 F-316L

ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE

2 SEAT RING

SS-410 + ST.6 SS-410 + ST.6 SS-410 + ST.6 SS-410 + ST.6 SS-410 + ST.6 SS-304 SS-316 + ST.6 SS-316 + ST.6

ASTM A 217 GR. ASTM A 217 GR. ASTM A 217 GR. ASTM A 217 GR. ASTM A 217 GR. ASTM A 351 GR. ASTM A 351 GR. ASTM A 351 GR.

3 WEDGE

CA-15 CA-15 + ST.6 CA-15 + ST.6 CA-15 + ST.6 CA-15 CF8 CF8M CF8M

ASTM A 182 GR. ASTM A 182 GR. ASTM A 182 GR. ASTM A 182 GR. ASTM A 182 GR. ASTM A 182 ASTM A 182 ASTM A 182

4 STEM

F6a F6a F6a F6a F6a F-304 F-316 F-316

SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL

5 GASKET WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED +

GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE

ASTM A 182 ASTM A 182 ASTM A 182

6 BONNET ASTM A105N ASTM A105N ASTM A 182 F11 ASTM A 182 F22 ASTM A 182 F91

F-304 F-316 F-316L

ASTM A 193 ASTM A 193 ASTM A 193 GR. ASTM A 193 GR. ASTM A 193 GR. ASTM A 193 ASTM A 193 GR. ASTM A 193 GR.

7 HEX BOLT

GR. B7 GR. B7 B16 B16 B16 GR. B8 B8M B8M

EYE BOLT ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE

8

PIN SS-410 SS-410 SS-410 SS-410 SS-410 SS-304 SS-316 SS-316

GLAND ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE

9

BUSH SS-410 SS-410 SS-410 SS-410 SS-410 SS-304 SS-316 SS-316

ASTM A 193 ASTM A 193 ASTM A 193 ASTM A 193 ASTM A 193 ASTM A 193 ASTM A 193 GR. ASTM A 193 GR.

10 EYE BOLT

GR. B7 GR. B7 GR. B7 GR. B7 GR. B7 GR. B8 B8M B8M

GLAND ASTM A 182 ASTM A 182 ASTM A 182

11 ASTM A105N ASTM A105N ASTM A105N ASTM A105N ASTM A105N

FLANGE F-304 F-316 F-316

EYE BOLT ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 GR. ASTM A 194 GR.

12 ASTM A 194 GR. 8

NUT GR. 2H GR. 2H GR. 2H GR. 2H GR. 2H 8M 8M

YOKE ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR.

13

SLEEVE SS-416 SS-416 SS-416 SS-416 SS-416 SS-303 SS-303 SS-303

ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 GR. ASTM A 194 GR. ASTM A 194 GR.

14 STEM NUT

GR. 2H GR. 2H GR. 2H GR. 2H GR. 2H 8M 8M 8M

NAME

15 STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL

PLATE

HAND

16 MI / SGIRON MI / SGIRON MI / SGIRON MI/SGIRON MI/SGIRON MI / SGIRON MI / SGIRON MI / SGIRON

WHEEL

GLAND FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE

17

PACKING GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS

18 BACK SEAT INTEGRAL INTEGRAL INTEGRAL INTEGRAL INTEGRAL INTEGRAL INTEGRAL INTEGRAL

www.cranecpe.com Crane ChemPharma & Energy 3

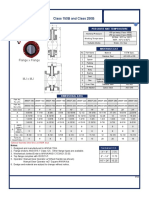

Forged Steel Gate Valve

Class 800 • Conventional Port • NPT

Figure Number: LB3604XUT Materials of Construction

• Gate Valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING ASTM A 276 TYPE SS-410 + ST.6

• OS&Y

3 WEDGE ASTM A 217 GR. CA-15

• NPT Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP C H OPEN H CLOSE ϴWH

3⁄8 *003 3.3 2.87 0.25 0.55 5.94 5.31 3.39

1/2 *004 3.3 2.87 0.37 0.55 5.94 5.31 3.39

3/4 *006 3.96 3.15 0.50 0.63 6.18 5.39 3.39

1 *010 6.82 3.94 0.69 0.79 7.32 6.38 4.57

1 1/4 *012 13.86 4.72 0.94 0.79 9.33 7.91 5.91

1 1/2 *014 13.42 4.72 1.13 0.94 9.33 7.91 5.91

2 *020 18.26 5.12 1.44 1.02 10.55 8.78 5.91

Technical Requirements

1. Design and Manufacture conform to API 602 Performance Standard

2. Test and Inspect conform to API 598

3. Face-to-face dimension conform to manufacturer's standard Class 800

4. NPT ends conform to ANSI B1.20.1 Shell/Body 3000 PSI

5. Compliant to API 624 for low emissions Hydro Test Pressure Seat 2175 PSI

Back Seat 2175 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

4 Crane ChemPharma & Energy www.cranecpe.com

Forged Steel Gate Valve

Class 800 • Conventional Port • Socket Weld

Figure Number: LB3604XUW Materials of Construction

• Gate Valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING ASTM A 276 TYPE SS-410 + ST.6

• OS&Y

3 WEDGE ASTM A 217 GR. CA-15

• Socket Weld Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP ϴA B H OPEN H CLOSE ϴWH

3/8 *003 3.3 2.87 0.25 0.69 0.37 5.90 5.31 3.39

1/2 *004 3.3 2.87 0.37 0.86 0.37 5.90 5.31 3.39

3/4 *006 3.96 3.14 0.50 1.07 0.49 6.18 5.39 3.39

1 *010 6.82 3.93 0.69 1.33 0.49 7.32 6.38 4.57

1 1/4 *012 13.86 4.72 0.94 1.68 0.49 9.33 7.91 5.91

1 1/2 *014 13.42 4.72 1.13 1.92 0.49 9.33 7.91 5.91

2 *020 18.26 5.12 1.44 2.41 0.63 10.55 8.78 5.91

Technical Requirements

1. Design and Manufacture conform to API 602 Performance Standard

2. Inspection and test as per API 598

3. Face-to-face dimension conform to manufacturer's standard Class 800

4. SW ends conform to ASME B16.11 Shell/Body 3000 PSI

5. Compliant to API 624 for low emissions Hydro Test Pressure Seat 2175 PSI

Back Seat 2175 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

www.cranecpe.com Crane ChemPharma & Energy 5

Forged Steel Gate Valve

Class 1500 • Conventional Port • NPT

Figure Number: LB3804XUT Materials of Construction

• Gate valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING ASTM A 276 TYPE SS-410 + ST.6

