Professional Documents

Culture Documents

Westermann Table 7

Uploaded by

muhd.qasimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Westermann Table 7

Uploaded by

muhd.qasimCopyright:

Available Formats

4 Westermann Tables

Additional symbols

Denoting special properties

Steel quality Treatment given

A–Non-ageing quality R–Rimming quality a–Annealed or softened o–Spherodized

E–Stabilized against stress corrosion G–Grain size controlled c–Case carburized p–Patented

L–Control cooled to ensure freedom from flakes H–Hardenability controlled d–Hard drawn, cold reduced q–Hardened and tempered

D–Fully killed I–Inclusion controlled h–Hot-rolled s–Stress relieved

D2–Semi killed M–Structural homogeneity n–Normalized t–Tempered

guaranteed by Macro-etch test

e.g., St 42 An–Non-ageing steel with 42 kgf/mm2 15 Cr 3c–Chromium steel with average percentages

minimum tensile strength-normalizedof C = 0.15, Cr = 3.0 and case carburized

E–Electric Furnace Steel; R–Open Hearth Steel; BO–Basic Oxygen

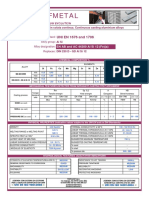

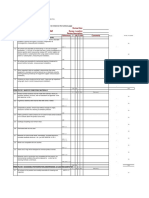

Grey iron castings IS:210–1970

Transverse test

Code for Grades Tensile strength Breaking load Corresponding transverse Deflection Typical applications

designation Min, kgf/mm2 Min, kgf rupture stress kgf/mm2 Min, mm

FG 15 15 15 800 34.0 4.0 Parts requiring no special grades for general

FG 20 20 20 900 38.2 4.5 structural purposes

FG 25 25 25 1000 42.4 5.0 Parts subjected to severe strains such as

FG 30 30 30 1100 46.7 }

5.5 cylinder parts, etc.

FG 35 35 35 1350 57.3 5.5

FG 40 40 40 1500 63.7 }

5.5 For extraordinary use

IS:2108–1962

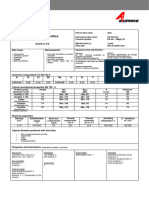

Malleable iron castings IS:2640–1964

IS:2107–1962

Code for Grades Tensile strength, 0.5% Proof Elongation % (gauge Brinell Phosphorous Typical applications

designation Min, kgf/mm2 stress, Min, length = 3 dia of hardness contact

kgf/mm2 test bars) Min HB Max % Max

BM 35 A 35 21 14 149 0.12 Thin walled castings; mass

BM 30 C 30 – 6 163 0.20 production parts wheels,

PM 70 A 70 55 2 241 to 285 0.12 keys, Parts for locks and

PM 45 E 45 28 7 149 to 201 0.12 sewing machine parts.

WM 42 A 42 26 4 217 0.15

WM 35 B 35 – 3 217 0.15

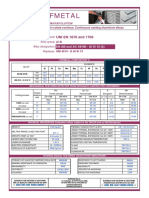

Steel castings IS:1030–1962

Code for Grades Tensile strength Elongation % on gauge S % Max P % Max Typical applications

designation Min, kgf/mm2 length 5.65 S0 , Min,

CS 55 1 55 12 0.060 0.060 Used for general engineering purposes instead of grey

CS 47 2 47 17 0.060 0.060 iron castings if greater strength and tenacity are

CS 41 3 41 18 0.060 0.060 to be met.

CS 65 1 65 17 0.050 0.050 High strength, good toughness and high abrasion

CS 85 2 85 12 0.050 0.050 resistance properties; used in transportation

CS 125 3 125 5 0.050 0.050 equipment and agricultural machinery parts.