• OS&Y

3 WEDGE ASTM A 217 GR. CA-15

• NPT Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP C H OPEN H CLOSE ϴWH

1/2 *004 4.8 3.15 0.37 0.55 5.94 5.43 3.39

3/4 *006 8.3 3.94 0.5 0.63 7.01 6.38 4.57

1 *010 12.1 4.72 0.63 0.79 8.94 8.15 5.91

1 1/4 *012 14.9 4.72 0.87 0.79 8.94 8.15 5.91

1 1/2 *014 20.9 5.12 1.06 0.94 10.08 8.81 5.91

2 *020 49.5 5.51 1.37 1.02 11.93 10.35 9.84

Technical Requirements

Performance Standard

1. Design and Manufacture conform to API 602

2. Test and Inspect conform to API 598 Class 1500

3. Face-to-face dimension conform to manufacturer's standard Shell/Body 5550 PSI

4. NPT ends conform to ANSI B1.20.1 Hydro Test Pressure Seat 4125 PSI

5. Compliant to API 624 for low emissions Back Seat 4125 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

6 Crane ChemPharma & Energy www.cranecpe.com

Forged Steel Gate Valve

Class 1500 • Conventional Port • Socket Weld

Figure Number: LB3804XUW Materials of Construction

• Gate Valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING ASTM A 276 TYPE SS-410 + ST.6

• OS&Y

3 WEDGE ASTM A 217 GR. CA-15

• Socket Weld Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP ϴA B H OPEN H CLOSE ϴWH

3/8 *003 4.8 2.87 0.25 0.69 0.37 5.90 5.43 3.39

1/2 *004 4.8 3.14 0.37 0.86 0.37 5.90 5.43 3.39

3/4 *006 8.3 3.93 0.5 1.07 0.49 7.01 6.38 4.57

1 *010 12.1 4.72 0.63 1.33 0.49 8.94 8.15 5.91

1 1/4 *012 14.9 4.72 0.87 1.68 0.49 8.94 8.15 5.91

1 1/2 *014 20.9 5.12 1.06 1.92 0.49 10.08 8.82 5.91

2 *020 49.5 5.51 1.37 2.41 0.63 11.93 10.35 9.84

Technical Requirements

1. Design and Manufacture conform to API 602 Performance Standard

2. Inspection and test as per API 598

3. Face-to-face dimension conform to manufacturer's standard Class 1500

4. SW ends conform to ASME B16.11 Shell/Body 5550 PSI

5. Compliant to API 624 for low emissions Hydro Test Pressure Seat 4125 PSI

Back Seat 4125 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

www.cranecpe.com Crane ChemPharma & Energy 7

Forged Steel Globe Valves BOMs

Globe Valves

PART

ITEM A105N/Trim 8 A105N/Trim 5 F11/Trim 5 F22/Trim 5 F91/Trim 8 F304/304 F316/Trim 12 F316L/Trim 12

NAME

ASTM A 182 ASTM A 182 ASTM A 182

1 BODY ASTM A105N ASTM A105N ASTM A 182 F11 ASTM A 182 F22 ASTM A 182 F91

F-304 F-316 F-316L

ASTM A 182 ASTM A 182

ASTM A 182

2 SEAT RING INTEGRAL + ST.6 INTEGRAL + ST.6 INTEGRAL + ST.6 INTEGRAL + ST.6 INTEGRAL + ST.6 F-316 INTEGRAL F-316L INTEGRAL

F-304 INTEGRAL

+ ST.6 + ST.6

WEDGE/ ASTM A 217 GR. ASTM A 217 GR. ASTM A 217 GR. ASTM A 217 GR. ASTM A 217 GR. ASTM A 351 GR. ASTM A 351 GR. ASTM A 351 GR.

3

PLUG CA-15 CA-15 + ST.6 CA-15 + ST.6 CA-15 + ST.6 CA-15 CF8 CF8M CF8M

ASTM A 182 GR. ASTM A 182 GR. ASTM A 182 GR. ASTM A 182 GR. ASTM A 182 GR. ASTM A 182 ASTM A 182 ASTM A 182

4 STEM

F6a F6a F6a F6a F6a F-304 F-316 F-316

SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL

5 GASKET WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED +

GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE

ASTM A 182 ASTM A 182 ASTM A 182

6 BONNET ASTM A105N ASTM A105N ASTM A 182 F11 ASTM A 182 F22 ASTM A 182 F91

F-304 F-316 F-316L

ASTM A 193 ASTM A 193 ASTM A 193 GR. ASTM A 193 GR. ASTM A 193 GR. ASTM A 193 ASTM A 193 GR. ASTM A 193 GR.

7 HEX BOLT

GR. B7 GR. B7 B16 B16 B16 GR. B8 B8M B8M

EYE BOLT ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE

8

PIN SS-410 SS-410 SS-410 SS-410 SS-410 SS-304 SS-316 SS-316

GLAND ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE

9

BUSH SS-410 SS-410 SS-410 SS-410 SS-410 SS-304 SS-316 SS-316

ASTM A 193 ASTM A 193 ASTM A 193 ASTM A 193 ASTM A 193 ASTM A 193 ASTM A 193 GR. ASTM A 193 GR.

10 EYE BOLT

GR. B7 GR. B7 GR. B7 GR. B7 GR. B7 GR. B8 B8M B8M

GLAND ASTM A 182 ASTM A 182 ASTM A 182

11 ASTM A105N ASTM A105N ASTM A105N ASTM A105N ASTM A105N

FLANGE F-304 F-316 F-316

EYE BOLT ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 GR. ASTM A 194 GR.

12 ASTM A 194 GR. 8

NUT GR. 2H GR. 2H GR. 2H GR. 2H GR. 2H 8M 8M

YOKE ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR. ASTM A 582 GR.

13

SLEEVE SS-416 SS-416 SS-416 SS-416 SS-416 SS-303 SS-303 SS-303

ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 ASTM A 194 GR. ASTM A 194 GR.

14 STEM NUT ASTM A 194 GR. 8

GR. 2H GR. 2H GR. 2H GR. 2H GR. 2H 8M 8M

NAME

15 STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL

PLATE

HAND

16 MI / SGIRON MI / SGIRON MI / SGIRON MI / SGIRON MI / SGIRON MI / SGIRON MI / SGIRON MI / SGIRON

WHEEL

GLAND FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE FLEXIBLE

17

PACKING GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS GRAPHITE RINGS

18 BACK SEAT INTEGRAL INTEGRAL INTEGRAL INTEGRAL INTEGRAL INTEGRAL INTEGRAL INTEGRAL

8 Crane ChemPharma & Energy www.cranecpe.com

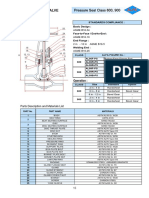

Forged Steel Globe Valve

Class 800 • Conventional Port • NPT

Figure Number: LB3644XUT Materials of Construction

• Globe valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING INTEGRAL + ST.6

• OS&Y

3 WEDGE/PLUG ASTM A 217 GR. CA-15

• NPT Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP C H OPEN H CLOSE ϴWH

3⁄8 *003 3.52 2.87 0.25 0.55 6.26 5.63 3.39

1/2 *004 3.52 2.87 0.37 0.55 6.26 5.63 3.39

3/4 *006 3.96 3.15 0.50 0.62 6.38 5.75 3.39

1 *010 6.82 3.94 0.69 0.79 7.52 6.73 4.57

1 1/4 *012 12.1 5.71 0.94 0.79 8.98 7.83 5.91

1 1/2 *014 13.86 5.71 1.13 0.94 8.98 7.83 5.91

2 *020 20.68 6.30 1.44 1.02 10.43 9.29 5.91

Technical Requirements

1. Design and Manufacture conform to API 602 Performance Standard

2. Test and Inspect conform to API 598

3. Face-to-face dimension conform to manufacturer's standard Class 800

4. NPT ends conform to ANSI B1.20.1 Shell/Body 3000 PSI

5. Compliant to API 624 for low emissions Hydro Test Pressure Seat 2175 PSI

Back Seat 2175 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

www.cranecpe.com Crane ChemPharma & Energy 9

Forged Steel Globe Valve

Class 800 • Conventional Port • Socket Weld

Figure Number: LB3644XUW Materials of Construction

• Globe valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING INTEGRAL + ST.6

• OS&Y

3 WEDGE/PLUG ASTM A 217 GR. CA-15

• Socket Weld Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP ϴA B H OPEN H CLOSE ϴWH

3/8 2.87 0.25 0.69 0.37 6.26 5.63 3.39

1/2 *004 3.52 2.87 0.37 0.86 0.37 6.26 5.63 3.39

3/4 *006 3.96 3.14 0.5 1.07 0.49 6.38 5.75 3.39

1 *010 6.82 3.93 0.69 1.33 0.49 7.52 6.73 4.57

1 1/4 *012 12.1 4.72 0.94 1.68 0.49 8.98 7.83 5.91

1 1/2 *014 13.86 4.72 1.13 1.92 0.49 8.98 7.83 5.91

2 *020 20.68 5.12 1.44 2.41 0.63 10.43 9.29 5.91

Technical Requirements

1. Design and Manufacture conform to API 602 Performance Standard

2. Inspection and test as per API 598

3. Face-to-face dimension conform to manufacturer's standard Class 800

4. SW ends conform to ASME B16.11 Shell/Body 3000 PSI

5. Compliant to API 624 for low emissions Hydro Test Pressure Seat 2175 PSI

Back Seat 2175 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

10 Crane ChemPharma & Energy www.cranecpe.com

Forged Steel Globe Valve

Class 1500 • Conventional Port • NPT

Figure Number: LB3844XUT Materials of Construction

• Globe valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING INTEGRAL + ST.6

• OS&Y

3 WEDGE/PLUG ASTM A 217 GR. CA-15

• NPT Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP C H OPEN H CLOSE ϴWH

1/2 *004 4.8 3.15 0.31 0.55 6.30 5.83 3.39

3/4 *006 8.5 3.94 0.35 0.62 7.36 6.85 4.57

1 *010 13.2 5.71 0.55 0.79 8.82 8.03 5.91

1 1/4 *012 17.6 5.71 0.79 0.79 8.82 8.03 5.91

1 1/2 *014 26.4 6.30 0.98 0.94 10.28 9.41 5.91

2 *020 51.7 6.77 1.06 1.02 12.53 11.42 9.84

Technical Requirements

Performance Standard

1. Design and Manufacture conform to API 602

2. Test and Inspect conform to API 598 Class 1500

3. Face-to-face dimension conform to manufacturer's standard Shell/Body 5550 PSI

4. NPT ends conform to ANSI B1.20.1 Hydro Test Pressure Seat 4125 PSI

5. Compliant to API 624 for low emissions Back Seat 4125 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

www.cranecpe.com Crane ChemPharma & Energy 11

Forged Steel Globe Valve

Class 1500 • Conventional Port • Socket Weld

Figure Number: LB3844XUW Materials of Construction

• Globe valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING INTEGRAL + ST.6

• OS&Y

3 WEDGE/PLUG ASTM A 217 GR. CA-15

• Socket Weld Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP ϴA B H OPEN H CLOSE ϴWH

3⁄8 *003 4.8 2.87 0.20 0.69 0.37 6.30 5.82 3.39

1/2 *004 4.8 3.15 0.32 0.86 0.37 6.30 5.82 3.39

3/4 *006 8.5 3.94 0.30 1.07 0.49 7.36 6.85 4.57

1 *010 13.2 5.71 0.55 1.33 0.49 8.82 8.03 5.91

1 1/4 *012 17.6 5.71 0.79 1.68 0.49 8.82 8.03 5.91

1 1/2 *014 26.4 6.30 0.98 1.92 0.49 10.28 9.41 5.91

2 *020 51.7 6.77 1.06 2.41 0.63 12.52 11.42 9.84

Technical Requirements

1. Design and Manufacture conform to API 602 Performance Standard

2. Inspection and test as per API 598

3. Face-to-face dimension conform to manufacturer's standard Class 1500

4. SW ends conform to ASME B16.11 Shell/Body 5550 PSI

5. Compliant to API 624 for low emissions Hydro Test Pressure Seat 4125 PSI

Back Seat 4125 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

12 Crane ChemPharma & Energy www.cranecpe.com

Forged Steel Globe Valve

Class 800 • Conventional Port • Socket Weld

Figure Number: GYW3644XUW Materials of Construction

• Y-Globe valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Welded Bonnet 2 SEAT RING INTEGRAL + ST.6

• OS&Y

3 WEDGE/PLUG ASTM A 217 GR. CA-15

• Socket Weld Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP ϴA B H OPEN H CLOSE ϴWH