IS:3038–1965

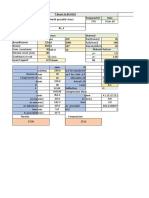

Alloy steel castings for high temperature service

IS:2856–1964

Grades Tensile Elongation % Yield stress C% Si % Mn % S% P% Typical applications

strength on 5.56 S0 gauge or 0.5% proof Max Max

Min, kgf/mm2 length, Min stress Min, kgf/mm2

1 55 17 35 0.20–0.25 0.15–4.40 1.25–1.45 0.050 0.050 Cast parts which

2 47 17 25 0.25 Max 0.20–0.50 0.50–1.00 0.050 0.050 preferably are to

3 52 15 31 0.15 Max 0.40 Max 0.40–0.80 0.050 0.050 withstand temperatures

4 49 17 28 0.20 Max 0.60 Max 0.50–0.80 0.050 0.050 between 300°C to

5 52 17 31 0.08–0.15 0.35 Max 0.30–0.70 0.050 0.050 525°C

6 63 15 43 0.20 Max 0.75 Max 0.40–0.70 0.050 0.050

7 63 15 43 0.20 Max 1.00 Max 0.30–0.70 0.050 0.050

CSN–C20 42 20 21 0.25 Max 0.60 Max 0.70 Max 0.050 0.050 Parts which to be

CSw–C25 49 18 25 0.30 Max 0.60 Max 1.00 Max 0.050 0.050 fusion welded

You might also like

- Westermann Table 8Document1 pageWestermann Table 8muhd.qasimNo ratings yet

- Stainless Steel 321 Technical DataDocument2 pagesStainless Steel 321 Technical Datasmith willNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Welding ConsumablesDocument79 pagesWelding Consumablesazam RazzaqNo ratings yet

- Casting Material Austenitic Ductile Iron in ASTM A439Document3 pagesCasting Material Austenitic Ductile Iron in ASTM A439Alex007No ratings yet

- Aisi E50100, E52100: 154/amoyDocument6 pagesAisi E50100, E52100: 154/amoyahmad hafizNo ratings yet

- ASTM C91000 - CuSn15 - Tin Bronze AlloysDocument1 pageASTM C91000 - CuSn15 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- Kme STOL76 C19010 enDocument1 pageKme STOL76 C19010 enMattia Terri TerrandoNo ratings yet

- Carbon Steel Fact SheetDocument2 pagesCarbon Steel Fact Sheettshepo hlakudiNo ratings yet

- EN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationDocument5 pagesEN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationNaiduNo ratings yet

- Design Calculations: Sheet 1 of 12Document12 pagesDesign Calculations: Sheet 1 of 12Shawkat Ali Khan100% (1)

- IS2002 Steel SpecDocument2 pagesIS2002 Steel Speceraman_meNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- Beam Design LRFD Aci 318-14Document6 pagesBeam Design LRFD Aci 318-14Usman AfzalNo ratings yet

- CWC-BookletF1 24Document1 pageCWC-BookletF1 24Jagannath SahuNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- 15B21H, 15B21RHDocument4 pages15B21H, 15B21RHGil CabreraNo ratings yet

- Gaskets - Graphite PDFDocument4 pagesGaskets - Graphite PDFSH1961No ratings yet

- AISI 8720 SteelDocument1 pageAISI 8720 SteelSIVASUTECH ENTERPRISESNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Eriks - Composites Epratex Phenol PDFDocument1 pageEriks - Composites Epratex Phenol PDFravindra erabattiNo ratings yet

- Keystone 322Document4 pagesKeystone 322Angel BarrantesNo ratings yet

- Chinese Specification For Cast Iron and S. G. IronDocument1 pageChinese Specification For Cast Iron and S. G. IronRahul KhoslaNo ratings yet

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)prasadjoshi781429No ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88No ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNo ratings yet

- 6063 ProfilesDocument1 page6063 ProfilesBPP-Tech PythonNo ratings yet

- FlangeDocument10 pagesFlangeNurul LailyahNo ratings yet

- MAI R32N&S 9851 2230 01cDocument2 pagesMAI R32N&S 9851 2230 01cesteban muñozNo ratings yet

- Miginox 347 / Tiginox 347: Classification: ApprovalsDocument1 pageMiginox 347 / Tiginox 347: Classification: ApprovalsJagannath SahuNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- BS en 1706 - En44100 PDFDocument2 pagesBS en 1706 - En44100 PDFDhamodaran RNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- Böhler Ti 2 Ni T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 2 Ni T-FD: Seamless Cored WireThanh TamNo ratings yet

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNo ratings yet

- m705 grn360 Kv20series20flyDocument2 pagesm705 grn360 Kv20series20flyKek Siang MingNo ratings yet

- Guage Thickness MM Weight KG/SQ.M Specification Application: HR Sheet / HR PlateDocument1 pageGuage Thickness MM Weight KG/SQ.M Specification Application: HR Sheet / HR Platecalvin.bloodaxe4478No ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Ok Tubrod 14.30a PDFDocument1 pageOk Tubrod 14.30a PDFqaNo ratings yet

- RC Tie Beam DesignDocument8 pagesRC Tie Beam DesignArfel BartianaNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Teves, Eric Venz C. Bsce 3-4 Ce-Pc 325 Laboratory 1Document71 pagesTeves, Eric Venz C. Bsce 3-4 Ce-Pc 325 Laboratory 1Teves, Eric Venz C.No ratings yet