1/2 *004 5.51 3.35 0.35 0.86 0.37 7.09 6.89 4.57

3/4 *006 8.82 3.94 0.47 1.07 0.49 8.74 8.35 5.91

1 *010 10.14 4.13 0.67 1.33 0.49 9.09 8.62 5.91

1 1/2 *014 28.66 5.71 1.10 1.92 0.49 12.76 12.17 9.84

2 *020 33.07 5.71 1.42 2.41 0.63 13.57 13.00 9.84

Technical Requirements Performance Standard

1. Design and Manufacture conform to API 602 Class 800

2. NPT ends to conform to ASME B1.20.1 Shell/Body 3000 PSI

3. Face-to-face dimension conform to manufacturer's standard Hydro Test Pressure Seat 2175 PSI

4. Inspection and test as per API 598 Back Seat 2175 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

www.cranecpe.com Crane ChemPharma & Energy 13

Forged Steel Globe Valve

Class 1500 • Conventional Port • Socket Weld

Figure Number: GYW3844XUW Materials of Construction

• Y-Globe valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Welded Bonnet 2 SEAT RING INTEGRAL + ST.6

• OS&Y

3 WEDGE/PLUG ASTM A 217 GR. CA-15

• Socket Weld Ends

4 STEM ASTM A 182 GR. F6a

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 EYE BOLT PIN ASTM A 276 TYPE SS-410

9 GLAND BUSH ASTM A 276 TYPE SS-410

10 EYE BOLT ASTM A 193 GR. B7

11 GLAND FLANGE ASTM A105N

12 EYE BOLT NUT ASTM A 194 GR. 2H

13 YOKE SLEEVE ASTM A 582 GR. SS-416

14 STEM NUT ASTM A 194 GR. 2H

15 NAME PLATE STAINLESS STEEL

16 HAND WHEEL MI / SGIRON

17 GLAND PACKING FLEXIBLE GRAPHITE RINGS

18 BACK SEAT INTEGRAL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP ϴA B H OPEN H CLOSE ϴWH

1/2 *004 5.51 3.35 0.32 0.86 0.37 7.09 6.89 4.57

3/4 *006 8.82 3.94 0.35 1.07 0.49 8.74 8.35 5.91

1 *010 10.14 4.13 0.55 1.33 0.49 9.09 8.62 5.91

1 1/2 *014 28.66 5.71 0.98 1.92 0.49 12.76 12.17 9.84

2 *020 33.07 5.71 1.06 2.41 0.63 13.58 13.00 9.84

Technical Requirements Performance Standard

1. Design and Manufacture conform to API 602 Class 1500

2. Socket weld ends to conform to ASME B1.20.1 Shell/Body 5550 PSI

3. Face-to-face dimension conform to manufacturer's standard Hydro Test Pressure Seat 4125 PSI

4. Inspection and test as per API 598 Back Seat 4125 PSI

Pneumatic Test Pressure Seat 100 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

14 Crane ChemPharma & Energy www.cranecpe.com

Forged Steel Check Valves BOMs

Lift Check Valves

PART

ITEM A105N/Trim 8 A105N/Trim 5 F11/Trim 5 F22/Trim 5 F91/Trim 8 F304/304 F316/Trim 12 F316L/Trim 12

NAME

ASTM A 182 ASTM A 182 ASTM A182

1 BODY ASTM A105N ASTM A105N ASTM A 182 F11 ASTM A 182 F22 ASTM A 182 F91

F-304 F-316 GR.F-316L

ASTM A 182 ASTM A182 GR.F-

ASTM A 182

2 SEAT RING INTEGRAL + ST.6 INTEGRAL + ST.6 INTEGRAL + ST.6 INTEGRAL + ST.6 INTEGRAL + ST.6 F-316 INTEGRAL 316L INTEGRAL

F-304 INTEGRAL

+ ST.6 + ST.6

ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A276 TYPE

3 PLUG

SS-410 SS-410 + ST.6 SS-410 + ST.6 SS-410 + ST.6 SS-410 SS-304 SS-316 SS-316

ASTM A 313 ASTM A 313 ASTM A 313 ASTM A 313 ASTM A 313 ASTM A 313 ASTM A 313 ASTM A313

4 SPRING

SS-304 SS-304 SS-304 SS-304 SS-304 SS-304 SS-316 SS-316L

SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL

SS-316 SPW +

5 GASKET WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED +

GRAPHITE

GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE

CHECK ASTM A 182 ASTM A 182 ASTM A182 GR.

6 ASTM A105N ASTM A105N ASTM A 182 F11 ASTM A 182 F22 ASTM A 182 F91

PLATE F-304 F-316 F316L

ASTM A 193 ASTM A 193 ASTM A 193 GR. ASTM A 193 GR. ASTM A 193 GR. ASTM A 193 ASTM A 193 GR. ASTM A193 GR.

7 HEX BOLT

GR. B7 GR. B7 B16 B16 B16 GR. B8 B8M B8M

NAME

8 STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL

PLATE

Swing Check Valves

PART

ITEM A105N/Trim 8 A105N/Trim 5 F11/Trim 5 F22/Trim 5 F91/Trim 8 F304/304 F316/Trim 12 F316L/Trim 12

NAME

ASTM A 182 ASTM A 182 ASTM A182

1 BODY ASTM A105N ASTM A105N ASTM A 182 F11 ASTM A 182 F22 ASTM A 182 F91

F-304 F-316 GR.F-316L

ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE

2 SEAT RING

SS 410 + ST.6 SS 410 + ST.6 SS 410 + ST.6 SS 410 + ST.6 SS 410 + ST.6 SS 304 SS 316 + ST.6 SS 316+ST.6

ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE

3 DISC

SS 410 SS 410 + ST.6 SS 410 + ST.6 SS 410 + ST.6 SS 410 SS 304 SS 316 SS 316

ASTM A 351 GR. ASTM A 351 GR. ASTM A 351 GR. ASTM A 351 GR. ASTM A 351 GR. ASTM A 351 GR. ASTM A 351 GR. ASTM A 351 GR.

4 HINGE

CF8M CF8M CF8M CF8M CF8M CF8M CF8M CF8M

ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE ASTM A 276 TYPE

5 HINGE PIN

SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316

ASTM A 182 ASTM A 182 ASTM A182

6 BONNET ASTM A105N ASTM A105N ASTM A 182 F11 ASTM A 182 F22 ASTM A 182 F91

F-304 F-316 GR.F-316L

ASTM A 193 ASTM A 193 ASTM A193 ASTM A193 ASTM A193 ASTM A 193 ASTM A 193 GR. ASTM A 193 GR.

7 HEX BOLT

GR. B7 GR. B7 GR.B16 GR.B16 GR.B16 GR. B8 B8M B8M

SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL SS-316 SPIRAL

8 GASKET WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED + WOUNDED +

GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE GRAPHITE

NAME

9 STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL STAINLESS STEEL

PLATE

www.cranecpe.com Crane ChemPharma & Energy 15

Forged Steel Piston Check Valve

Class 800 • Conventional Port • NPT

Figure Number: GB3674XUT Materials of Construction

• Piston Check Valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING INTEGRAL + ST.6

• NPT Ends

3 PLUG ASTM A 276 TYPE SS-410

4 SPRING ASTM A 313 SS-304

SS-316 SPIRAL

5 GASKET

WOUNDED+GRAPHITE

6 CHECK PLATE ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 NAME PLATE STAINLESS STEEL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP C H

3⁄8 *003 2.2 2.87 0.25 0.55 2.09

1/2 *004 2.2 2.87 0.37 0.55 2.09

3/4 *006 2.64 3.15 0.50 0.63 2.20

1 *010 4.62 3.94 0.69 0.79 2.60

1 1/4 *012 10.56 5.71 0.94 0.79 3.39

1 1/2 *014 10.34 5.71 1.13 0.94 3.39

2 *020 16.94 6.30 1.44 1.02 4.09

Performance Standard

Class 800

Shell/Body 3000 PSI

Hydro Test Pressure

Seat 2175 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

Technical Requirements

1. Design and Manufacture conform to API 602

2. Test and Inspect conform to API 598

3. Face-to-face dimension conform to manufacturer's standard

4. NPT ends conform to ASME B1.20.1

16 Crane ChemPharma & Energy www.cranecpe.com

Forged Steel Piston Check Valve

Class 800 • Conventional Port • Socket Weld

Figure Number: GB3674XUW Materials of Construction

• Piston Check Valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING INTEGRAL + ST.6

• Socket Weld Ends

3 PLUG ASTM A 276 TYPE SS-410

4 SPRING ASTM A 313 SS-304

SS-316 SPIRAL

5 GASKET

WOUNDED+GRAPHITE

6 CHECK PLATE ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 NAME PLATE STAINLESS STEEL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP ϴA B H OPEN

3⁄8 *003 2.2 2.87 0.25 0.69 0.37 2.09

1/2 *004 2.2 2.87 0.37 0.86 0.37 2.09

3/4 *006 2.64 3.14 0.5 1.07 0.49 2.2

1 *010 4.62 3.93 0.69 1.33 0.49 2.6

1 1/4 *012 8.8 5.71 0.94 1.68 0.49 3.39

1 1/2 *014 10.34 5.71 1.13 1.92 0.49 3.39

2 *020 16.94 6.30 1.44 2.41 0.63 4.09

Performance Standard

Class 800

Shell/Body 3000 PSI

Hydro Test Pressure

Seat 2175 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

Technical Requirements

1. Design and Manufacture conform to API 602

2. Test and Inspect conform to API 598

3. Face-to-face dimension conform to manufacturer's standard

4. SW ends conform to ASME B1.20.1

www.cranecpe.com Crane ChemPharma & Energy 17

Forged Steel Piston Check Valve

Class 1500 • Conventional Port • Socket Weld

Figure Number: GB3874XUW Materials of Construction

• Piston Check Valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING INTEGRAL + ST.6

• Socket Weld Ends

3 PLUG ASTM A 276 TYPE SS-410

4 SPRING ASTM A 313 SS-304

SS-316 SPIRAL

5 GASKET

WOUNDED+GRAPHITE

6 CHECK PLATE ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 NAME PLATE STAINLESS STEEL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP ϴA B H OPEN

3⁄8 *003 3.3 2.87 0.19 0.69 0.37 2.2

1/2 *004 3.3 3.14 0.31 0.86 0.37 2.2

3/4 *006 6.1 3.93 0.35 1.07 0.49 2.6

1 *010 10.1 5.71 0.55 1.33 0.49 3.39

1 1/4 *012 16.2 5.71 0.79 1.68 0.49 3.39

1 1/2 *014 19.8 6.3 0.98 1.92 0.49 4.09

2 *020 49.9 6.77 1.06 2.41 0.63 5

Performance Standard

Class 1500

Shell/Body 5550 PSI

Hydro Test Pressure

Seat 4125 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

Technical Requirements

1. Design and Manufacture conform to API 602

2. Test and Inspect conform to API 598

3. Face-to-face dimension conform to manufacturer's standard

4. SW ends conform to ASME B1.20.1

18 Crane ChemPharma & Energy www.cranecpe.com

Forged Steel Swing Check Valve

Class 800 • Conventional Port • NPT

Figure Number: GB3675XUT Materials of Construction

• Swing Check valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING ASTM A 276 TYPE SS 410 + ST.6

• NPT Ends

3 DISC ASTM A 276 TYPE SS 410

4 HINGE ASTM A 351 GR. CF8M

5 HINGE PIN ASTM A 276 TYPE SS 316

6 BONNET ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

9 NAME PLATE STAINLESS STEEL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP C H

1/2 *004 2.2 2.87 0.37 0.55 2.09

3/4 *006 2.64 3.15 0.50 0.59 2.20

1 *010 4.62 3.94 0.69 0.75 2.60

1 1/4 *012 10.56 4.72 0.94 0.75 3.39

1 1/2 *014 10.34 4.72 1.13 0.75 3.39

2 *020 16.94 5.12 1.44 0.79 4.09

Performance Standard

Class 800

Shell/Body 3000 PSI

Hydro Test Pressure

Seat 2175 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

Technical Requirements

1. Design and Manufacture conform to API 602

2. Test and Inspect conform to API 598

3. Face-to-face dimension conform to manufacturer's standard

4. NPT ends conform to ASME B1.20.1

www.cranecpe.com Crane ChemPharma & Energy 19

Forged Steel Swing Check Valve

Class 800 • Conventional Port • Socket Weld

Figure Number: GB3675XUW Materials of Construction

• Swing check valve No. Part Material

• Conventional Port 1 BODY ASTM A105N

• Bolted Bonnet 2 SEAT RING INTEGRAL + ST.6

• Socket Weld Ends

3 PLUG ASTM A 276 TYPE SS-410

4 SPRING ASTM A 313 SS-304

5 GASKET SS-316 SPIRAL WOUNDED+GRAPHITE

6 CHECK PLATE ASTM A105N

7 HEX BOLT ASTM A 193 GR. B7

8 NAME PLATE STAINLESS STEEL

Dimensions (in.) & Weights (lbs.)