- Nyfgby 2 X (1.5-300) MM 0.6/1 KVDocument4 pagesNyfgby 2 X (1.5-300) MM 0.6/1 KVBagus Arief WibowoNo ratings yet

- Extrusion Ingot: ApplicationDocument4 pagesExtrusion Ingot: ApplicationilkerNo ratings yet

- BW FOX+NiCuCr EN 2019 GL 233 PreviewDocument2 pagesBW FOX+NiCuCr EN 2019 GL 233 PreviewRaviTeja BhamidiNo ratings yet

- Design of Vertical Lift Service Gates Salarond Barrage: 1.0 Technical DetailsDocument23 pagesDesign of Vertical Lift Service Gates Salarond Barrage: 1.0 Technical DetailsRanjeet Singh MoreyNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- 32 Koenig 2013Document1 page32 Koenig 2013shashibagewadiNo ratings yet

- Comment - Draft - Comp Girder-26.34-R6Document61 pagesComment - Draft - Comp Girder-26.34-R6Nilay GandhiNo ratings yet

- Adi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Document2 pagesAdi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Milton Pereira JúniorNo ratings yet

- T Beam To BS 8110Document11 pagesT Beam To BS 8110Samitha SoysaNo ratings yet

- Westermann Tables: Steels For Hardening and TemperingDocument1 pageWestermann Tables: Steels For Hardening and Temperingmuhd.qasimNo ratings yet

- Materials: Classification and CategoriesDocument1 pageMaterials: Classification and Categoriesmuhd.qasimNo ratings yet

- Westermann Table 5Document1 pageWestermann Table 5muhd.qasimNo ratings yet

- 160 Principles of HVAC, 8th Edition: Table 5-11 Relative Thermal Resistances of Building MaterialDocument1 page160 Principles of HVAC, 8th Edition: Table 5-11 Relative Thermal Resistances of Building Materialmuhd.qasimNo ratings yet

- Seismic Zones of PakistanDocument1 pageSeismic Zones of Pakistanmuhd.qasimNo ratings yet

- Table 4-1 Maximum Allowable Shell Stresses: (Not For Use For Reconstructed Tanks, See Note 6)Document1 pageTable 4-1 Maximum Allowable Shell Stresses: (Not For Use For Reconstructed Tanks, See Note 6)muhd.qasimNo ratings yet

- Flow Power of ExchangerDocument1 pageFlow Power of Exchangermuhd.qasimNo ratings yet

- 1.0 Scope of This ManualDocument1 page1.0 Scope of This Manualmuhd.qasimNo ratings yet

- Air Compressor PowerDocument1 pageAir Compressor Powermuhd.qasimNo ratings yet

- Tehsil Seismic Zone Tehsil Seismic Zone Tehsil Seismic Zone: BCP SP-2007 CH-02Document1 pageTehsil Seismic Zone Tehsil Seismic Zone Tehsil Seismic Zone: BCP SP-2007 CH-02muhd.qasimNo ratings yet

- Seismic Zones of Pakistan Part 2Document1 pageSeismic Zones of Pakistan Part 2muhd.qasimNo ratings yet

- Nozzle/Pro Load Cases and Combinations: NozzleproDocument1 pageNozzle/Pro Load Cases and Combinations: Nozzlepromuhd.qasimNo ratings yet

- Index 7thedDocument4 pagesIndex 7thedmuhd.qasimNo ratings yet

- 15 .3 Load Criteria: 15.3.1 ScopeDocument1 page15 .3 Load Criteria: 15.3.1 Scopemuhd.qasimNo ratings yet

- LRFD Bridge Design Specifications Method B Procedure. Shear ModulusDocument1 pageLRFD Bridge Design Specifications Method B Procedure. Shear Modulusmuhd.qasimNo ratings yet

- Heating Load Calculation ExampleDocument1 pageHeating Load Calculation Examplemuhd.qasimNo ratings yet

- Design of Conveyor in Metric UnitsDocument10 pagesDesign of Conveyor in Metric Unitsmuhd.qasimNo ratings yet

- Composite Welded Steel Plate GirderDocument1 pageComposite Welded Steel Plate Girdermuhd.qasimNo ratings yet

- Wind On Noise WallDocument1 pageWind On Noise Wallmuhd.qasimNo ratings yet

- Belt Conveyor Travel PathsDocument1 pageBelt Conveyor Travel Pathsmuhd.qasimNo ratings yet

- Admission Form: School / College Name PercentageDocument1 pageAdmission Form: School / College Name Percentagemuhd.qasimNo ratings yet

- Process Design Report SummaryDocument3 pagesProcess Design Report Summarymuhd.qasimNo ratings yet