SIZES LBS. F/F ϴP ϴA B H OPEN

1/2 *004 2.2 2.87 0.37 0.86 0.37 2.09

3/4 *006 2.64 3.15 0.50 1.07 0.49 2.20

1 *010 4.62 3.94 0.69 1.33 0.49 2.60

1 1/4 *012 8.8 4.72 0.94 1.68 0.49 3.39

1 1/2 *014 10.34 4.72 1.13 1.92 0.49 3.39

2 *020 16.94 5.12 1.44 2.41 0.63 4.09

Performance Standard

Class 1500

Shell/Body 3000 PSI

Hydro Test Pressure

Seat 2175 PSI

Suitable Temp. -20~800° F

Suitable Media Water, Steam, Oil, Etc.

Technical Requirements

1. Design and Manufacture conform to API 602

2. Test and Inspect conform to API 598

3. Face-to-face dimension conform to manufacturer's standard

4. SW ends conform to ASME B16.11

20 Crane ChemPharma & Energy www.cranecpe.com

Pressure Temperature A105N

Max Pressure (PSI)

Temperature °F

800# Valves 1500# Valves

-20–100 1975 3705

200 °F 1810 3395

300 °F 1745 3270

400 °F 1690 3170

500 °F 1610 3015

600 °F 1515 2840

650 °F 1465 24745

700 °F 1415 2665

750 °F 1350 2535

*800 °F 1100 2055

*Max temperature is 800°F

Max Pressure (MPa)

Temperature °C

800# Valves 1500# Valves

-29–38 13.62 25.53

50 °C 13.37 25.06

100 °C 12.43 23.3

150 °C 12.02 22.54

200 °C 11.68 21.9

250 °C 11.18 20.9

300 °C 10.62 19.91

325 °C 10.32 19.36

350 °C 10.02 18.78

375 °C 9.7 18.18

400 °C 9.26 17.36

*425 °C 7.67 14.38

*Max temperature is 425°C

www.cranecpe.com Crane ChemPharma & Energy 21

Ordering Information

Body Material

Bonnet Type

End Type

Figure #

Prefix

Trim

Mod

Size

-

*

L B 3604 LU W - F316 * 010 *

Prefix Trim

L API 624 LE Graphite (Gate or Globe) Code API # Disc Seat Stem

G Check Valve U 5 HF HF 410 ss

XU 8* 410ss HF 410 ss

A 9# Monel Monel Monel

Bonnet Type

L 10 316ss 316 ss 316 ss

B Bolted Bonnet

AU 11# Monel HF Monel

W Welded Bonnet

LU 12 316ss HF 316 ss

P Pressure Seal Bonnet

T 13 Alloy 20 Alloy 20 Alloy 20

F(_) Full Port (_) Bonnet

TU 14 Alloy 20 HF Alloy 20

Y(_) Y Pattern (_) Bonnet

LUU 16 HF HF 316 ss

TUU 18 HF HF Alloy 20

Figure #

3510 Gate 150 (Flanged Only)

End Type

3514 Gate 300 (Flanged Only)

B Butt Weld

3604 Gate 600 (Flanged Only)

F Flanged

3604 Gate 800

R Ring Joint

3804 Gate 1500

T Threaded

3904 Gate 2500

T x W Threaded x Socket weld

3655 Globe 150 (Flanged Only)

W Socket Weld

3656 Globe 300 (Flanged Only) NACE MRO 175 - Add N after End code

3644 Globe 600 (Flanged Only)

3644 Globe 800

3844 Globe 1500 Body Material Size

3944 Globe 2500 ø A105N 002 1/4"

3664 Lift Check 150 (Flanged Only) LF2 LCC 003 3/8"

3684 Lift Check 300 (Flanged Only) F11 WC6 004 1/2"

3674 Lift Check 600 (Flanged Only) F22 WC9 006 3/4"

3674 Lift Check 800 F5 C5 010 1"

3874 Lift Check 1500 F91 C12A 012 1 1/4"

3974 Lift Check 2500 F304 304ss 014 1 1/2"

3665 Swing Check 150 (Flanged Only) F316 316ss 020 2"

3685 Swing Check 300 (Flanged Only)

3675 Swing Check 600 (Flanged Only)

3675 Swing Check 800

3875 Swing Check 1500

3975 Swing Check 2500

22 Crane ChemPharma & Energy www.cranecpe.com

Notes

www.cranecpe.com Crane ChemPharma & Energy 23

Crane ChemPharma & Energy

Crane Energy Headquarters

4526 Research Forest Drive, Suite 400

The Woodlands, Texas 77381 U.S.A

Phone: +1 936-271-6500

Fax +1 936-271-6510

www.cranecpe.com

CRANE Cast Steel Customer Service

2129 3rd Avenue, S.E.

Cullman, Alabama 35055

Tel.: (1) 256-775-3800

Fax.: (1) 256-775-3860

brands you trust.

CPE-CRANE-FORGEDSTEEL-TDS-EN-LT-2019_10_14

Crane Co., and its subsidiaries cannot accept responsibility for possible errors in catalogues, brochures, other printed materials, and website information. Crane Co.

reserves the right to alter its products without notice, including products already on order provided that such alteration can be made without changes being necessary

in specifications already agreed. All trademarks in this material are property of the Crane Co. or its subsidiaries. The Crane and Crane brands logotype, in alphabetical

order, (ALOYCO®, CENTER LINE®, COMPAC-NOZ®, CRANE®, DEPA®, DUO-CHEK®, ELRO®, FLOWSEAL®, JENKINS®, KROMBACH®, NOZ-CHEK®, PACIFIC VALVES®, RESISTOFLEX®,

REVO®, SAUNDERS®, STOCKHAM®, UNI-CHEK®, WESTLOCK CONTROLS®, WTA®, and XOMOX®) are registered trademarks of Crane Co. All rights reserved.

© Crane ChemPharma & Energy

You might also like

- N O Part Name Carbon Steel 1 / Chrome 2 / Chrome 9Cr-1Mo-V 316 StainlessDocument3 pagesN O Part Name Carbon Steel 1 / Chrome 2 / Chrome 9Cr-1Mo-V 316 StainlesskvijaymurNo ratings yet

- FastnersDocument18 pagesFastnersraghbirNo ratings yet

- Astm Master SpecDocument1 pageAstm Master SpecPramzNo ratings yet

- Comparison-Of-steel-grades ASTM UNS DIN enDocument17 pagesComparison-Of-steel-grades ASTM UNS DIN ennebojsa70No ratings yet

- Piping Material CombinationDocument1 pagePiping Material Combinationvicsierey_974092471100% (1)

- ANSI 1500 Rotary Control ValvesDocument60 pagesANSI 1500 Rotary Control ValvesellisforheroesNo ratings yet

- ASTM and Material Grades GuideDocument19 pagesASTM and Material Grades Guidekaleem surtiNo ratings yet

- ASTM Standards: Range of Products & Material GradeDocument1 pageASTM Standards: Range of Products & Material GradePratik KarekarNo ratings yet

- Alloys Poured at Tech Cast PDFDocument7 pagesAlloys Poured at Tech Cast PDFTomy NoviadiNo ratings yet

- Material GradeDocument1 pageMaterial Gradeelarab29No ratings yet

- FlowBiz Forged Steel Globe ValveDocument14 pagesFlowBiz Forged Steel Globe ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- Material AsmDocument6 pagesMaterial Asmrawalepushkar123No ratings yet

- Arita Gate ValveDocument8 pagesArita Gate Valvemr_fahmiNo ratings yet

- Gate ValveDocument1 pageGate ValvebloggerparthiNo ratings yet

- ASTM Standards: Range of Products & Material GradeDocument1 pageASTM Standards: Range of Products & Material Gradeeko kusumoNo ratings yet

- Walworth 5202F 150lb GatesDocument5 pagesWalworth 5202F 150lb GatesAnthonyNo ratings yet

- Kirloskar Process Pump - GK (P) : ISO 2858 / DIN EN 22858 / ISO 5199Document12 pagesKirloskar Process Pump - GK (P) : ISO 2858 / DIN EN 22858 / ISO 5199Amit pumpXpertzNo ratings yet

- Stainless Steel BarDocument2 pagesStainless Steel BarSudhi Ks100% (1)

- FlowBiz Forged Steel Globe Valve Reduced BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Reduced BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- Butterfly ValvesDocument27 pagesButterfly ValvesИгорьNo ratings yet

- Threaded End Connection: Series S Ductile IronDocument1 pageThreaded End Connection: Series S Ductile IronptnusadharmafNo ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- Trunnion Ball ValveDocument16 pagesTrunnion Ball ValveDavid ZhuangNo ratings yet

- Cast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDDocument3 pagesCast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDAnonymous 6ZWS6IG2J9No ratings yet

- 102819Document10 pages102819Louis BujandaNo ratings yet

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 pagesSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNo ratings yet

- Ss Hex BoltDocument2 pagesSs Hex BoltJEVNo ratings yet

- Gate Valve 150Document2 pagesGate Valve 150Masih BelajarNo ratings yet

- TPS Supply - RangeDocument8 pagesTPS Supply - RangedosenmarioNo ratings yet

- Specs Chart PDFDocument1 pageSpecs Chart PDFsojeckNo ratings yet

- Estimasi Harga Material Perpipaan Nike Project No Quantity Size (Inch)Document4 pagesEstimasi Harga Material Perpipaan Nike Project No Quantity Size (Inch)Agus SupriadiNo ratings yet

- Ma Specifications ChartDocument1 pageMa Specifications ChartgabisaNo ratings yet

- Steeltrade PipeDocument30 pagesSteeltrade Pipewataneta valveNo ratings yet

- 1118F 1318F 1618F SeriesDocument4 pages1118F 1318F 1618F SeriesĐức Thiện HuỳnhNo ratings yet

- Floating Ball Valves: GloriousDocument12 pagesFloating Ball Valves: GloriousDharmendra JadejaNo ratings yet

- T301WFPDocument1 pageT301WFPcristian villegasNo ratings yet

- FlowBiz Forged Steel Globe Valve Full BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Full BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- OTSG MaterialDocument14 pagesOTSG MaterialLeon PeterNo ratings yet

- Common Materilas For CS PipingDocument2 pagesCommon Materilas For CS PipingValiullah SarpanchNo ratings yet

- Data Sheets for Globe ValvesDocument4 pagesData Sheets for Globe Valvesmohamed abd eldayemNo ratings yet

- JIS Standard ValveDocument8 pagesJIS Standard ValveJong JavaNo ratings yet

- KSP Piping Materials Product GuideDocument5 pagesKSP Piping Materials Product GuideTejas DesaiNo ratings yet

- Pressure Seal Cast Check Valves for Power Industry ApplicationsDocument4 pagesPressure Seal Cast Check Valves for Power Industry ApplicationsessnelsonNo ratings yet

- Boq ValveDocument6 pagesBoq Valveelias susantoNo ratings yet

- SolidEdge Piping Library ST2 Tcm1023-21382Document60 pagesSolidEdge Piping Library ST2 Tcm1023-21382kpm_2486No ratings yet

- 3118F 3318F 3618F-SeriesDocument6 pages3118F 3318F 3618F-SeriesDavid CandoNo ratings yet

- EN232400202-02Document1 pageEN232400202-02bevara santhoshkumarNo ratings yet

- Process Specification for Passivation and Pickling of Metallic MaterialsDocument9 pagesProcess Specification for Passivation and Pickling of Metallic MaterialsJaroslaw KoniecznyNo ratings yet

- Sac, Çubuk & Kütükler Shapes, Plates &bars Sac, Çubuk & Kütükler Astm/Asme DIN StasDocument4 pagesSac, Çubuk & Kütükler Shapes, Plates &bars Sac, Çubuk & Kütükler Astm/Asme DIN StaseragornNo ratings yet

- AÇO A350 355 Tabela1Document8 pagesAÇO A350 355 Tabela1Roberto GomesNo ratings yet

- Butterfly Valves GuideDocument28 pagesButterfly Valves GuideLAWRENCENo ratings yet

- Construction of Petroleum Storage Depot at Pali, Rajasthan: Doc No.: NAYA-PALI-SP-80 Rev: 00 Date: 25-04-2019Document4 pagesConstruction of Petroleum Storage Depot at Pali, Rajasthan: Doc No.: NAYA-PALI-SP-80 Rev: 00 Date: 25-04-2019chintanNo ratings yet

- Hidrante Seco Mod F0733Document1 pageHidrante Seco Mod F0733Julio FloresNo ratings yet

- Especificacion de Materiales Y Tabla de Compatibilidad Base Comercial SAE AstmDocument4 pagesEspecificacion de Materiales Y Tabla de Compatibilidad Base Comercial SAE AstmFrancisco VillaNo ratings yet

- 11 Tips PipingDocument1 page11 Tips PipingSudheepNo ratings yet

- FMSRV61 (DN20-50) Tis R1Document2 pagesFMSRV61 (DN20-50) Tis R1RishavNo ratings yet

- Base Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4Document3 pagesBase Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4MAT-LIONNo ratings yet

- Cast Steel Globe Valve Pressure Seal Class 1500, 2500Document3 pagesCast Steel Globe Valve Pressure Seal Class 1500, 2500Andri AjaNo ratings yet

- Krohne OPTIBAR PM 3050Document44 pagesKrohne OPTIBAR PM 3050Cherbee FerrerNo ratings yet