- Design of Conveyor BeltDocument10 pagesDesign of Conveyor Beltmuhd.qasim100% (1)

- Tube Lay Out Gas ExchangerDocument1 pageTube Lay Out Gas ExchangerHudaFiHayyatNo ratings yet

- SDLG L938F L948F Wheel Loader BrochureDocument4 pagesSDLG L938F L948F Wheel Loader Brochureabdelhadi houssinNo ratings yet

- Thermal Systems Design Fundamentals and Projects 2Nd Edition Richard J Martin Full ChapterDocument67 pagesThermal Systems Design Fundamentals and Projects 2Nd Edition Richard J Martin Full Chapterernest.phillips644100% (3)

- Feild Inspection of Shell and Tube Heat ExchangersDocument4 pagesFeild Inspection of Shell and Tube Heat ExchangersMatthew BennettNo ratings yet

- 54 16 5000Document2 pages54 16 5000Anonymous VKPfb3No ratings yet

- AMI Equipment Design Task Force Checklist (6-22-2004)Document4 pagesAMI Equipment Design Task Force Checklist (6-22-2004)AnnNo ratings yet

- Catalogo INDEXATOR Rotator EngelskaDocument20 pagesCatalogo INDEXATOR Rotator EngelskaLars Y. Aray C.No ratings yet

- Engineering Mechanics 2 Marks and 11 MarksDocument89 pagesEngineering Mechanics 2 Marks and 11 MarksHemachandran100% (1)

- Amanat, K. M., & Hoque, E. (2006) - A Rationale For Determining The Natural Period of RC Building Frames Having InfillDocument8 pagesAmanat, K. M., & Hoque, E. (2006) - A Rationale For Determining The Natural Period of RC Building Frames Having InfillMax ShashkinNo ratings yet

- 2 - Kinematics of Linear MotionDocument50 pages2 - Kinematics of Linear MotionShivaranjini RamendranNo ratings yet

- TL 98q Maquina JukiDocument34 pagesTL 98q Maquina JukiSandra GutiérrezNo ratings yet

- s91 Operator ManualDocument199 pagess91 Operator Manualjuliocesar.caNo ratings yet

- Design of Steel STAADDocument61 pagesDesign of Steel STAADPrashant Sunagar100% (1)

- Genset ManualDocument15 pagesGenset ManualR. Mega MahmudiaNo ratings yet

- Combined Cycle Power Plant Fundamentals: Online CourseDocument7 pagesCombined Cycle Power Plant Fundamentals: Online CourseOtuagaNo ratings yet

- CBG7370 en Service MaterialDocument8 pagesCBG7370 en Service Materialluis martinezNo ratings yet

- CNC Programming CyclesDocument8 pagesCNC Programming CyclesParveen KumarNo ratings yet

- Plane Stress Model: Transforming Stress Components and DirectionsDocument7 pagesPlane Stress Model: Transforming Stress Components and DirectionsEngr Aizaz AhmadNo ratings yet

- EDP - DSP-90 - Air - NEXTDocument2 pagesEDP - DSP-90 - Air - NEXTmongojerryNo ratings yet

- VAC-U-MAX Piping Network Best PracticesDocument8 pagesVAC-U-MAX Piping Network Best PracticesVincent IrawanNo ratings yet

- BORESCOPEINSPECTIONSDocument7 pagesBORESCOPEINSPECTIONSaras aliNo ratings yet

- Spreadsheet Slope Stability CalculatorDocument37 pagesSpreadsheet Slope Stability Calculatorali jamiilNo ratings yet

- Localizator Componenete ElectriceDocument33 pagesLocalizator Componenete Electricedavidoff29No ratings yet

- Plant MaintenanceDocument18 pagesPlant MaintenanceSalim82 LK100% (5)

- Hydraulic Control Valve (Advanced Hand Control System) - 863 PDFDocument5 pagesHydraulic Control Valve (Advanced Hand Control System) - 863 PDFPartagon PowNo ratings yet

- ACI 318 15 April 2015 Minutes (Ver 4)Document261 pagesACI 318 15 April 2015 Minutes (Ver 4)Sebastian Alvarez CadavidNo ratings yet

- Solar TrackerDocument36 pagesSolar TrackerdivyeshNo ratings yet

- Finite Element Analysis of Skew Curved RC Box Girder BridgeDocument8 pagesFinite Element Analysis of Skew Curved RC Box Girder BridgeTran Tien DungNo ratings yet

- Nema Induction MotorsDocument20 pagesNema Induction MotorsErik Huang100% (1)

- Rolling BearingsDocument22 pagesRolling BearingsFully YoursNo ratings yet