- Ultracote 635 HBDocument3 pagesUltracote 635 HBCherbee Ferrer100% (1)

- Ultracote Ultracote Ultracote Ultracote: Ultrazinc 2120Document3 pagesUltracote Ultracote Ultracote Ultracote: Ultrazinc 2120Cherbee FerrerNo ratings yet

- Deltapilot S FMB70: Technical InformationDocument48 pagesDeltapilot S FMB70: Technical InformationCherbee FerrerNo ratings yet

- Control Valve - Straight Through With Flanges and Shaft Guided Plug DN 15 - 150Document24 pagesControl Valve - Straight Through With Flanges and Shaft Guided Plug DN 15 - 150Cherbee FerrerNo ratings yet

- P808E214457Document1 pageP808E214457Cherbee FerrerNo ratings yet

- Technical Data Sheet: Forged Steel Gate, Globe, and Check ValvesDocument24 pagesTechnical Data Sheet: Forged Steel Gate, Globe, and Check ValvesCherbee FerrerNo ratings yet

- 02 - Stobu PN16-40Document1 page02 - Stobu PN16-40Cherbee FerrerNo ratings yet

- GP1000 GP1000EN Pilot Type Internal Sensing Pressure Reducing ValveDocument5 pagesGP1000 GP1000EN Pilot Type Internal Sensing Pressure Reducing ValveCherbee FerrerNo ratings yet

- Workplace HIV/AIDS PolicyDocument4 pagesWorkplace HIV/AIDS PolicydebaynNo ratings yet

- 880 Series Inverted Bucket Steam TrapsDocument2 pages880 Series Inverted Bucket Steam TrapsCherbee FerrerNo ratings yet

- P&id PDFDocument36 pagesP&id PDFCherbee FerrerNo ratings yet

- DRUG FREE Workplace Policy ProgramDocument6 pagesDRUG FREE Workplace Policy ProgramRupert VillaricoNo ratings yet

- Erba Actime - APTTDocument2 pagesErba Actime - APTTthinh.ho2No ratings yet

- Mindanao State University at Naawan: College of Agriculture and ForestryDocument18 pagesMindanao State University at Naawan: College of Agriculture and ForestryAlgenesis Adam CascoNo ratings yet

- Duplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojDocument7 pagesDuplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojAyyappanSubramanianNo ratings yet

- Arsenic Limit Test Silver Diethyldithiocarbamate Colorimetric MethodDocument4 pagesArsenic Limit Test Silver Diethyldithiocarbamate Colorimetric MethodShikha AgrawalNo ratings yet

- CHY1701 - ENGINEERING-CHEMISTRY - ETH - 1.0 - 46 - CHY1701 - Engineering ChemistryDocument3 pagesCHY1701 - ENGINEERING-CHEMISTRY - ETH - 1.0 - 46 - CHY1701 - Engineering ChemistryLikhita NarraNo ratings yet

- Laboratory Exercise 4Document2 pagesLaboratory Exercise 4Ivy RetuyaNo ratings yet

- Fire Safety & Prevention TipsDocument31 pagesFire Safety & Prevention TipsLakshmi BalaNo ratings yet

- Gas OrsatDocument11 pagesGas Orsatsirsa11100% (1)

- LAB GravimetricAnalysisSulfateMixtureDocument3 pagesLAB GravimetricAnalysisSulfateMixtureDNo ratings yet

- Bionic Technology BV: Invisible Particles Engineered To Visible High-PerformanceDocument17 pagesBionic Technology BV: Invisible Particles Engineered To Visible High-PerformanceLong An ĐỗNo ratings yet

- Toe To Heal Air Injection - THAIDocument5 pagesToe To Heal Air Injection - THAIAnthon100% (2)

- Chemistry SS2 Second TermDocument5 pagesChemistry SS2 Second TermKel FelixNo ratings yet

- Plastic Bricks PPT First ReviewDocument18 pagesPlastic Bricks PPT First Review19TUCV038 SHUHAIL AKTHAR.ANo ratings yet

- Inventario A 30 SeptiembreDocument6 pagesInventario A 30 SeptiembreAlexandra LopezNo ratings yet

- Welcome To Science ClassDocument35 pagesWelcome To Science ClassLouie IralNo ratings yet

- CRM Quartz Indian - Reference - Material ICPOESDocument5 pagesCRM Quartz Indian - Reference - Material ICPOESIKC MadhaparNo ratings yet

- Chapter 13Document17 pagesChapter 13Oscar Espinosa BonillaNo ratings yet

- Final - HE 2.4 Performing Simple Calculations in CaregivingDocument36 pagesFinal - HE 2.4 Performing Simple Calculations in CaregivingJasmine EnriquezNo ratings yet

- Agrodok-Series No. 41 - Small-Scale Mushrooms Cultivation 2Document86 pagesAgrodok-Series No. 41 - Small-Scale Mushrooms Cultivation 2Ezekiel BulusNo ratings yet

- Acid Base Titration Experiment 4Document10 pagesAcid Base Titration Experiment 4pokesurfer100% (3)

- Wedeco Portfolio Appl O3 UVDocument72 pagesWedeco Portfolio Appl O3 UVadmin DeptNo ratings yet

- Biology ExamDocument12 pagesBiology ExamRaulemarNo ratings yet

- XLP Rear Wheel Reuse and Salvage Inspection GuideDocument25 pagesXLP Rear Wheel Reuse and Salvage Inspection GuideAlan GonzalezNo ratings yet

- Masteremaco S 5410 Ci Tds PDFDocument3 pagesMasteremaco S 5410 Ci Tds PDFSolomon AhimbisibweNo ratings yet

- BIOCHEMISTRYDocument3 pagesBIOCHEMISTRYashleydimaranan20No ratings yet

- Characterisation of Fluorescence Background in Dye TracingDocument7 pagesCharacterisation of Fluorescence Background in Dye TracingALCIRA VALERIA CÉSPEDES VARGASNo ratings yet

- Kathonlx1 5%TDSDocument9 pagesKathonlx1 5%TDSPablo Manu Gomez VNo ratings yet

- THE COMPLETE Chemistry Notes for Railway ExamsDocument39 pagesTHE COMPLETE Chemistry Notes for Railway ExamsPravinNo ratings yet

- Rehabilitation and Maintenance of Narayan NiwasDocument28 pagesRehabilitation and Maintenance of Narayan NiwasYuvraj PanchalNo ratings yet

- Training With Answers, About Most Frequent Questions Asked by ClientsDocument4 pagesTraining With Answers, About Most Frequent Questions Asked by ClientsNicole UnaNo ratings yet